Biomass Briquetting Plant - General Use: Industrial

Price: 2251000.00 INR / Number

(2251000.00 INR + 0% GST)

Get Latest Price

MRP:

2251000.00 INR / Piece

Weight :

8500.00 Kilogram

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Color | Other |

| Product Type | Briquetting Plant |

| General Use | Industrial |

| Computerized | No |

| Automatic | Yes |

| PLC Control | Yes |

| Cooling System | Air Cooling System |

| Voltage | 220-440 Volt (v) |

| Motor | AC Motor |

| Pressure Form | Hydraulic Pressure |

| Structure Form | Double Roller Single Pressure |

| MoistureÃÂ OfÃÂ Material | Alloy Steel |

| Warranty | Yes |

| Payment Terms | Cash in Advance (CID) |

| Supply Ability | 10 Per Month |

| Delivery Time | 30 Days |

| Sample Available | Yes |

| Main Export Market(s) | Asia, North America, Middle East, Africa |

| Main Domestic Market | All India |

| Color | Other |

| Currency | INR |

| Stock Quantity | 5 |

| Brand Name | RADHE ENGINEERING CO |

| Mop | 1 |

| Unit Type | Piece/Pieces |

| Moq | 1 |

| Price Type | fixed |

| MRP | 2251000.00 INR |

| Pkg Box Height | 1.00 inches |

| Weight | 8500.00 Kilogram |

| Pkg Box Length | 1.00 inches |

| Pkg Box Breadth | 1.00 inches |

| Packsize | 1 |

| Returnable | No |

| Price | 2251000.00 INR (Approx.) |

| Shipping Type | actual |

| Product Unit | 1 Piece/Pieces |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

| GSTIN | 0% |

Company Details

With More than 25+ Years of Domain Experiance, Radhe Engineering Co is a Pioneer & Leader in;

- Biomass Briquetting Machine

- Biomass Pellet Machine-16mm & 25mm

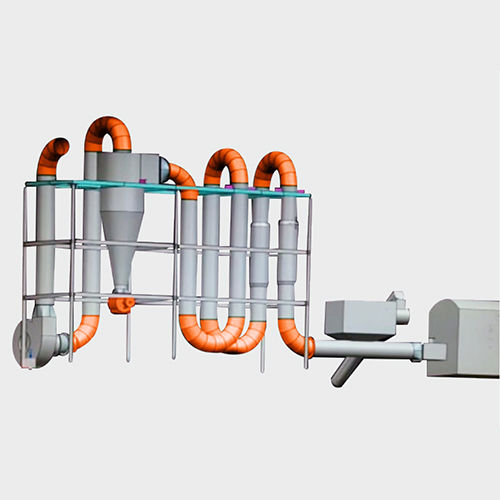

- Biomass Dryer - Flash Type

- Biomass Hammer Mill/Wood Dust M/C

- Biomass Drum Chipper (For Making Wood Chips).

Application: Biomass Briquetting Plant is for converting agro forestry waste (Bio-mass) to Briquettes (Bio-coal).

Description:

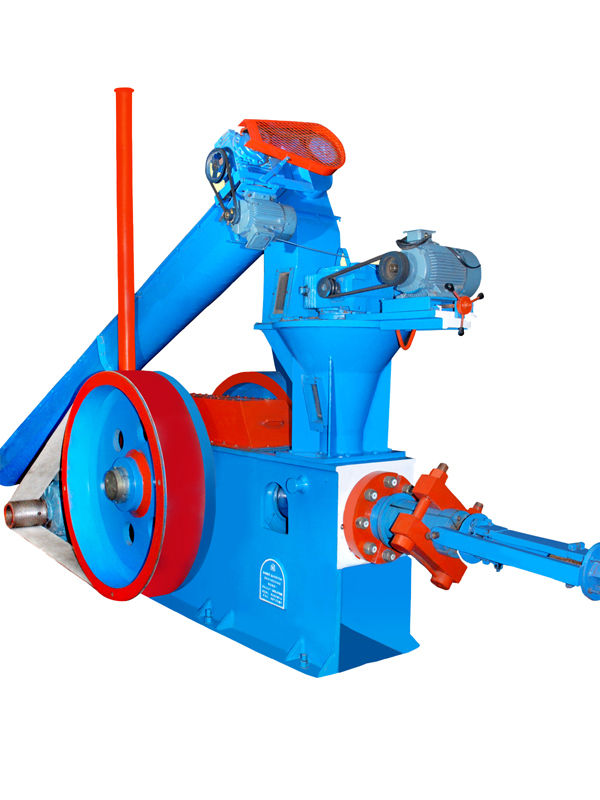

The Briquetting Plant is a ram type press designed for continuous heavy-duty operation with two load wheels. One of the load wheels acts as a pulley, and driven by the main motor through a flat belt. Forced lubrication is provided by oil lubrication system which gives a longer life to the bushes.

Dry agro - forestry waste as a raw material is fed through the screw conveyor to Kupy by means of vertical screws, with its own-geared motor. It pre-compress and forces the material downward into the feeder box. From the feeder box the material is forced by the Ram through Taper die and due to high pressure & heat, raw material (Biomass) is converted into solid cylindrical briquettes. Finally finished briquettes come out from die holder and passes through natural cooling lines.

During Process lignin content in the raw material (Biomass) is transformed into liquid form & acts as a natural binder. Therefore it is called the Binder less Technology.

Features:

- Standard genuine parts with applicable MOC and process

- Compact but ideal design reference to Jumbo-90

- Temperature sensors to all bushes to prevent life of bushes.

- Auto control feeding as reference to main motor load and auto restart

- VFD to screw conveyor to change speed of feeding

Business Type

Exporter, Manufacturer, Service Provider, Distributor, Supplier, Trading Company, Wholesaler, Retailer, Dealer, Fabricator, Producer

Employee Count

20

Establishment

1995

Working Days

Monday To Saturday

GST NO

24AHGPK9910L1Z3

Payment Mode

Cheque, Telegraphic Transfer (T/T), Western Union, Paypal

Certification

ISOQAR

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AHGPK9910L1Z3

Rajkot, Gujarat

Ceo

Mr Vijay C. Kalavadia

Members since

2 Years

Address

D-111, Rajdoot Industrial Estate, 5-Umakant Udyognagar, Near Mavdi Plot, Near Ashok Garden, Rajkot, Gujarat, 360004, India

biomass briquette press in Rajkot

Report incorrect details