- Tradeindia

- Plasma Cutting Machines

- Cnc Plasma Cutting Machine

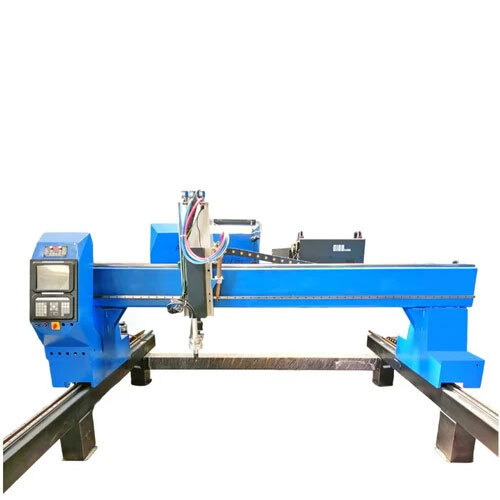

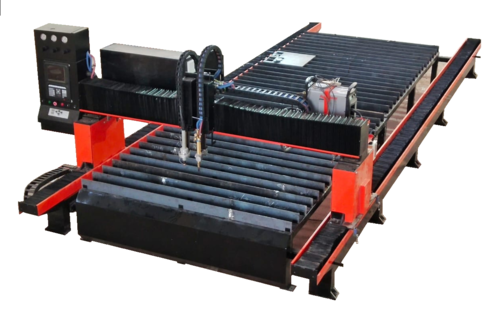

Cnc Plasma Cutting Machine

(563 products)Cnc Plasma Cutting Machine - Feature: Low Energy Consumption

Price: 1050000 INR/Unit

MOQ1 Unit/Units

Product TypeCNC Plasma Cutting Machine

General UseCNC Cutting

MaterialStainless Steel

TypeHorizontal

ComputerizedYes

AutomaticYes

View More

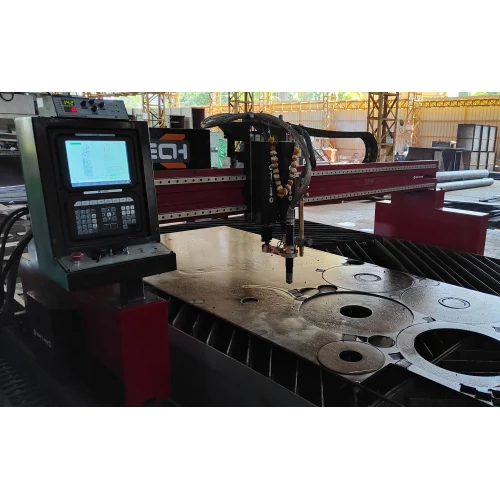

Flash Cut Cnc Oxy Fule And Plasma Cutting Machine - Color: Black

Price : 1250000.00 INR

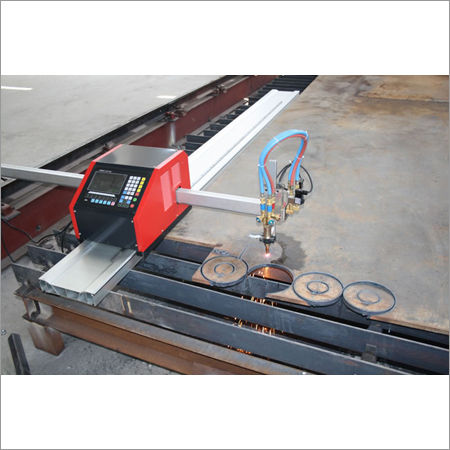

Portable Cnc Plasma Cutting Machine - Feature: Low Energy Consumption

Price : 195000 INR

Table Top Cnc Plasma Cutting Machine - Feature: Low Energy Consumption

Price : 775000 INR

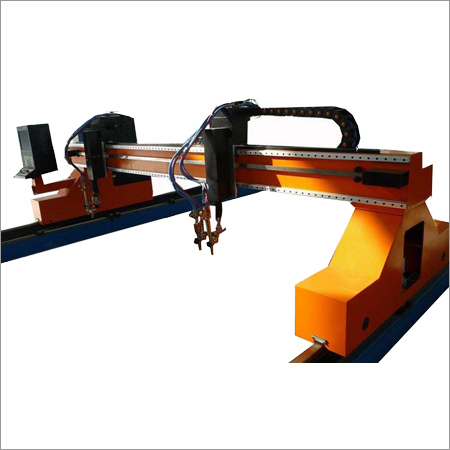

Cnc Gantry Type Plasma Cutting Machine - Feature: Low Energy Consumption

Price : 880000 INR

Cnc Plasma Cutting Machine - Premium Grade Heat Resistant Anti Rust Corrosion Proof Durable Coating | Low Maintenance Easy Functionality

