Industrial Rollers

(2584 products)

Explore More Categories

Guide Rollers

17 Years

Business Type: Manufacturer | Exporter

HI-TECH APPLICATOR

Made in India

Polypropylene Roller

9 Years

Business Type: Manufacturer | Distributor

MNT INDUSTRIES

Indian Inquiries Only

Made in India

Steel Kaju Cutting Roller

Product Type - Kaju Cutting Roller

Color - Silver

Material - Stainless Steel

6 Years

Business Type: Manufacturer | Trading Company

JACKSON MACHINE

Made in India

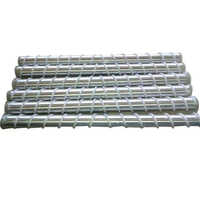

High Quality Industrial Rock Rollers

MOQ - 10 Unit/Units

Usage - Industrial

Size - Different Sizes Available

Material - Stainless Steel

2 Years

Business Type: Manufacturer | Distributor

Klr Industries Limited

Clinker Grinder Rolls

15 Years

Business Type: Manufacturer | Supplier

HRI ENGINEERING COMPANY

Made in India

Plate Mill Roller

10 Years

Business Type: Manufacturer | Exporter

H C & COMPANY

Made in India

Embossing Roller

Price Trend: 7000.00 - 20000.00 INR (Approx.)/Box

MOQ - 1 Box/Boxes

6 Years

Business Type: Manufacturer | Supplier

PRINT PACK STEREO

Made in India

Excellent Finished O Groove Rollers

10 Years

Business Type: Manufacturer | Distributor

IBK ENGINEERS PVT. LTD.

Made in India

Cricket Pitch Diesel Cum Electric Roller (1.5 Ton Capacity) Application: Ups Igbt

Price: 495000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Weight - 1000 Kilograms (kg)

2 Years

Business Type: Manufacturer | Exporter

Ajaib Enterprises LLP

Made in India

De 360 Roller Screed Paver, Usage/Application: Road Construction Work

3 Years

Business Type: Manufacturer | Distributor

SANA DIAMOND ENGI-MECH LLP

Made in India

Silver 0.8Mm Wire Feeder Roller

MOQ - 100 Unit/Units

Product Type - Feeder Roller

Size - Different Size

Usage - Industrial

1 Years

Business Type: Trading Company

ARCWELD ENGINEERS PVT LTD

Made in India

Silver Vertical Guide Roller

MOQ - 200 Unit/Units

Product Type - Vertical Guide Roller

Size - Different Available

Color - Silver

21 Years

Business Type: Manufacturer | Exporter

DELITE SYSTEMS ENGINEERING (I) PVT. LTD.

Made in India

Polyurethane Natural Rubber Roller - Color: Multicolored

Price: 350 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Size - various

Color - MULTICOLORED

Usage - Industrial

2 Years

Business Type: Manufacturer | Supplier

Shorathiya Rubber Industries

Made in India

Light Duty Tyre Cord Centralizer

Price Trend: 125000.00 - 425000.00 INR (Approx.)/Set

MOQ - 1 Set/Sets

15 Years

Response Rate: 82.35%

Business Type: Manufacturer | Distributor

BELMARK INDUSTRIES

Made in India

Idler Roller

5 Years

Business Type: Manufacturer | Exporter

VIKASH INDUSTRIES

Made in India

Dpic Rolls Usage: Industrial

Price: 10000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Usage - Industrial

15 Years

Business Type: Manufacturer | Supplier

INDIA FACTORY

Single Horizontal Roller Buffer

Price: 225 INR (Approx.)/Piece

MOQ - 200 Piece/Pieces

22 Years

Business Type: Manufacturer | Exporter

PVH INDUSTRIES

Made in India

Grey Anilox Roll

MOQ - 1 Unit/Units

Size - Different Size

Product Type - Anilox Roll

Color - Grey

1 Years

Business Type: Manufacturer | Supplier

IMAGEGRAVURES

Made in India

Sisic (Rbsic) Roller - Color: Black

Price: 30 USD ($) (Approx.)/Piece

MOQ - 10 Piece/Pieces

Product Type - Sintered Silicon Carbide Roller

Length - 1000-5000 Millimeter (mm)

Diameter - Dia.27-70 Millimeter (mm)

1 Years

Business Type: Manufacturer | Distributor

Firller Industry Technology Co.,Ltd.

