- Tradeindia

- Briquettes Making Machines

- Biomass Briquetting Machine

Biomass Briquetting Machine

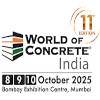

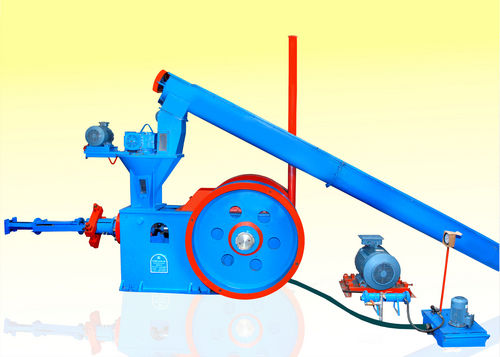

(68 products)Industrial Briquetting Press Machine Produce White Coal

Price: 1500000 INR/Plant

MOQ1 Plant/Plants,

ColorRED & BLUE

TypeBriquetting machine

General Useproduce white coal

MaterialCoal Dust

Automatic GradeAutomatic

Production Capacity1200-2000 Kg/hr

View More

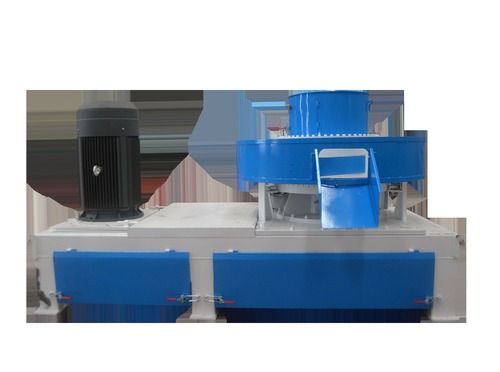

Biomass Briquetting Plant - 650-2000 Kg/hr Capacity | Binderless Technology, High Efficiency, Water Cooling System

Get Best Deal

Biomass Briquetting Machine Briquette Size: 70Mm Dia.

Price : 100000 INR

White Coal Machine - Automatic Grade: Semi-Automatic

Get Best Deal

Briquette Making Machine Briquette Size: 90 Mm

Price : 500000 INR

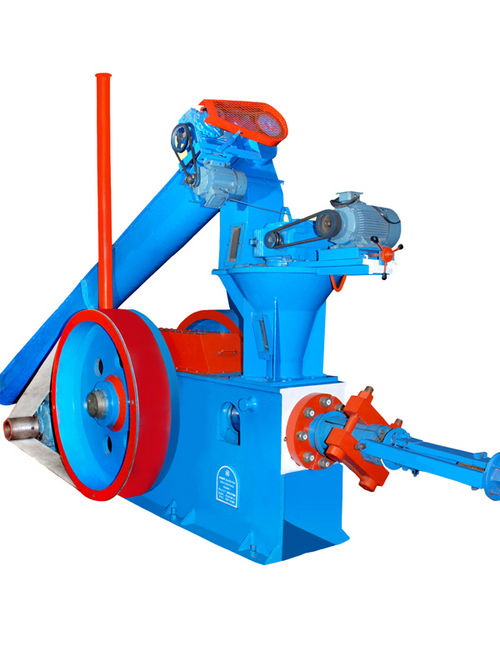

Biomass Briquette Machine - 47 HP Power, 1000-1500 kg/hr Production Capacity | Automatic, Manual, Semi-Automatic Operation, Robust Design

Price Trend: 500000.00 - 1600000.00 INR/Piece

MOQ1 Piece/Pieces

TypeBriquette Press Machine, Briquette Machines

Ecostan India Pvt Ltd

Ludhiana

Trusted Seller

Trusted Seller Premium Seller

Premium Seller11 Years

View More

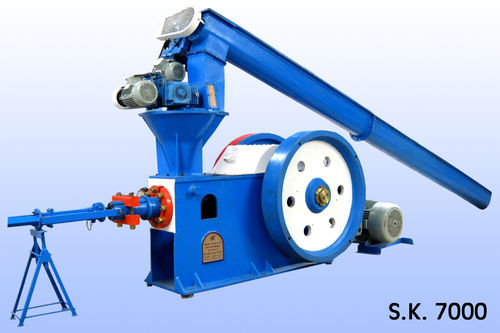

Dual Feed Combo Pellet Cum Briquette Machine

Price Trend : 500000.00 - 1600000.00 INR

Briquette Press Machine - 250-2500 KG/H Production Capacity | Yellow, Semi-Automatic, 1 Year Warranty, Electric Power Source

