- Tradeindia

- Coil Winding Machines

- Ceiling Fan Winding Machines

Ceiling Fan Winding Machines

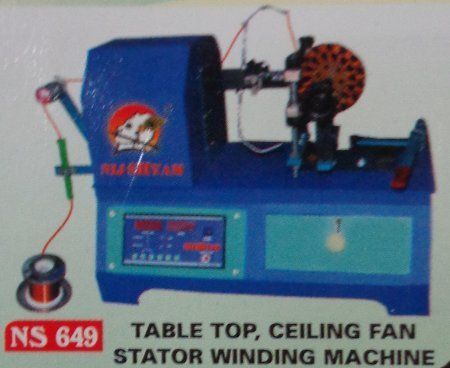

(77 products)Table Top Ceiling Fan Stator Winding Machine - Feature: Low Energy Consumption

24000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Drive TypeElectric

View More

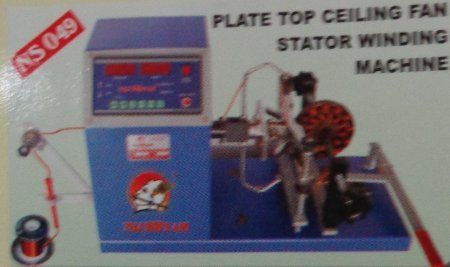

Plate Top Ceiling Fan Stator Winding Machine - Feature: High Speed

Price : 22000 INR

Ceiling Fan And Field Coil Winding Machine - Feature: Low Energy Consumption

Price : 27000.00 INR

Mild Steel Ceiling Fan Stator Winding Machine - Feature: Low Energy Consumption

Price : 27000.00 INR

Single Phase Ceiling Fan Stator Winding Machine - Feature: High Precision

Price : 28000.00 INR

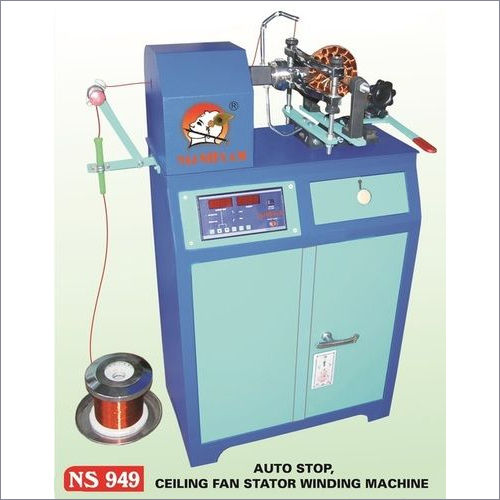

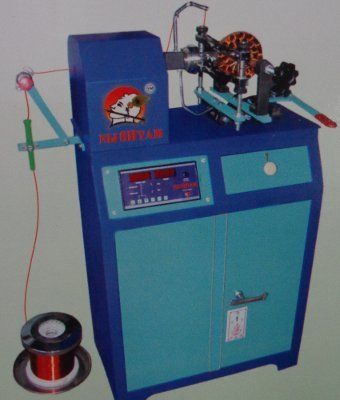

Auto Stop Ceiling Fan Stator Winding Machine - Feature: High Speed

Price : 28000.00 INR

Table Top Ceiling Fan Stator Winding Machine - Feature: Low Energy Consumption

24000 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Drive TypeElectric

View More

Plate Top Ceiling Fan Stator Winding Machine - Feature: High Speed

Price : 22000 INR

Ceiling Fan And Field Coil Winding Machine - Feature: Low Energy Consumption

Price : 27000.00 INR

Mild Steel Ceiling Fan Stator Winding Machine - Feature: Low Energy Consumption

Price : 27000.00 INR

Single Phase Ceiling Fan Stator Winding Machine - Feature: High Precision

Price : 28000.00 INR

Auto Stop Ceiling Fan Stator Winding Machine - Feature: High Speed

Price : 28000.00 INR

Automatic Ceiling Fan Winding Machine - Stainless Steel, 40X30X60 Cm, 50Kg/Hr Capacity | Consistent Cuts, Durable Design, Easy Operation, Efficient, Fast Cutting, Versatile

MaterialStainless Steel

Dimensions40X30X60 Cm

Weight25Kg

Power1 Hp

Voltage220V

BladesStainless Steel

K. D. Dowls & Keys

Faridabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller18 Years

View More

Cnc Ceiling Fan Motor Winding Machines (Dual Drive)

Get Best Deal

KDDK-199 CNC Single Drive Dual Head Ceiling Fan Motor Winding Machine - Stainless Steel, 2 Winding Spindles, Electric Powered, Automatic High-Speed Operation

