Hydraulic Products & Equipment

(9238 products)

Hydraulic equipment encompasses a wide range of products, from hydraulic truck unloaders and power packs to hydraulic cylinders and filters. These products are crucial for industries such as material handling, construction, and manufacturing. Hydraulic equipment utilizes hydraulic power to generate force and motion, enabling the efficient operation of machinery and systems. It offers advantages like high power density, precise control, and the ability to transmit power over long distances. Hydraulic equipment is essential for tasks requiring controlled movement, lifting, and force generation.

...show moreThere are multiple types of Hydraulic Products & Equipment available, including hydraulic pumps, hydraulic cylinders, hydraulic valves, hydraulic hoses, and hydraulic fittings.

Hydraulic Products & Equipment are used in various industries, such as construction, manufacturing, agriculture, and transportation. They are used to power hydraulic systems, which are used to lift, move, and control heavy objects.

When choosing Hydraulic Products & Equipment, it is important to consider the specific application, the required pressure and flow rate, and the environmental conditions. It is also important to consider the compatibility of the products with your existing system.

Hydraulic Products & Equipment require regular maintenance to ensure optimal performance and safety. Maintenance tasks may include checking for leaks, replacing worn parts, and cleaning the system.

There are many resources available online and from manufacturers that provide information about Hydraulic Products & Equipment. You can also consult with a qualified hydraulics professional for assistance.

Top Hydraulic Products & Equipment Categories

Explore More Categories

Product Showcase

Made in India

Hydraulic Scissor Lift Table Warranty: 1 Year

Price Trend: 500000.00 - 1500000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Warranty - 1 Year

16 Years

Business Type: Manufacturer | Supplier

FUTURE INDUSTRIES PVT. LTD.

Made in India

Hydraulic Power Pack

12 Years

Business Type: Manufacturer | Exporter

MULTICUT MACHINE TOOLS

Manifold Block - Color: Silver

Price: 2000 INR (Approx.)/Piece

MOQ - 1000 Piece/Pieces

Weight - 300 Grams (g)

Product Type - Manifold For DCV Series

Size - 1/4"

5 Years

Response Rate: 86.67%

Business Type: Manufacturer | Exporter

UFLOW AUTOMATION

Made in India

Baling Machine Body Material: Steel

Price: 500000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Product Type - Baling Machine

Size - Different Available

Usage - Industrial

13 Years

Business Type: Manufacturer | Supplier

AKASH PACK TECH PVT. LTD.

Rust Proof Four Wheels Color Coated Hydraulic Scissor Lifting Table Trolleys Capacity: 200 Kg/Hr Kg/Hr

Color - Orange and Black

Product Type - Hydraulic Scissor Lifting Table Trolleys

1 Years

Business Type: Manufacturer | Exporter

VEDANT LIFT

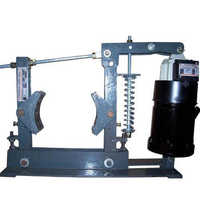

Durable and Rust Proof 34 Kg Electro Hydraulic Thruster

Price: 7000 INR (Approx.)/Piece

MOQ - 5 Piece/Pieces

Usage - EOT Cranes , Hoist , Winches

Weight - 21 Kilograms (kg)

Color - Black

12 Years

Business Type: Manufacturer | Distributor

GUNATIT ELECTROPOWER PRIVATE LIMITED

Heavy Duty Hydraulic Cold Forming Tee Machine

11 Years

Business Type: Manufacturer | Supplier

GUO ZHONG INTERNATIONAL LIMITED

50Hz Electric Torque Wrench Body Material: Stainless Steel

Price: 385000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Color - Gray & Black

Weight - 35-40 Kilograms (kg)

Usage - Industrial

8 Years

Business Type: Manufacturer | Exporter

ASMI ENGINEERING

Laser PIV System

Price Trend: 50000.00 - 500000.00 INR (Approx.)/Pack

MOQ - 1 Pack/Packs

10 Years

Business Type: Manufacturer | Distributor

DIDAC INTERNATIONAL

Verified Exporter

( Accepts only Foreign Inquiry)

Made in India

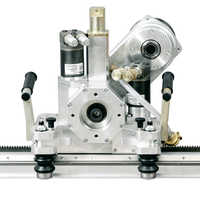

Gamut Hydraulic Lathe Tracer

14 Years

Business Type: Manufacturer | Distributor

GAMUT MACHINE TOOLS

Gray Jmdg16 Radial Piston Hydraulic Motors

Price: 62000 INR (Approx.)/Piece

MOQ - 10 Piece/Pieces

Color - Gray

Product Type - Radial Piston Hydraulic Motors

Usage - Industrial

12 Years

Business Type: Manufacturer | Distributor

JACKTECH HYDRAULICS

Made in India

Hydraulic Honed Tubes

Price Trend: 50000.00 - 100000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

8 Years

Business Type: Manufacturer | Supplier

PRECIHOLE MACHINE TOOLS PVT. LTD.

