Agarbatti Making Machines

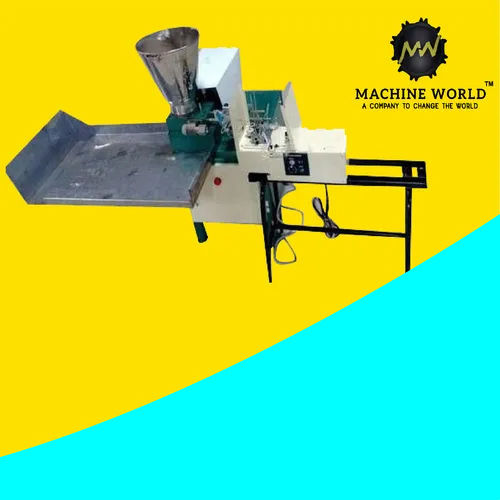

(927 products)Agarbatti Making Machine Power: 2 Horsepower (Hp)

60000 INR (Approx.)/Piece

MOQ1 Piece/Pieces

Product TypeOther, Agarbatti Making Machine

Power SourceElectricity

Power2 Horsepower (HP)

Warranty12 Months

Production Capacity15 Kg/hr

Usage & ApplicationsAgarbatti Making Machine

Stick Sambrani Machine - Feature: Highly Efficient

Price: 70000.0 INR/Piece

MOQ1 Unit/Units

FeatureHeavy Duty Machine, Durable, Rust Proof, Highly Efficient, Less Power Consumable, Done

ConditionNew Machine

Qualityvery good

OriginIndia

Weight (kg)100 Kilograms (kg)

TypeSemi Automatic

Fully Automatic Agarbatti Making Machine - Frequency: 50 Hertz (Hz)

Price: 85000 INR/Unit

MOQ1 Unit/Units

Frequency50 Hertz (HZ)

Qualityvery good

ConditionNew

Warranty2 Year

Machine World

Kolkata

Premium Seller

Premium Seller7 Years

Automatic Maggi Making Machine, Output: 100-200 kg/hr

Product DescriptionAutomatic Maggi Making Machine

Auto Hydraulic Dhoop Stick Machine - Color: Black And Yellow

Price: 3000000.00 INR/Unit

MOQ1 Unit/Units

ColorBlack and Yellow

OriginIndia

FeatureHeavy Duty Machine, Durable

ConditionNew

TypeAutomatic

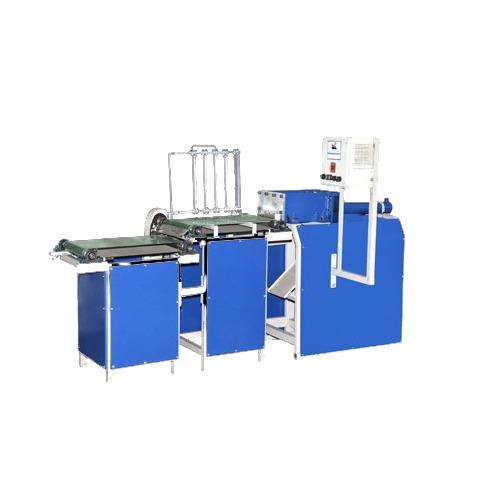

Blue Incense Stick Dryer 500 Kgs Diesel Fired

Price: 700000 INR/Unit

MOQ1 Unit/Units

ConditionBranded and New

Product TypeLatest and Automatic

Production Speed15 Product/Hour

Power415 Volt (v)

ColorBlue

Fuel TypeElectric, Diesel, Gas, Biomass briquette

Steamtech Innovative Machinery Private Ltd

Rajkot

Silver Incense Stick Making Machine

Price: 65000 INR/Unit

MOQ1 Unit/Units

ColorSilver

FeatureDurable

ConditionNew

OriginIndia

TypeAutomatic

WarrantyYes

Vinpat Machinery (opc) Private Limited

Lucknow

Automatic Agarbatti Making Machine Dimension(L*W*H): 48*30*48 Inch (In)

Price: 45000.00 INR/Piece

MOQ1 Piece/Pieces

Production Speed200-250 Pieces/Minute

FeatureHeavy Duty Machine, Durable, Highly Efficient, Less Power Consumable

Qualityvery good

ConditionNEW

Power Consumption1-1.5 UNIT Horsepower (HP)

Motor Power1 Horsepower (HP)

Automatic Dhoop Batti Making Machine Capacity: 30-40 Kg/Hr

Price: 80000 INR/Piece

MOQ1 Piece/Pieces

ConditionNew Brand

OriginIndia

Power Consumption1100 Watt Watt (W)

Qualityvery good

Capacity30-40 Kg/hr

Weight (kg)300 kg Kilograms (kg)

Automatic Long Cottonwick Making Machine Capacity: 6 Kg/Day

Price: 30000 INR/Thousand

MOQ1 Thousand

Motor Power24 Volt (V)

Qualityvery good

FeatureHeavy Duty Machine

Conditionnew

Originindia

Production SpeedAUTOMATIC Pieces/Hour

1 Hp Agarbatti Making Machine - Color: Green

Price: 55000.0 INR/Unit

MOQ1 Unit/Units

Power Consumption1 Horsepower (HP)

OriginIndia

Frequency50-60 Hertz (HZ)

ConditionNew

FeatureHeavy Duty Machine

ColorGreen

Rasu Machine House Private Limited

Kolkata

Industrial Fully Automatic Agarbatti Making Machine - Capacity: 100 Kg/10Hr Kg/Hr

Price: 80000 INR/Unit

MOQ1 Unit/Units

Motor Power1 Horsepower (HP)

OriginIndia

FeatureDurable

ColorRed

ConditionNew

Capacity100 Kg/10hr Kg/hr

Royal Business Industries

Kolkata

Premium Seller

Premium Seller1 Years

Sambrani And Wet Dhoop Stick Making Machine Capacity: 250-300 Kg Kg/Day

Price Trend: 165000.00 - 165000.00 INR/Set

MOQ1 Set/Sets

Frequency50 Hertz (HZ)

ConditionNew

Qualityvery good

ColorSilver

OriginIndia

FeatureHighly Efficient, Durable, Heavy Duty Machine

Industrial Agarbatti Making Machine - Color: Silver

Price: 65000.0 INR/Unit

MOQ1 Unit/Units

OriginIndia

FeatureHeavy Duty Machine

Motor Power1 Horsepower (HP)

ConditionNew

ColorGREEN

Power Consumption230 Volt (V)

Metal Agarbatti Making Machine - Capacity: 25 Kg/Hr

Price: 140000 INR/Unit

MOQ1 Unit/Units

Production Speed200 Pieces/Hour

ConditionNew

Frequency50 Hertz (HZ)

Capacity25 Kg/hr

Stick typeRound

Stick Length10 Inch (in)

Small Business Industries

Patna

Industrial Camphor Making Machine - Color: Blue

Price: 100000 INR/Unit

MOQ1 Number

OriginIndia

ConditionNew

ColorBlue

TechnologyCNC

Power SourceElectricity

Operating TypeSemi Automatic

Industrial Agarbatti Making Machine Frequency: 50 Hertz (Hz)

Price: 55000 INR/Unit

MOQ1 Unit/Units

ConditionNew

FeatureHeavy Duty Machine

Frequency50 Hertz (HZ)

Qualityvery good

Power Consumption220-240 Volt (V)

TypeAutomatic

Agarbatti Making Machine 23, Weight: 125-150 Kg

Product DescriptionAgarbatti Making Machine 23

Hung Tuan - Piston Incense Machine - Elegava - Capacity: 5-10 Kg/Hr Kg/Hr

Price: 10000 INR/Piece

MOQ1 Piece/Pieces

Qualityvery good

ConditionNew

OriginIndia

ColorSilver

Capacity5-10 kg/hr Kg/hr

Weight (kg)76-100 Kg Kilograms (kg)

Agarbatti Trolley Dryer - 240 Kg/Day Capacity, 1 HP Motor, 10 mm Bamboo Diameter | 20% Moisture Absorption, Durable and Efficient Design

Price: 24000 INR/Set

MOQ1 Set/Sets

ConditionNEW

Motor Power1 Horsepower (HP)

Bamboo Diameter10 Millimeter (mm)

Moisture (%)27

FeatureDurable, Less Power Consumable, Highly Efficient

Qualityvery good

Cow Dung Sambrani Cup Machine - Mild Steel, 10-15 Kg/hr Production Capacity, Silver Color | Manual Operation, Durable Design, Very Good Quality, Warranty Included

Price: 7000 INR/Unit

MOQ1 Unit/Units

ConditionNew

ColorSilver

FeatureDurable

OriginIndia

Qualityvery good

Capacity10-15 Kg/hr

Vadariya Industries

Rajkot

Trusted Seller

Trusted Seller2 Years

Incense Stick Making Machine 25, Part Type: All

Product DescriptionIncense Stick Making Machine 25

Agarbatti Packing Machine 4, Material: MS

Product DescriptionAgarbatti Packing Machine

Industrial Agarbatti Machine - Origin: India

Price: 60000 INR/Unit

MOQ1 Unit/Units

OriginIndia

Qualityvery good

ConditionNew

FeatureHeavy Duty Machine

TypeSemi Automatic

WarrantyYes

52 Cavity Fully Automatic High Speed Dhoop Stick Making Machine With Auto Feeder &Staking - Color: Brown

Price: 550000.00 INR/Piece

MOQ1 Piece/Pieces

OriginIndia

ConditionNew

FeatureHighly Efficient

Frequency50 Hertz (HZ)