Price Trend: 500000.00 - 2500000.00 INR/Unit

MOQ1 Unit/Units

TypeCnc Plasma Cutting Machine

View More

CNC Plasma Cutting Machine - High Quality Raw Material Modern Technology Integration Precision Engineering

Get Best Deal

Automatic Table Cnc Plasma And Oxyfuel Cutting Machine

Price : 800000 INR

Red Automatic Cnc Plasma Cutting Machine

Price : 700000 INR

Green Fully Automatic Heavy Duty Cnc Plasma Cutting Machine

Price : 400000 INR

Automatic Cnc Plasma And Oxy Fuel Cutting Machines

Price : 900000 INR

Automatic Feeding Esab Swift-Cut Pro Cnc Plasma Cutting System

Price: 1990000 INR/Piece

MOQ1 Piece/Pieces

Product TypePlasma Cutting System

MaterialSteel

AutomaticYes

Control SystemPLC Control

Cutting FunctionFull Automatic

Drive TypeElectric

Crossbow Portable CNC Plasma Cutting Machine

TypeCNC Plasma Cutting Machine

ColorOther Multi color

View More

Grey Portable Plasma Cutting Machine

Price : 3000 USD ($)

Cnc Gantry Plasma Cutting Machine

Get Best Deal

Gantry Type Cnc Plasma Cutting Machine - Color: Black

Price: 875000 INR/Unit

MOQ1 Unit/Units

ColorBlack

Product TypePlasma Cutting Machine

General UseCommercial

MaterialSteel

TypeMetal Cutting Machine

AutomaticYes

View More

Gantry CNC Flame Plasma Cutting Machine

Get Best Deal

Automatic Desktop Type Cnc Plasma Cutting Machine

Price : 560000 INR

Automatic Cnc Plasma Flame Cutting Machine

Get Best Deal

Automatic Mild Steel Gantry Type Cnc Plasma Cutting Machine

Price : 485000 INR

Plasma Cnc Cutting Machine - Automatic Grade: Automatic

Price: 700000 INR/Unit

MOQ1 Unit/Units

Product Typeplasma cnc cutting machine

MaterialMetal

CNC Or NotCNC

ComputerizedNo

Automatic GradeAutomatic

Cooling ModeAir Cooling

CNC Plasma Cutting Machine

Price Trend: 1200000.00 - 1600000.00 INR/Piece

MOQ1 Piece/Pieces

Payment TermsLetter of Credit (L/C) Telegraphic Transfer (T/T) Cheque Cash Advance (CA)

