Shrink Wrapping Machines

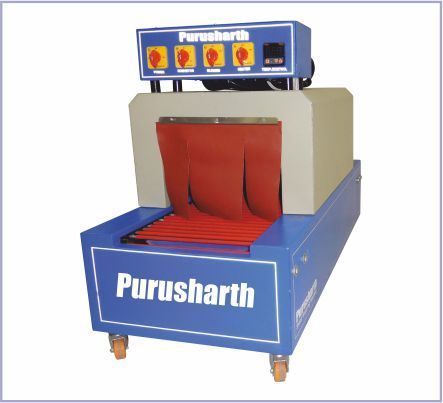

(1135 products)Shrink Wrapping Machine - MS Material, 1560x700x1100 mm Size, Gray Color | Semi-Automatic Type, Electric Drive, 30-50 Capacity

44500 INR (Approx.)/Piece

MOQ1 Unit/Units

ColorGray

TypeL -Sealer Shrink Chamber Machine SPS300

Product TypeShrink Machine Chamber Type

MaterialMS

Capacity30-50 Pcs/min

Auxiliary Packaging Machine TypeOther

Shrink Wrapping Machine - 180kg Stainless Steel, 220V Voltage, 120KW Power | Automatic Operation, Electric Drive, Hassle-Free Functionality

MOQ1 Piece/Pieces

TypeWrapping Machines

MaterialSS

Automatic GradeAutomatic

Drive TypeElectric

Power120KW Watt (w)

Voltage220 Volt (v)

Myild Steel Shrink Wrapping Machine Coimbatore

31000 INR (Approx.)/Number

MOQ1 Number

TypeSHRINK

MaterialMYILD STEEL

Voltage222 Electromagnetic (emu)

WarrantyONE YEAR

Shrink Wrapping Machine - MS Material, 1560x700x1100 mm Size, Gray Color | Semi-Automatic Type, Electric Drive, 30-50 Capacity

44500 INR (Approx.)/Piece

MOQ1 Unit/Units

ColorGray

TypeL -Sealer Shrink Chamber Machine SPS300

Product TypeShrink Machine Chamber Type

MaterialMS

Capacity30-50 Pcs/min

Auxiliary Packaging Machine TypeOther

Mild Steel Shrink Wrapping Machine - Automatic Grade: Automatic

78000 INR (Approx.)/Unit

MOQ1 Unit/Units

ColorOther

TypeWrapping Machines

MaterialMS

FeatureDurable, Rust Proof, Heavy Duty Machine, Less Power Consumable, Other, Highly Efficient

Automatic GradeAutomatic

Control SystemHuman Machine Interface

High Speed Automatic Shrink Wrapping Machine - Mild Steel, 380V, Three Phase | Enhanced Package Quality with Intuitive Controls, Time-Saving Design

Price: 9500000 INR/Unit

MOQ95 lakhs Foot/Feet

MaterialMild Steel

Automatic GradeAutomatic

Web Sealer With Shrink Tunnel Machine - High-Quality Raw Material, Reliable Performance | Industrial Compliance, Optimal Efficiency, Enhanced Durability

Main Domestic MarketAll India

Shri Vinayak Packaging Machine Pvt. Ltd.

New Delhi

Web Sealer Shrink Machine - Automatic Grade: Automatic

Price: 350000 INR/Unit

MOQ1 Unit/Units

ColorGrey

TypeWeb and Sleeve Shrink Machine

MaterialSS

Automatic GradeAutomatic

Voltage220/380/415V Volt (v)

Dimension (L*W*H)2850 x 1570 mm Millimeter (mm)

Industrial Heat Shrink Tunnel - Automatic Grade: Automatic

Price: 5000000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

MaterialMild Steel

ComputerizedNo

Automatic GradeAutomatic

Control SystemHuman Machine Interface

Warranty1 Year

Web Sealer With Shrink Tunnel - Automatic Grade: Semi-Automatic

Price: 390000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

TypeWeb Sealer With Shrink Tunnel

MaterialMild Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Voltage440 Volt (v)

Fully Automatic Shrink Wrap Machine - Color: Blue

Price: 1550000 INR/Unit

MOQ1 Unit/Units

ColorBlue

TypeShrink Wrapping Machine

MaterialMild Steel

Automatic GradeAutomatic

Control SystemHuman Machine Interface

Voltage220/380/415 V Volt (v)

Foreview Engineering & Technology Pvt. Ltd.

