- Tradeindia

- Flexo Printing Machinery

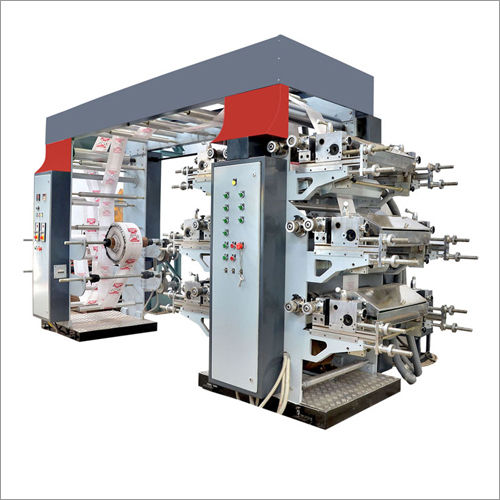

- Multi Color Flexo Printing Machine

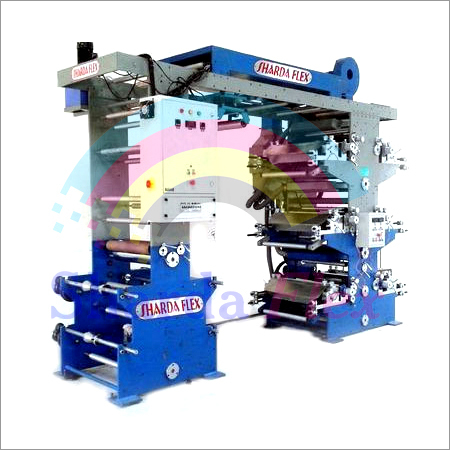

Multi Color Flexo Printing Machine

(258 products)Six Color Flexo Printing Machine - High-Speed Automatic Unit for Diverse Mediums | Features Double Winder & Unwinder, Reverse Printing Arrangement, 80-150m/Min Speed, PLC Control, High Insulation

1600000.00 INR/Number

MOQ1 Number

General UseIndustrial

ComputerizedNo

AutomaticYes

Control SystemPLC Control

Voltage220-240 Volt (v)

FeatureHigh Insulation

Flexographic Printing Machine - Capacity: 1500 T/Hr

Price: 280000.0 INR/Piece

MOQ1 Piece/Pieces

Product TypeFlexographic Printing Machine

General UseIndustrial

TypePrinting machine

Capacity1500 T/hr

Weight (kg)700 Kilograms (kg)

ComputerizedNo

Unique Fluid Controls

Coimbatore

Trusted Seller

Trusted Seller Super Premium

Super Premium Premium Seller

Premium Seller8 Years

2 To 8 Pp Fabric Eight Colour Flexographic Printing Machine

Price: 1150000 INR/Piece

MOQ1 Unit/Units

Color2 to 8

Printing MaterialPE

ComputerizedYes

AutomaticYes

Control SystemPLC Control

Printing Width20 inches Inch (in)

Mohindra Mechanical Works

New Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller23 Years

Two Color 1200Mm Flexo Printing Machine - Automatic Grade: Automatic

Price: 950000 INR/Kilograms

MOQ1 Container/Containers

Color ManagementDensity Adjustment

TypeRoll to Roll Printing Machine

MaterialNon Woven Fabric

Capacity10-60m/min m3/hr

Printing Speed10-60m/min m2/hr

ComputerizedYes

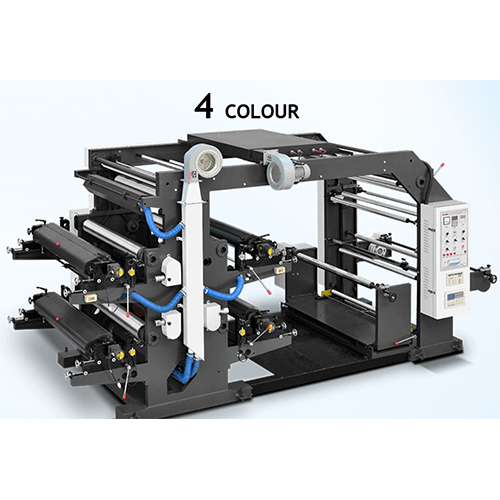

Four Colour Flexographic Printing Machine - Mild Steel, 24 Inch Width, 50m/min Speed | Automatic, Hydraulic Plate Lifting, Vibration Free Printing