Price : 255000 INR

Kddk-149 Cnc Single Drive Single Head Cnc Ceiling Fan Motor Winding Machine - Feature: High Speed

Get Best Deal

Ceiling Fan And Field Coil Winding Machine - Feature: Low Energy Consumption

Price: 27000.00 INR/Unit

MOQ1 Unit/Units

General UseIndustrial

MaterialStainless Steel

ComputerizedNo

AutomaticYes

Drive TypeElectric

FeatureLow Energy Consumption

View More

Automatic Ceiling Fan Coil Winding Machine - Feature: High Speed

Price : 24000.00 INR

Mild Steel Ceiling Fan Stator Winding Machine - Feature: Low Energy Consumption

Price : 27000.00 INR

Single Phase Ceiling Fan Stator Winding Machine - Feature: High Precision

Price : 28000.00 INR

Auto Stop Ceiling Fan Stator Winding Machine - Feature: High Speed

Price : 28000.00 INR

Plate Top Ceiling Fan Stator Winding Machine - Feature: High Speed

Price : 22000 INR

Industrial Ceiling Fan Winding Machine - Dimension (L*W*H): 81.3 X 114.3 X 86.4 Centimeter (Cm)

Price: 12500 INR/Unit

MOQ1 Unit/Units

General UseFan Winding

MaterialOther, Mild Steel

Weight (kg)62 Kilograms (kg)

AutomaticNo

Power SourceElectric

Winding Head1 Piece

Ceiling Fan Making Machine

Price: 12600 INR/Unit

MOQ1 , Unit/Units

ColorYellow

Control SystemManual

FeaturesCompact design easy operation

Machine TypeCeiling Fan Making Machine

Product TypeOther, Ceiling Fan Making Machine

Power SourceElectric, Other

Bharat Machine Tools Industries

Kolkata

Trusted Seller

Trusted Seller16 Years

Electric Ceiling Fan Winding Machine - Feature: Low Energy Consumption

Price: 26500 INR/Piece

MOQ1 Piece/Pieces

MaterialStainless Steel

TypeWire Winding Machine

ComputerizedNo

AutomaticYes

Control SystemSemi automatic

Power SourceElectric

View More

Ceiling Fan Rewinding Machine

Get Best Deal

Ceiling Fan Stator Winding Machine

Price : 35000 INR

Auto Stop Ceiling Fan Winding Machine - Color: Blue

Price : 35000 INR

Ceiling Fan And Field Coil Winding Machine - Color: Blue

Price : 28500 INR

Ceiling Fan Stator Winding Machine - Color: Blue

Price : 28500 INR

Ceiling Fan Winding Machine - Color: Blue

MOQ1 Unit/Units

General UseIndustrial

MaterialStainless Steel

AutomaticYes

Power SourceElectric

Winding Head1 Piece

Voltage220 Volt (v)

Fully Automatic Ceiling Fan Stator Winding Machine (Mini Cnc) Kij 100 - Color: Red

Price: 165000.00 INR/Unit

MOQ1 Unit/Units

ColorRed

Product TypeCeiling Fan Stator Winding Machine

General UseProduction

MaterialOther

Weight (kg)120 Kilograms (kg)

ComputerizedYes

View More

Ceiling Fan Winding Machine - Stainless Steel Build, 4 Piece Master Die Set, 15 Years Warranty, LED Screen Meter, Double Sariya Design

Price Trend : 19000.00 - 21000.00

Green Ceiling Fan And Coil Winding Machine

Price : 44000 INR

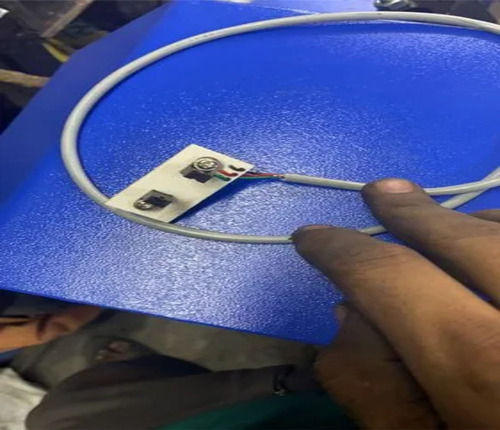

Reel Cover For Ceiling Fan Stator Winding Machine - Color: Chromium

Price : 350.00 INR

Ceiling Fan Stator Winding Machine - Copper & Aluminum, 86.36x33.2x73.6mm, 0.25HP Motor, 60 Fans/8 Hours, Automatic Operation, 5-Year Warranty