Supply Ability100 Per Month

Delivery Time10 Days

Low Energy Consumption Sheet Metal Cnc Plasma Cutting Machine

MOQ1 Unit/Units

Product TypeSheet Metal CNC Plasma Cutting Machine

General UseIndustrial

AutomaticYes

FeatureLow Energy Consumption

WarrantyYes

Cnc Plasma And Flame Cutting Machine - Color: Green & Black

Price: 800000 INR/Piece

MOQ1 Piece/Pieces

Product TypeCnc Plasma Cutting Machine

ColorGreen & Black

UsageIndustrial

MaterialStainless Steelcarbon Steel

Display TypeAnalog Only

View More

Cnc Flame Cutting Machine (Plasma Or Multi Head) - Color: Gray

Price : 1500000 INR

CNC Oxyfuel-Plasma Profile Cutting Machine

Cutting Width5200 Mm

Model No.3500

MaterialSteel

DimensionsLarge

PowerHigh

WeightHeavy

View More

Cnc Plasma Kjellberg Machine Cutting Speed: 0-500 Mm/Min

Price : 10000 onwards INR

CNC-Plasma-Hi Focus 360i Plasma Cutting Machine

Price : 10000 onwards INR

Stainless Steel Omni Cut Cnc Plasma Cutting Machines

Get Best Deal

CNC-Plasma-Hi Focus 360i Plasma Cutting Machine

Price : 10000 onwards INR

Omnimat Cnc Plasma Cutting Machines

Get Best Deal

Metalmaster Cnc Plasma Cutting Machines

Get Best Deal

CNC Plasma Cutting Machine

Price: 450 INR/Unit

MOQ1 Unit/Units

Product DescriptionCNC Plasma Cutting Machine

CNC Plasma Cutting Machine

MOQ1 Unit/Units

Payment TermsTelegraphic Transfer (T/T) Cash Against Delivery (CAD) Cash in Advance (CID) Cheque Cash Advance (CA)

Delivery Time4 Week

Packaging DetailsAs Per Product

Top Rated Products

FAQs Related to Cnc Plasma Cutting Machine

Who are the top cnc plasma cutting machine manufacturers in India?

- Intimate Machine Tools

- Egp Sales Corporation

- Solar Cnc Automation

- Success Technologies

- K Tech Cnc

- Impex Engineering & Equipments Co.

- Chongqing Senci Wugu Agricultural Machinery Imp & Exp Co. Ltd.

- Mehta Cad Cam Systems Pvt. Ltd.

- Dhatvik India Private Limited

- Esab India Limited

Which cities have the largest number of cnc plasma cutting machine suppliers?

- Mumbai

- Pune

- Chennai

- Delhi

- Bengaluru

- Hyderabad

- Kolkata

- Jaipur

- Faridabad

- Ahmedabad

- Vadodara

- Coimbatore

- Surat

- Ghaziabad

- Nagpur

- Rajkot

- Pimpri

- Thane

- Noida

- Ludhiana

What is the price range for cnc plasma cutting machine offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| SLV Technologies | INR | CNC Plasma Cutting Machine | 1000000 |

| SHRI KHODIYAR MACHINE TOOLS | INR | 125 Amp Cnc Plasma Cutting Machine | 425000 |

| WELDDOR | INR | Thermacut 125HD Plasma Cutting Machine | 526000 |

| Wila CNC India Private Limited | INR | CNC Plasma Cutting Machine | 700000 |

| Welfare Welding Automation | INR | CNC Plasma Cutting Machine | 350000 |

| Flame Tech Cutting Systems | INR | Cnc Flame And Plasma Cutting Machine | 1850000 |

| YKS ENGINEERINGS | INR | CNC Plasma Cutting Machine | 1150000 |

| AMAN ENTERPRISE | INR | Cnc Plasma Cutting Machine | 900000 |

| DRUPE ENGINEERING PRIVATE LIMITED | INR | Cnc Plasma Cutting Machine | 650000 |

How many trusted sellers are available for cnc plasma cutting machine?

- SOLAR CNC AUTOMATION

- STAR ENGINEERS

- ESAB INDIA LIMITED

- HARON CUTTING MACHINES CO. LTD

- TECH PRO ENGINEERING CO.

- LAVANYA ENTERPRISE

- INTIMATE MACHINE TOOLS

- NANJING PRIMA CNC MACHINERY CO. LTD.

- WELDING AIDS

- MEHTA SANGHVI & CO.

- EXCEL METAL & ENGG INDUSTRIES

- ULTRACUT INNOVATION TECHNOLOGY

- ALPHA ELECTRICALS AND AGENCIES

- GRUNTECH MECHANISM PRIVATE LIMITED

- EGP SALES CORPORATION

- K TECH CNC

- MEHTA CAD CAM SYSTEMS PVT. LTD.

- UMA TECHNO FAB

- BHAVYA MACHINE TOOLS LLP

- CHONGQING SENCI WUGU AGRICULTURAL MACHINERY IMP & EXP CO. LTD.