Made in India

Qc Coupling Body Material: Stainless Steel

Price: 350.00 INR (Approx.)/Piece

MOQ - 10 Piece/Pieces

Color - Silver

Product Type - Coupling

Body Material - Stainless Steel

20 Years

Response Rate: 86.00%

Business Type: Manufacturer | Distributor

BRILLIANT ENGINEERING WORKS

Yellow High Raised Hydraulic Scissor Lift

Price: 350000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Usage - Industrial

Color - Yellow

Product Type - High Raised Hydraulic Scissor Lift

9 Years

Business Type: Manufacturer | Distributor

SIDDH KRUPA STEEL FAB

Hydraulic Machine - Body Material: Steel

Price: 100000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Usage - Industrial Use

Size - Customized

Product Type - Semi Automatic Industrial Hydraulic Machine

13 Years

Business Type: Manufacturer | Exporter

S. S. ENGINEERING WORKS

Made in India

Power Operated Hydraulic Press

6 Years

Business Type: Manufacturer | Distributor

HARDIC Engineering

Made in India

Jumbo Industrial Power Pack

Price Trend: 100000.00 - 150000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

6 Years

Business Type: Manufacturer | Exporter

JINDAL HYDRO PROJECTS INC.

Made in India

Yellow White Hydraulic Forming Press For Roof Lining

Price: 700000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Usage - Industrial

Product Type - Hydraulic Forming Press

Color - Yellow White

22 Years

Business Type: Manufacturer | Supplier

SANTEC EXIM PRIVATE LTD

Made in India

Baling Press Machine Body Material: Steel

Price: 500000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Product Type - Baling Press Machine

Usage - Industrial

Color - Blue-Orange

2 Years

Business Type: Manufacturer | Exporter

PRAGYA PRECISION EQUIPMENT PRIVATE LIMITED

Made in India

Conveyor Type Chapati Rolling Machine For Industrial Capacity 300 Pcshrs, Machine Size(ft.): 4x3x2 ft

6 Years

Business Type: Manufacturer | Trading Company

JACKSON MACHINE

Easy Installation Hydraulic Zero Scissor Lift Table (Load Capacity 1-2 Ton)

Price: 300000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Height - 10 feet Foot (ft)

Usage - Material Handling use

Color - yellow,red,blue black

2 Years

Business Type: Manufacturer

BESTO MATERIAL HANDLING EQUIPMENTS

Made in India

Verified Quality Hydraulic Ironworker

MOQ - 11 unit

5 Years

Business Type: Manufacturer

RUDRAKSH ENGINEERING

Made in India

Ferrule Crimping Machine

14 Years

Business Type: Manufacturer | Distributor

ANISH HYDRAULICS PVT. LTD.

Made in India

Hydraulic Iron Worker

3 Years

Business Type: Manufacturer | Exporter

WELDOR ENGINEERING PVT. LTD.

Made in India

Hydraulic Deep Drawing Press Machine

10 Years

Business Type: Manufacturer | Exporter

VIVEK MACHINE TOOLS

Made in India

Hydraulic Iron Worker

4 Years

Business Type: Manufacturer | Exporter

BERLIN MACHINERIES PRIVATE LIMITED

Floor Mounted Round Shape Heavy-Duty Hydraulic Rotary Platforms For Industrial

Product Type - Rotary Platforms

Size - Customized

Usage - for Industrial

7 Years

Business Type: Manufacturer | Supplier

M.B. Engineering Inds.

Made in India

Heavy Duty Industrial Hydraulic Rock Breaker

Usage - Rock breaker

Product Type - Hydraulic rock hammer

Weight - 950 Kilograms (kg)

