- Tradeindia

- Briquettes Making Machines

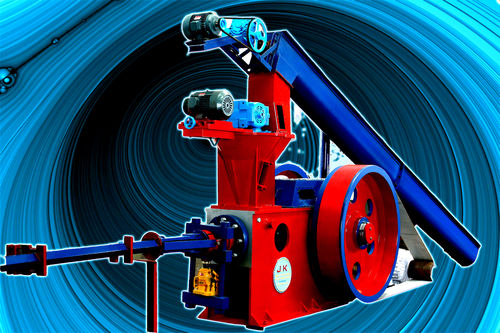

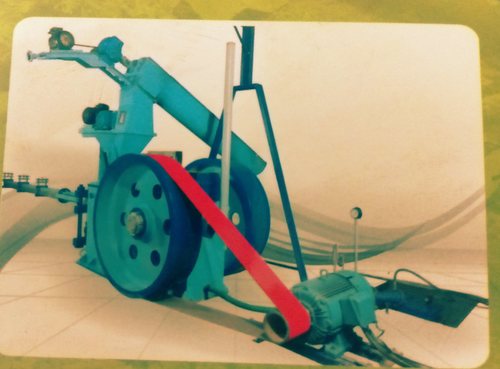

- Bio Coal Briquetting Machine

Bio Coal Briquetting Machine

(38 products)White Coal Briquetting Machine Dimension(L*W*H): 2.2X2.5X2.6 Millimeter (Mm)

Voltage220, 380, 415, 460 Volt (v)

Dimension (L*W*H)2.2x2.5x2.6 Millimeter (mm)

Karunanand Hydro-pneumatic Controls Pvt. Ltd.

Ambernath

Trusted Seller

Trusted Seller2 Years

Super Seller

Super SellerCompact Structure Electric Briquette Making Plant

Price: 100000 INR/Unit

MOQ1 Unit/Units

Product TypeBriquette Plant

Production CapacityUp to 2000 Kg/hr

Product ShapeCylinder

Biocoal Briquette Machine

Price Trend: 500000.00 - 1600000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability1 Per Week

Delivery Time30 Days

Ecostan India Pvt Ltd

Ludhiana

Trusted Seller

Trusted Seller10 Years

Premium Seller

Premium SellerBiomass Briquetting Machine Jumbo-90 1500 Kg/Hr - Briquette Size: 90Mm

Price: 2251000 INR/Unit

MOQ1 Unit/Units

ColorOther

Product TypeBIOMASS BRIQUETTING MACHINE JUMBO-90

MaterialSawdust

Radhe Engineering Company

Rajkot

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerBiomass Briquetting Machine

Price: 2100000.00 INR/Unit

MOQ1 Unit/Units

Payment TermsLetter of Credit (L/C), Cash on Delivery (COD), Paypal, Western Union, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Against Delivery (CAD), Cash Advance (CA), Others, Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque

Delivery Time5 Days

Sample AvailableYes

Ask Engineering Works

Hyderabad

Trusted Seller

Trusted Seller9 Years

Premium Seller

Premium SellerBio Coal Briquettes Plant System - Feature: High Efficifiency

Price: 1000000 INR/Unit

MOQ1 Unit/Units

Product TypeBio Coal Briquettes Plant System

General UseIndustrial

MaterialOther, Mild Steel And Stainless Steel

Roller Briquetting Machine

Price Trend: 3000000.00 - 7000000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability10 Per Month

Delivery Time1 Week

Santec Baling And Recycling Systems

New Delhi

Trusted Seller

Trusted Seller6 Years

Premium Seller

Premium SellerBriquette Double Acting Machine

Product DescriptionWe are involved in the business of manufacturing, exporting and supplying of premium quality Briquette Double Acting Machine from Coimbatore, Tamil Nadu, India. The offered machine is made by our experts using sophisticated machines and tested raw material, which is procured from the authentic vendo

Agro Waste Briquetting Plant

Product DescriptionOur industry bring forth for our estimated costumers a superior quality Agro Waste Briquetting Plant. While fabricating these Agro Waste Briquetting Plant, we take extra care of quality so our clients get best product. Our clients can avail from us these products at most reasonable rates.\015\012

Briquette Plant

Product Descriptionwe are the leading manufacturer of Briquette Plant in which we have different size for different capacity we can supply to our client as per their requirement n their application. Total customer satisfaction has remained our preferred choice since our inception. We never compromise on matters of qua

Energy Saving Briquette Machine

Price Trend: 650000.00 - 1450000.00 INR/nos

MOQ1 nos

General UseBriquette Manufacturing

MaterialSawdust

Production Capacity1000-1200 T/hr

Top Rated Products

White Coal Briquetting Machine Dimension(L*W*H): 2.2X2.5X2.6 Millimeter (Mm)

Karunanand Hydro-pneumatic Controls Pvt. Ltd.

