Packaging Machine

(9685 products)

Packaging Machines excel in automating the packaging process, ensuring efficiency and precision. These machines are highly adaptable, catering to diverse industries and packaging needs. The ZIGMA 266 excels in wafer packaging, while the 69 arm development board packaging equipment is tailored for electronic components. The packaging equipment solar power system streamlines the packaging of solar panels, and the automatic packaging machines handle various products seamlessly. The MK-4 deep freezer food packaging containers are ideal for food preservation. Overall, Packaging Machines offer versatility and efficiency, making them indispensable tools for businesses.

...show moreThe provided context does not mention what a packaging machine is.

The provided context does not mention the different types of packaging machines.

The provided context does not mention how packaging machines work.

The provided context does not mention the benefits of using packaging machines.

The provided context does not mention the factors to consider when choosing a packaging machine.

Top Packaging Machine Categories

Explore More Categories

Made in India

Automatic Industrial Powder Packaging Machine

Price: 130000 INR (Approx.)/Unit

MOQ- 1 Unit/Units

Color - Silver

Material - Stainless Steel

Feature - Heavy Duty Machine, Highly Efficient

3 Years

National Pouch Packing Machine

Made in India

Automatic Alu Blister Packing Machine Capacity: 200 Kg/Hr

Price: 1800000 INR (Approx.)/Piece

MOQ- 1 Piece/Pieces

Type - Pharmaceutical Packaging Machine

Material - Stainless Steel

Feature - Other

21 Years

Jicon Technologies Private Limited

Product Showcase

Made in India

Less Power Consumable Biscuit Packing Machines (Family Pack)

Price: 7500000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Type - Packaging Line

Material - Stainless Steel

Feature - Highly Efficient, Less Power Consumable

13 Years

Business Type: Manufacturer | Supplier

AKASH PACK TECH PVT. LTD.

Made in India

Stainless Steel Reliable Machine At The Price Of A Strapping Tool

Price: 220000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Material - Stainless Steel

Warranty - Yes

17 Years

Business Type: Manufacturer | Supplier

JOIN PACK MACHINES (PVT.) LTD.

Indian Inquiries Only

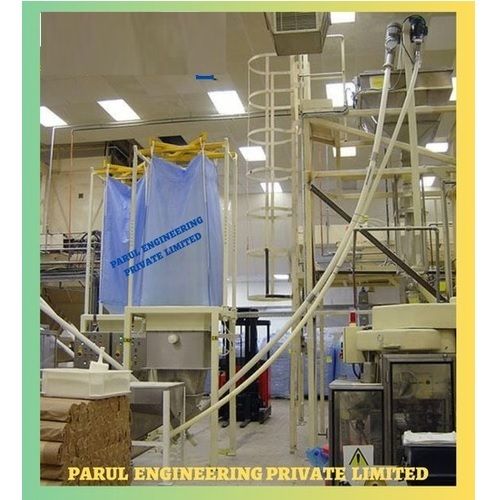

Jumbo Bag Unloading System

Price: 450000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Type - Other, Jumbo Bag Unloading System

Feature - Highly Efficient

Automatic Grade - Automatic

2 Years

Business Type: Manufacturer | Supplier

PARUL ENGINEERING PRIVATE LIMITED

Semi-Automatic Semi Automatic Pouch Packaging Machine

Price Trend: 70000.00 - 120000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Type - Other, Semi Automatic Pouch Packaging Machine

Material - Stainless Steel

Feature - Heavy Duty Machine

3 Years

Business Type: Manufacturer

AUTO POWER PACK

Stainless Steel Automatic Noodles Packaging Machine

Price: 425000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Material - Stainless Steel

Automatic Grade - Automatic

Drive Type - MOTO,PULLE, Other

13 Years

Business Type: Manufacturer | Supplier

RISING INDUSTRIES

Made in India

Ss Innovative Powder Semi-Automatic Filling Machine Model Iapfm001

Price: 250000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Color - metallic grey, Other

Type - Filling Machine

Material - SS

3 Years

Business Type: Manufacturer

INNOVATIVE ENGINEERING WORKS

Tea Leaf Vacuum Packing Machine

20 Years

Business Type: Manufacturer | Supplier

SHRI VINAYAK PACKAGING MACHINE PVT. LTD.

Indian Inquiries Only

Made in India

Automatic Auger Filler Machine

Price Trend: 150000.00 - 550000.00 INR (Approx.)/Piece

MOQ - 5 Piece/Pieces

Type - Filling Machine

Material - Stainless Steel

Feature - Highly Efficient, Less Power Consumable, Durable

4 Years

Business Type: Manufacturer | Supplier

TIRUMALA ENGINEERING INDUSTRIES

Indian Inquiries Only

Compress Packaging Machine - Automatic Grade: Automatic

MOQ - 1 Unit/Units

Type - Packaging Line

Material - Stainless Steel

Feature - Highly Efficient

7 Years

Business Type: Manufacturer | Supplier

SHRI VINAYAK PACKAGING MACHINE PRIVATE LIMITED

Indian Inquiries Only

Made in India

Stainless Steel Jet-Pf120-4 Automatic Powder Filling Machine

Price: 3200000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Material - Stainless Steel

Automatic Grade - Automatic

Drive Type - Electric

7 Years

Business Type: Manufacturer | Exporter

JETPACK MACHINES PVT. LTD.

PLC Control Automatic Dry Fruit Packing Machine

Price: 750000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Color - Other, Yellow

Type - Auxiliary Packaging Machine

Material - Stainless Steel

2 Years

Business Type: Manufacturer | Distributor

ELITE PACKTECH

Indian Inquiries Only

Made in India

Semi-Automatic Double Chamber Vacuum Packing Machine

Price: 200600.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Color - Other

Type - Vacuum Packing Machines

Material - SS & MS

9 Years

Response Rate: 70.42%

Business Type: Manufacturer | Distributor

SMART PACKAGING SYSTEM

Indian Inquiries Only

Automatic weighmetric big bag packaging line ( 5 to 50 kg )

Price: 2000000 INR (Approx.)/Set

MOQ - 1 Set/Sets

4 Years

Business Type: Manufacturer | Supplier

LABH PROJECTS PVT. LTD.

Verified Exporter

( Accepts only Foreign Inquiry)

Made in India

Shrink Packaging Machine

Price: 175000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Color - Grey

Type - Shrink Packaging Machine

Material - Mild Steel

19 Years

Business Type: Manufacturer

JOY PACK INDIA PVT LTD

Indian Inquiries Only

Made in India

Semi-Automatic M-Series Hffs Pouch Packaging Machine

MOQ - 1 Unit/Units

Material - Stainless Steel

Feature - Heavy Duty Machine

Computerized - No

3 Years

Business Type: Manufacturer | Distributor

MAMATA MACHINERY PVT. LTD.

Made in India

Industrial 220 V Single Phase Weighing and Bagging Systems

Price: 90000. INR (Approx.)/Unit

MOQ - 1 Unit/Units

Color - Silver

Material - Stainless Steel

Feature - Highly Efficient, Less Power Consumable, Rust Proof

2 Years

Business Type: Manufacturer | Exporter

KRISHNA GRAIN SYSTEMS PVT. LTD.

Made in India

Automatic Flour Packing Machine

Price: 1400000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Color - Other, Gray

Type - Multi-Function Packaging Machines

Material - Stainless Steel

11 Years

Business Type: Manufacturer | Supplier

AVM PACKAGING SYSTEMS

Made in India

Mineral Water Packing Machine 2, Certifications: ISO

5 Years

Business Type: Manufacturer | Supplier

SHREE KRISHNA PACKGING MACHINERY

Made in India

Automatic Juice Packaging Machine

Price: 800000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Material - Metal

Automatic Grade - Automatic

Control System - Human Machine Interface

2 Years

Business Type: Manufacturer | Distributor

KB ASSOCIATES

Made in India

Automatic Carton Sealer Auto Packing Line

Price Trend: 85000.00 - 185000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Material - Mild steel

Feature - Durable, Highly Efficient

Automatic Grade - Automatic

4 Years

Business Type: Manufacturer | Service Provider

SHRI VINAYAK PACKAGING MACHINE PVT. LTD.

Indian Inquiries Only

Automatic Auger Pouch Packing Machine

Price Trend: 550000.00 - 950000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Type - Packaging Line

Material - Stainless steel

Automatic Grade - Automatic

10 Years

Business Type: Manufacturer | Exporter

SHREEM ENGINEERS

Automatic Cellophane Overwrapping Machine Dimension (L*W*H): 1800X850X1200 Millimeter (Mm)

Price: 800000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Color - Other, Gray

Type - Wrapping Machines

Material - Stainless Steel

2 Years

Business Type: Manufacturer | Distributor

WENZHOU TRUSTAR MACHINERY TECHNOLOGY CO., LTD.

Made in India

Manual Cellophane Overwrapping Machine

Price: 40000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Type - Other, Manual Cellophane Overwrapping Machine

Computerized - No

Automatic Grade - Manual

2 Years

Business Type: Manufacturer | Exporter

SOARMLICH ENGINEER

Made in India

Blister Packing Machine

Price Trend: 450000.00 - 1500000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Type - Packaging Line

Material - SS

Automatic Grade - Automatic

7 Years

Response Rate: 76.92%

Business Type: Manufacturer | Distributor

ALLMACH PHARMA MACHINERY PRIVATE LIMITED

Made in India

ORBITAL FV350 Orbital Wrapping Machine

Price Trend: 200000.00 - 1000000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

3 Years

Business Type: Manufacturer

FROMM PACKAGING SYSTEMS INDIA PVT. LTD.

Indian Inquiries Only

Made in India

Automatic L Sealer

Price: 1150000 INR (Approx.)/Unit

MOQ - 01 Unit/Units

Automatic Grade - Automatic

Power - Auto L Sealer 220V, Shrink Tunnel 220V / 380V Volt (v)

Dimension (L*W*H) - Automatic L Sealer- 2100x930x1580, Shrink Tunnel-1865x720x1450 Millimeter (mm)

5 Years

Response Rate: 99.1%

Business Type: Manufacturer | Distributor

MANILAL PACKPLAST LLP

Made in India

Ss304 Automatic Double Head Pouch Packing Machine 1Kg

Price: 295000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Type - Other

Material - SS304

Feature - Highly Efficient, Less Power Consumable, Heavy Duty Machine, Rust Proof, Other

6 Years

Response Rate: 87.65%

Business Type: Manufacturer | Distributor

SHRI RAM PACKAGING SYSTEM

Made in India

Automatic M3-11 Auto Cartonating Machine

Price: 1200000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Color - Blue

Type - Packaging Line

Material - Mild Steel

3 Years

Business Type: Manufacturer | Supplier

SHREEJI SHRINK SYSTEM

Packaging Machine Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Shri Vinayak Packaging Machine Pvt. Ltd. | New Delhi, India | 20 Years |

| Joy Pack India Pvt Ltd | Delhi, India | 19 Years |

| Join Pack Machines (Pvt.) Ltd. | Delhi, India | 17 Years |

| Akash Pack Tech Pvt. Ltd. | Faridabad, India | 13 Years |

| Rising Industries | Kolkata, India | 13 Years |

| Avm Packaging Systems | Mumbai, India | 11 Years |

| Shreem Engineers | Ahmedabad, India | 10 Years |

| Smart Packaging System | Indore, India | 9 Years |

| Shri Vinayak Packaging Machine Private Limited | New Delhi, India | 7 Years |

| Jetpack Machines Pvt. Ltd. | Vasai, India | 7 Years |

The Importance of Packaging Machines in the Food Industry.

When it comes to providing consumers with high-quality food and drinks, nothing is more crucial than the packaging used to transport, store, sell, and distribute those goods. In addition, it protects perishable foods from damage caused by rough handling during shipment. The evaluation, production, and design of packages are only some of the many needs that can be fulfilled by the cutting-edge capabilities and processes included in the packaging machines. The customer benefits from knowing more about the product's price, quality, efficiency, safety, environment, branding, logistics, and relevant laws.

The demand for faster and more aesthetically pleasing packaging of food goods has led to the development of increasingly sophisticated packing equipment.

Several areas of the food industry can benefit from the high-tech and advanced features of today's packaging machinery.

- Gives customers access to a high-quality product

- Reduced need for human intervention.

- Put in place stringent safeguards to prevent damage to products.

- Food tastes fresh after a long time

- Maximize the durability of your products.

- Save money on labor

- Accelerate the ordering process.

- Continuous backing throughout the years.

- Strengthen potentials

- To increase sales and profits, it is important to have packaging that stands out.

What is a Packaging Machine

From the initial product packaging to the final distribution packets, packaging machinery is used in every step of the packaging process. Manufacturing, filling, sealing, cleaning, labeling, combining, palletizing, and overwrapping is all part of the packaging process.

Because of the high cost and high risk involved in developing an entirely new type of Packaging Machine, it is recommended that manufacturers base their new designs on modifications to existing formats that can be accommodated by modifying existing technology.

The process of packaging involves unrolling a sheet of material, cutting it to size, bending it into shape, filling it, and then sealing it. Obviously, the "cutoff" and "web" dimensions of the container should be reflected in the printed materials.

How does a packaging machine work

Here are the processes of packaging machine functions:

1. Bag loading

Using a readymade pouch packing machine begins with the loading of the bags. Here, the bags that will be utilized to package the item are loaded into the machine. The bags are typically placed in a hopper at the top of the device.

The bags are fed from a hopper into a sealing mechanism, where they are subsequently sealed. After the sealed bags are opened, the merchandise is placed inside. When the bag is full, it is sealed and prepared for packaging.

2. Printing of Dates

Packaged goods must have dates for several reasons. Their primary value lies in the fact that they inform buyers of the exact moment their purchases were made. Yet another justification is that they can serve as a promotional tool for the goods.

An integral part of using a packing machine for manufactured pouches is printing the date on the packaging.

At this point, the bag receives its date stamp. Typically, the pouch's front or rear bears the current date. The printer utilized is determined by the machine.

It's not enough to simply print the date on the pouch; the date must also be encoded. The date is represented by a code printed on the pouch.

3. Packaging & Sealing

The next phase in the packaging process for a prepared pouch packaging machine is the packaging and sealing process.

At this point, the goods are placed into the pouch for shipping. Products are typically loaded into a hopper at the top of the machine. The product is fed from the hopper into a sealing mechanism, and the pouch is then sealed around the product.

Once the sealed pouch is opened, the item is shipped. Ultrasonic sealing is a feature of other pouch-packing devices as well. Ultrasonic sealing is a type of packaging in which the bag is sealed using ultrasonic waves.

To keep the contents of the pouch from escaping, ultrasonic waves are employed to generate heat. This approach is frequently employed in the packaging of food products since it helps to maintain the product's flavor and freshness.

4. Deflation

To deflate means to empty a pouch of its air content. The product's freshness and shelf life are both increased by this measure.

Deflation can be accomplished in two primary ways: manually and automatically. When deflating anything manually, you do so with your hands, while when deflating something automatically, the machine does it.

5. Cleaning

The packaging machine must be cleaned after each usage. This ensures the machine keeps running smoothly and the product is packed properly.

Premade pouch packaging machines have different cleaning procedures that need to be followed. However, most machines call for the product to be withdrawn from the machine and the sealing mechanism to be cleaned.

The machine's immediate surroundings should also be tidied up. For the sake of the machine's cleanliness and the quality of the output, this is essential.

6. Cooling

The chilling procedure aids in maintaining a cool environment, shielding the product from air.

Cold air and water are the two most common means of cooling a space. Products can be cooled with cold air by having it blown on them, or with water by having it sprayed on them.

Different machines and different products call for different cooling techniques.

As soon as the product has been packaged, it needs to be cooled down. This prevents the product from being exposed to air and serves to prolong its shelf life.

Types of packaging machine and equipment

1. Palletizers

When installed on an assembly line, a dependable palletizer can drastically cut down the time it takes for a newly packaged product to reach the market. The precision of packing machines like the compact palletizer offered by Trident Pack is enhanced by their use of 4 axes of motion and servo motors.

2. Coders and Printers

The product coders are among the most versatile on the market, capable of printing logos, QR codes, date codes, and more onto a wide variety of substrates. Especially useful are laser coders for creating anti-counterfeiting marks on high-end goods.

3. Labelling Machines

The label on a product is its primary means of identification, and it should also provide useful information to the buyer. Print-and-apply machines use thermal technology to create high-resolution labels, and they can be either direct thermal printers, which can handle a broad variety of labeling needs or thermal transfer printers, which generate prints that are more robust and long-lasting.

4. Case Erectors

You'll save time on the assembly line thanks to these robots' ability to quickly assemble boxes. Case sealers, which use tape or glue to close the box, are often used in tandem with case packers. The erector and sealer functions of some packing machines are combined. In particular, the 3-in-1 case packer offered by Trident Pack is able to assemble the case, pack the contents, and seal the lid all in one convenient unit.

5. Case Packers

Manual packing is not only inefficient in terms of time, but it also poses a risk of injury to assembly line workers due to repetitive motion. Employing a case-packing machine allows businesses to free up workers for more complex tasks while increasing productivity. Up to 50 picks per minute are possible with some case packers.

6. Strapping/Bundling Machines

Heavy boxes should be strapped shut in addition to being taped shut, and long pieces of lumber and metal should be bundled together. This facilitates shipping and reduces the potential for injury or damage to goods.

7. Heat Sealing Machines

Products, especially those used in the food or pharmaceutical industries, typically need to be sealed to prevent tampering or contamination. A package can be sealed with a heat sealing machine, which melts plastic film or glue. In addition, certain models have the capacity to shrink-wrap packages, which involves removing excess air from the container before sealing.

8. Sterilization Machines

Sterilization equipment eliminates pathogens including bacteria, viruses, and spores so that food is safe to eat. This makes sure that the products may enter the market without any problems and won't end up being unsafe for consumers.

9. Filling/Bottling Machines

Automated filling lines transport bulk materials like grains and liquids to storage containers. While the Matrix TECNA G-V is made to handle flat wine, most bottling machines are tailored to a certain beverage. Machines like these need to be precise because they are responsible for continuously filling thousands of containers to the same height.

Conclusion

It's no surprise that developing nations are driving the increase in packing machinery demand. Possessing the infrastructure to safely store and transport perishable goods is a major step toward achieving national self-sufficiency. Packaging companies can differentiate their wares from the competition by utilizing unique labels that feature corporate logos and catchphrases printed using a labeling machine.

Have you thought about what kinds of tools you'll need? If you want a productive and trustworthy manufacturing line to emerge from this process, the next step should be to consult with professionals.

FAQs: Packaging Machines

Q. Are packaging equipment and packaging machines the same?

Ans. Yes, they’re same! All phases of packaging, from initial packaging to final distribution packs, require the use of packaging machinery.

Q. Benefits of packaging machines?

Ans. Here are the benefits:

Easily Keeps Up with the Increasing Demand

Helps Keep Wages Down

Aids in Minimizing Both Waste and Rejected Goods

Improved Quality Control

Quicker rates of production

Q. Types of packaging machines?

Ans. The different types of packaging machines include carbonators and pasteurizers, Sterilization machines, Heat Sealing machines, Strapping and Bundling machines, and Case packers.

Q. Drawbacks of packaging machines?

Ans.The drawbacks are:

You can’t rotate the machine because of heavyweight

You need to get insurance on time

Too much expensive

Timely repairing cost

Related Topic:

Top 10 Packaging Machine Manufacturers, Suppliers & Exporters in India

Related Categories

Agarbatti Making Machines

Agricultural Machines & Tools

Bag Closing Machine

Bag Making Machine

Bag Packaging Machines

Banking Automation Products

Bending Machines

Billing Machine

Biscuit Making Machinery

Block Making Machine

Blow Moulding Machines

Box Making Machines

Braiding Machine

Brick Making Machine

Briquettes Making Machines

Briquetting Plants

CNC Machines

Cable Machinery

Carton Folding & Gluing Machines

Cashew Processing Machine

Cement Plant Machinery

Ceramic Machinery

Chapati Making Machines

Chemical Machinery

Chemical Processing Plants

Chuck

Coating Machine

Coil Winding Machines

Coir Machinery

Compression Testing Machines

Concrete Batching Plant

Confectionery Machinery

Construction Equipment

Construction Machinery

Cotton & Synthetic Spinners

Cutting Machine

Cylindrical Grinding Machinery

Dairy Equipment

Dairy Products Machinery

Decorative Laminate Machinery

Diamond Cutting Blades

Diamond Cutting Discs

Diamond Cutting Machines

Diamond Cutting Tools

Diamond Cutting Wheels

Diamond Grinding Wheel

Diamond Polishing Pads

Diamond Polishing Wheels

Dispenser Machine

Earth Moving Equipment & Machinery

Electrical Cable Machine

Embroidery Machine

Extraction Plants & Machinery

Extruder

Filter Machinery

Fishery Machinery

Flexo Printing Machinery

Flour Mill Machinery & Accessories

Food Processing Machinery

Footwear Machinery

Forest Machinery

Fruit & Vegetable Processing Machine

Gas Generation Equipment

Glass Processing Machines

Granite Processing Machinery

Grinding & Milling Machinery

Home Sewing Machine

Horticulture, Gardening & Irrigation Machinery

Hosiery Machinery

Ice Cream Machines

Ice Cream Plants

Industrial Gas Plants

Industrial Machinery & Parts

Injection Moulding Machine

Jewelry Making Tools & Machinery

Jute Mill Machinery

Knitting Machinery

Knitting Needles

Label & Sticker Labeling Machine

Lamination Machinery

Lamp Making Machinery

Laser Cutting Machines

Lathe Machine

Leather Machinery

Liquid Filling Machines

Machine Tools

Machine Tools Accessories

Machineries

Machinery & Parts

Marine Equipment

Metallic Processing Machinery

Metallurgy Lab Equipment

Mining, Exploration & Drilling Machinery

Mosaic Tiles Machinery

Oil & Gas Field Machinery & Equipment

Oil Expeller

Oil Extraction Machine

Oil Mill Machinery

Oil Refinery Plant

Oil Seed Extraction Machinery

Other Machinery

Oxygen & Nitrogen Gas Plants

PU False Twister

Packaging Machine

Paint Manufacturing Machines

Paper Printing & Book Binding Machine

Paper, Paper Converting Machinery

Pharmaceutical Machinery

Planetary Mixer

Plant & Machinery

Plasma Cutting Machines

Plasma Welding Machines

Plastic Processing Machinery

Plastic Sealing Devices

Plywood Machinery

Polish & Polishing Material/Machinery

Polyurethane Foaming Machines

Pressure Fingers

Printing Ink Machinery

Printing Machinery

Processing Machines & Equipment

Pulverizers

Ribbon Blender

Rice Machinery

Rice Mill Machinery

Road Construction Machinery

Roll Forming Machinery

Rolling Mill Machinery

Rotogravure Printing Machine

Rotomoulding Machines

Rubber Extrusions

Rubber Machinery

Rubber Moulding Machines

Sealing Machine

Seed Processing Machinery

Sewing Machine

Sewing Machine Parts & Accessories

Shearing Machine

Shredding Machine

Shrink Wrapping Machines

Soap Making Machine

Soaps & Detergent Plants

Soda Making Machine

Sorting Machine

Special Purpose Machines

Spinning Machinery

Stamping Machine

Starch and Starch Machinery

Steel Rolling Mills Machinery

Strapping Machines

Stretch Wrapping Machines

Sugar Machinery

Tea & Coffee Machines

Textile & Garment Machinery

Textile Dyeing Machinery

Textile Finishing Machinery

Textile Machinery Spares, Components & Accessories

Textile Printing Machinery

Textile Processing Machinery

Tyres Repair & Retreading Machinery

Universal Testing Machines

Used Machinery

Vending Machine

Waste Tyre Recycling Plant

Water Jet Cutting Machine

Weaving Machinery

Weighbridge

Weighing Machines

Welding Electrode Plant & Machinery

Welding Machine

Wire Drawing Machines

Wire Machinery

Wire Winding Machines

Woodworking Machinery

Worsted Spinners