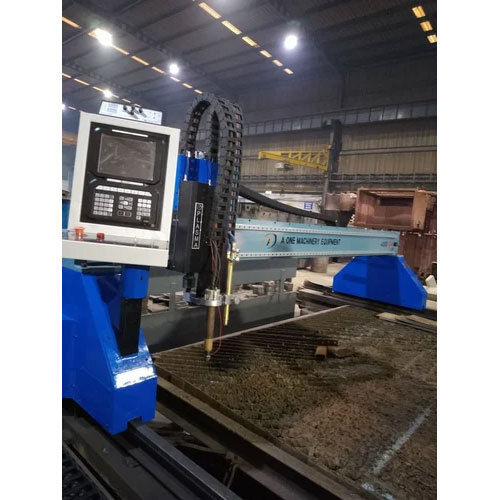

- A ONE MACHINERY EQUIPMENT

- SWARAJ CNC MACHINERY

- Mech-X

- DHATVIK INDIA PRIVATE LIMITED

- FINE CUTTING SOLUTION

- IMPEX ENGINEERING & EQUIPMENTS CO.

What is the minimum order quantity for cnc plasma cutting machine?

Do listed companies have registration & certifications?

- INTIMATE MACHINE TOOLS

- SUCCESS TECHNOLOGIES

- EGP SALES CORPORATION

- MEHTA CAD CAM SYSTEMS PVT. LTD.

- BHAVYA MACHINE TOOLS LLP

What is the get latest price feature?

What types of payment methods are accepted by the cnc plasma cutting machine suppliers?

Cnc Flame Plasma Cutting Machine - Cutting Area: 2600*6600 Square Millimeter (Mm2)

Price: 850000.00 INR/Unit

MOQ1 Unit/Units

ColorWhite

TypeCNC Flame Plasma Cutting Machine

MaterialOther

Automatic GradeAutomatic

Cutting FunctionFull Automatic

Drive TypeElectric

View More

CNC Plasma Cutting Machine - Mild Steel Stainless Steel Aluminum | 1500 x 3000 mm Working Area Automatic Operation Dual Drive System Integrated Dust Extraction

Price : 650000.00 INR

Portable Cnc Plasma Cutting Machine - Automatic Grade: Automatic

Price : 750000.00 INR

15-50 Kg/Hr Capacity Automatic Cnc Plate + Pipe Plasma Cutting Machine

Price : 550000 INR

Cnc Profile Cutting Machine - General Use: Industrial

Price: 950000 INR/Unit

MOQ1 Unit/Units

Product TypeCNC Cutting Machine

General UseIndustrial

MaterialMetal

AutomaticYes

PLC ControlYes

Power SourceElectric

View More

Cnc Plasma Gas Cutting Machine - Automatic Grade: Semi-Automatic

Price : 1250000.00 INR

CNC Plasma Oxy Fuel Cutting Machine - Automatic Control Air Cooling System | High Performance Electric Drive Full Automatic Function

Price: 740000 INR/Unit

MOQ1 Unit/Units

ColorBlack

TypeCnc Plasma Oxy Fuel Cutting Machine

ComputerizedYes

Automatic GradeAutomatic

Control SystemFrequency Speed Control

Cutting FunctionFull Automatic

View More

Good Quality Cnc Ms Plasma Cutting Machine

Price : 95000 INR

View More

Metal Master Cnc Plasma Cutting Machine

Get Best Deal

CUTFIRE 65i CNC Plasma Cutting Machine

Get Best Deal

PA-S70 W CNC Plasma Cutting Machine

Get Best Deal

PA-S45 W CNC Plasma Cutting Machine

Get Best Deal

Placut Plasma Machine

Get Best Deal

Cnc Plasma Cutting Machine - Metal 1500 mm x 3000 mm White and Black | High Precision CNC Control Adjustable Cutting Speed Air Cooling System

Price: 700000.00 INR/Unit

MOQ1 Set/Sets Set/Sets Set/Sets

Drive MotorServo Motor

ColorOther White and Black

Product TypeCNC Plasma Cutting Machine

General UseIndustrial Metal Cutting

MaterialOther Iron

TypeOther Industrial Cutting Machine

View More

K-TECH Plasma CNC cutting Machine

Price : 700000.00 INR

Heavy Duty Cnc Plasma Cutting Machine

FeaturesPrecise Cuts High Speed Durable Build Easy Operation Versatile Materials Efficient Process Cost Effective

View More

CNC Plasma Cutting Machine PL

Price : 1100000.00 INR

CNC Plasma Cutting Machines - High Precision Cutting System | Versatile Material Compatibility Advanced Speed Control User-Friendly Interface

Price : 950000.00 INR

CNC Plasma Cutting Machine PL 1325

Price : 1100000.00 INR

Fully Automatic Cnc Plasma Cutting Machine

Get Best Deal

Ms Cnc Plasma Cutting - Automatic Grade: Semi-Automatic

Price: 118000 INR/Liter

MOQ1 Liter/Liters

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

Cutting FunctionSemi Automatic

Drive TypeElectric

Cnc Plasma Cutting Machine For Industrial Use

TypeCNC Plasma Cutting Machine

ColorOther Multi Color

CNC Plasma Cutting Machine For Industrial Applications

TypeCNC Plasma Cutting Machine

MaterialMetal

ColorOther Multi Color

Senci Metal Cutting Cut 80 80A Cnc Plasma Cutter Machine - Dimension (L*W*H): 500*260*450 Millimeter (Mm)

Price: 24710.03 INR/Unit

MOQ1 Unit/Units

Voltage220-380 Volt (v)

Frequency50 Hertz (HZ)

UsageIndustrial

Dimension (L*W*H)500*260*450 Millimeter (mm)

TypeCnc Plasma Cutting Machine

ConditionNew

Chongqing Senci Wugu Agricultural Machinery Imp & Exp Co. Ltd.

Chongqing

Semi-Automatic Cut 160 Igbt Semi Automatic Inverter Plasma Cutting Machine

Price: 185000 INR/Unit

MOQ1 Unit/Units

TypeInverter Plasma Cutting Machine

MaterialMetal

Automatic GradeSemi-Automatic

Cutting Thickness30 Millimeter (mm)

View More

Cnc Plasma Cutting Machine Helical Gearbox In Faridabad A One Machinery Equipment Material: Mild Steel

Get Best Deal

Cnc Heavy Gentry Plasma And Flame Cutting Machines In Faridabad A One Machinery Equipment Voltage: 220

Get Best Deal

Cnc Gentry Type Plasma And Flame Cutting Mschine - Material: Mild Steel

Price : 700000 INR

Automatic CNC Plasma Cutting Machine - Stainless Steel Semi-Automatic Drive with Frequency Speed Control | Electric Operation Precision Cutting Function

Price: 1250000 INR/Unit

MOQ1 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

Cutting FunctionSemi Automatic

Drive TypeElectric

Cnc Plasma Cutting Machine Pg 4000H - Automatic Grade: Automatic

Price: 16000000 INR/Unit

MOQ1 Piece/Pieces

TypeCNC Plasma Cutting Machine

MaterialStainless Steel

ComputerizedYes

Automatic GradeAutomatic

Cutting Thickness100 mm oxy 25 mm Plasma Millimeter (mm)

Cutting FunctionFull Automatic

View More

Pg 4000L Cnc Plasma Cutting Machine - Automatic Grade: Automatic

Price : 800000 INR

Pg 3000H Cnc Plasma Cutting Machine - Automatic Grade: Automatic

Price : 1600000 INR

Ralli Wolf Cnc Plasma / Flame Cutting Machine (Rwcut 2500) - Application: Industrial

Price: 2478000 INR/Number

MOQ1 Number

ApplicationIndustrial

MaterialSteel Aluminium Iron

ComputerizedNo

Automatic GradeAutomatic

FeatureHigh Performance

WarrantyYes

Semi-Automatic Light Gantry Cnc Plasma Cutting Machine

Price: 300000 INR/Unit

MOQ5 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

Cooling SystemAir Cooling

Drive TypeElectric

Fine Cutting Solution

Faridabad

Trusted Seller

Trusted Seller Premium Seller

Premium SellerView More

Semi-Automatic Cnc Plasma Cutting Machine

Price : 235000 INR

Semi-Automatic Cnc Flame Plasma Cutting Machine

Price : 700000 INR

CNC Portable Plasma Cutting Machine - Stainless Steel Semi-Automatic Design | Frequency Speed Control Air Cooling System Electric Drive Type

Price : 150000 INR

Semi-Automatic Cnc Table Plasma Cutting Machine

Price : 700000 INR

Cnc Plasma Cutting Machine - Heavy-Duty Steel Precise Cuts Up to 1 inch Thick | High-Speed Operation User-Friendly Interface Versatile Metal Compatibility

Price: 1 INR/Meter

MOQ10 Meter/Meters

Supply Ability100 Per Day

Delivery Time1 Week

View More

CNC Flame Plasma Cutting Machines

Price : 1 INR

Latest from Cnc Plasma Cutting Machine

Ready To Ship Cnc Plasma Cutting Machine

Choosing the Right CNC Plasma Cutting Machine

The purchase of a CNC plasma cutting system for the workshop has been approved. It may be time to bring your profile cutting in-house if you've been outsourcing it. Whatever it may be there are many things to consider when buying or renting a cutting machine.

For those looking to buy sell or hire CNC cutting machinery our experienced team can provide unbiased advice. Over the years we have supplied all makes and models throughout the world.

Because we offer such a wide range of plasma-cutting machines we are often asked "Which is the best? We always have to be aware of the intended use of the machine before we can answer this question.

Machine power ratings range from 30A for thin material and light workloads to 800A for industrial fabrication. Mild steel stainless steel and aluminium can have material thicknesses from 6mm to 160mm.

It is wise to consider the potential applications for which the machine will be required before making a choice. Requirements for productivity and accuracy as well as the cost/budget available for the initial purchase and ongoing running costs.

Types of CNC Plasma Cutting Machines

Different forms of plasma are used on different systems although CNC plasma cutting tables are designed for a specific process metal. Depending on the products you make and the volume of work you do you should choose the best plasma source for your CNC table. Let's look at some common plasma subtypes:

Air Plasma Air plasma tables are often used on entry-level steel fabrication machines and are perfect for low-volume production.

Oxygen plasma

Offering a step up in quality from air plasma oxygen plasma is often used by mid-range fabrication shops.

High Definition Plasma

High Definition Plasma is the best option for companies that specialise in high volume processing such as steel service centres. It is also the choice for the highest quality fabrications.

CNC Plasma Cutters

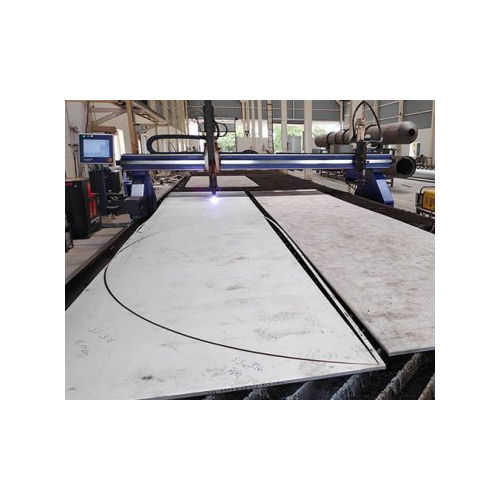

CNC plasma cutters can produce consistent high quality cuts.

How does it work?

"Computer Numerical Control or CNC is the abbreviation for an automated process. Steel fabricators use CNC software to programme a multi-axis bevel to do the job rather than risk damaging the material by working freehand with a portable torch. Potential problems with the shape or profile can be found in the software before fabrication begins saving time and money. In fact CNC systems often work in conjunction with CAM (Computer Aided Machining) and CAD (Computer Aided Design) software to produce accurate fabrications.

Advanced Features of CNC Plasma Cutting Machines

You can achieve consistency accuracy and efficiency in all your cutting tasks by automating the machining process with Computer Numerical Control (CNC) plasma cutting. Many already believe that the use of plasma cutting is a more effective and precise technique than oxyfuel or high-pressure waterjet cutting.

In the past CNC equipment was largely restricted to large industrial companies due to its extremely high cost. Today a wide range of CNC machines are available for smaller companies. There are even entry-level machines suitable for amateur use. It's important to understand some of the jargon involved and what accessories you may need when using a CNC plasma cutter to get the best results.

Height Control

The automatic height control technology found in CNC plasma cutting machines helps to achieve correct pierce and cut heights.

Gantry A gantry is used to provide an X-Y coordinate configuration that facilitates the horizontal movement of the torch. A gantry is either pedestal or floor mounted and has a powerful rail system. Another option is to integrate a gantry into the side of a workbench. Gantries come in a variety of sizes from setups that provide cutting areas just a few feet long to ones that span 100 feet.