Price : 22000 INR

Ceiling Fan Stator Winding Machine - Kij 123 - Color: Red

Price : 31500.00 INR

Low Energy Consumption Ceiling Fan Winding Machine

MaterialSteel, Plastic

Dimensions50x40x30 cm

Power220V

Weight50kg

SpeedVariable

Capacity100 coils/hr

Ceiling Fan Winding Machine - Premium Grade, Adjustable Speed, Blue and White | High Precision, Energy-Efficient, Automatic Operation, Low Noise, Multi-Functional

Price: 10000 INR/Piece

MOQ5 Piece/Pieces

ColorBlue and white

Product TypeCeiling Fan Winding Machine

AutomaticYes

FeatureHigh Precision, Low Energy Consumption, High Speed

Ceiling Fan Startor Winding Machine

MaterialSteel

Dimensions100x50x80 cm

Power220V

Weight50kg

SpeedVariable

Capacity100pcs/hr

View More

Ceiling Fan Winding Machine - Color: Y

Price : 20000 INR

Ceiling Fan Winding Machines - Metal, 22" x 9" x 15" | Adjustable Stack Height, Digital Counter, 1440 RPM, 8-10 Stators/Hour, Power Fail Detection

MaterialMetal

Dimensions22" x 9" x 15"

Power220V AC

Motor1/4 HP

Speed1440 RPM

Poles12, 14, 16

View More

Ceiling Fan Stator Winding Machine

Price : 26000 INR

235 Motorised Ceiling Fan Stator Winding Machine In Rajkot Sanghani Electricals, Power: 350W

Get Best Deal

Table Top Mild Steel Ceiling Fan Stator Winding Machine In Rajkot Sanghani Electricals, Frequency: 50 Hz

Get Best Deal

Low Energy Consumption Ceiling Fan Winding Machine

Price : 25500.00 INR

Table Top Ceiling Fan Winding Machine Power Source: Electric

Price : 25500.00 INR

Ceiling Fan Winding Machine Die Set

Price : 2000 INR

Medium Winding Machine

MaterialSteel

Dimensions36x24x48 inches

Power1 HP

SpeedVariable

Weight200 kg

Voltage220V

FAQs Related to Ceiling Fan Winding Machines

Fan sales are better with aluminium winding because the material is more malleable and thus easier to wind during manufacturing.

Winding machine varieties:

Film winding machine.

Cop winding machine.

Paper winding machine.

Coil winding machine.

Rope winding machine.

Spool winding machine.

Foil winding machine.

Roll winding machine.

Ceiling Fan Stator Winding Machine - Mild Steel, Max Stator Diameter 110mm To 200mm | Adjustable Stack Height, Digital Counter, Automatic, Clockwise & Anticlockwise, Power Fail Detect

MaterialMild Steel

Voltage220 V AC

PhaseSingle Phase

Wire Diameter30SWG To 40SWG

Winding Speed1440 RPM

Stack Height10mm To 30mm

View More

M-230 Ceiling Fan Stator Winding Machine

Price : 200-200000 INR

Ceiling Fan Stator Winding Machine (M-220)

Get Best Deal

Ceiling Fan Stator Winding Machine M-230

Get Best Deal

Heavy Duty Ceiling Fan Winding Machine

Get Best Deal

Fully Automatic Cnc Ceiling Fan Winding Machine

Price : 200-200000 INR

Ceiling Fan Winding Machine

Get Best Deal

Ceiling Fan Winding Machine - Plastic & Steel, 70x50x40 cm, 1 HP, 220V, 5000 RPM | Auto Winding, Durable Design, Variable Speed, Improved Efficiency, Precise Control

Motor Power1 HP

Dimensions70x50x40 cm

Weight50 kg

MaterialSteel, Plastic

Voltage220V

Winding SpeedVariable

230 Watt Stainless Steel Complete Dia Sett Ceiling Fan Winding Machines Air Pressure: 0.7 Mpa

MaterialStainless steel

Dimensions700x1500x750 mm

Weight35 kg

Power230 watts

Winding heads1 piece

Spindles2 pieces

Fan Coil Winding Machine - Color: White And Orange

MaterialSteel

Dimensions100x50x150cm

Power220V

Weight150kg

SpeedVariable

Capacity2 units

Ceiling Fan Winding Machine

Price: 21000 INR/Piece

MOQ2 Piece/Pieces

ColorWhite and blue

Product TypeCeiling Fan Winding Machine

Power SourceElectric

Drive TypeElectric

Voltage220-440 Volt (v)

FeatureHigh Speed

View More

Automatic Two Axis Ceiling Fan Stator Winding Machine - 20x15x20 Inch, 10-40mm Coil Diameter, 280W Power | High Precision, Low Energy Consumption, Sturdy Performance

Price : 15500.00 INR

Semi Automatic Fan Coil Winding Machine - Cast Iron, High Speed, Blue | Durable, Computerized Control System, 2 Piece Winding Head