Navi Mumbai

Ss Steam Shrink Tunnel Machine Air Pressure: 5 To 7 Kgf/M2

Price Trend: 300000.00 - 340000.00 INR/Piece

MOQ1 Piece/Pieces

TypeSS Steam Shrink Tunnel

MaterialMetal

Air Pressure5 to 7 kgf/m2

ColorOff White

WarrantyYes

Tk304Pd(Double Servo) Hfp Pillow Pack Machine - Automatic Grade: Automatic

Price: 500000 INR/Unit

MOQ1 Unit/Units

TypePillow Pack Machine

MaterialMild Steel

Capacity100-350 packs/min Pcs/min

ComputerizedNo

Automatic GradeAutomatic

Control SystemPLC Control

Stainless Steel Automatic Shrink Sleeve Label Machine

Price: 1425000 INR/Piece

MOQ1 Piece/Pieces

MaterialStainless Steel

Automatic GradeAutomatic

Control SystemPLC Control

Voltage420 Volt (v)

Barvaya Packaging Industries

Ahmedabad

Horizontal Coil Wrapping Machine - Capacity: 500 Ltr/Hr

Price: 3500000 INR/Unit

MOQ1 Unit/Units

Typeshrink machine

Materialms

Capacity500 Ltr/hr

Shrink Speed20 m/hr

Automatic Box Over Wrapping Machine with Collator

Product DescriptionWe are an illustrious company which is engaged in manufacturing, supplying and exporting an extensive range of Automatic Box Over Wrapping Machine with Collator. This range machines are designed and developed using supreme quality raw material and components that source from trusted and authentic ve

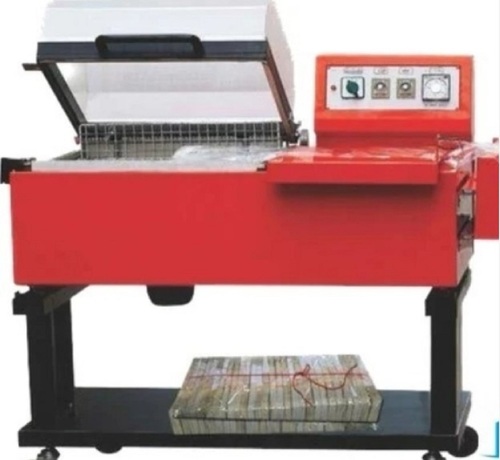

Semi-Automatic Economic Shrink Wrapping Machine

Price Trend: 32500.00 - 285000.00 INR/Unit

MOQ1 Unit/Units

TypeEconomic Shrink Wrapping Machine

Automatic GradeSemi-Automatic

ColorMulti

White Ql5545 Automatic L Type Sealer Shrink Tunnel

Price: 525000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

TypeQl5545 Automatic L Type Sealer Shrink Tunnel

MaterialMild Steel

ComputerizedNo

Automatic GradeAutomatic

Control SystemHuman Machine Interface

Industrial Shrink Wrapping Machine - Mild Steel, Silver - Semi-Automatic, 230 Volt, Frequency Speed Control, 1-Year Warranty

MOQ1 Unit/Units

MaterialMild Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

Voltage230 Volt (v)

ColorSilver

R V Packaging Machinery Solution Co

Nadiad

White Shrink Tunnel Machine Inbuilt With High Quality Heating Elements

Price: 42000.00 INR/Number

MOQ1 Number

ColorWhite, Red and Green

TypeShrink Tunnel Machine

MaterialMetal

Automatic 200 Bpm Shrink Wapping Machine

Price: 2800000 INR/Unit

MOQ1 Unit/Units

ColorSilver

Type200 BPM Shrink Wapping Machine

MaterialStainless Steel

Automatic GradeAutomatic

Voltage440 V Volt (v)

WarrantyYes

Shree Krishna Packging Machinery

Ahmedabad

Collating and Shrink Wrapping Machine

Price Trend: 950000.00 - 1250000.00 INR/Piece

MOQ1 , Piece/Pieces

TypeShrink Wrap

MaterialMs Powder coated

Capacity5- 7 Pcs/min

ComputerizedYes

Automatic GradeSemi-Automatic

Control SystemPLC Control

Flow Wrapping Machine - Semi-Automatic, 220-440 Volt HMI Control System | Reliable Packaging Solution with Warranty

Price: 520000 INR/Unit

MOQ1 Unit/Units

TypeFlow Wrapping Machine

Automatic GradeSemi-Automatic

Control SystemHuman Machine Interface

Voltage220-440 Volt (v)

WarrantyYes

Web Sealer Shrink Machine - Stainless Steel/Solid Steel, Auto Collating Up to 10ppm, PLC Controlled, SS Wire Mesh Conveyor Belt for Quality Shrinking

Price: 175000 INR/Piece

MOQ1 Piece/Pieces

Product DescriptionWe are well known for offering our customers a vast range of Web Sealer Shrink Machine at the market leading rates with the following features:\015\012* MS / SS construction available.\015\012* Auto Collating available up to 10ppm.\015\012* PLC controlled.\015\012* SS Wire Mesh Conveyor Belt for goo

Shrink Tunnel Machine For Oil Jar - 5 And 5 Liter Jars Model - Automatic Grade: Automatic

Price: 85000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

ComputerizedNo

Automatic GradeAutomatic

Control SystemPLC Control

Dimension (L*W*H)66x22x30 Millimeter (mm)

Warranty1 Year

Sleeve Applicator - Stainless Steel, 1850x680x1800 mm, Silver | Fully Automatic, PLC Controlled, 100 Pcs/min Capacity, Easy One-Touch Operation

Price: 800000 INR/Piece

MOQ1 Number

ColorSilver

TypeSleeve Applicator

MaterialStainless Steel

Capacity100 Pcs/min

ComputerizedYes

Automatic GradeAutomatic

Industrial Shrink Wrapping Machines - Automatic Grade: Automatic

Price: 460000.0 INR/Unit

MOQ1 Unit/Units

ColorWhite

TypeShrink Wrapping Machines

MaterialStainless Steel

ComputerizedNo

Automatic GradeAutomatic

Lower Energy Consumption Fully Automatic Bulk Shrink Machine

Price: 945000 INR/Unit

MOQ1 Unit/Units

Product TypeBottling Grouping & Sealing Machine

ApplicationBeverage, Other

ComputerizedNo

Automatic GradeAutomatic

Control SystemHuman Machine Interface

Drive TypeElectric

Excel Filtration Pvt. Ltd.

Ahmedabad

Jay Chamunda Shrink Wrapping Machines Application: For Automotive Use

Product DescriptionWe, Jai Chamunda Engineering Company is one of the leading Company of shrink wrapping machines in Mumbai, Maharashtra, India, Sufficiently equipped with necessary resources and network of alliance partners, You can rest-assure to receiving timely potential benefits in order to attain decisive compet

Aarem Engineering India Private Limited

Mumbai

Box Stretch Wrapping Machine - Metal Build, 1400mm x 650mm x 1160mm Size, 500mm Width | Fast Operation, Easy Installation, Durable Design, Efficient Packaging

Price Trend: 95000.00 - 300000.00 INR/Piece

MOQAs per requirement Piece/Pieces

TypeWrapping Machine

MaterialMetal

ComputerizedNo

Automatic GradeManual

Control SystemHuman Machine Interface

Shri Vinayak Print Pack

New Delhi

Shrink Tunnel Machine - Color: Black

Price: 38000 INR/Unit

MOQ1 Unit/Units

ColorBlack, Orange

TypeShrink Tunnel Machine

MaterialMS

Voltage220-440 Volt (v)

WarrantyYes

Automatic Bottle Shrink Wrap Machine

Price: 270000 INR/Unit

MOQ1 Unit/Units

ColorWhite & Blue

Typebottle shrink wrap machine

MaterialStainless Steel & MS

Automatic GradeAutomatic

Voltage120-440 Volt (v)

Warranty6 Months

Pack Maker Packaging Solution

Rajkot

Semi-Automatic Shrink Wrapping Machine - Steel, 1370x920x1800 mm | High Packing Speed 10-12 Pcs/Min, Adjustable Conveyor Height 800 mm

Price: 305000 INR/Unit

MOQ1 Unit/Units

TypeHeat Shrinking, Web Sealer

MaterialSteel

Capacity12 -15 Pcs/min

Automatic GradeSemi-Automatic

Shrink Speed12 m/m

Air Pressure6 kgf/m2

Shree Raj International Private Limited

Kolkata

Latest From Shrink Wrapping Machines

Ready To Ship Shrink Wrapping Machines

Overview Of Shrink Wrapping Machine

A shrink wrap machine is one that dispenses film which is folded over a product. The film is heated and forms a tight wrap around the product. It is widely used in many packaging fields, including food and beverage, pharmaceuticals, cosmetics, printing and publishing, retail, and e-commerce, in order to provide protection, tamper-evident packaging, and visual appeal to products. The equipment can be used for multiple packaging of products either in loose form, packaged in trays, or prepacked in cartons.

This is a type of packaging equipment used for wrapping products in a shrinkable film. It is commonly used in different industries for protecting and packaging items, providing a secure and tight seal. Shrink wrapping machines come in numerous sizes and configurations, ranging from manual tabletop models suitable for small-scale operations to fully automated systems for high-volume production.

Shrink wrapping machines can vary in design, features, and automation levels. Some machines may incorporate additional functions like speed settings, adjustable temperature controls, conveyors, or automated feeding systems for accommodating specific packaging requirements.

Importance of Shrink Wrapping Machines in Packaging Industries

Shrink wrapping machines play an important role in packaging industries for several reasons as follows:

Product Protection: It provides a protective barrier around products, hence safeguarding them from moisture, dust, and other environmental factors. The shrink film conforms to the shape of the item tightly, creating a secure seal that helps prevent damage during transportation, handling, and storage.

Tamper-Evident Packaging: Shrink wrapping can be used for creating tamper-evident packaging. If the film is broken or removed, it indicates that the product might have been tampered with. This enhances product safety and consumer confidence.

Improved Shelf Appeal: Shrink wrapping enhances the visual presentation of products as the transparent film allows customers to see the product inside, making it visually appealing and providing a clear view of the item's features and quality.

Bundling and Multipacking: Shrink wrapping machines are often used for bundling multiple items together or creating multipacks. This is useful for products that are sold as sets, like beverage bottles, cans, or promotional items. It helps in holding the items together securely, making them easier to transport, handle, and display.

Cost-Effective Packaging: Shrink wrapping can be a feasible packaging solution as compared to other methods. The shrink film itself is inexpensive, and the machines are efficient too, capable of handling a wide array of product shapes and sizes. This helps in reducing labor costs and increasing packaging speed, leading to overall cost savings.

Versatility and Adaptability: These machines can accommodate different product shapes, sizes, and materials. They can be used for packaging items of variegated dimensions and materials, including boxes, bottles, jars, cans, and more. This versatility makes them suitable for diverse industries, such as pharmaceuticals, food and beverage, electronics, cosmetics, and household goods.

Environmental Benefits: Shrink wrapping typically requires less packaging material compared to other methods like cardboard boxes. This reduces waste generation and overall packaging material consumption. These shrink film materials are also recyclable.

Working of Shrink Wrapping Machines

The working of a shrink wrapping machine involves numerous steps to wrap and shrink a film tightly around a product. Here's a general overview of how it works:

Film Loading: The shrink wrapping machine has a shrink film roll, made of PVC or polyolefin, mounted on a film holder. The film is unwound from the roll and fed into the machine.

Product Loading: The items to be wrapped are loaded onto the conveyor belt, or product tray, or manually placed into the film.

Film Unwinding: The machine unwinds the film from the roll and passes it over a set of rollers or through a film delivery system, for ensuring smooth and controlled movement of the film.

Sealing: As the product enters the sealing area, the machine uses a sealing mechanism, that can be an impulse sealer or a constant heat sealer.

Cutting: Once the sealing process is completed, the machine cuts the film by using a cutting blade or a hot wire cutting system, separating the wrapped package from the rest of the film roll.

Shrink Tunnel: The wrapped packages are then transferred into a shrink tunnel which consists of a heated chamber or conveyor system that exposes the packages to controlled heat. Here the film shrinks and conforms tightly to the shape of the product to create a secure and tight wrap.

Cooling and Discharge: The packages then go through a cooling process, which solidifies the film around the product for ensuring that the shrink wrap remains tight and secure. Once cooled, the packages are discharged from the machine onto a conveyor belt for further handling or distribution.

Types Of Shrink Wrapping Machines

There are numerous types of shrink wrapping machines available, each designed for specific packaging needs and production requirements. Below mentioned are some common types of shrink wrapping machines:

-

L-Bar Sealers: L-Bar sealers are extensively used for sealing and shrinking individual or multiple products. They have an "L" shaped sealing bar that comes down for creating a seal around the product.

-

Side Sealers: Side sealers are suitable for sealing long and narrow products such as magazines, books, or CDs. These machines have a sealing bar that moves vertically or horizontally, creating a seal on one side of the product.

-

Chamber Shrink Wrap Machines: Chamber shrink wrap machines are commonly used in small to medium-sized operations. The product is placed inside a shrink film bag, and the bag is sealed in a heated chamber. The chamber is equipped with a heat source for creating a seal.

-

Sleeve Wrapping Machines: Sleeve wrapping machines are designed for wrapping products with a sleeve of shrink film. The film is formed into a tube and passes through a sealing and cutting unit, creating a sleeve around the product. Heat is then applied to shrink the film tightly around the product.

-

Automatic Shrink Wrappers: These are fully automated systems suitable for high-volume production. The wrappers incorporate conveyor systems, automatic product feeding, sealing, and shrinking processes for increased efficiency and productivity by minimizing manual intervention.

-

Manual Shrink Wrappers: These machines are compact and economical options for small-scale operations. They require manual product loading, film sealing, and shrinking. These machines are suitable for low-volume production environments.

-

Continuous Band Sealers: Continuous band sealers are used for sealing and shrinking continuous rolls of shrink film around products. They are used for sealing packages like pouches or bags, creating a continuous seal along the film.

-

Shrink Tunnels: Shrink tunnels are not standalone machines but are an essential component of the shrink wrapping process. They are used for applying controlled heat to the wrapped packages, causing the film to shrink tightly around the product.

The choice of machine depends on factors such as the size and shape of the products, desired automation level, production volume, and specific packaging requirements of the industry or application.

Applications Of Shrink Wrapping Machines

Shrink wrapping machines have a wide range of applications across several industries. Some of the industries include:

• Food and Beverage Industry

• Pharmaceutical Industry

• Cosmetics and Personal Care Products

• Printing and Publishing

• Retail and Consumer Goods

• Promotional and Gift Items

• Industrial and Automotive Parts

• E-commerce and Logistics

• Beverage Industry

• Industrial Packaging

Cost of Shrink Wrapping Machines

The cost of shrink wrapping machines in Indian rupees can vary significantly depending on several factors such as the type of machine, its features, brand, capacity, and supplier. Here are some approximate price ranges for different types of shrink wrapping machines:

-

Manual Tabletop Shrink Wrapping Machines: The price can range from around a 10,000 to a 30,000.

-

Semi-Automatic Shrink Wrapping Machines: The price for these machines range from a 50,000 to a 2,00,000.

-

Automatic Shrink Wrapping Machines: These machines can range from a 2,00,000 to a 10,00,000 or more.

-

Shrink Tunnels: These that can be integrated with other machines and generally range from a 1,00,000 to a 5,00,000 or more, as per the size and capabilities.

These price ranges are approximate and can vary based on market conditions, supplier pricing, and additional features or customization required.

FAQs: Shrink Wrapping Machine

Q. What is shrink wrapping machine?

Ans. A shrink wrapping machine is a packaging equipment that wraps products in a shrinkable film and applies heat to shrink the film tightly around the product. It provides protection, tamper-evident packaging, and visual appeal to items.

Q. How is shrink wrap machine used?

Ans. A shrink wrap machine is used for wrapping products in a shrinkable film, providing a secure and protective packaging solution. Following are the steps on how to use a shrink wrap machine:

• Preparation

• Machine Setup

• Load the Film

• Product Loading

• Sealing

• Cutting

• Shrink Tunnel

• Shrink Process

• Cooling and Discharge

Q. How many types of shrink wrap machines are available in the market?

Ans. There are several types of shrink wrap machines available in the market for catering to different packaging needs and production requirements. Some common types of shrink wrap machines include:

• L-Bar Sealers

• Side Sealers

• Chamber Shrink Wrap Machines

• Sleeve Wrapping Machines

• Automatic Shrink Wrappers

• Manual Shrink Wrappers

• Continuous Band Sealers

• Shrink Tunnels

Manufacturers & Suppliers of Shrink Wrapping Machines

Company Name | Member Since |

|---|---|

Shri Vinayak Packaging Machine Pvt. Ltd. New Delhi, India | 20 Years |

Joy Pack India Pvt Ltd Delhi, India | 20 Years |

Durapak Chennai, India | 18 Years |

Shri Balaji Packers Delhi, India | 18 Years |

Purusharth Packaging Rajkot, India | 15 Years |

3Teck Engineering Thane, India | 14 Years |

Ramesh Engineering Works Mumbai, India | 14 Years |

Pack Maker Packaging Solution Rajkot, India | 14 Years |

Avm Packaging Systems Mumbai, India | 12 Years |

Join Pack Machines (Pvt.) Ltd. Delhi, India | 10 Years |

Popular Products