10 Years

Business Type: Manufacturer | Exporter

EMTEX MACHINERY PRIVATE LIMITED

Hydraulic Products & Equipment Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Santec Exim Private Ltd | Gurugram, India | 22 Years |

| Brilliant Engineering Works | Mumbai, India | 20 Years |

| Future Industries Pvt. Ltd. | Ahmedabad, India | 16 Years |

| Gamut Machine Tools | Dombivli, India | 14 Years |

| Anish Hydraulics Pvt. Ltd. | Pune, India | 14 Years |

| Akash Pack Tech Pvt. Ltd. | Faridabad, India | 13 Years |

| S. S. Engineering Works | Coimbatore, India | 13 Years |

| Multicut Machine Tools | Vadodara, India | 12 Years |

| Gunatit Electropower Private Limited | Rajkot, India | 12 Years |

| Jacktech Hydraulics | Ahmedabad, India | 12 Years |

Hydraulic Products & Equipment

A wide variety of machining tasks may be accomplished by hydraulic machinery because of the pressurized fluid that it employs. An engine or motor is often used to operate the pump in hydraulic equipment, which then pressurizes the hydraulic fluid. After that, the fluid is routed via hydraulic tubes and delivered to the machine's actuators. These actuators make use of the pressure generated by the fluid in order to accomplish the duty that has been given to them. After going through the filter, the fluid is recirculated to the pump to undergo a second round of pressurization. Mineral oil organophosphate or polyalphaolefin ester is the typical composition of hydraulic fluid; however, a wide variety of other chemicals may also be utilized.

Hydraulic Products & Equipment Functions

Many different kinds of machinery in many different kinds of businesses are driven by hydraulic power. Because of its adaptability as well as the great levels of power that may be accomplished with very uncomplicated techniques, its use is really popular. Hydraulic power is often used by the majority of heavy construction equipment. The hydraulic pumps that pressurize hydraulic fluid are powered by gas engines, which are used in all types of cranes, lifts, bulldozers, and diggers. Following that, the power that was saved is used to move the lifting mechanisms, machine blades, and arms. Hydraulic power is another essential component found in the vast majority of manufacturing facilities. Hydraulic power is often either directly or indirectly accountable for the movement of the majority of automated components. Hydraulics are often used in the operation of clutches, industrial hammers, punches, pullers, and brakes. Presses, lathes, and robotic arms all include hydraulics in their designs.

For hydraulic equipment to function properly, a wide variety of valves, pumps, filters, and actuators are required. Hydraulic cylinders transform fluid pressure into mechanical force, usually by pushing a piston, while check valves prevent liquid from flowing backward or leaking out of the system. Within a hydraulic system, the tubes and seals also have a significant amount of significance. They must be able to sustain tremendous pressures while often maintaining some degree of elasticity. For hydraulic applications, a wide variety of specialized fluid circulation systems and seals are developed.

Importance of Hydraulic Products & Equipment

One of the fundamental components that contribute to the development of many industries is hydraulic. Hydraulics may be of substantial assistance, whether they are added to your heavy-duty vehicles or used to power your machines. The knowledgeable staff at the hydraulic firm utilizes the hydraulic system for a variety of applications in the industrial sector. An experienced hydraulics manufacturer provides a number of options to their customers so that they may fulfill their needs in a variety of ways. Hydraulics is the workhorse of the heavy industry. It employs fundamental principles of physics to carry out all of the tasks necessary to ensure that the lift continues to function appropriately in large-scale building projects. The functionality of mechanical devices that are dependent on hydraulic components is improved. The use of hydraulic systems in the manufacturing business comes with a number of benefits, the most important of which are as follows:

- During design changes and efforts to maximize production capacity, the flexibility, and utility of a hydraulic system are crucial assets to have.

- When compared to pneumatic systems, hydraulic systems are more efficient since they generate less heat and use less energy than pneumatic systems.

- Because it can be modified with a little amount of effort on the part of the mechanism, a hydraulic system makes it possible to integrate brand-new items into already-established production lines in an effortless manner.

- A hydraulic system enables more control over the settings of the machine, which in turn reduces the amount of time that is lost and the number of mistakes that occur throughout the manufacturing process.

How To Find Hydraulic Equipment

Hydraulic equipment can be found in multiple hardware stores both online and offline. You could even hop on to amazon, IndiaMART, TradeIndia, etc., and buy it right now.

Most Common Hydraulic Products & Equipment

Hydraulic systems are made up of a variety of components, some of which include the valves, the fluid, the electric motor, the hydraulic pump, the reservoir, and the hydraulic cylinder. In order to accommodate the wide variety of uses for hydraulic systems, the designs of these components often undergo several iterations.

- Actuator: The hydraulic fluid's potential energy is converted into usable mechanical energy by the actuator. Rotary or linear motion may be produced by an actuator. Actuators are available in a wide variety of designs, the most common of which is the piston type.