Qualityvery good

ColorBrown

Dhoop Making Machine - Capacity: 15 Kg/Hr

Price: 75000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite And Green

ConditionNew

Qualityvery good

Capacity15 Kg/hr

TypeAutomatic

Stick typeRound

Samarth Enterprises

Pune

Trusted Seller

Trusted Seller3 Years

Automatic Dhoopbatti Making Machine Capacity: 50 Kg/Hr

Price: 130000 INR/Piece

MOQ1 Piece/Pieces

Frequency50 Hertz (HZ)

ConditionNew

Motor Power3 Horsepower (HP)

FeatureDurable, Highly Efficient

OriginIndia

Capacity50 Kg/hr

Agarbatti Masala Mixer Machine - Premium Quality Raw Material | Advanced Mixing Techniques, Industrial Compliance, Flawless Performance

Payment TermsTelegraphic Transfer (T/T), Western Union, Paypal, Others

Delivery Time1 Week

Sample PolicyContact us for information regarding our sample policy

Latest From Agarbatti Making Machines

Agarbatti Making Machines 14

By:

Shree Jagannath Udyog Private Limited

1 Hp Agarbatti Making Machines

By:

Heny Industries

Ready To Ship Agarbatti Making Machines

All About Agarbatti Making Machines

The production of incense sticks has been transformed by the invention of agarbatti producing equipment, which has increased productivity and convenience for producers. From mixing the raw components to shaping and packing the finished product, these machines are made to speed up the whole production process. Manufacturers can now satisfy the growing demand for incense sticks while keeping consistent quality thanks to agarbatti producing equipment. These devices can make a lot of incense sticks in a little amount of time. The time and effort needed for manual labor are considerably reduced by these devices. These machines are now absolutely necessary for producers because of their speed, precision, safety features, and sustainability advantages.

Various Types of Agarbatti Making Machines

The traditional method of creating handcrafted incense sticks using agarbatti has undergone a transformation. These devices exist in a variety of sorts, each created to improve efficiency and streamline the production process. A common form is the automated agarbatti maker, which uses cutting-edge mechanics to manage several jobs with little assistance from humans. These devices can efficiently carry out tasks including feeding bamboo sticks, applying the paste, rolling sticks, and drying incense. Because of their automated processes, businesses can create agarbattis in enormous quantities with a lot less work being needed.

The semi-automatic form of an agarbatti maker is another type. The balance between manual labor and automated functionality is achieved by this machine. Small-scale producers appreciate the adaptability of manual control like this kind of equipment.

People who are looking for less expensive choices might discover manually operated agarbatti-making equipment. These gadgets need expert craftsmanship and can only be operated by human hands. While their automated competitors might be able to produce incense sticks at a higher rate, these hand-held tools give each stick a unique flavor. Agarbatti manufacturers who value the quality and originality of their creations frequently favor employing such hand tools.

There has been an increase in demand for environmentally friendly agarbatti-making tools during the last few years. These gadgets are made with an eye on reducing their environmental effect by adopting eco-friendly materials and energy-saving methods. They frequently include elements like recycling initiatives, energy-saving devices, and eco-friendly packaging choices.

Working Principles of Agarbatti Making Machines

Agarbatti-making machines' operating principles are sophisticated and interesting, demonstrating the clever engineering that goes into them. To effectively turn raw materials into exquisitely created incense sticks, these machines function according to well-established criteria.

The bamboo stick feeding mechanism is the brains of most agarbatti-making devices. The base of the incense sticks, bamboo sticks, are kept in constant supply thanks to this technology. The machine meticulously positioned the bamboo sticks so they are ready for the next steps.

Applying the incense paste is the next step once the bamboo sticks have been set up. The machine evenly distributes the needed amount of paste onto the bamboo sticks accurately and uniformly.

The agarbatti-producing machine then rolls the sticks after applying the paste. The bamboo sticks are expertly wrapped using this method with the additives and fragrances needed to produce the ideal olfactory combination. The rolling procedure makes sure that all of the parts are tightly joined, resulting in cohesive incense sticks.

The agarbatti-making machine moves on to the drying stage when the rolling stage is finished. In this instance, the machine has drying mechanisms that make it easier to remove moisture from newly manufactured incense sticks. This step is essential to increase the agarbattis' lifespan and quality, making sure they burn smoothly and provide a seductive smell.

Intelligent control systems are frequently used by agarbatti-making equipment throughout these procedures. To ensure consistent quality and maximize production effectiveness, these systems track and control numerous factors including stick length, paste application rate, and drying temperature.

Key Components of Agarbatti Making Machines

Agarbatti producing machines are made up of a number of essential parts that cooperate to speed up production and guarantee the effective production of incense sticks. These parts have been painstakingly integrated and developed to handle various production phases.

The bamboo stick feeder is a crucial part of agarbatti-making equipment. This system makes it easier to feed bamboo sticks into the machine continuously and precisely. It guarantees a consistent supply of the building blocks, enabling production to proceed without interruption.

The paste application system is an additional significant element. The incense paste is applied evenly to the bamboo sticks using this procedure. It guarantees that the appropriate quantity of paste is consistently applied, producing well-coated sticks that emit a consistent smell when burnt.

Another crucial element of agarbatti-making machinery is the rolling mechanism. With the help of this mechanism, the coated bamboo sticks are precisely rolled while optionally combining scents, binders, and colorants. In order to produce a cohesive and fragrant incense stick, the rolling procedure makes sure that all the ingredients are fully combined.

The machine's drying components are also crucial. These elements are in charge of eliminating moisture from freshly rolled incense sticks, so extending and improve their quality. To hasten the evaporation of moisture during the drying process, heated chambers or air circulation systems may be used.

Sensors and control panels are also essential parts of agarbatti-making equipment. An easy-to-use interface is provided by the control panels for configuring the system.

Factors to Consider when Choosing Agarbatti Making Machines

In order to find the best agarbatti-making machinery for your needs, a number of criteria must be taken into consideration. You may enhance the efficacy and efficiency of your incense stick production by taking into account these elements and making an informed decision.

Production capacity should be prioritized as a key aspect. Analyze your needs and calculate the number of agarbattis you must manufacture. It is crucial to choose a machine whose production capacity matches your expected output because different machines have different capabilities.

Another important consideration is the caliber of the agarbattis that the machine produces. Look for equipment that produces sticks with a good coating and a balanced aroma in a consistent, uniform manner.

It is important to consider aspects like durability and upkeep while assessing solutions. Prioritize machines made with premium materials and components to locate ones with fewer ongoing repairs and longer lifespans.

Energy efficiency is a crucial factor in today's ecologically aware culture. To reduce its influence on the environment, look for equipment that makes the best use of resources and contains energy-saving features.

Assessing the machine's cost-effectiveness within your budget is also crucial. It's critical to compare the features, capabilities, and reputation of various manufacturers to make sure you get the most for your money. Think at the machine's possible long-term advantages and return on investment before making a choice.

FAQs: Agarbatti Making Machines

Q. What are the advantages of using Agarbatti making machines?

Ans: Numerous benefits that greatly improve the effectiveness and productivity of the incense stick production process come with using agarbatti-producing equipment. These devices offer a variety of advantages to producers, making them an excellent investment for the sector.

The significantly increased production capacity of agarbatti-producing equipment is one of their main benefits. Large amounts of raw materials may be handled by these machines, which can also automate different steps in the production process.

The increase in manufacturing efficiency is a further noteworthy benefit. Agarbatti-making machines carry out duties quickly, precisely, and consistently, doing away with any potential for a human mistake or inconsistency in manual manufacturing.

Finally, agarbatti manufacturing equipment provides a platform for creativity and customization. The adaptability of these devices allows manufacturers to experiment with various scents, additives, and stick designs. Agarbattis of various sizes and shapes may be accommodated by the machines, allowing for personalization in accordance with consumer and industry trends.

Q. Can Agarbatti making machines produce different sizes and shapes of Agarbattis?

Ans: Yes, agarbatti-making machines are adaptable and can create agarbattis in a variety of sizes and forms based on the particular specifications of manufacturers. These devices are made to support a variety of customization requirements, enabling organizations to meet a range of client preferences and market expectations.

Manufacturers & Suppliers of Agarbatti Making Machines

Company Name | Member Since |

|---|---|

Rising Industries Kolkata, India | 14 Years |

Fire Tech Engineers Ahmedabad, India | 11 Years |

Steamtech Innovative Machinery Private Ltd Rajkot, India | 9 Years |

Shree Hari Traders Rajkot, India | 9 Years |

Bannariamman Traders Coimbatore, India | 8 Years |

Jackson Machine Ahmedabad, India | 7 Years |

Machine World Kolkata, India | 7 Years |

Ganesh Technology Ahmedabad, India | 7 Years |

Krishna International Overseas Surat, India | 6 Years |

Vinpat Machinery (Opc) Private Limited Lucknow, India | 5 Years |

Popular Products