Price Trend : 500000.00 - 1600000.00 INR

Automatic Agro Biomass Briquetting Plant

Price Trend : 500000.00 - 1600000.00 INR

Biomass Briquetting Plant - Durable Steel Machinery | Eco-Friendly Energy Solution for Industrial Sustainability

MaterialSteel

DimensionsVariable

PowerCustomizable

CapacityVariable

EfficiencyHigh

WeightHeavy

Radhe Engineering Company

Rajkot

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

View More

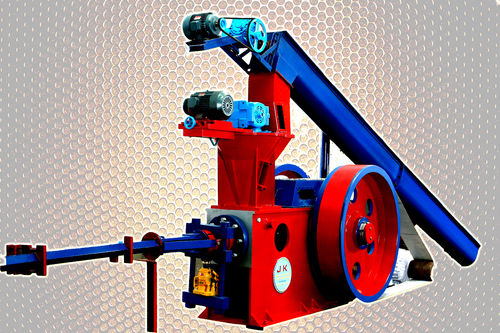

Biomass Briquetting Machine Jumbo-90 1500 Kg/Hr - Briquette Size: 90Mm

Price : 2251000 INR

Biomass Briquetting Press Machines

Get Best Deal

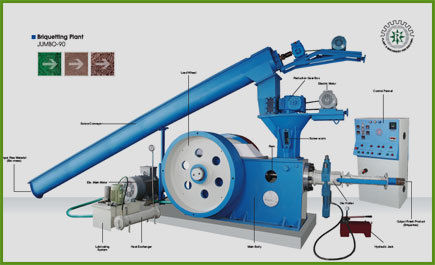

Briquette Machine - 60mm Size with 40 HP Power | Non-Automatic, Non-Computerized

Price: 1350000 INR/Number

MOQ1 Number

Product TypeBriquette machine

TypeBriquette Machines

ComputerizedNo

AutomaticNo

Biomass Agro Waste Briquetting Machine

Motor Power15 Hp

Production Capacity1000-1500 Kg/Hr

Briquette Size90 Mm

MaterialMild Steel

Dimensions3M X 2M X 2M

Weight1000 Kg

View More

Biocoal Biomass Briquetting Machine Jumbo 90

Price : 1790000.00 INR

Biomass Briquetting Machinery - Precision Engineered Components, High Performance Assurance

Get Best Deal

Biomass Briquetting Machine - High Grade Quality Raw Materials, Customizable Design, Durable Performance

Get Best Deal

Biomass Briquetting Machine

Price: 2100000.00 INR/Unit

MOQ1 Unit/Units

Payment TermsLetter of Credit (L/C), Cash on Delivery (COD), Paypal, Western Union, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Against Delivery (CAD), Cash Advance (CA), Others, Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque

Delivery Time5 Days

Sample AvailableYes

Ask Engineering Works

Hyderabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller10 Years

View More

Biomass Briquetting Machine C12H12N2O

Get Best Deal

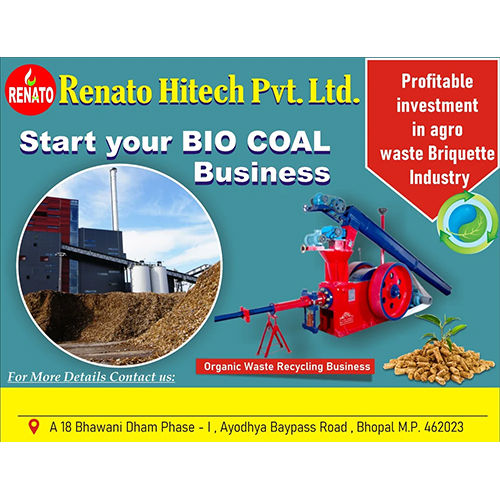

Biomass Briquetting Plant Machinery - General Use: Industrial

MOQ1 Unit/Units

Product TypeBiomass Briquetting Plant Machinery

General UseIndustrial

MaterialOther, Mild Still And Stainless Steel

ComputerizedNo

AutomaticYes

Warranty1 Year

Renato Hitech Private Limited

Bhopal

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Blue Horizontal Biomass Pellet Burner