MaterialMild Steel

Printing Width24 inch

Printing Speed50m/min

Frequency50 Hz

Power SourceElectric

Color PrintingColor Printing

Four Color Non Woven Flexo Printing Machine - Color: Grey Blue

Price: 1250000 INR/Set

MOQ1 Set/Sets

ColorGrey Blue

Product TypeFour Color Non Woven Flexo Printing Machine

General UseIndustrial

ComputerizedNo

AutomaticYes

Control SystemPLC Control

Kamtronics Technology Private Limited

New Delhi

Trusted Seller

Trusted Seller11 Years

Electric Automatic Fried Gram Color Sorting Machine Additional Ingredient: Aam Papad

Price: 450000 INR/Unit

MOQ50 Unit/Units

TypeElectric Automatic Fried Gram Color Sorting Machine

Power220 Volt (v)

Usagedal color sorting

Control SystemPLC Control

Swan Sorter Systems Pvt. Ltd.

Bengaluru

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

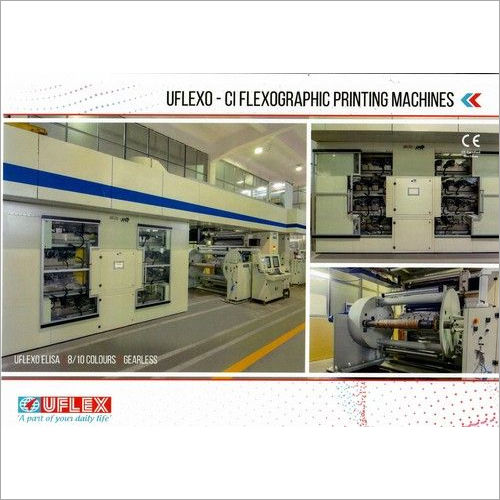

Automatic Ci Flexo Printing Press Model- Elisa

Price: 90000000 INR/Piece

MOQ1 Piece/Pieces

TypePrinting mahcine

ComputerizedYes

Automatic GradeAutomatic

4 Colour Flexo Printing Machine - Automatic Grade: Automatic

Price: 1450000 INR/Unit

MOQ1 Unit/Units

Type4 Colour Flexo Printing Machine

MaterialMild Steel

ComputerizedNo

Automatic GradeAutomatic

SizeStandard

Weight (kg)4300 Kilograms (kg)

Multi Color Flexo Printing Machine - Electric, Rust Free, New Industrial Grade | Automatic, PLC Control, Touch Screen, High Insulation, Lower Energy Consumption

Price: 1200000 INR/Unit

MOQ1 Unit/Units

ColorWhite, Blue

Product TypeMulti Color Flexo Printing Machine

General UseIndustrial

AutomaticYes

Control SystemPLC Control

FeatureLower Energy Consumption, High Insulation, Touch Screen

Moksha Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller9 Years

Blue Flexo Printer Slotter Combine Machine

Price: 1100000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeFlexo Printer Slotter Combine Machine

TypeFlexo Printer Slotter Combine Machine

AutomaticYes

Voltage220-440 Volt (v)

FeatureHigh Efficiency

Shree Krishna Engineering Works

Surat

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

Multicolor Flexographic Printing Machine - Automatic Grade: Automatic

Price: 350000 INR/Unit

MOQ1 Unit/Units

Product TypeFlexographic Printing Machine

General UsePrinting

MaterialMetal

Printing Speed100 m/m

Automatic GradeAutomatic

ComputerizedYes

Multi Color Flexo Printing Machine 2, Number Of Colors: 4-6

Printing MethodFlexography

Number Of ColorsFour-color

Max Printing Width1000mm

Printing Speed150m/min

Power50kW

Weight5000kg

Top Rated Products

Electric Automatic Fried Gram Color Sorting Machine Additional Ingredient: Aam Papad

Swan Sorter Systems Pvt. Ltd.

FAQs Related to Multi Color Flexo Printing Machine

What is stack flexo printing machine?

What is flexographic machine?

How does flexo printing work?

What type of ink is used in flexo printing?