FAQs Related to Bio Coal Briquetting Machine

Who are the top bio coal briquetting machine manufacturers in India?

- Jay Khodiyar Machine Tools

- Ronak Engineering

- Ecostan India Pvt Ltd

- Ask Engineering Works

- Santec Baling And Recycling Systems

- Posh Dynotech (india)

- Mahadev Projects Consultancy

- Karunanand Hydro-pneumatic Controls Pvt. Ltd.

- Radhe Engineering Company

- Renato Hitech Private Limited

Which cities have the largest number of bio coal briquetting machine suppliers?

- Delhi

- Rajkot

- Coimbatore

- Ahmedabad

- Ludhiana

- Ambernath

- Aurangabad

- Zhengzhou

- Gongyi

- Nanyang

- Shanghai

- Wuxi

What is the price range for bio coal briquetting machine offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| Renato Hitech Private Limited | INR | Bio Coal Briquettes Plant System | 1000000 |

| Radhe Engineering Company | INR | BIOMASS BRIQUETTING MACHINE JUMBO-90 1500 KG/HR | 2251000 |

| REAL TECH ENGINEERING | INR | Biomass Briquette Press Machine | 1650000 |

| ASK ENGINEERING WORKS | INR | Biomass Briquetting Machine | 2100000 |

How many trusted sellers are available for bio coal briquetting machine?

- KARUNANAND HYDRO-PNEUMATIC CONTROLS PVT. LTD.

- ECOSTAN INDIA PVT LTD

- Radhe Engineering Company

- ASK ENGINEERING WORKS

- SANTEC BALING AND RECYCLING SYSTEMS

- Unitek Hydraulics

- Shree Khodiyar Engineering Works

- POSH DYNOTECH (INDIA)

What is the minimum order quantity for bio coal briquetting machine?

Do listed companies have registration & certifications?

- JAY KHODIYAR MACHINE TOOLS

- ECOSTAN INDIA PVT LTD

- Radhe Engineering Company

- RONAK AGROTECH ENGINEERING PVT. LTD.

- Henan Doing Mechanical Equipment Co., Ltd.

What is the get latest price feature?

What types of payment methods are accepted by the bio coal briquetting machine suppliers?

Usa Coal Moisture (%): 5%

Price Trend: 5000.00 - 12000.00 INR/Inch

MOQ50 Ton/Tons

Product TypeCoal, Other

Moisture (%)5%

Bio Briquetting Plant

Product DescriptionIn the World of Bio Briquetting Plant Manufacturer, We the Radhe Industrial Corporation are working since 1992 and also achieved the top place in this field. In India We (Radhe) had started with small capacity machine model known as Super 60 in 1992 and after words We have launched a new model with

Bio Coal Briquetting Machine

Product DescriptionWe are manufacturing Bio coal Briquetting Machine. through this machine we can convert any type of agro/forestry waste into briquette form which is known as Bio Coal

Bio Briquetting Plant

Product DescriptionWith firm commitment to quality, we are engaged in manufacturing and supplying the supreme quality Bio Briquetting Plant . It is used for extracting energy efficient bio fuel briquettes from agriculture and forestry waste without adding any chemicals. By the use of quality approved components and

Small Ore Powder Briquette Machine

Product DescriptionSmall ore powder briquette machine manufacturer can press coal/charcoal powder into briquettes. It can press the powders into different shapes by changing different molds. It can produce solid or hollow shaped charcoal.The final charcoal can be used as fuel, BBQ, boiler and so on. Specification: 1.Y

Industrial Briquette And Carbon Black Briquette Machine

Product DescriptionWe are involved in manufacturing, exporting and supplying excellent quality Industrial Briquette And Carbon Black Briquette Machine to our most valued clients. Our offered Industrial Briquette And Carbon Black Briquette Machine is widely appreciated by our clients which are situated all round the na

High Efficiency Coal Briquette Machine

Product DescriptionWe are exporting of High Efficiency Coal Briquette Machine to our consumers. Coal Briquetting Machine is used to produce the green energy briquette with pillow or cubic shape which is suitable for transporting and also saving energy. Operating Principle: The type of briquette machine have two larger

Multifunctional Briquette Machine

Product DescriptionWe are engaged in manufacturing and exporting excellent quality Multifunctional Briquette Machine in Shanghai, Shanghai, China. The briquetting machine is a kind of mechanical equipment designed for making powdery material into briquette by high pressure double roller compressing. This briquette mak

Briquette Machine With Environmental Protection

Product DescriptionWe are engaged in manufacturing and exporting excellent quality Briquette Machine With Environmental Protection to our valuable clients. Zhongzhou series Briquette machine,mainly used to suppress difficult molding powder materials, characterized by forming pressure, the host rpm adjustable, with a s

Hydraulic Automatic Metal Scrap Powder Briquette Baler Machine With Conveyor

Product DescriptionWe are engaged in offering excellent quality Hydraulic Automatic Metal Scrap Powder Briquette Baler Machine With Conveyor to our valuable clients. Y83W-3600 is used for cold pressing metal scraps including powdery grainy cast iron scrap, ductile cast iron scrap, alloy scrap, steel scrap, aluminum sc

Briquette Plant

Product DescriptionMaheshwari Agrotech Engineering, founded in 2009, and engaged in manufacturing, exporting and supplying a wide range of Briquette Plant in Rajkot, Gujarat, India. From the days of manufacturing of POWER 90" type Briquetting plant of pneumatic and mechanical type to our present range of bio-mass briq

More details...

More details...

More details...

More details...

Latest from Bio Coal Briquetting Machine

Bio Coal Briquetting Machines

By:

Lehra Fuel Tech Pvt. Ltd.

Biocoal Briquetting Machine

By:

Jay Khodiyar Machine Tools

Coal Briquette

By:

Ronak Agrotech Engineering Pvt. Ltd.

Bio Coal Briquetting Machine

By:

Radhe Equipments India

Explore in hindi

जैव कोयला ब्रिकेटिंग मशीन

Bio coal briquetting machines produce bio coal by heating biomass in an inert atmosphere. These machines convert various types of agricultural waste into high density and energy concentrated bio coal briquettes through the mechanism of compression. Such machines use two types of compaction techniques to produce bio coal. One is high or medium pressure compaction in which no binders are required, while the other is low pressure compaction in which either organic or inorganic binders are required to combine the biomass into uniformly sized briquettes.

These briquetting machines are sturdy, require little maintenance and have a long service life. Furthermore, these have enhanced safety features that ensure no human contact with the machine's moving parts takes place. The machines are available in a wide assortment with respect to dimension and working mechanism, with the option of customization also available.

Geographical Usage Patterns of Bio Coal Briquetting Machines

It's common knowledge now that briquettes made from biomass have several advantages over traditional fuel sources such as coal, charcoal. Some of these advantages are eco friendly and renewable nature of bio coal briquettes, economical price, higher heat output etc.

As the aforementioned benefits have dawned on people, the usage of bio coal briquetting machines has also started gradually increasing in the western countries. Briquettes produced by these machines are commonly being used in boilers, furnaces, industrial heating there. As for the developing countries, since the usage of bio coal briquettes is still in it's nascent stage, thus bio coal briquetting machines are yet to find favor amongst people. Given the range of benefits that bio coal briquettes provide, it becomes pertinent that the usage of bio coal increases significantly.

Features of Bio Coal Briquetting Machines

These are resistant to corrosion.

Also resistant to chips and scratches.

The machines are power efficient.

These work flawlessly in all weather conditions.

These have minimal noise levels, thus ensuring no hearing problem in people working around the machines.

These generally have very fast briquette making speed that ranges between 600-1000 briquettes per hour.

Advantages Accorded by the Briquettes Produced by Bio Coal Briquetting Machines

These have very high specific density and bulk density as compared to loose biomass.

The briquettes can withstand the shocks of long distance transport.

These have a comparatively lesser moisture content than loose biomass, thus resulting in increased boiler efficiency.

The briquettes have a much higher practical thermal value and a much lower ash content.

Bio coal briquettes are easy to burn- lower ignition temperature required as compared to coal or loose biomass.

Bio Coal Briquetting Machine Price List

Product Name | Expected Price |

|---|---|

| Bio Coal Briquettes Plant System | 1000000 |

| Bio Coal Briquetting Plant | 1000000 |

| BIOMASS BRIQUETTING MACHINE JUMBO-90 1500 KG/HR | 2251000 |

| Bio Coal Briquette And Biomass briquette | 100000 |

| Biomass Briquette Press Machine | 1650000 |

| Biomass Briquetting Machine | 2100000 |

This Data was Last Updated on 2024-12-10

Bio Coal Briquetting Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Jay Khodiyar Machine Tools Rajkot, India | 19 Years |

Ronak Engineering Rajkot, India | 18 Years |

Ecostan India Pvt Ltd Ludhiana, India | 10 Years |

Ask Engineering Works Hyderabad, India | 9 Years |

Santec Baling And Recycling Systems New Delhi, India | 6 Years |

Posh Dynotech (india) Gwalior, India | 6 Years |

Mahadev Projects Consultancy Ahmedabad, India | 3 Years |

Karunanand Hydro-pneumatic Controls Pvt. Ltd. Ambernath, India | 2 Years |

Radhe Engineering Company Rajkot, India | 1 Years |

Renato Hitech Private Limited Bhopal, India | 1 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

China Home Furnishing Expo 2025

Thu, 06 Mar, 2025 - Sun, 09 Mar, 2025

Popular Categories