Price: 220000 INR/Unit

MOQ1 Unit/Units

UsageBiomass Pellet Burner

Colorblue

ConditionNew

MaterialStainless Steel

Gcv Of Briquette And Biofuel Test Machine - Operating Type: Semi Automatic

Price: 185000 INR/Unit

MOQ1 Unit/Units

TechnologyMagnetism

Power SourceElectricity

Operating TypeSemi Automatic

Surface TreatmentGalvanized

WarrantyYes

High Efficifiency Hydraulic Biomass Briquetting Machine

Price: 700000 INR/Unit

MOQ1 Unit/Units,

Product TypeBriquetting Machine

MaterialMetal, Other

AutomaticNo

FeatureHigh Efficifiency

Warranty1 Year

Santec Baling And Recycling Systems

New Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller7 Years

View More

Fully Automatic Hydraulic Biomass Briquetting Machine - High-Efficiency Steel Build | Energy-Saving Design, User-Friendly Operation, Eco-Friendly Production

Price : 1500000 INR

Hydraulic Biomass Briquetting Machine Application: Industrial

Price : 2500000.00 INR

Fully Automatic Hydraulic Biomass Briquetting Machine

Price : 1500000 INR

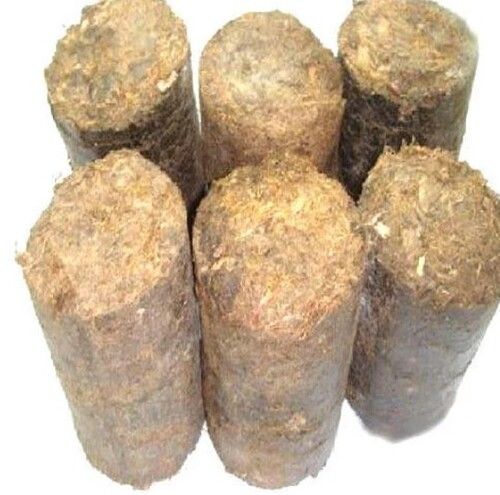

90Mm Biomass Briquette - Material: Wood

Price: 6000 INR/Ton

MOQ300 Ton/Tons

Product TypeOther, Biomass Briquette

MaterialWood

ShapeBriquette

Moisture (%)Nil

Sulphur Content (%)98-99%

Phosphorus Content (%)Nil

Detail Project Report on Biomass

Price: 19000 INR/Number

MOQ1 Number

Product DescriptionDetail Project Report on Biomass

Top Rated Products

Briquette Machine - 60mm Size with 40 HP Power | Non-Automatic, Non-Computerized

Real Tech Engineering

Gcv Of Briquette And Biofuel Test Machine - Operating Type: Semi Automatic

Prime Scientific Industries

FAQs Related to Biomass Briquetting Machine

Biomass Briquetting Machine 2000-2500 Kn - Color: Green

Price: 2000000 INR/Piece

MOQ1 Piece/Pieces

Voltage220-440 Volt (v)

Control SystemFully Automatic

Frequency50 Hertz (HZ)

Product TypeOther, Biomass Briquetting Machine 2000-2500 KN

Power SourceElectricity

Operating TypeAutomatic

View More

Biomass Briquetting Machine - Color: Green

Price : 2000000 INR

Hammer Mill Grinder Briquetting Machine

Product DescriptionHammer Mill Grinder Briquetting Machine

View More

Biomass Briquette Press Machine - Color: Blue

Get Best Deal

Biomass Briquetting Press Machine

Get Best Deal

Industrial And Commercial Surface Painted Biomass Briquetting Press Machine

Product TypeBriquetting Machine

General UseBiomass Briquetting Press

MaterialOther, Metal

Product ShapeCylinder

ComputerizedNo

AutomaticYes

Flammable Carbon Briquetting Machines - Briquette Size: Customized

Price: 939100 INR/Unit

MOQ1 Unit/Units

Product TypeBriquette Making Machines

General UseBriquette Making Machines

MaterialCharcoal

Production Capacity1000 Pcs/hr

Product ShapeCustomized

Weight (kg)2000 Kilograms (kg)

View More

Biomass Briquetting Machine - Steel, Variable Capacity, CE Certified, Heavy Weight | High Efficiency, Durable Design, Easy Operation, Low Maintenance, Eco-Friendly, Versatile Use, Increased Output

MaterialSteel

DimensionsVaried

PowerElectric/Diesel

CapacityVariable

WeightHeavy

Warranty1 Year

Biomass Briquetting Machine - 700-1000 Kg/Hr Production Capacity, 70 mm Diameter Cylindrical Output - Superior Design for Industrial Applications

Product DescriptionWhen both development as well as protection of environment is necessary a range of superbly crafted, innovatively designed machines is highly desired. We are offering Biomass Briquetting Machine which is highly applicable for various industrial purposes. Our advanced manufacturing unit is capable of

View More

Biomass Briquetting Plant - 700-1000 Kg/Hr Production Capacity | 70 mm Diameter Cylindrical Briquettes

Get Best Deal

Biomass Briquettes Plant

Get Best Deal

Briquettes Making Machinery

Get Best Deal

Jumbo Biomass Briquetting Machine

Get Best Deal

Brown Color Round Shape Industrial Biomass Briquette

Price: 500000 INR/Piece

MOQ1 Piece/Pieces

Product TypeOther, Industrial Biomass Briquette

ShapeOther, Round

Biomass Pellet Making Machine - 200 Kg/hr Capacity, 220-240 Volt Electric | Durable, High Efficiency, Long Functional Life, Semi-Automatic Operation

Price: 145000 INR/Unit

MOQ1 Unit/Units

Voltage220-240 Volt (v)

Control SystemSemi-Automatic

ColorMulticolour

Machine TypeBiomass Pellet Making Machine

Power SourceElectricity

Operating TypeSemi Automatic

Automatic Biomass Briquetting Machine Application: Industrial

Product TypeAutomatic Biomass Briquetting Machine

UsageIndustrial

MaterialMild Steel

ApplicationIndustrial

Biomass Briquetting Machine - Binder Less Technology, Uses Agricultural and Forestry Waste, Cylindrical Shape for Heating and Steam Generation

MaterialSteel

DimensionsVariable

CapacityVariable

PowerVariable

WeightVariable

Feed SizeVariable

Cow Dung Briquetting Plant

MaterialSteel

Dimensions700X500X1000Mm

Power5Hp

Capacity70Kg/Hr

Weight500Kg

Die Size50-70Mm

View More

Biomass Briquetting Plant - Agro Waste Conversion System | Eco-Friendly Solid Fuel Production

Get Best Deal

Biomass Briquetting Plant - Agro Waste & Forestry Residue Converter | Eco-Friendly Bio Coal Production Machine

Get Best Deal

Biomass Briquetting Plant Machine - Compact Solid Composites Production | High-Density Pressure Application

Get Best Deal

Bio Coal Machine

Get Best Deal

Biomass Briquette Machine - Steel, Material Size: 3-30Mm, Density: 0.8-1.2T/M3 | Adjustable Density, Easy Operation, High Efficiency, Quick Heating, Stable Performance

MaterialSteel

DimensionsVariable

PowerVariable

CapacityVariable

Moisture16-30%

Size3-30Mm

Bagasse Briquetting Machine

Price: 350000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeBagasse Briquetting Machine

MaterialOther, Mild Steel

Production Capacity550 Kg/hr

TypeBriquette Machines

ComputerizedYes

Biomass Briquette Machine - 100-150 Kgs/Hr Capacity, 12 KW Power, 550 Kgs Weight - Ideal for 3-5 mm Raw Material with 8-12% Moisture

Capacity100-150 Kg/Hr

Raw Material3-5 Mm

Moisture8-12%

Power12 Kw

Briquette Size50-55 Mm

Weight550 Kg

Optimum Strength Biomass Briquetting Machine - Stalk Material, 1.5-2.5t/h Capacity | Automatic Feeding, Water Cooling System, Rust Resistance, Energy Saving, Corrosion Resistance, Rugged Design, PLC Control

Price: 32000 USD ($)/Set

MOQ1 Set/Sets

Product TypeBriquetting machine

MaterialStalks

Production Capacity1.5-2.5t/h Kg/hr

Product ShapeOther

Weight (kg)1-5 Tonne

ComputerizedYes

High Efficifiency Biomass Briquetting Machine

Product TypeBiomass Briquetting Machine

FeatureEnergy Saving, High Efficifiency, Low Consumption

Latest from Biomass Briquetting Machine

Biomass Briquetting machine

By:

Mahadev Projects Consultancy

Automatic Biomass Briquetting Machine

By:

Lehra Fuel Tech Pvt. Ltd.