- Hydraulic fluids: Within hydraulic systems, the hydraulic fluid functions as the channel for the transmission of energy. There is a very wide variety of hydraulic fluids available for use in a variety of settings. Many different kinds of applications make use of hydraulic fluids that are based on oil because of their qualities that it has. Oil-based fluids have the potential to be engineered to provide the anti-corrosion, anti-wear, and viscosity qualities that are needed, all while presenting only minimum challenges in terms of safety, operation, and maintenance. However, there are several circumstances in which oil-based fluids are not the appropriate choice. For the same reason, oil-based fluids are prohibited from use in fire and rescue operations because they pose a risk of ignition. Therefore, these processes may employ hydraulic fluids that are fire-resistant, such as polyol and phosphate esters, water-glycol, and invert emulsion, in place of oil-based fluids.

- Reservoir: The hydraulic fluid is stored in the reservoir, which is situated in a place that is easily accessible by the pump intake. In addition to this, it removes heat from the system, helps remove excess air and moisture from the fluid, and makes it possible for solid impurities to settle out.

- Valves: Both the flow and the pressure in the system are controlled by the valves. They regulate the flow of fluid both between the reservoir and the pump, as well as between the pump and the actuator, as well as inside the actuator itself.

- Hydraulic Pump: Hydraulic energy is produced when mechanical energy and motion are converted into hydraulic energy by the hydraulic pump. The hydraulic pump transports hydraulic liquid via the hydraulic tool. The energy needed to run the pump may come from a variety of sources, including air pressure, an internal combustion engine, an electric motor, or a power take-off. There are many distinct types of pumps, such as pistons, vane, and gear pumps. But they all function according to the same concept, which involves pushing fluid volume against a load or pressure that is acting as resistance.

Conclusion

The capacity of hydraulic machines to transmit a significant amount of power via pliable hoses and narrow tubes accounts for the widespread use of these devices. Hydraulic systems are superior to mechanical, pneumatic, and electrical systems in terms of their capacity to carry higher weights and produce more force. They maintain a consistent torque and force no matter the speed of the system, which is not achievable with other types of mechanisms.

FAQs: Hydraulic Products & Equipment

Q. What is hydraulic equipment usage?

Ans. Hydraulics are used in lifting and lowering mechanisms found in several types of machinery, including cranes, forklifts, jacks, pumps, and fall arrest safety harnesses. Airplanes. To operate their control panels, they make use of hydraulic machinery.

Q. What are hydraulic products and their types?

Ans. Both closed-loop and open-loop hydraulic systems are considered to be kinds of hydraulic systems. In a system with an open loop, there will be fluid flow but there will be no pressure when the actuating mechanism is not in use. When the pump is in operation inside a system with a closed loop, there will be pressure for the fluids.

Q. Why is hydraulic equipment important?

Ans. Here are some reasons why hydraulic equipment is important:

- Starting, stopping, accelerating, and decelerating may all be accomplished with relative ease because of the presence of a few straightforward levers and pushbuttons.

- Accurate: The controls improve the ease of operation of the equipment, which in turn decreases the likelihood of errors caused by human operators.

- handles a wide variety of weights: Fluid-based hydraulic systems are devoid of levers, pulleys, and gears. This indicates that it can readily tolerate varying amounts of weight.

- Consistent force and torque are provided by the pressurized fluid system, and variations in speed have no influence on these properties.

- Because there are fewer moving components, the hydraulic system is simplified, making it safer and simpler to maintain. In comparison to electrical and mechanical systems, this also contributes to their cost-effectiveness.

- Because it does not ignite, hydraulic systems are suitable for use in hazardous environments such as mines and chemical factories

Q. How is hydraulic equipment used?

Ans. The operation of a great number of components in heavy equipment is governed by hydraulic systems. They make it possible for lifted arms to move higher, buckets to collect soil and other materials, and booms to swing back and forth. They also play an important part in the functioning of the drive system, which is what makes it possible for the engine to operate effectively.