Cutting guides

Cut more accurately with the help of cutting guides. There are special guides for lines circles and other special cuts. A great idea is to buy a guide pack that includes the most popular guides.

Air purifiers

A plasma cutter's filtration system is a crucial part that helps get rid of contaminants and moisture that can damage the torch and result in subpar cuts. Get a good filtration kit with a replacement filter element and only use premium filters that have a high level of efficiency and can remove particles as small as .85 microns.

Safety equipment

When using any type of plasma cutter specific safety equipment is always required. Wear adequate eye protection and a pair of heavy duty leather gloves designed exclusively for high heat operations. When using a CNC plasma cutter always follow the recommended safety precautions. Ensure that your work area is adequately ventilated.

Consumables

Some components often referred to as "consumables" will eventually need to be replaced due to normal wear and tear. These include nozzles swirl rings electrodes shields and retaining caps. A spares kit should be kept on hand so that these components can be easily replaced to reduce downtime.

Software

The right software is a critical component of CNC machining. Basic shape libraries and other built-in programming are features of many computer-controlled plasma cutters. Other software can be used to create unique designs. Modern CNC software programs can help you increase productivity and efficiency by analysing material data including cost and waste and converting your drawings and sketches into machine instructions.

Advantages of Using CNC Plasma Cutting Machine

Advantages

- All conductors can be cut. Only ferrous metals can be cut by flame cutting although it is also effective on thick metals.

- Excellent quality up to 50 mm thickness.

- 150 mm maximum thickness is the limit.

- Reasonably priced for medium thickness cuts.

- The best method for cutting aluminium and stainless steel of medium thickness.

- High precision and repeatability are provided by CNC machines.

- Can cut through water reducing HAZ. Also reduces noise levels

- Smaller kerf size than flame cutting.

- Higher cutting speed compared to oxyfuel.

- The same machine can be used for plasma welding by adjusting the parameters.

Factors to Consider When choosing a CNC Plasma Cutting Machine

Plate and sheet sizes first

The first consideration when choosing a CNC plasma cutter is the size of the plate you'll need to cut - choose the largest plate size you need to cut - 4' x 8' 8' x 10' 10' x 40' or sheets.

Each type of machine is capable of cutting a range of sizes but if the size you need to cut is outside this range you'll need to upgrade to a larger model.

Work areas

Another thing to consider is the layout of the work areas. The CNC plasma cutting table on the simplest CNC plasma machine can hold one sheet at a time because it has only one work area. However this means that after cutting a sheet you have to clear the machine of debris and cut pieces before loading a new sheet. That's acceptable in low-volume scenarios or small shops.

However many companies believe that the ability to load and unload materials while the industrial machine is cutting will increase the machine's efficiency. So do you buy two individual cutting tables or one large CNC plasma cutting table? It doesn't matter if it's a downdraft table or a water table - both are acceptable.

Flowchart of tools

Selecting a model is also aided by a clear understanding of the type of cutting tools you need. Do you need two plasma stations or just one? Do you need just one oxy-fuel torch or perhaps four or eight?

The more tools you have the wider the machine becomes. The only reasons for this are the 'cross-cut' requirements and the amount of space each tool takes up on the gantry.

For example consider a machine with four oxy-fuel torches and one plasma torch. The plasma torch must be able to cross cut the entire 10' wide plate to cut it.

Software

Never underestimate the value of nesting and programming software. You still need to be able to write code to make the CNC work even in a small shop where you don't need nesting capabilities.

Nowadays many modern CNCs come with programming features such as shape libraries or manual programme editors. Many also have the ability to 'post-process' a DXF or DWG file into M and G code for the CNC to run. Even then you need to be aware of your plan for creating and editing the CAD files that the CNC will ingest.

FAQs: CNC Plasma Cutting Machine

Q. What is a CNC plasma cutting machine?

Ans. A "CNC plasma" system is a piece of equipment that can move a plasma torch along a path specified by a computer. "CNC" stands for "Computer Numerical Control" which refers to the use of a computer to control the motion of a machine using numerical codes contained in a programme.

