- Tradeindia

- Bag Making Machine

- Carry Bag Making Machine

Carry Bag Making Machine

(240 products)Automatic Sand Bag Packing Machine

Price: 756000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

TypePackaging Line

FeatureHighly Efficient, Durable

Capacity400 Kg/hr

Automatic GradeAutomatic

Drive TypeElectric

Sigma Instrumentation

Ahmedabad

Trusted Seller

Trusted Seller15 Years

Super Premium

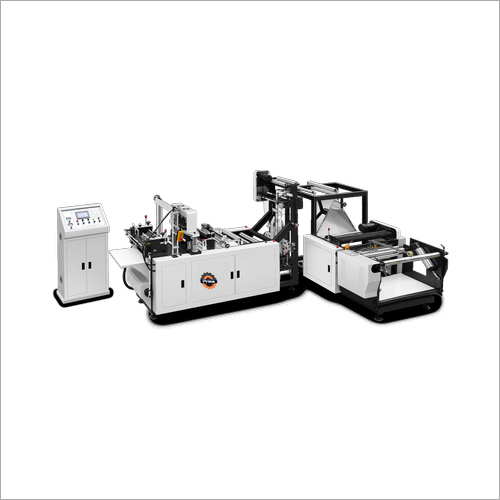

Super PremiumBiodegradable Carry Bag Making Machine - Automatic Grade: Automatic

Price: 1400000 INR/Piece

MOQ1 Piece/Pieces

ColorRed & White

Product TypeBiodegradable Carry Bag Making Machine

General UseIndustrial

Automatic GradeAutomatic

Drive TypeElectric

Bag TypeOther

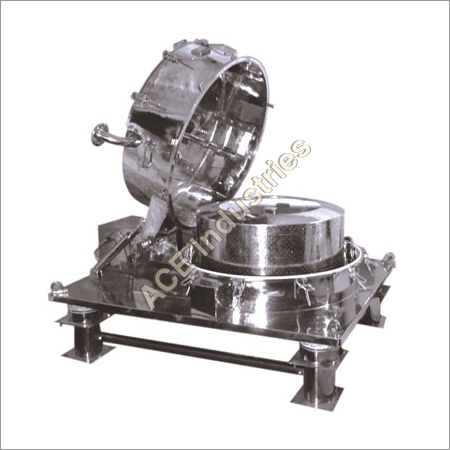

Silver Dome Open Machine With Lifting Bag

Price Trend: 450000.00 - 2800000.00 INR/Unit

MOQ1 Unit/Units

ColorSilver

UsageIndustrial

Product TypeDome Open Machine

SizeStandard

MaterialSS

Warranty1 Year

Ace Industries (india) Private Limited

Mumbai

Trusted Seller

Trusted Seller15 Years

Super Seller

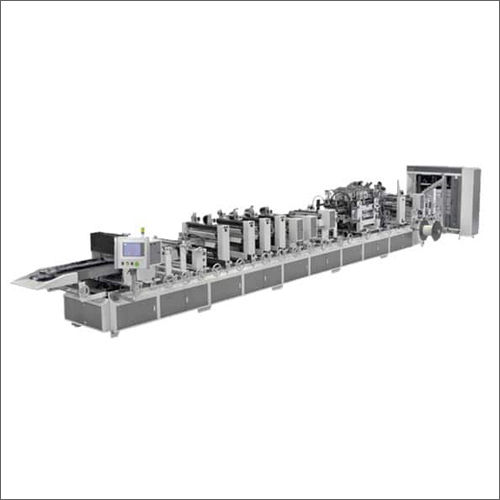

Super SellerNon Woven Shopping Bag Welding Machinery

Product DescriptionWe have gained a reputed position in our domain by manufacturing, exporting and supplying a varied variety of Non Woven Shopping Bag Welding Machinery in Ahmedabad, Gujarat, India. Our offered range of machine is designed and assembled using optimum grade raw materials. The raw material source from

Sheetal Enterprises

Ahmedabad

Trusted Seller

Trusted Seller10 Years

Super Seller

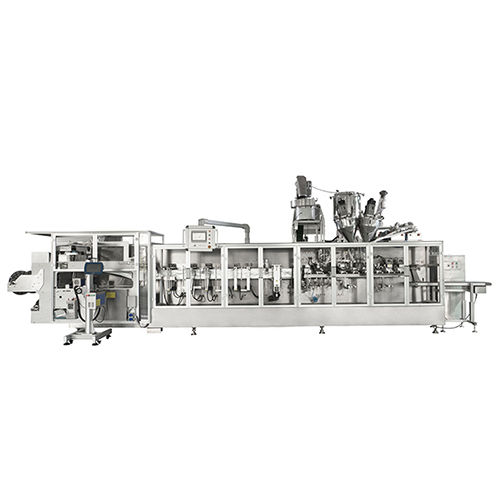

Super SellerMulti Head Weigher Type Pre-Made Made Bag Packaging Machine - Application: Industrial

MOQ1 Unit/Units

Voltage220-440 Volt (v)

ConditionNew

TypeMulti Head Weigher Type Pre-Made Made Bag Packaging Machine

ApplicationIndustrial

ColorSilver

Automation GradeAutomatic

Qualipak Machinery Hi Tech Ltd.

Wenzhou

Trusted Seller

Trusted Seller3 Years

Super Seller

Super SellerBiodegradable Bag Making Plant

Price: 5051000 INR/Unit

MOQ1 Unit/Units

Delivery Time10-15 Days

Automatic Carry Bag Making Machine Efficiency: High

Price: 7000000 INR/Unit

MOQ1 Unit/Units

Product TypeCarry Bag Making Machine

General UseIndustrial

EfficiencyHigh

Automatic GradeAutomatic

Drive TypeElectric

FeatureHigh Quality

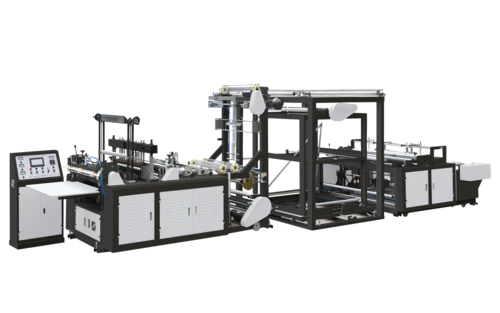

Semi Automatic Non-Woven Bag Making Machine

Price: 1500000 INR/Unit

MOQ1 Unit/Units

ColorBlack And White

Product TypeNon-Woven Bag Making Machine

General UseFor Carry Bag Use

Automatic GradeAutomatic

Drive TypeElectric

Bag TypeCarry Bag

Automatic D Cut Bag Making Machine

Price: 1400000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite-Black

Product TypeD Cut Bag Making Machine

General UseCarry Bag, Handbag, Shopping Bag

EfficiencyHigh

Automatic GradeAutomatic

Drive TypeElectric

Bag Packing Machine - Stainless Steel, 500-550 Bags Per Hour | Automatic, Highly Efficient, 220V Power Consumption, 1 Year Warranty

Price: 250000 INR/Unit

MOQ1 Unit/Units

TypePackaging Line

MaterialStainless steel

FeatureHighly Efficient

ComputerizedNo

Automatic GradeAutomatic

Drive TypeElectric

Vegam Engineers Private Limited

Ghaziabad

Trusted Seller

Trusted Seller4 Years

Super Seller

Super SellerSemi-Automatic Double Special Shaped Self Supporting Bag Packaging Machine

MOQ10 Unit/Units

MaterialStainless Steel

FeatureHighly Efficient

ComputerizedNo

Automatic GradeSemi-Automatic

Drive TypeElectric

Wenzhou Trustar Machinery Technology Co., Ltd.

Ruian

Trusted Seller

Trusted Seller3 Years

Premium Seller

Premium SellerBag Packing Machine - Automatic Grade: Automatic

Price: 450000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

TypeOther

MaterialStainless Steel

FeatureHeavy Duty Machine, Durable, Highly Efficient

Capacity500 Kg

ComputerizedNo

G S International

Khanna

Trusted Seller

Trusted Seller5 Years

Premium Seller

Premium SellerTop Rated Products

Multi Head Weigher Type Pre-Made Made Bag Packaging Machine - Application: Industrial

Qualipak Machinery Hi Tech Ltd.

FAQs Related to Carry Bag Making Machine

The price is between 2 lakhs to 15 lakhs in India.

Bio Degradable Bag Making Machine - Automatic Grade: Automatic

Price: 400000 INR/Piece

MOQ1 Piece/Pieces

Product TypeBio Degradable Bag Making Machine

General UseBag Making

Efficiency99.9 %

Automatic GradeAutomatic

Drive TypeElectric

Fully Automatic Non Woven Laminated Box Bag Making Machine

Price: 8500000 INR/Set

MOQ1 Set/Sets

Weight (kg)9500 Kilograms (kg)

Automatic GradeAutomatic

White Automatic Non Woven Fabric Bag Making Machine

Price: 1295000 INR/Piece

MOQ1 Piece/Pieces

ColorWHITE

Product TypeShopping Bag

Automatic GradeAutomatic

Drive TypeElectric

Voltage380 Volt (v)

MaterialOther, Non Woven

Automatic Biodegradable Corn Starch Bag Film Making Machine

Price: 665000 INR/Unit

MOQ1 Unit/Units

ColorCUSTOMER CHOICE

Product TypeCARRY BAG AND GARBAGE BAG

General UseCARRY BAG

Food Safety GradeYes

HardnessSoft

Weight (kg)1700 Kilograms (kg)

240 V Bag(Bcs) Making Machine - Automatic Grade: Automatic

Price: 1150000 INR/Piece

MOQ1 Piece/Pieces

TypeOther, 240 V Bag(BCS) Making Machine

FeatureHighly Efficient

ComputerizedNo

Automatic GradeAutomatic

Drive TypeElectric

Voltage240V Volt (v)

Black/White Fully Automatic Bag Making Machine

Price: 1650000 INR/Unit

MOQ1 Unit/Units

ColorBlack/White

Product TypeFully Automatic Bag Making Machine

General UseBag Making

Automatic GradeAutomatic

Drive TypeElectric

Warranty1 Years

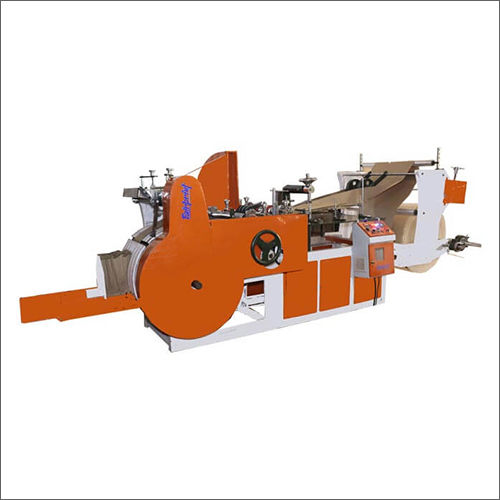

Automatic Paper Bag Making Machine - Bag Length: 60 Centimeter (Cm)

Price: 550000.00 INR/Unit

MOQ1 Unit/Units

Product TypePaper Bag Making Machine

General UsePaper Bag Making

Weight (kg)1250 Kilograms (kg)

Automatic GradeAutomatic

Drive TypeElectric

ComputerizedNo

Raschel Bag Making Machine Dimension (L*W*H): Different Available Millimeter (Mm)

MOQ1 Unit/Units

Driven TypeElectric

Dimension (L*W*H)Different Available Millimeter (mm)

Output Frequency50 Hertz (HZ)

WeightVaries as per model Kilograms (kg)

FunctionFor Textile

Automatic Leader Box Bag Making Machine - Color: White & Red

Price: 6500000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite & Red

Product TypeBAG MAKING MACHINE

General UseIndustrial

Automatic GradeAutomatic

Drive TypeElectric

ComputerizedNo

Fair Deal Engineers

Faridabad

Trusted Seller

Trusted Seller13 Years

Premium Seller

Premium SellerAutomatic Jute Bag Fusing Machine 20''*24 inch

Price: 85000 INR/Piece

MOQ1 Piece/Pieces

ColorGrey

Product TypeOther

TechnologyCNC

Power SourceElectricity

Operating TypeAutomatic

Power3500 Watt (w)

Courier Bag Making Machine

Price: 1550000 INR/Unit

MOQ1 Unit/Units

FOB PortJaipur

Payment TermsTelegraphic Transfer (T/T)

Supply Ability10 Per Day

Shree Jagdamba Industries

Jaipur

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerWhite Bardana Bag Making Machine

Price: 125000 INR/Unit

MOQ1 Unit/Units

ColorWhite

General UseIndustrial

ComputerizedNo

AutomaticYes

WarrantyYes

Automatic Bio-Degradable Bag Making Machine (40Mm Blowing Plant)

MOQ1 Unit/Units

TypeBio-degradable Bag Making Machine

MaterialMetal

Automatic GradeAutomatic

Control SystemHuman Machine Interface

Drive TypeElectric

WarrantyYes

Small Business Solution

New Delhi

Trusted Seller

Trusted Seller9 Years

Premium Seller

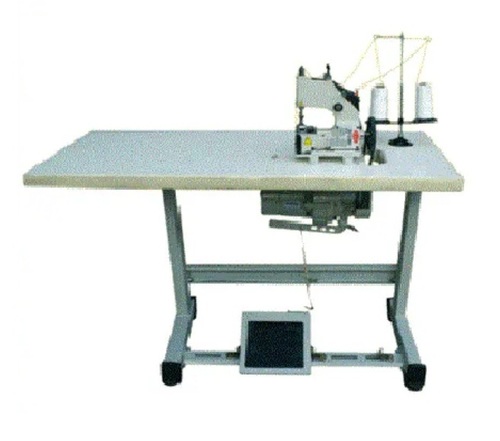

Premium SellerPlastic Bag Making Machine - Color: White

Price: 12500 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

Voltage220 Volt (v)

Product TypeSewing Machines

Power230 Volt (v)

Operate MethodAutomatic, Electric

Fully Automatic Carry Bag Making Machine - General Use: Industrial

Price: 1300000 INR/Unit

MOQ1 Unit/Units

Product TypeFully Automatic Carry Bag Making Machine

General UseIndustrial

Automatic GradeAutomatic

Drive TypeElectric

ComputerizedNo

Voltage220-240 Volt (v)

White And Blue Paper Carry Bag Making Machine

Price: 550000.00 INR/Unit

MOQ1 Unit/Units

ColorWhite and Blue

Product TypePaper Carry Bag Making Machine

Weight (kg)4 Tonne

Latest from Carry Bag Making Machine

Explore More Cities

Ready To Ship Carry Bag Making Machine

Carry Bag Making Machine Price List

Product Name | Expected Price |

|---|---|

| Carry Bag Making Machine | 330000 |

| Elite Pro Paper Bag Making Machine | 325000 |

| Plastic Carry Bag Bottom Sealing Making Machine | 450000 |

| Fully Automatic Carry Bag Making Machine | 1300000 |

| Fully Automatic Carry Bag Making Machine | 1300000 |

| Fully Automatic Carry Bag Making Machine | 500000 |

| Industrial Paper Bag Making Machine | 850000 |

| Paper Carry Bag Making Machine | 650000 |

| Fully Automatic Paper Bag Making Machine | 520000 |

| Bag Making Machine | 1550000 |

This Data was Last Updated on 2025-03-03

Carry Bag Making Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Sigma Instrumentation Ahmedabad, India | 15 Years |

Ace Industries (india) Private Limited Mumbai, India | 15 Years |

Sahil Graphics Faridabad, India | 14 Years |

Perfect Machinery New Delhi, India | 14 Years |

Fair Deal Engineers Faridabad, India | 13 Years |

Disposable Machinery Kolkata, India | 11 Years |

Kamtronics Technology Private Limited New Delhi, India | 11 Years |

Sheetal Enterprises Ahmedabad, India | 10 Years |

Small Business Solution New Delhi, India | 9 Years |

Mahalaxmi Machine Jaipur, India | 9 Years |

Upcoming Tradeshows

CWIEME Shanghai 2025

Wed, 25 Jun, 2025 - Fri, 27 Jun, 2025

Bakery and Commercial Kitchen Equipment 2025

Thu, 12 Jun, 2025 - Sat, 14 Jun, 2025

Vietnam Sport Show 2025

Thu, 14 Aug, 2025 - Sat, 16 Aug, 2025

Water Expo Bhubaneswar 2025

Thu, 10 Apr, 2025 - Sat, 12 Apr, 2025

Singapore International Jewelry Expo 2025

Thu, 10 Jul, 2025 - Sun, 13 Jul, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

Food & Bakery Expo 2025

Fri, 29 Aug, 2025 - Sun, 31 Aug, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

PU TECH 2025

Wed, 09 Apr, 2025 - Fri, 11 Apr, 2025

Popular Categories