- Tradeindia

- Plant & Machinery

- Fly Ash Brick Plant

Fly Ash Brick Plant

(252 products)Automatic Fly Ash Brick Machine - Vibration Type: Platform Vibration

1200000 INR/Plant

MOQ - 1/Plant

Kailash Engineering

Fire Resistant Chirag Simple And Easy Operating Fly Ash Brick Plant

2500000 - 7500000 INR/Set

MOQ - 1/Set

Chirag International

Automatic Fly Ash Brick Plant Capacity: 1500-2000 Pcs/Min

1125000 INR/Piece

MOQ - 1/Piece

Everon Industries

Ms Endeavour-Ifbp1600 Automatic Fly Ash Brick Plant

1750000 INR/Unit

MOQ - 1/Unit

Endeavour Intelligent Equipments Pvt. Ltd.

Automatic Fly Ash Brick Plant - Automatic Grade: Semi-Automatic

1690000 INR/Piece

MOQ - 1/Piece

Tara Machines & Tech Services Pvt. Ltd.

Premium High-Pressure Fly Ash Brick Making Machine - 3 kVT Capacity, Compact Design | Easy Installation, Effective Cooling, Automatic Operation, Fire Resistant & Heat Insulation

250000 INR/Piece

MOQ - 1/Piece

Atlas Industries

Fly Ash Brick Making Machine - 3500 kg Weight | Fully Automatic Operation

Price: 1500000.00 INR/Unit

MOQ1 Unit/Units, Unit/Units, Unit/Units

Weight (kg)3500 Kilograms (kg)

AutomaticYes

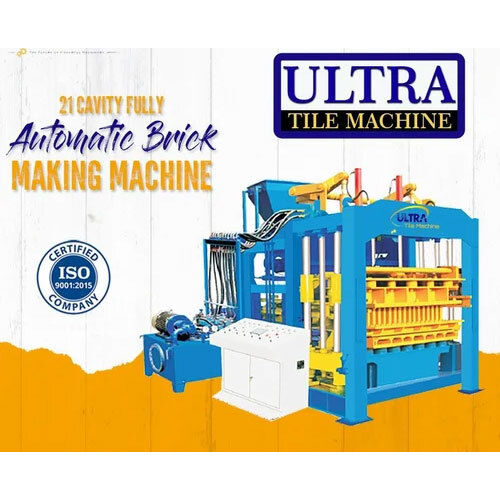

Brick Making Machines - Color: Blue

Price: 1700000 INR/Piece

MOQ1 Set/Sets

ColorBlue

Product TypeBrick Making Machine

MaterialFly Ash

Laxmi Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium10 Years

White Automatic Fly Ash Bricks Making Machine Plant

MOQ1 Unit/Units

TypeFly Ash Bricks Plant

MaterialMetal

ComputerizedNo

Automatic Fly Ash Brick Machine - Vibration Type: Platform Vibration

Price: 1200000 INR/Plant

MOQ1 Plant/Plants

General UseFor Making Fly ash bricks and Paver block

MaterialFly Ash

ComputerizedYes

Automatic Fly Ash Brick Plant 26, Automation Grade: Automatic

Product DescriptionAutomatic Fly Ash Brick Plant 26

Automatic Fly Ash Bricks Plant [ENDEAVOUR-iF 1500]

Price: 1660000 INR/Set

MOQ1 Set/Sets

Payment TermsCash in Advance (CID)

Supply Ability5 Per Month

Delivery Time1 Months

Endeavour Intelligent Equipments Pvt. Ltd.

Mehsana

Trusted Seller

Trusted Seller Super Seller

Super Seller8 Years

Fine Fly Ash Application: For Construction Use

Price: 300 INR/Kilograms

MOQ200 Bag/Bags

ApplicationFor Construction Use

Product TypeFine Fly Ash

Main MaterialFly Ash

Mohta Cement Pvt Ltd

Indore

Trusted Seller

Trusted Seller Premium Seller

Premium Seller13 Years

Fly Ash Brick Plant

Product DescriptionWe specialize in manufacturing, supplying and exporting a broad range of Fly Ash Brick Plant in Ahmedabad, Gujarat, India. Fabricated using advanced technology, our variety of fly ash brick plant are extensively used in building and construction industries. All the products are designed & developed

Fly Ash Brick Making Machine By Myravya Engineering India Pvt. Ltd.