Q. Can CNC plasma cutting machines be used for cutting aluminum?

Ans. Modern CNC plasma cutting systems offer an affordable and effective technique for cutting aluminium although historically plasma cutting hasn't always been the best option for aluminium fabrication.

Q. How do I properly maintain CNC plasma cutting machine?

- Sanitise the torch body.

- Sanitise the torch cable.

- Sanitise the power source.

- Check the torch cooling parts.

- Check the water quality.

- Check the plasma.

- Clean the rails gears racks and other parts of the machine.

- Align and level the rails.

Q. What are some common issues that can arise with CNC plasma cutting machines?

Ans. Problems with cut quality result from cutting too fast or too slow. If the speed is too slow the cut pieces will develop "low speed dross" a significant accumulation of bubbles of dross along the bottom edge. Widening of the kerf and heavy top spatter can also result from slow speeds.

Client Testimonials & Reviews

GaneshSuvarna

AIR PLASMA HOUSE

We are leading manufacturer cum dealer in all types of air plasma cutting torches and consumables in Mumbai. We are registered member of tradeindia.com for web promotion in domestic as well as in international markets. We are getting more and more coverage in this global world through their services like call me free trust stamp language converter option and many more. We are proud to be associated with the tradeindia since last three years and we are totally satisfied with their services as well as CRM support given by them time to time. We are thankful for the support and hope it will continue year after year.

RajenderBansal

AMBAY INDUSTRIAL CORPORATION

Our products are listed on tradeindia.com online portal after availing their paid services. I can say definitely increased our product reach and generated good number of business inquiries. I will make sure to upload my latest products to get more business. Thank you tradeindia and Good Luck.

Cnc Plasma Cutting Machine Price List

Product Name | Expected Price |

|---|---|

| CNC Plasma Cutting Machine | 1000000 |

| CNC Plasma Profile Cutting Machine | 1500000 |

| 125 Amp Cnc Plasma Cutting Machine | 425000 |

| Thermacut 125HD Plasma Cutting Machine | 526000 |

| CNC Plasma Cutting Machine | 700000 |

| CNC Plasma Cutting Machine | 350000 |

| Cnc Flame And Plasma Cutting Machine | 1850000 |

| CNC Plasma Cutting Machine | 1150000 |

| Cnc Plasma Cutting Machine | 900000 |

| Cnc Plasma Cutting Machine | 650000 |

This Data was Last Updated on 2025-06-13

Cnc Plasma Cutting Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Intimate Machine Tools Rajkot India | 15 Years |

Egp Sales Corporation Faridabad India | 15 Years |

Solar Cnc Automation Vadodara India | 13 Years |

Success Technologies Ahmedabad India | 11 Years |

K Tech Cnc Hyderabad India | 11 Years |

Impex Engineering & Equipments Co. Mumbai India | 9 Years |

Chongqing Senci Wugu Agricultural Machinery Imp & Exp Co. Ltd. Chongqing China | 6 Years |

Mehta Cad Cam Systems Pvt. Ltd. Ahmedabad India | 5 Years |

Dhatvik India Private Limited Nagpur India | 5 Years |

Esab India Limited Chennai India | 4 Years |

Upcoming Tradeshows

IFSEC INDIA 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

STEEL CONSTRUCTION EXPO 2025

Thu, 27 Nov, 2025 - Sat, 29 Nov, 2025

INDIAN ICE CREAM CONGRESS & EXPO 2025

Mon, 06 Oct, 2025 - Wed, 08 Oct, 2025

The Harit Bharat Expo 2025

Fri, 25 Jul, 2025 - Sun, 27 Jul, 2025

Auto EV Bharat 2025

Wed, 19 Nov, 2025 - Fri, 21 Nov, 2025

CBD - China (Guangzhou) International Building Decoration Fair 2025

Tue, 08 Jul, 2025 - Fri, 11 Jul, 2025

Mercom India Renewables Summit 2025

Thu, 24 Jul, 2025 - Fri, 25 Jul, 2025

Shanghai World of Packaging (swop) 2025

Tue, 25 Nov, 2025 - Thu, 27 Nov, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

The 5th China International Corrugated & Folding Carton Festival 2025

Thu, 30 Oct, 2025 - Sat, 01 Nov, 2025

Popular Categories