- Primarily made of water and pigment, but also contains a variety of additives, such as defoamers and agents for drying and adhesion

- Among all ink kinds, typically have the highest surface tension

- Suitable for all types of elastomers, but natural mixes are the most popular

- Widely used in the corrugated packaging sector

- consisting mainly of pigments, alcohols and acetates, with a typical initial composition of 80-90% alcohols and 10-20% acetates.

- It is usually recommended to use water based EPDM elastomers, which typically have much lower surface tensions.

- Consists of monomers, photoinitiators, pigments and prepolymers.

- Dries and bonds only when exposed to electron beam or UV light.

- Increased viscosity

- Typically EPDM elastomer is recommended due to its ozone resistance.

- Often used in food packaging as an outer wrap

- including hydrocarbons, dyes and occasionally soya oil

- Mixed solvents such as naphtha and hexane are quite harsh.

- Mineral oil is sometimes used.

- The use of Buna/Nitrile elastomer is recommended.

- Widely used in publication printing

Multi Color Printing Machine

DimensionsLarge

MaterialSteel

WeightHeavy

Power3-Phase

SpeedVariable

Print WidthCustomizable

R. S. Converting Machinery

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller6 Years

Automatic Four Color Reel To Reel Flexo Printing Machine

Price: 2250000 INR/Unit

MOQ1 Unit/Units

TypeFlexo Printing Machine

MaterialMild Steel

ComputerizedYes

Automatic GradeAutomatic

Ink TypeUV Curing Ink

Warranty1 Year

Aluminium Foil & Solvent Printing Machine - Web Width 20" to 80", 1-8 Colors, Speed Up to 250 m/min | Durable, Low Maintenance, User-Friendly Design, 500 kg Weight

Price: 1000000.00 INR/Unit

MOQ1 Unit/Units

ColorWhite and Blue

Product TypeRice Bag Printing Machine

General UseBag Printing Machine

Weight (kg)500 Kilograms (kg)

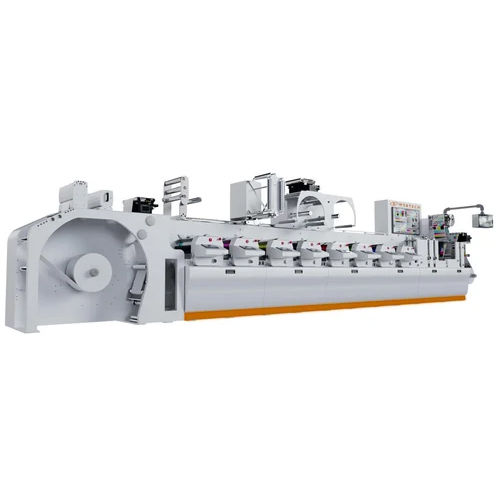

Multi Color Flexo Label Printing Press - Mild Steel, 0-500 mm Printing Length, 0-450 mm Printing Width | Automatic Operation, Lower Energy Consumption, More Than 8 Color Printing

Price: 6000000 INR/Unit

MOQ1 Unit/Units

ColorYes

Product TypeMulti Color Flexo Label Printing Press

General UseIndustrial

AutomaticYes

Control SystemManual

Printing Length0-500 Millimeter (mm)

Webtech International Machineries

Faridabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

View More

Automatic Multi Color Flexographic Label Printing Press Machine

Price : 8000000 INR

Gearless Ci Flexo Press - Color: White

Price: 50000000.0 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

Product TypeGearless Ci Flexo Press

General UseIndustrial

TypeGearless Ci Flexo Press

AutomaticYes

FeatureHigh Efficiency

Yellow Four Color Flexo Paper Printing Machine

Price: 1750000 INR/Unit

MOQ1 Unit/Units

ColorYellow

Product TypeFlexo Paper Printing Machine

General UseIndustrial

TypeFlexo Paper Printing Machine

ComputerizedNo

AutomaticYes

Flexo Printer

DimensionsLarge

MaterialSteel

WeightHeavy

PowerElectric

SpeedVariable

Print WidthCustomizable

Single Color Flexo Printing Machine - Best Grade Raw Materials, 1300x2200mm Printing Size | Durable Performance, Affordable Market Rates

Frequency50 Hz

Plate Size4-12 Inch

Paper Gsm200-400 Gsm

Production1000-2000/Hour

Voltage280V

MaterialSteel

Agarwal Trafin Private Limited

Kolkata

Trusted Seller

Trusted Seller Premium Seller

Premium Seller6 Years

8 Colour Flexographic Printing Machine - Color: Blue

Price: 180000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeFlexographic Printing Machine