Price : 13000 INR

Blue Double Head Ceiling Fan Stator Winding Machine

Price : 95000.00 INR

Ceiling Fan Stator Winding Machine Installation Type: Wall Mounted

Motor Power1 HP

Voltage220V

Dimensions100x50x80 cm

Weight150 kg

MaterialSteel, Copper

Winding SpeedVariable

View More

Ceiling Fan Winding Machine

Get Best Deal

Ceiling Fan Vertical Automatic Winding Machine

Get Best Deal

Ceiling Fan

Motor typeAC

Sweep1200 mm

Speeds3

MaterialMetal, Plastic

Weight4.5 kg

Power consumption75W

Fan Winding Machine - Steel, 1000mm x 600mm x 1200mm | 1.5 kW Power, 1000 RPM Winding Speed, 150 kg Weight

MaterialSteel, Plastic

Dimensions48X24X60 Inches

Weight150 Kg

Power3 Kw

Voltage415V

SpeedVariable

Blue Auto Stop Ceiling Fan Winding Machine

Price Trend: 18000.00 - 50000.00 INR/Unit

MOQ1 Unit/Units

Product TypeAuto Stop Ceiling Fan Winding Machine

General UseFor Winding Use

MaterialOther

TypeWire Winding Machine

ComputerizedNo

AutomaticNo

View More

Table Top Ceiling Fan Stator Winding Machine

Get Best Deal

Winding Machine Spares For Industrial

Price : 350 INR

Ns049 Plate Top Ceiling Fan Stator Winding Machine

Price : 22000 INR

Blue Table Top Ceiling Fan Stator Winding Machine

Price Trend : 10000.00 - 20000.00 INR

Plate Top Ceiling Fan Stator Winding Machine

Get Best Deal

High Accuracy Stator Winding Machine - 700x1500x750 mm, 1.5 kW Power, High Precision, High Speed, Low Energy Consumption

Weight (kg)310 Kilograms (kg)

ComputerizedYes

AutomaticYes

Power SourceElectric

Power Consumption1.5 Kilowatt (kW)

Winding Head1 Piece

Low Energy Consumption Ceiling Fan Stator Winding Machine

Capacity250/day

Pipe MaterialPlastic, Steel

Wire Diameter0-1.5mm, >1.5mm

Production Capacity250 Fans/Day

Guarantee7 Years

Machine TypeAutomatic

Ceiling Fan Automatic Winding Machine

ColorGreen

MaterialSteel, Plastic

DimensionsLxwxh

Weight50Kg

Power220V

MotorAc

Manually Operated Electric Twin Spindle Ceiling Fan Stator Winding Machine - Cast Iron, Customized Size | High-Performance, Lightweight, Corrosion-Resistant, Rust-Proof, Easy to Install, Easy to Operate

MaterialSteel

DimensionsCustomized

SpindlesTwin

OperationManual

SurfacePolished

InstallationFloor

View More

Twin Spindle Ceiling Fan Stator Winding Machines

Get Best Deal

As Shown In The Image Manually Operated Electrical Armature Cum Ceiling Fan Winding Machine

Get Best Deal

Armature Cum Ceiling Fan Winding Machines

Get Best Deal

Auto Stop Ceiling Fan Stator Winding Machine - Steel, Customizable Dimensions | Auto Stop, Cost Effective, Durable Design, Efficient Winding, 220V Power, Adjustable Speed, 1 Year Warranty

MaterialSteel

DimensionsCustomizable

Power220V

WeightVariable

SpeedAdjustable

CapacityHigh

Pearl Ceiling Fan Blade Diameter: 1200 Millimeter (Mm)

MaterialAluminum, Copper

Blade Span1200 mm

Motor Power75W

Sweep1200mm

Weight4kg

Speed380 RPM

Fan Winding Machine - High Efficiency Design, Approved Performance Standards

MaterialMetal, plastic

Dimensions10x5x7 cm

Weight1kg

Power220V

DisplayDigital

Accuracy±0.5%

Popular Ceiling Fan Winding Machines

Client Testimonials & Reviews

N.VeeraRao

DELTA AUTOMATION SYSTEMS

Tradeindia is very useful business portal. We are happy to be a part of tradeindia.com, We grow along with your valuable support.

Ceiling Fan Winding Machines Price List

This Data was Last Updated on 2025-12-21

Ceiling Fan Winding Machines Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

K. D. Dowls & Keys Faridabad, India | 18 Years |

Bharat Machine Tools Industries Kolkata, India | 16 Years |

Nishan Electric Ahmedabad, India | 7 Years |

Nij Shyam Electric Ahmedabad, India | 4 Years |

Tahseen Machine Mart New Delhi, India | 1 Years |

Naresh Vidyut Indore, India | 1 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories