Machinery

Product Showcase

Machineries

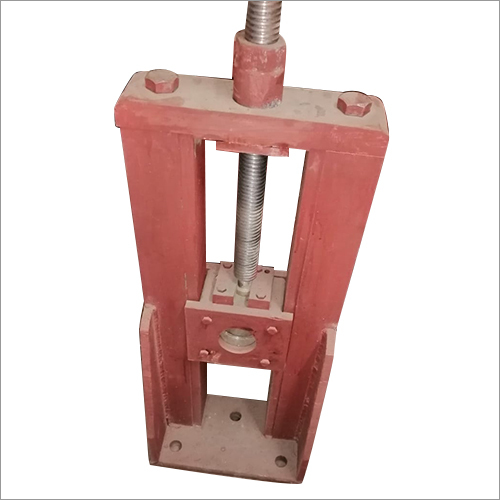

Lid Press Machine

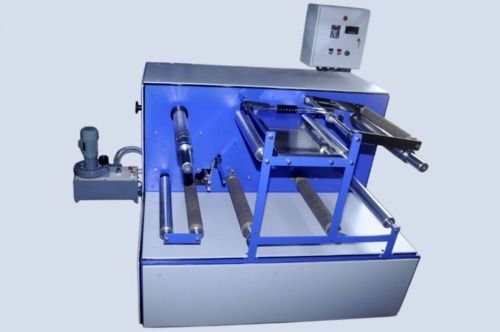

Automatic lid Pressing Machine

Price:350000 INR /Set

Automatic square can bottom lid curling and lining machine

Price:50000.0 USD ($) /Set

Automatic Linear Tray Cap Pressing Machine

Price:1800000 INR /Number

Lid Press Machine

Price:90000 INR /, Number

Aluminium Foil Making Machine

Fully automatic double Cavity Aluminium Foil Container Making Machine asain

Price:1850000.0 INR /Piece

Aluminium Foil Container Machine

Price:875000 INR /Piece

Aluminium Foil

Price:350.00 INR /Pack

Aluminium House Foil Roll Manufacturing Machine

Price:125000 INR /Unit

ALUMINIUM FOIL CORRUGATION AND CUTTING MACHINE

Price:550000.0 INR /Piece

Distilled Water Machine

Distilled Water 1 LTR

Price:15 INR /Piece

Vertical hot pressure distilled water machine

Price:30000.0 USD ($) /Unit

Distilled Water Supply Service For Laboratory Reagents

Price:150000 INR /Unit

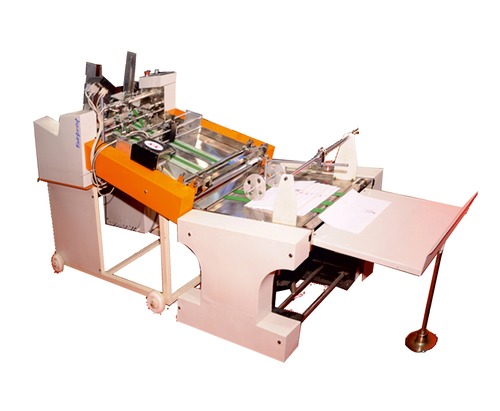

Doctoring Machines

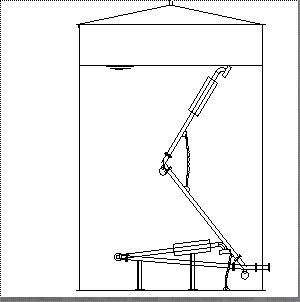

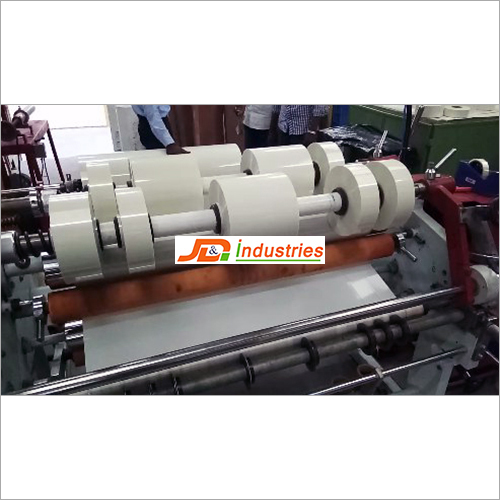

Doctoring Winding Rewinding Machine

Price:175000 INR /Unit

Roll to Roll Doctoring Machine

Price:500000 INR /Unit

Autodoct Doctoring Machine

Price:30000 INR /Unit

Bucket Handle Making Machine

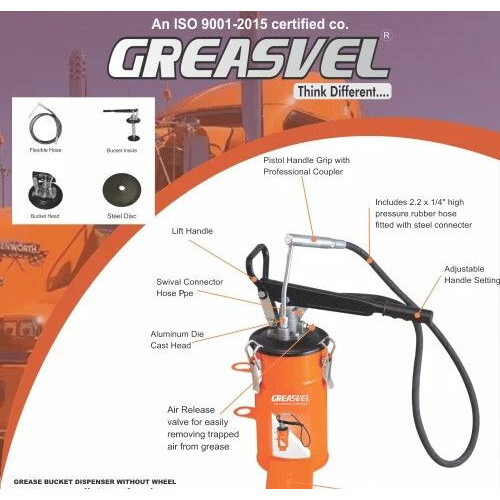

GS 350 Oil Double Power Single Bucket Machine

Price:60000 INR /Piece

Spray Type Single Bucket Milking Machine With Full Engine Set

Price:35000 INR /Unit

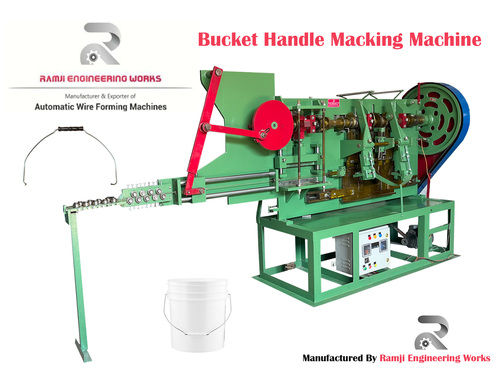

Bucket Handle Making Machine

Price:720000 INR /Unit

Bucket Handle Making Machine

Price:650000 INR /Unit

Popular Posts Related to Machineries

Top 10 Vertical Machining Center (VMC Machine) Manufacturers and Exporters in India

Vertical machining centers (VMCs) are used for VMC machining. These machine tools are vertically inclined, hence the name. Metals like aluminum and steel are typically used in conjunction with these machines to create machined parts.

VMC Machines: Top Manufacturers and Suppliers in India - 2023

Looking for the top manufacturers & suppliers of VMC machines in India for 2023? Read about the most reliable & trustworthy VMC machine manufacturers.

How To Start Ball Pen Making Business in India?

Get the essential tips to Start Ball Pen Making Business in India in 2020. Step-by-step guidance for a successful ball pen-making business.

Top 11 Considerations When Purchasing a Mixing Machine

Every baker and cook should be familiar with the incredible mixing attachments available for this equipment. Industrial mixers rely on the same principles.

Top 15 Pellet Making Machine Manufacturers & Suppliers in India

Examine all about the pellet making machine, pellet making machine price along with 15 best pellet making machine manufacturers & suppliers in India

How To Start A Staple Pin Manufacturing Business in India

Read all about staple pin including how to start staple pin manufacturing business in India

Industrial Machinery & Parts

Doctoring Machines

Doctoring Winding Rewinding Machine

Price:175000 INR /Unit

Roll to Roll Doctoring Machine

Price:500000 INR /Unit

Autodoct Doctoring Machine

Price:30000 INR /Unit

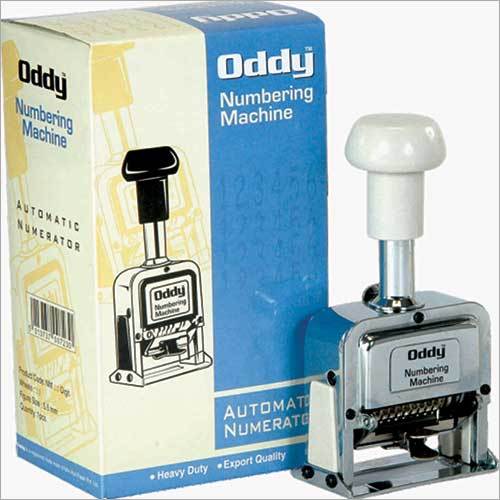

Numbering Machine

Digital Numbering Machine

Price:390000 INR /Piece

Answer Sheet Numbering Machine

Price:690000 INR /Piece

Automatic Numbering Machine

Price:1099 INR /Piece

Blitz 2253 Numbering Machine

Price:4500 INR /Unit

Egg Tray Machine

High quality waste paper recycling equipment pulp molding machine industrial paper packaging machine

Price:100000 USD ($) /Kit

Egg Tray Machine (SH-3000)