Automatic Agro Biomass Briquetting Plant

By:

Ecostan India Private Limited

Popular Biomass Briquetting Machine

Biomass Briquetting Machine

Biomass briquetting machines are used for making briquettings of wood, rice husk, groundnut shells etc. The machines are ideal for converting low density biomass into high density briquetting pieces through compression. The briquettings can then be used as an alternate fuel source for various industrial and domestic purposes. These machines are power efficient, easy to operate and make briquettings that are uniform in size and shape, thus ensuring optimum suitability of the produced briquettings to any specific requirement.

Biomass briquetting machines generally produce between 600 to 1000 briquettings per hour. Robustly designed, these are available in automatic as well as in manual working mode. Furthermore, these are also designed to resist fatigue arising out from continuous vibration. Along with automatic and manual, the machines are available in various other specification and with different features, making these fit for every kind of briquetting making requirement.

Ideal Design, Manufacture and Working of Biomass Briquetting Machines

The parameters for measuring whether the design, manufacture and working of biomass briquetting machines are ideal are following:

The machines should be made using conventional methods such as welding, casting, milling or any other conventional machining process.

The briquetting machines should ideally weigh between 100 to 200 kilograms.

These should resist corrosion in case of contact with water.

These should have a minimal functional life span of 8 years.

Biomass briquetting machines should be easy to operate and have proper safety measures for the operator.

The machines should have a low center of gravity along with optimum stability during function.

Principle of Operation of Biomass Briquetting Machines

Powder from biomass such as sawdust, rice husk etc is poured into the machine's cylinders. In manual briquetting machines, a person rotates the machine's rotating arm, while in automatic ones, this rotation is not required. Afterwards, the machine's pistons squeeze the powdered biomass into cylindrical dies. As a result of this compaction, biomass particles deform and thus interlock, producing briquettings.

Most biomass briquetting machines do not need binders for producing briquettings. Due to the high pressure exerted by these, the biomass in solid or powder form compacts and takes the shape of pre defined cylindrical dies.

Types of Biomass Briquetting Machines

The biomass briquetting machines come in a wide range of forms encompassing both manual and automatic mode. Some examples are :

1. Human operated vertical compaction briquetting machine.

2. Human powered horizontal screw briquetting machine.

3. Human powered reciprocating briquetting machine.

4. Motorized screw press briquetting machine.

5. Motorized piston press briquetting machine.

6. Heavy duty combined briquetting machine.

Biomass Briquetting Machine Price List

This Data was Last Updated on 2025-07-30

Biomass Briquetting Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Jay Khodiyar Machine Tools Rajkot, India | 20 Years |

Ronak Engineering Rajkot, India | 19 Years |

Kuldeep Engineering Works New Delhi, India | 17 Years |

Ecostan India Pvt Ltd Ludhiana, India | 11 Years |

Ask Engineering Works Hyderabad, India | 10 Years |

Biomass Energeons India Kota, India | 8 Years |

Hitech Agro Projects Pvt Ltd Ballabgarh, India | 8 Years |

Santec Baling And Recycling Systems New Delhi, India | 7 Years |

Real Tech Engineering Coimbatore, India | 6 Years |

Indian Agro Fuel Sangrur, India | 4 Years |

Upcoming Tradeshows

Autoserve 2025

Thu, 09 Oct, 2025 - Sat, 11 Oct, 2025

China (Guzhen) International Lighting Fair 2025

Wed, 22 Oct, 2025 - Sat, 25 Oct, 2025

Delhi Water Expo 2025

Thu, 21 Aug, 2025 - Sat, 23 Aug, 2025

INDUS-Tech Expo 2025

Fri, 19 Dec, 2025 - Mon, 22 Dec, 2025

Aesthetic Masterclass 2025

Thu, 28 Aug, 2025 - Fri, 29 Aug, 2025

Aquatech China 2025

Wed, 05 Nov, 2025 - Fri, 07 Nov, 2025

World Food India 2025

Thu, 25 Sep, 2025 - Sun, 28 Sep, 2025

WORLD OF CONCRETE INDIA 2025

Wed, 08 Oct, 2025 - Fri, 10 Oct, 2025

Water Expo Kochi 2025

Thu, 18 Sep, 2025 - Sat, 20 Sep, 2025

INTEXT Expo 2026

Fri, 16 Jan, 2026 - Mon, 19 Jan, 2026

Popular Categories