General UseIndustrial

ComputerizedNo

AutomaticYes

Control SystemManual

Romco Offset Private Limited

Faridabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

6 Colour Flexo Printing Machine - Capacity: 1000 Kg/Hr

Price: 1800000 INR/Unit

MOQ1 Unit/Units

Capacity1000 Kg/hr

ComputerizedNo

AutomaticYes

Single Color Flexo Printer Machine, Power Source: Electric

Printing TypeFlexographic

ColorsSingle

Print SpeedVariable

Maximum Width1000 mm

Power3KW

MaterialSteel

Mano Industrial Machine Tools

Chennai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Industrial Multicolor Flexo Printing Machine - 220-240 Volt, Automatic PLC Control | Heavy Duty, Trouble Free Performance, Long Lasting Service, Easy to Operate, Lower Energy Consumption

Product TypeFlexo Printing Machine

General UseFlexo Printing

ComputerizedNo

AutomaticYes

Control SystemPLC Control

Voltage220-240 Volt (v)

4/6/8 COLOUR FLEXO PRINTING MACHINE WITH PLC AND WEB CAMERA

Price: 4800000 INR/Piece

MOQ1 Piece/Pieces

Color ManagementOther, 4/6/8 Color Printing

TypeFlexo Printing Machine

MaterialPaper Film and Other Flexible Materials

CapacityHigh Capacity

Printing Speed120-150 meters/min

ComputerizedYes

Advanced Flexo Printing Machine - Feature: High Insulation

Price: 1050000 INR/Piece

MOQ1 Piece/Pieces

Product TypeAdvanced Flexo Printing Machine

General Useprinting on boxes

Capacity70 to 80 m3/hr

ComputerizedYes

AutomaticYes

Control SystemManual

Automatic Flexo Printing Machine - 220V, 440V Voltage | Electric Drive, 10-15kw Power, Red Color, PLC Control

Price: 95000 INR/Unit

MOQ1 Unit/Units

ColorRed

Product TypeFlexo Printing Machine

General UseFlex Printing

TypePrinting Machine

ComputerizedNo

AutomaticYes

View More

Semi-Automatic Multi Color Flexo Printing Machine

Price : 665500 INR

White Mild Steel Flexo Printing Machine

Price: 3000000.0 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

Product TypeFlexo Printing Machine

AutomaticYes

Control SystemPLC Control

Voltage380 Volt (v)

Dimension (L*W*H)5300x2100x3000 Millimeter (mm)

Latest from Multi Color Flexo Printing Machine

Multi Color Flexographic Label Printing Press Machine

8000000 INR

By:

Webtech International Machineries

Multi Color Flexo Printing Machine 5

By:

Krupa Engineering

Multi Color Flexo Printing Machine 2

By:

Friends Engineering Corporation

Multi Color Flexo Printing Machine

By:

M. S. Machine Tools

Popular Multi Color Flexo Printing Machine

All About Multi Color Flexo Printing Machine

Stack type four-colour high speed flexographic printing machine guarantees easy operation and precise colour processing, especially for long print runs on all materials. With CMYK, it is possible to print multiple colours or specific shades on rolling material.

The print quality and stability of this bridge flexo press is superior and it can print on HDPE, LDPE, PP, roll paper, non-woven and other materials.

Non-woven surfaces with coarse texture are suitable for printing. Fine colour patterns are produced in lines. It has strong adhesion, high colour saturation, good smoothness and high speed.

The first flexographic printing press was invented in 1890 in Liverpool, England by Bibby, Baron and Sons as a printing technique based on the idea of the rubber stamp. In the early 1900s, the process used an oil-based aniline ink, hence the term 'aniline printing'.

Flexo printing was used for food packaging in the USA in the early 20th century, but the FDA later deemed the ink unsuitable for use on food. It wasn't until the middle of the century that safer inks were developed. This printing technique was given the name flexography in 1951.

- Flexible start-up, easy operation and precise colour registration.

- The print quantity can be changed using the metre counter. When the material is cut or the quantity is reached, the machine stops automatically.

- Pneumatic print cylinder lifts and lowers, automatically stirring the ink after lifting.

- The anilox cylinder distributes the ink evenly.

- A reliable drying system, synchronised with high speed rotation, which automatically interrupts the circuit when the machine stops.

- 360° continuous and variable longitudinal register.

- Frequency-controlled motor speed to accommodate different printing speeds.

- When the plate is mounted, the machine is easy to operate thanks to the jogging/stopping buttons on the material roller rack and plate roller base.

Types of Multi Color Flexo Printing Machine

There are three different types of flexographic presses: stack presses, in-line presses, and CI presses.

Uses of Multi Color Flexo Printing Machine

The process of flexographic printing, also known as flexo printing, involves the transfer of quick-drying inks from flexible printing plates to a substrate.

It is primarily used to print text and images on a wide range of materials, including plastics, metal foils, paper and non-wovens. Flexo printing has many advantages, such as

- The speed of the production process, which is fully automated once the initial set-up is complete.

- Access to a wide range of inks

- Environmentally friendly method when using water-based inks

- Low maintenance and long life of parts.

Top Manufacturers and Suppliers of Multi Color Flexo Printing Machine

Top manufacturers and suppliers of multi color flexo printing machine are mentioned below-

- Flexor Allied India. 3.3.

- Gabbar Industries Pvt Ltd. 4.6.

- R K Label Printing Machinery Pvt Ltd. 4.7.

- C. Innovative Flexotech Pvt Ltd.

- K P Tech Machine INDIA Pvt Ltd. 3.9.

- Alpha Roto Machines Pvt Ltd. 4.4.

- Krishna Engineering Works (Manufacturing Unit) 3.4.

- Pth Pharma Industries. 2.7.

Uses of Multi Color Flexo Printing Machine

The main purpose is to print text and images on a wide range of materials, including plastics, metal foils, paper and non-wovens.

Multi Color Flexo Printing Machine Price List

Product Name | Expected Price |

|---|---|

| Vertical Flexo Printing Machine | 2700000 |

| Multi Color Flexo Label Printing Press | 13000000 |

| Long Lasting Flexo Graphic Printing Machine | 1150000 |

| Hdpe Bag Flexographic Printing Machine | 410000 |

| Multicolor Flexographic Printing Machine | 2551100 |

| Four Color Flexo Printing Machine | 550000 |

| 8 Color Flexo Machine | 1400000 |

| 4 Color Flexo Machine | 1200000 |

| Multicolor Flexographic Printing Machine | 350000 |

| Flexo Printing Machine | 500000 |

This Data was Last Updated on 2025-11-26

Multi Color Flexo Printing Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Uflex Limited (engineering Division) Noida, India | 24 Years |

Mohindra Mechanical Works New Delhi, India | 23 Years |

Friends Engineering Corporation New Delhi, India | 22 Years |

Perfect Machinery New Delhi, India | 14 Years |

Kamtronics Technology Private Limited New Delhi, India | 11 Years |

Care Polypack Pune, India | 10 Years |

Moksha Engineering Works Ahmedabad, India | 9 Years |

Samir Machinery Vadodara, India | 9 Years |

Unique Fluid Controls Coimbatore, India | 8 Years |

Surya Laxmi Industries Delhi, India | 8 Years |

Upcoming Tradeshows

Pune's 1st Fire, Safety & Security Expo 2026 (PFSS)

Thu, 07 May, 2026 - Sat, 09 May, 2026

17th Coating Korea - Coating Adhesive Film Industry Expo 2026

Wed, 25 Mar, 2026 - Fri, 27 Mar, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

FOOTWEAR INDIA EXPO 2026

Fri, 23 Jan, 2026 - Sun, 25 Jan, 2026

The Harit Bharat Expo 2026

Fri, 16 Jan, 2026 - Sun, 18 Jan, 2026

Power On 2026

Fri, 23 Jan, 2026 - Sun, 25 Jan, 2026

SVUM 2026 INTERNATIONAL TRADE SHOW

Wed, 11 Feb, 2026 - Fri, 13 Feb, 2026

GrainEx India 2026

Fri, 06 Feb, 2026 - Sun, 08 Feb, 2026

CIFF - China International Furniture Fair Guangzhou 2026

Wed, 18 Mar, 2026 - Sat, 21 Mar, 2026

ET TECH X 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Popular Categories