Price:USD100000-250000 USD ($) /Set

Egg Tart Making Machine With 36 Pcs/Min

Price:1000 USD ($) /Set

High Performance Egg Tray Making Machine

Price:11800 USD ($) /Set

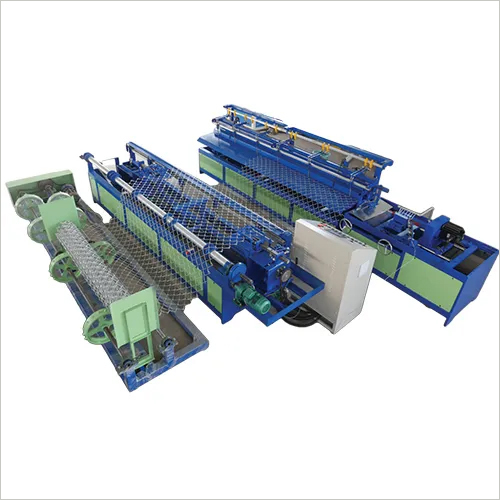

Chain Link Fence Making Machine

5HP Fully Automatic Chain Link Fence Machine

Price:1069000.0 INR /Unit

Fully Automatic Chain Link Fencing Making Machine

Price:1170000 INR /Piece

Fully Automatic Chain Link Fence Machine

Price:1000000 INR /Set

Fully Automatic Single Wire Chain Link Weaving Machine

Price:700000.0 INR /Piece

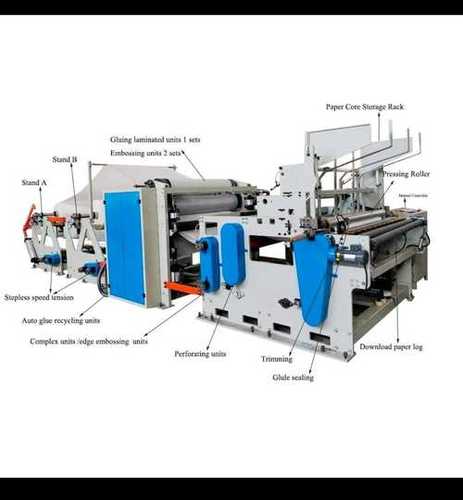

Toilet Roll Making Machines

Single Toilet Roll Packing And Sealing Making Machine

Price:390000 INR /Unit

Toilet Paper Making Machine

Price:700000 INR /Unit

Toilet Tissue Paper Roll Making Machine - Production Plant

Price:1000000 INR /Set

Toilet Roll Making Machine

Price:1 INR /Unit

Automatic Toilet Roll Log Rewinding Machine

Price:550000 INR /Unit

Machinery & Parts

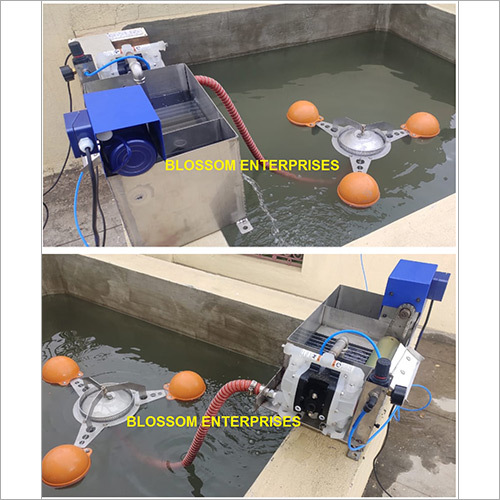

Floating Suction Assembly

Floating Suction Type Oil Skimmer

Price:145000 INR /Piece

Floating Suction Assembly

Price:210000 INR /, Unit

Float Arm Assembly

Price:1250 INR /Piece

SUCTION PUMP

Price:19000 INR /Unit

Idler Wheel

MS Idler Roller

Price:250 INR /Unit

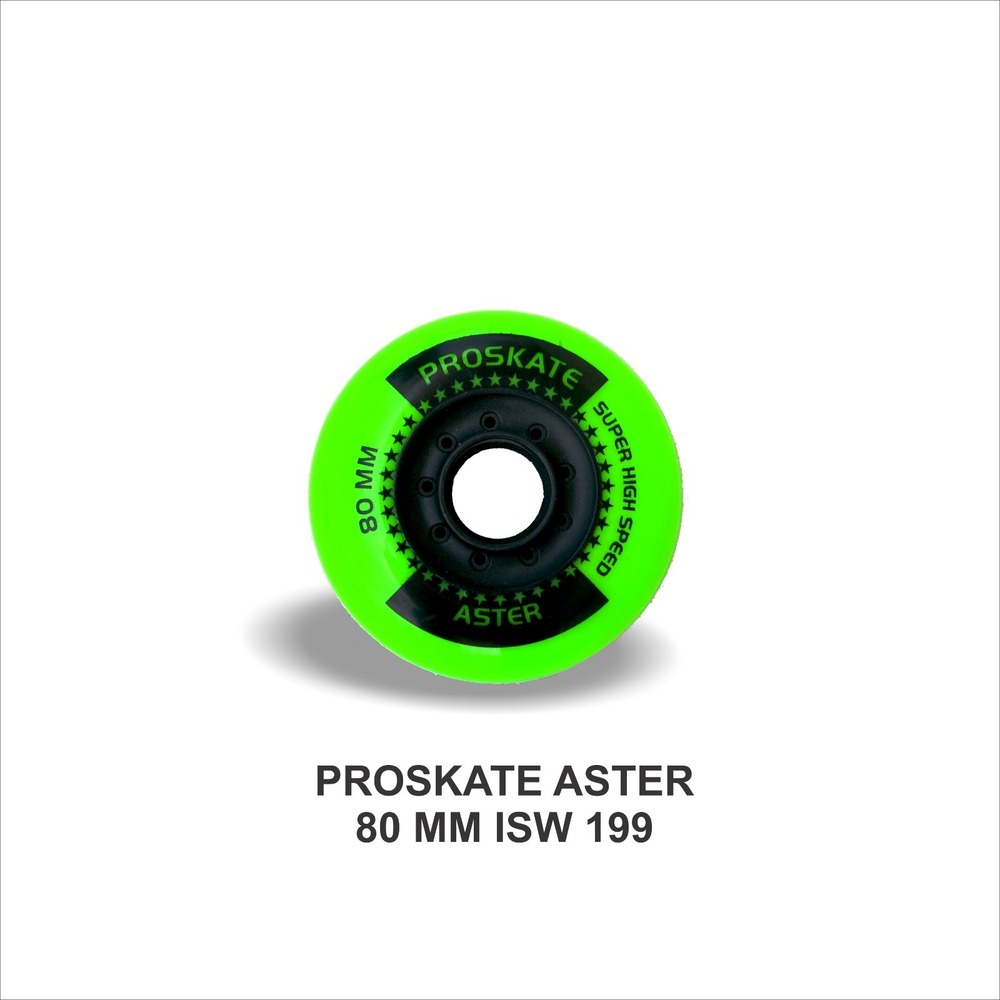

PROSKATE ASTER 80 INLINE WHEEL ISW 199

Price:4199 INR /Pack

Rubber Idler Ring

Price:60 INR /Piece

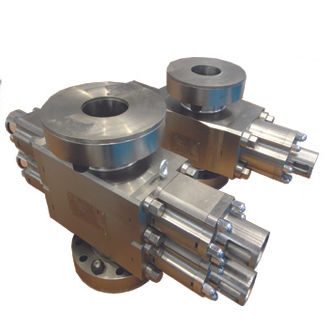

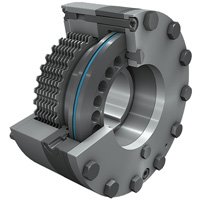

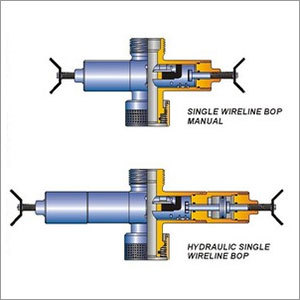

Blowout Preventer

Blowout Preventers

Price:502 USD ($) /Unit

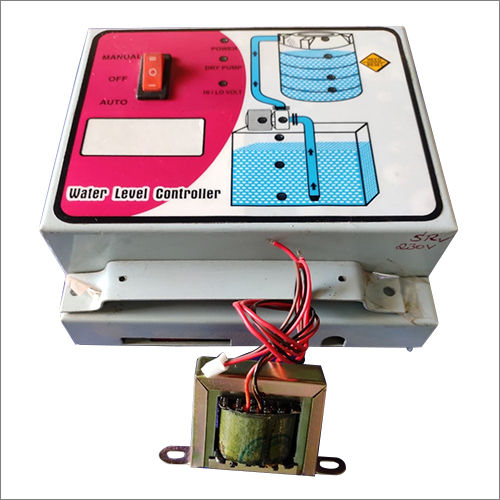

Water Level Transformer Preventer Unit

Price:105 INR /Unit

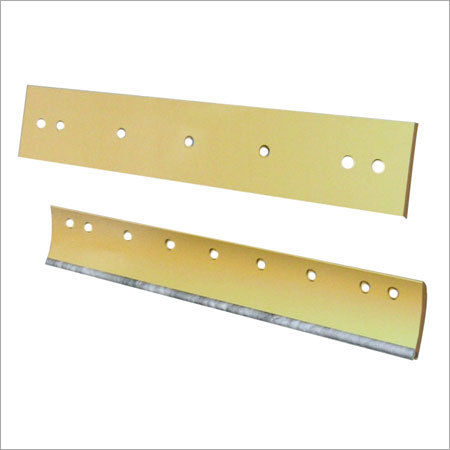

Cutting Machine

Bar Cutting Machine

JAYMAC BAR CUTTING MACHINE.

Price:200000.00 INR /Piece

Rebar Cutting Machine GQ45

Price:70000.00 INR /Piece

Bar Cutting Machine

Price:85000 INR /Piece

Portable Bar Cutting Machine

Price:62000.0 INR /Piece

GQ52 - Rebar cutting machine

Price:85000 INR /Piece

Bar Cutter

Bar Cutting C-50-GQ50

Price:93200 INR /Piece

Jaymac TMT Bar Cutting Machine

Price:200000.00 INR /Set

Bar Cutting Machine