Price: 560000 INR/Unit

MOQ1 Unit/Units

Payment TermsOthers, Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

Supply Ability2 Per Month

Delivery Time25 Days

White Fly Ash Brick Plant And Concrete Block Plant

MOQ1 Unit/Units

Product TypeBrick Plant And Concrete Block Plant

General UseMaking Brick, Block

AutomaticYes

Aimax Equipment Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Fly Ash Brick Plant Capacity: 500-1000 T/Hr

Price: 1125000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypeFly Ash Brick Plant

General UseIndustrial, Construction

Top Rated Products

FAQs Related to Fly Ash Brick Plant

Fly Ash Brick Making Machine - Color: Blue

Price: 1800000 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypeFly Ash Brick Making Machine

General UseBrick Making

Industrial Fly Ash Brick Making Machine

Price: 1900000 INR/Piece

MOQ1 Piece/Pieces

Main Domestic MarketAll India

High Durability Automatic Fly Ash Bricks Plant

Price: 950000 INR/Unit

MOQ1 Unit/Units

Product TypeAutomatic Fly Ash Bricks Plant

General UseMaking Brick

AutomaticYes

Shankar Engineering Corporation

Burdwan

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Fly Ash Brick Making Machine - Feature: High Quality

Price: 225000 INR/Unit

MOQ1 Unit/Units

Product TypeFly Ash Brick Making Machine

General UseConstruction

AutomaticYes

Ludhiana Engineering Works

Hapur

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

High Durability Mild Steel Fly Ash Bricks Making Machine

Price: 1200000 INR/Unit

MOQ1 Unit/Units

Product TypeFly Ash Bricks Making Machine

General UseIndustrial

MaterialOther

35Hp Fully Automatic Fly Ash Brick Plant In Ahmedabad Narsinh Industries, Usage/Application: Brick Making

Product Description35Hp Fully Automatic Fly Ash Brick Plant In Ahmedabad Narsinh Industries

Blue Vibro Press Fly Ash Bricks Making Plant

Price Trend: 175000.00 - 475000.00 INR/Unit

MOQ1 Unit/Units

Product TypeBricks Making Plant

MaterialSteel

Weight (kg)900-1200 Kilograms (kg)

Megacon Construction Equipments India Private Limited

Pune

21 Years

High Durability Pm16000 Fly Ash Brick Making Plant

MOQ1 Unit/Units

General UseIndustrial

ComputerizedNo

AutomaticYes

High Efficiency Fly Ash Bricks Batching Plant

MOQ1 Unit/Units

Product TypeFly Ash Bricks Batching Plant

General UseBricks Batching

MaterialCast Iron

Vishaw Karma Industries

Sriganganagar

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Automatic Fly Ash Brick Plant

Price: 1550000 INR/Set

MOQ1 Set/Sets

TypeBrick plant

Materialhydraulic machine

ComputerizedNo

Yellow Fly-Ash Brick Plant

MOQ1 Unit/Units

General UseFor Brick Making

TypeAAC Plant, Hollow Block Making Machine, Clay Brick Making Machine

AutomaticYes

Gray Fly Ash Bricks Concrete Batching Plant

Price: 2500000 INR/Unit

MOQ1 Unit/Units

ColorGray

Product TypeFly Ash Bricks Concrete Batching Plant

MaterialStainless Steel

Conveyortech Engineers

Coimbatore

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Automatic Fly Ash Bricks Plant - Color: Blue

Price: 1150000 INR/Unit

MOQ1 Unit/Units

Product TypeAutomatic Fly Ash Bricks Plant

MaterialFly Ash

ComputerizedNo

Green Lm-06 Fully Automatic Fly Ash Bricks Making Plant

Price: 1800000 INR/Piece

MOQ1 Piece/Pieces

ColorGreen

Product TypeFly Ash Bricks Making Plant

General UseCONSTRUCTION

Laxmi Engineering Works

Ajmer

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

80 Mt Fly Ash Brick Making Fully Auto Machine Capacity: 32 Pcs/Min

Price: 1412000.00 INR/Unit

MOQ1 Unit/Units

Product TypeFly Ash Bricks

General UseFly Ash Bricks Making Machine

MaterialFly Ash

Latest from Fly Ash Brick Plant

Automatic Fly Ash Brick Plant

By:

Sai Sri Enterprises

Fly Ash Brick Plant And Concrete Block Plant

By:

Aimax Equipment Private Limited

PMA10000 Automatic Fly Ash Brick Plant

By:

Possible Machineries

Automatic Fly Ash Brick Plant 19

By:

United Machines Company

Automatic Fly Ash Brick Plant 24

By:

The Spartan Machinery

Fly ash brick plant is used for making bricks of different sizes and shapes using fly ash in large quantity. These bricks are then used in building, bridges and civil engineering construction projects. It has super vibration and pressing system for maximum compaction and strength. The bricks manufactured by this plant have high compressive strength with low density and water absorption capacity. Fly ash brick plant has capacity to produce more bricks per hour. This plant is also known for its robust construction, rust proof finish and easy installation. It is available in different designs and configurations to fulfil the different requirements of the buyers.