Related Categories

Abrasives

Acoustic Products

Acrylic Sheets

Air Blowers

Air Compressors & Air Separation Plants

Air Cooler

Air Dryers

Air Receiver

Air Valves

Aluminum Castings

Anchors

Anti Vibration Mounts

Ball & Roller Bearings

Ball Valves

Ballast Making Machines

Bearing Parts & Components

Bearings

Bellows & Expansion Joints

Belt Pulleys

Boilers, Components & Spares

Bolts

Bright Bars

Bristles

Burners/Industrial Burners & Incinerators

Bushings & Bushing Parts

Butterfly Valves

CNC Machined Components

Cable Pulleys

Capital Goods

Carbon & Graphite Products

Castor Wheels

Centrifugal Pumps

Centrifuges

Ceramics

Chains & Chain Link Fence Fittings

Cleaning Equipment

Clips, Clamps

Coils

Combustion Equipment

Compression Springs

Compressors & Allied Equipment

Control Valves

Conveyor & Conveyor/Industrial Belts

Cooling Tower & Chilling Plants

Corrosion Protection Materials

Coupling

Cranes

Cryogenic Equipment

Cutting Tools, Broaches & Cutters

Departmental Shelving

Diaphragm Valves

Die Castings

Dies & Moulds

Dies,Jigs,Fixtures

Diesel Engine & Electric Locomotive Spares

Draught Fan

EOT Cranes

Electric Hoists

Electric Motors & Engines

Electroplating Chemicals & Equipment

Elevators, Lifts & Escalators

Energy Management System

Engine Valves

Engineering Goods & Equipment

Engineering Plastics

Engraving Equipment

Extruded Profiles

Fasteners

Fiberglass Products

Filter Cartridges & Media

Filter Cloth, Filter Industrial

Filters-Air, Gas, Liquid

Filtration & Sedimentation Units

Flat Metal Processing Equipment

Float Valves

Fork Lift Truck Parts

Fork Lift Trucks

Forklifts

Foundry Raw Material & Equipment

Furnace Manufacturers

Galvanized Fasteners

Gantry Cranes

Gaskets

Gate Valves

Gauges & Gauge Glasses

Gear Boxes, Reduction Gears & Gear Cutting

Girder Cranes

Glass & Glass Products

Glass Cutting Tools/Glass Cutters

Globe Valves

Goliath Cranes

Grating

Hand & Allied Tools

Hand Pump

Hardware & Tools

Heat Exchangers

Heating Elements

Hex Bolts

Hex Nuts

Hooks & Mounts

Hoses

Hot Air Oven

Humidification & Ventilation Equipment

Hydraulic Hoses & Flexible Metal

Hydraulic Press

Hydraulic Press Brakes

Hydraulic Products & Equipment

Hydraulic Valves

Induction Heating Equipment

Industrial Automation

Industrial Brakes

Industrial Brushes

Industrial Clothing

Industrial Clutches

Industrial Cylinders

Industrial Dryers

Industrial Evaporators

Industrial Knives

Industrial Nets

Industrial Ovens

Industrial Rollers

Industrial Supplies Stocks

Industrial Supplies-General

Industrial Tape

Industrial Tools

Industrial Valves

Industrial Vibrator

Inspection Equipment

Instrumentation

Internal Combustion Engine

Jib Cranes

Laboratory Furniture

Laboratory Glassware & Equipment

Laundry Equipment

Lined Valves

Machine Tools Accessories

Marking Systems

Material Handling Equipment

Measuring Tools & Equipment

Mechanical Seals

Metallised Capacitor Films

Mining Equipment

Mining, Exploration & Drilling Machinery

Model Making Materials

Motor Couplings

Moulded Components

Moulds

Needle Valves

Needles

Nuts

Oil Seals

Outdoor Cooling Systems

Overhead Cranes

PVC Hoses

PVC Products

Paint Brushes

Painting Equipments & Maintenance

Perforated Sheets

Plastic Processing Machinery Parts

Plastic Valves

Plastic Welding Equipment

Plate Valves

Plug Valves

Pneumatic Products & Tools

Pneumatic Valves

Polish & Polishing Material/Machinery

Power Press

Precision Brass Components

Pressed Components

Pressure Gauges

Pressure Vessels

Pulleys

Pulverizers

Pump Spares Parts

Pumps & Pumping Equipment

Radiators

Refrigeration & Equipment

Rope Pulleys

Rope,Twines & Webbings

Ropes

Rotary Valves

Rubber & Rubber Products

Rubber Gaskets

Rubber Roller

Rubber Seals

Rubber Transmission Belts

Screws

Seals

Sensors & Transducers

Shaft Couplings

Shafts & Shaft Collars

Sheet Metal Components & Parts

Solenoid Valves

Springs

Stainless Steel Bolts

Stainless Steel Fasteners

Stainless Steel Nuts

Stainless Steel Valves

Storage Systems

Storage Tanks

Submersible Pumps

Surface Finishing Equipment

Synthetic Industrial Diamonds

Testing & Measuring Equipment

Thermostatic Bimetals & Thermostats

Trolleys & Carts

Tungsten Carbide

Ultrasonic Equipment

V-Belts

Vacuum Equipment & System

Valves

Valves Fittings

Vibrating Screen

Washers

Water Coolers

Weighbridge

Welding & Soldering Supplies

Welding Electrodes

Welding Equipment

Winches

Wire Drawing Dies

Wire Rope Hoists

Wire Ropes