Price:80000 INR /Piece

Bar Cutter

Price:57000 INR /Piece

Compound Miter Saw

Compound Miter Saw

Price:12700 INR /Piece

C10FCE2 Compound Miter Saw

Price:15900 INR /Unit

Hikoki C12FDH Miter Saw

Price:25000 INR /Unit

Micro Slitter Machine

Best Mini Slitting Machine

Price:9700 USD ($) /Set

Micro Slitting Machine

Price:1050000.0 INR /Unit

NC Servo Thin Blade Slitter Scorer Machine

Price:20000 USD ($) /Set

PVC Film Slitter Machine

Price:2000000 INR /Unit

Packaging Machine

Nitrogen Flushing Machine

Vertical Packaging Machine With NITROGEN FLUSHING

Price:38500 INR /Piece

vacuum packing machine with nitrogen flushing

Price:104500 INR /Number

Nitrogen Gas Flushing Machine

Price:45000.0 INR /Piece

Band Sealer With Nitrogen Flushing and Vacuum Packing Machine

Price:75000 INR /Piece

Corrugated Packaging Machine

Oblique Corrugation Machine

Price:500000-700000 INR /Piece

Automatic Cut to Length Plant

Price:3000000.0 INR /Piece

Blister And Strip Carton Packaging Machine

Price:800000 INR /Set

Vffs Machine

VFFS Machine With Volume Metric Cup Filler for Powder Packing

Price:1600000 INR /Unit

Detergent Powder Packing Machine

Price:250000.00 INR /Unit

Automatic VFFS Machine

Price:1300000 INR /Unit

L And T Nx2000+ VFD

Price:10000 INR /Piece

Tablet Packing Machine

Capsule Counting Machine

Price:150000 INR /Piece

Fully Automatic PVC Alu Blister Packing Machine

Price:350000 INR /Unit

Automatic Pharmaceutical Packaging Machine

Price:700000.00 INR /Unit

Alu Alu Blister Packing Machine

Price:450000.00 INR /Unit

Homeopathy Tablet Counting & Filling Machine

Price:900000 INR /Unit

Vertical Band Sealer

Band Sealing Machine

Price:103000.00 INR /Unit

Heavy Duty Vertical Band Sealer

Price:151500 INR /Piece

Solid Ink Coding Band Sealer (SS)

Price:17500.00 INR /Piece

Heavy Duty Vertical Band Sealing machine

Price:135000.00 INR /Number

Vertical Band Sealer

Price:31000.0 INR /Piece

Popular Posts Related to Packaging Machine

Why Your Chemical Business Needs a Drum Filling System

A drum filling system boosts efficiency and safety in your chemical business by automating precise filling, reducing spills, and minimizing manual labor.

Discover How Jumbo Bag Filling Machine Fastrack the Industrial Packaging Process

Learn how jumbo bag filling machines accelerate industrial packaging processes, enhancing efficiency and saving time in your production line.

How to Operate a Jumbo Bag Filling Machine

Learn the step-by-step process of operating a jumbo bag filling machine effectively and safely.

Everything You Should Know About Rice Packaging Machines

Rice packaging machines streamline the packaging process, ensuring efficiency, accuracy, and hygiene. They handle tasks from weighing and filling to sealing and labeling.

Discover Top 10 Best Automatic packaging machines manufacturers and Suppliers in India

top 10 best automatic packaging machine manufacturers and suppliers in India, offering advanced solutions for various industries.

Top 10 Cement Packing Machine Manufacturers, Exporters & Suppliers in India

top 10 Cement Packing Machine Manufacturers & Suppliers in India for 2024. Find reliable and innovative solutions for your cement packaging needs with these industry leaders.

![Top 10 Bag Filling Machine Manufacturers in India - [2024]](https://www.tradeindia.com/blog/content/images/2022/09/Top-10-Bag-Filling-Machine-Manufacturers-in-India.jpg)

Top 10 Bag Filling Machine Manufacturers in India - [2024]

best bag filling machine manufacturers & suppliers in India in 2024 with our comprehensive guide.

List of 10 Biggest Tea Packaging Machine Manufacturers in India

Explore India's top tea packaging machine manufacturers innovative designs to reliable machinery, the 10 leading companies shaping the future of tea packaging in the nation.

10 Most Popular Zipper Pouch Machine Manufacturers in India

India's Best zipper pouch machine manufacturers, providing cutting-edge technology for efficient packaging solutions.

Best 10 Flour Packing Machine Manufacturers & Suppliers in India

Find the top 10 flour packing machine manufacturers & suppliers in India. Explore reliable solutions for efficient packaging in the flour industry. Explore More!

10 Best Bottle Capping Machine Manufacturers & Suppliers in India

Find the top 10 bottle capping machine manufacturers & suppliers in India. Explore reliable solutions for efficient packaging with the best equipments. Explore More!

11 Best Powder Filling Machine Manufacturers & Suppliers in India

Discover India's 11 top Powder Filling Machine Manufacturers & Suppliers. Get reliable solutions from trusted brands. Find the best fit today

Grinding & Milling Machinery

Wood Grinding Machine

Wood Chipper Knife Grinding Machine

Price:100000 INR /Number

Saw Dust Grinding Pulverizer

Price:135000 INR /Piece

Blade Grinder for Wood

Price:34000 INR /Piece

Power Press 30 Ton

Price:200000 INR /Unit

Hydraulic Surface Grinder Machine

Automatic Surface Grinding Machine

Price:1000000 INR /Number

GMT 225 X 350 Manual Surface Grinder Machine

Price:225000 INR /Piece

1400 KURODA SURFACE GRINDER

Price:700000 INR /Unit

Small Bench Hydraulic Surface Grinder Tat618s

Price:3500-3900 USD ($) /Set

Cylinder Grinder Machine

Price:60000 USD ($) /Set

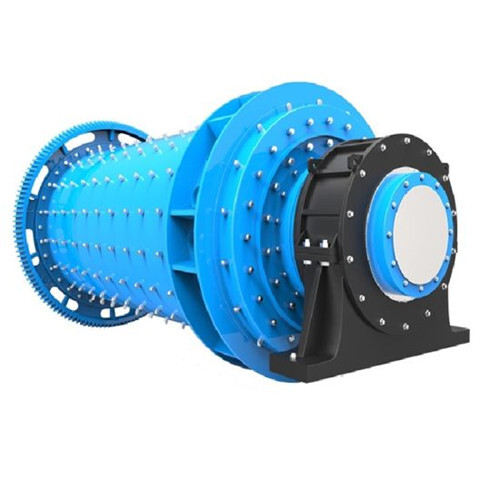

Mining Crusher

Industrial Branch Crusher

Price:10000 USD ($) /Unit

Wood Crusher

Price:12000 - 300000 INR /Unit

Slow Speed Online Crusher

Price:132000.0 INR /Unit

External Grinding Machine

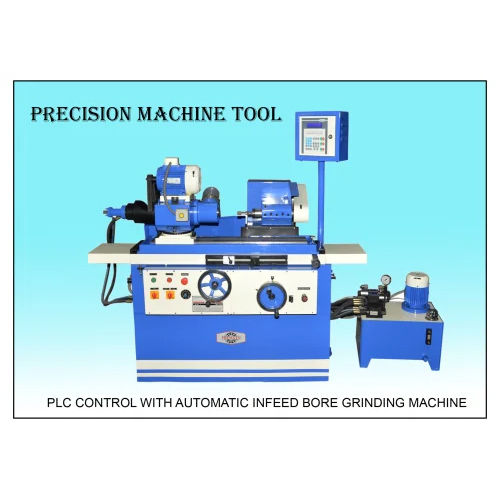

Precision External Grinding Machine

Price:500000 INR /, Unit

PLC Controlled Internal Bore Grinding Machines

Price:950000.00 INR /Piece

Grinding Machine with Internal Grinding Attachment.

Price:0.001 INR /Piece

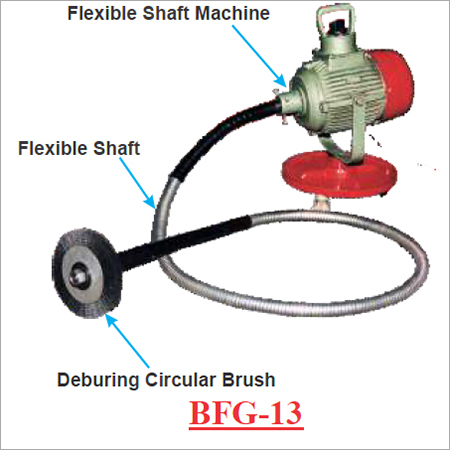

Flexible Shaft Grinders

Ralli wolf FLEXIBLE SHAFT GRINDER (FSG2)

Price:20069 INR /Number

KPT KF2 Flexible Shaft Grinder

Price:13250 INR /Piece

Single Speed Flexible Shaft Grinder

Price:15000 INR /Piece

3 Speed Flexible Shaft Grinder

Price:18000 INR /Piece

Flexible Shaft Grinder

Price:7500 INR /Piece

Top Rated Companies from Machinery Category

FAQs Related to Machinery

What Are the Different Types of Industrial Machinery?

How Do You Choose the Right Industrial Machinery for Your Business?

What Is the Importance of Regular Maintenance for Industrial Machinery?

What are the new updates on industrial machinery?

How Can You Increase the Performance of Industrial Machinery?

What are the Safety Measures to Consider to Operate Industrial Machinery?

How Does Industrial Machinery Impact Productivity?

What are the Costs Included With Industrial Machinery?

What Is the Role of Industrial Machinery in Manufacturing?

What is Classified as Industrial Machinery?

What are the four types of Grinding Machines?

What Machines are Used in Construction?

Agricultural Machines & Tools

Cono Weeder

Agriculture Cono Weeder

Price:1800 INR /Piece

Manual Type Cono Weeder

Price:1750 INR /Unit

Cono Weeder

Price:1700 INR /Piece

Paddy Harrow

Compact Disc Harrow

Price:1700 USD ($) /Number

Disc Harrow

Price:95000 INR /Unit

Paddy Harrow

Price:28000 INR /Piece

Harrow Agricultural Machinery Equipment Agriculture Disc Harrow Cultivator

Price:580 USD ($) /Unit

Iron 14 Disc Double Frame Disk Harrow

Price:500 INR /Dozen

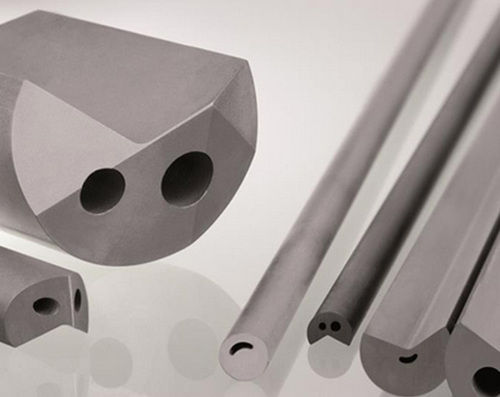

Cultivator Tines

Highly Durability And Extra Heavy Duty Spring Loaded Red Cultivator For Agriculture

Price:26.000 INR /Unit

30 mm Cultivator Tine

Price:73 INR /Kilograms

Cultivator Dry Tines

Price:180 INR /Piece

9 Tine Cultivator

Price:18500 INR /Piece

Profile cutting tine

Price:68 INR /Piece

Vacuum Destoner

Gravity Table Rice Destoner

Price:375000 INR /Unit

Vacuum Desicator

Price:3000.00 INR /Unit

Destoner, Cleaning & Grading Machine

Price:92000.00 INR /Unit

Vacuum Single Destoner

Price:285000 INR /Unit

Power Weeder

Power weeder cultivator petrol power weeder 7 HP

Price:29000 INR /Piece

REALLY 700G PETROL POWER WEEDER

Price:40000 INR /Number

63CC Cultivator Weeder

Price:55 USD ($) /Carton

Power Weeder -186FE With Head light model -Diesel

Price:111607.00 INR /Number

Seating Type Power weeder

Price:175000.00 INR /Number

Popular Posts Related to Agricultural Machines & Tools

How Advanced Agricultural Equipment Has Transformed Modern Farming

Explore how advanced agricultural equipment has revolutionized modern farming, enhancing efficiency, productivity, and sustainability.

Importance and Applications of Agricultural Shredder in Farming Industry

Discover the significance of agricultural shredders in modern farming. Learn how these machines enhance efficiency by reducing waste, aiding composting, and improving soil health, thereby boosting crop productivity.

Top 15 Agricultural Machinery in India - 2024

Discover the top 15 agricultural machinery in India, including tractors, harvesters, cultivators, and more, to enhance farming productivity.

Best 10 Agricultural Equipment Manufacturers in India

Explore the Best 10 Agricultural Equipment Manufacturers in India - Get companies detail, contact info, and more. Start your search today!

Top 10 Power Tiller Manufacturers & Dealers in India

Discover the top 10 power tiller manufacturers in India and their best products. Learn how power tillers can benefit small and medium-sized farms by reducing labor and improving crop developmen

How To Choose The Right Groundnut Digger For Farming?

Tips for choosing the right groundnut digger for farming. Also know about important considerations for selecting a suitable digger for agricultural use.

Top 10 Octagonal Blender Manufacturing Companies in India

Explore The Top 10 Octagonal Blender Manufacturing Companies in India. Discover top-quality blending solutions tailored to your industrial needs.

10 Biggest Rapid Mixer Granulator Manufacturers & Suppliers in India

Here are the top 10 Rapid Mixer Granulator manufacturers and suppliers in India. Explore the list of industry leaders providing high-quality solutions.

Top 9 Mass Mixer Manufacturers & Dealers in India

9 leading Mass Mixer Manufacturers & Dealers for quality solutions. Find top brands for your mixing needs.

10 Best Multi Mill Manufacturers & Suppliers in India

Discover top 10 Multi Mill Manufacturers and Suppliers in India offering quality milling solutions. Find reliable suppliers for your industrial needs.

Plant & Machinery

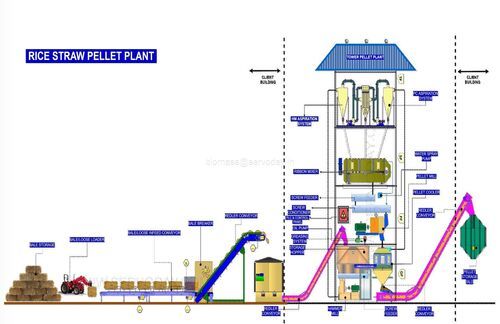

Biomass Plant

Biomass Briquetting Plant

Price:2251000.0 INR /Piece

Biomass Gasifier Plant

Price:500000.00 INR /Unit

Industrial Fully Automatic Tower Type Biomass Wood Pellet Plant

Price:400000 INR /Set

Bio Coal (Biomass Briquettes / White Coal)

Price:4500.0 INR /Metric Ton

Hot Dip Galvanizing Plant

Dip Type PT Plant With Barrel Rotation

Price:2500000 INR /Unit

Hot Dip Galvanizing Plants

Price:2500000.0 INR /Piece

Galvanizing Plant Dryer

Price:5000000 INR /Unit

Fractionation Plant

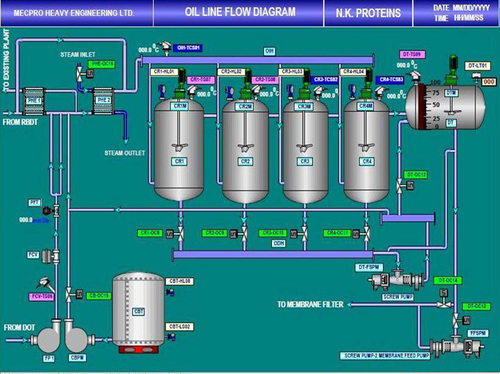

Edible Oil Fractionation Plant

Price:110.0 INR /Unit

Dry Fractionation Plants

Price:20000000 INR /Unit

Dry Fractionation Unit

Price:5000000 INR /Unit

Trending Videos Related to Machinery Categories

Namkeen Pouch Packing Machine

Conveyor Belt, Mixing Vessel Machine

Textile Machinery Spare Parts

Mining, Exploration & Drilling Machinery

Hitachi Drill Machine

Stanley 18V Li-ion Drill Driver SCD20S2K

Price:8850 INR /Piece

Hitachi Power Tools

Price:12000 INR /Piece

Hitachi Angle Grinder

Price:8500 INR /Unit

Hitachi Hammer Drill Machine

Price:4000 INR /Piece

Hitachi-Hikoki PD100M Grinder Machine

Price:2330 INR /Piece

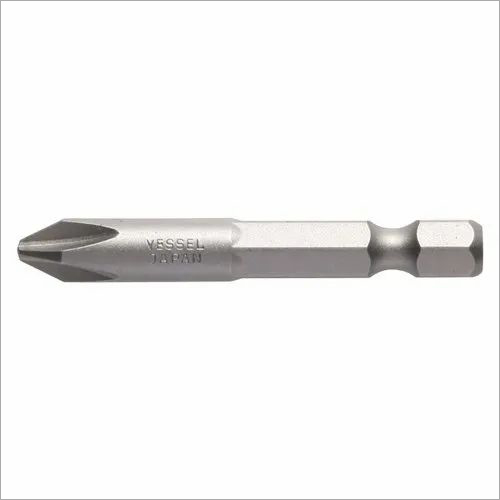

Dozer End Bits

Weight Dozer

Price:1800 INR /, Set

6.35mm (14) Hex Drive Single End Bit Vessel Japan

Price:84 INR /Piece

Food Processing Machinery

Peanut Roaster

Peanut Almond Cashew Hazelnut Walnut Butter Machine

Price:1000000 INR /Piece

Peanut Roasting machine

Price:1 INR /, Piece

Automatic Nut Roasting Machine

Price:2000000 INR /Unit

Pop Corn Roaster Machine

Price:500000-2500000 INR /Unit

Potato Peeler

Potato Peeler

Price:18000.00 INR /Piece

Potato peeler

Price:22500 INR /Thousand

Senso Potato Peeler Knifes

Price:48 INR /Dozen

3 in 1 Vegetable Peeler/Grater/Cutter for Food Preparation

Price:14 INR /Piece

Donut Machine

Donut Machine

Price:225000.00 INR /Piece

Donut Deep Fryer

Price:13500 INR /Piece

Donut machine

Price:15000 INR /Unit

Donut Maker Machine

Price:165000 INR /Piece

Samosa Making Machine

Samosa Making Machine

Price:65000 INR /Piece

Samosa Sheet Making Machine

Price:35000 INR /Piece

SAMOSA MAKING MACHINE

Price:180000.00 INR /Kilograms

Samosa Making Machine

Price:250000 INR /Piece

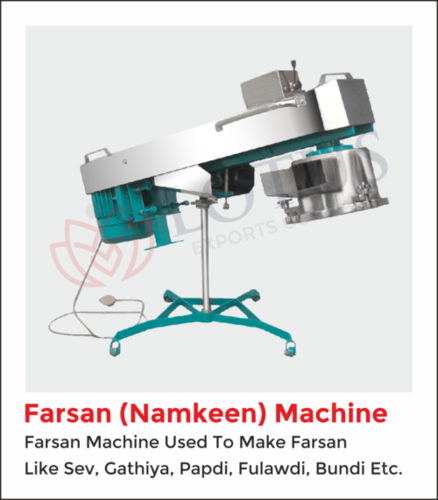

Farsan Machine

Farsan Making Machine

Price:22000 INR /Unit

Farsan Namkeen Making Machine

Price:18000 INR /Unit

Fafda Gathiya Making Machine

Price:16000 INR /Piece

Namkeen Making Machine

Price:23600 INR /Piece

FARSHAN MIXING MACHINE

Price:35000 INR /Piece

Popular Posts Related to Food Processing Machinery

Top 12 Masala Grinding Machine Brands in India

Discover the top 12 Masala Grinding Machine brands in India, offering high-quality and efficient solutions for your spice grinding needs.

12 Best Noodles Making Machine Manufacturing Companies in India

Checkout the 12 Best Noodles Making Machine Manufacturing Companies in India. Get their complete details of companies manufacturing and supplying top noodle machine.

Top 10 Affordable Popcorn Machines Manufacturers & Suppliers in India

Looking for the top popcorn machine manufacturers in India? Check out our list for 2023 and find the best popcorn machines for your business needs.

Top 5 Banana Chips Making Machine Manufacturers in India

Looking for a banana chips machine company? Visit top 5 banana chips making machine manufacturers, suppliers & exporters in India.

How to Do Machinery Export/Import Business?

Register Your Company

First, you will need to create a free seller account.

Get Your License

Request for your permits and licenses to become eligible.

Learn Regulations

Learn all about the rules and regulations of import & export business.

Hire Professional Shipping Company

Partner with ecommerce company to deliver your products.

Import/Export Business

Stepwise Process to Start the Import Export Business for Machinery Industry

Get Custom Clearance Document

Contact a custom clearing officer to get a go ahead to ship your products.

Recently Added Products in Machinery Categories

Policies & Schemes from Government of India for Machinery Industry

Agricultural machines take an important role to increase productivity with timely and precise fieldwork. To promote the usage of farm mechanization and increase the ratio of farm power to cultivable unit area up to 2.5 kW/ha, the scheme will be implemented in all the Indian states.

In order to address the skill gaps and infrastructure development and technology needs for the Capital Goods Sector, Phase I of the Capital Goods scheme was rolled out in November 2014 which has the total outlay of Rs 995.96 crores.

Ministry of Heavy Industries (MHI) notified the Phase 2 of the Scheme on January 25, 2022, with an objective to expand and enlarge the impact created by Phase I of the Capital Goods scheme, thereby providing greater impetus through creation of a strong and globally competitive capital goods sector.

Ministry of Heavy Industries, Government of India has notified Electric Mobility Promotion Scheme 2024 (EMPS 2024) with an outlay of Rs.500 crore for a period 4 months, w.e.f. 1st April 2024 till 31st July 2024. The scheme is introduced for faster adoption of electric two-wheeler (e-2W) and electric three-wheeler (e-3W - including registered e-rickshaws & e-carts and L5) to provide further impetus to the green mobility and development of electric vehicle (EV) manufacturing eco-system in the country.

Hon'ble Finance Minister, Smt Nirmala Sitharaman has announced an outlay of INR 1.97 Lakh Crores for the Production Linked Incentive (PLI) Schemes across 14 key sectors, to create national manufacturing champions and to create 60 lakh new jobs, and an additional production of 30 lakh crore during next 5 years.

Ministry of Micro, Small & Medium Enterprises (M/o MSME) envision a vibrant MSME sector by promoting growth and development of the MSME Sector, including Khadi, Village and Coir Industries, in cooperation with concerned Ministries/Departments, State Governments and other Stakeholders, through providing support to existing enterprises and encouraging creation of new enterprises.

Marketing, a strategic tool for business development, is critical for the growth and survival of MSMEs. Due to the lack of information, scarcity of resources and unorganized ways of selling/marketing, MSME sector often faces problems in exploring new markets and retaining the existing ones.

Government of India has undertaken various steps to promote manufacturing sector and to boost domestic and foreign investments in India. These include introduction of Goods and Services Tax, reduction in Corporate tax, interventions to improve ease of doing business, FDI policy reforms, measures for reduction in compliance burden, policy measures to boost domestic manufacturing through public procurement orders, Phased Manufacturing Programme (PMP), to name a few.

National Portal of India provides a single-window access to information and services that are electronically delivered from all Government Departments, Institutions and Organizations. It has been a popular source of information to a wide range of stakeholders - from citizens, to government, business and Indian Diasporas. It is a gateway to access Indian Government websites at Centre, State and District levels.