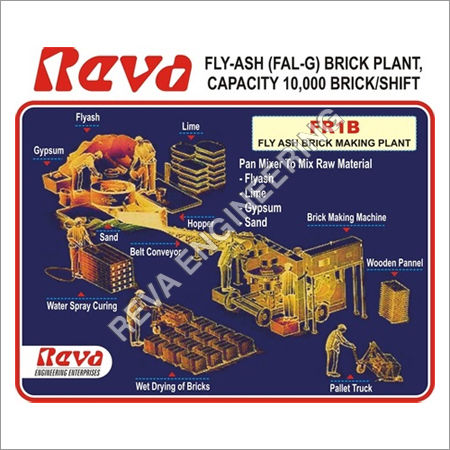

Fly ash brick plant consists of:

(i). Fly Ash Brick Machine

(ii). Muller mixer

(iii).

(iv). Hydraulic Power Station

(v). Control Panel

(vi). Main Feeder

(vii). Pallet Feeder

(viii). Pallet Conveying Rail

(ix). Mould

Client Testimonials & Reviews

SunilKumar

SHREYA POLYMERS

We are the leading manufactures of PP FRP equipment, chemical storage tanks, scrubber, expansion joints etc. Our network is already spread all across the global market. We are associated with tradeindia since 1 year. We Wish good luck for their bright future ahead.

MaheshPrajapati

SPINECORD ENGINEERS

We are very much satisfied with service of tradeindia and getting good response from one of the best B2B portal www.tradeindia.com, they always thinks for the business development of our company and working for generate good inquires for our product via promotion.

NareshMittal

BENTEX INDUSTRIALS PVT. LTD.

Trade India is a very good site for the exporters & importers. All the inquiries we receive are generally relevant to our products. Although some times sell offers are reveived to our own posted sell offers, which is being checked by Trade India and the individual users shall be able to use this excellent plateform more efficiently in future. We are satisfied with the services of Trade India as this back to back portal has helped us in generating business inquires. As a service provider & teamwork it's a good example in Indian context. We hope Trade India shall further improve its services and shall set up itself as one among the leading global trade sites.

FayazullaSayed

S. F. ENGINEERING WORKS

We are associated with Tradeindia for more than 4 years and getting good business through Tradeindia. We are happy and satisfied with the response and the inquiries being generated through Tradeindia.

Fly Ash Brick Plant Price List

Product Name | Expected Price |

|---|---|

| Fly Ash Brick Plant | 1050000 |

| Automatic Fly Ash Brick Plants | 1900000 |

| Fly Ash Brick Making Plant | 1700000 |

| Automatic Fly Ash Brick Plant | 2880000 |

| 25.5HP Automatic Fly Ash Bricks Plant | 1880000 |

| Automatic Fly Ash Brick Plant | 1800000 |

| Automatic Fly Ash Brick Plant | 2420000 |

| Automatic Fly Ash Brick Plant | 3250000 |

| Automatic Fly Ash Brick Plant | 3250000 |

| 17.25 kW Automatic Fly Ash Bricks Plant | 1880000 |

This Data was Last Updated on 2024-12-15

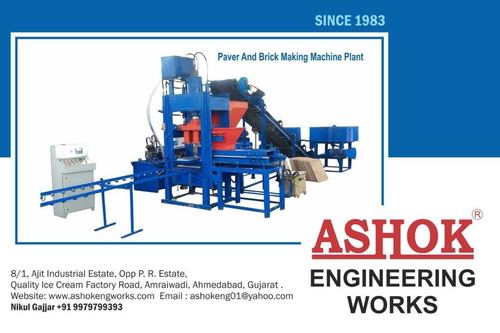

Fly Ash Brick Plant Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Megacon Construction Equipments India Private Limited Pune, India | 21 Years |

Reva Engineering Enterprises Ghaziabad, India | 16 Years |

Ab Engitech Jodhpur, India | 14 Years |

Constrarch Enviro Moradabad, India | 13 Years |

Mohta Cement Pvt Ltd Indore, India | 13 Years |

Gayatri Engimech Pvt. Ltd. Ahmedabad, India | 12 Years |

Myravya Engineering India Pvt. Ltd. New Delhi, India | 12 Years |

Laxmi Engineering Works Ahmedabad, India | 10 Years |

Endeavour Intelligent Equipments Pvt. Ltd. Mehsana, India | 8 Years |

Rexnear Systems Greater Noida, India | 8 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories

![Automatic Fly Ash Bricks Plant [ENDEAVOUR-iF 1500]](https://tiimg.tistatic.com/fp/3/005/127/automatic-fly-ash-bricks-plant-endeavour-if-1500--095.jpg)