Made in India

Baling Machine

Price: 350000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

10 Years

Business Type: Manufacturer | Exporter

ALINE CONVEYORS PRIVATE LIMITED

Made in India

Ground Roller

Price: 6500 INR (Approx.)/Number

MOQ - 10 Number

1 Years

Business Type: Manufacturer | Supplier

PRECISETECH INDIA PRIVATE LIMITED

Made in India

Red Polyurethane Rollers Diameter: 50-100 Millimeter (Mm)

Price: 600 INR (Approx.)/Piece

MOQ - 10 Piece/Pieces

Color - Red

Product Type - Red Polyurethane Rollers

Length - 300mm, 500mm - 1000mm Millimeter (mm)

9 Years

Business Type: Manufacturer | Supplier

GLORIOUS ENTERPRISES

Made in India

High Quality Rubber Roller

1 Years

Business Type: Manufacturer | Distributor

WESTERN BELTING PRIVATE LIMITED

Made in India

High Quality Red Polyurethane Roller

MOQ - 100 Piece/Pieces

Usage - Industrial

Product Type - Roller

Color - Red

Business Type: Manufacturer | Exporter

SARA INDUS PRODUCTS PRIVATE LIMITED

Made in India

Hdpe Blind Flange Standard: Din Standard

Price: 30 INR (Approx.)/Piece

MOQ - 20 Piece/Pieces

Usage - Automobile, Heavy Engineering, Railways and Pipeline Engineering.

Size - 20-630

Color - Black/Green/simona Grey

9 Years

Business Type: Manufacturer | Exporter

ASVA CORPORATION

Made in India

Primary Charger Roller And Magnet Roller

7 Years

Business Type: Manufacturer | Distributor

JET TECHNOLOGIES

MS Base Shell

MOQ - 1 Piece/Pieces

13 Years

Business Type: Manufacturer | Supplier

J. M. D. INDUSTRIES

Pellet Press Roller Shell

Price Trend: 30000.00 - 6000.00 INR (Approx.)/Pack

MOQ - 50 Pack/Packs

14 Years

Business Type: Manufacturer | Supplier

ORION ENGINEERING WORKS

Industrial Rollers Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Pvh Industries | Sonipat, India | 22 Years |

| Delite Systems Engineering (I) Pvt. Ltd. | Mumbai, India | 21 Years |

| Hi-Tech Applicator | Ahmedabad, India | 17 Years |

| Hri Engineering Company | Gurugram, India | 15 Years |

| Belmark Industries | Ahmedabad, India | 15 Years |

| India Factory | Malerkotla, India | 15 Years |

| Orion Engineering Works | Khanna, India | 14 Years |

| J. M. D. Industries | Bahadurgarh, India | 13 Years |

| H C & Company | Bhosari, India | 10 Years |

| Ibk Engineers Pvt. Ltd. | Bengaluru, India | 10 Years |

Introductions to Industrial Rollers

Industrial rollers are robust machine elements that are manufactured by using advanced production methods that give high dimensional accuracy and uniformity throughout their length. These heavy-duty machine parts are available in different types as per the applications where they are going to be installed. The offered rollers can be used in printing, manufacturing, material handling, winding & rewinding, packaging, and more. They are manufactured by using top-quality materials such as mild steel, stainless steel, and cast iron that give high strength and rigidity to resist loads and vibrations during operation. The protruding cylindrical ends of these machine spares make it easier to install them within plumber blocks to ensure smooth rotation. Industrial Rollers come in many different lengths and diameters as per the machines in which they are going to be installed.

Rollers for a Diverse Range of Industries

Industrial Machine rollers can be used in a wide range of industrial applications. Given below are some of the common industrial sectors where heavy-duty rollers are used:

-Manufacturing: In small to large-scale manufacturing facilities it is required to move various types of products along the assembly lines, this can be achieved with the help of roller conveyors.

-Printing: Highly finished steel rollers are used in industrial printing machines for efficient ink transfer on substrate sheets for quick printing.

-Inventory Management: Machines such as roller conveyors, gravity flow racks, and other material handling machines require steel rollers for the efficient transportation of goods.

-Farming Equipment: Rollers can also be used in agricultural machines for the cleaning, classification, and sorting of various types of raw food products.

-Dyeing: Heavy-duty machines such as textile printers and dyeing machines are equipped with steel rollers for the efficient transfer of colorants on various types of fabrics.

Industrial rollers for the Textile Industry

Industrial Rollers play an important role in various textile machines such as fabric printers, textile processing, and many more. They are designed to ensure smooth operation which ultimately leads to high productivity. There are many different heavy-duty rollers availed by our company which include squeezing rollers, spreader rollers, guide rollers, and many more. The offered textile rollers make it easier to efficiently perform various operations which include weaving, spinning, and finishing. They are made up of premium-grade materials such as aluminum, stainless steel, and high-density thermoplastic that give high strength and rigidity. The curved surfaces of textile rollers are treated with a smooth coating that greatly eliminates the risk of tearing fabric at high speeds. Rollers used in textile machines show excellent resistance against contaminations and can be easily cleaned.

Industrial Rollers for the Metal Foil Industry

Industrial rollers for metal foil manufacturing machines make it easier and more productive to produce metal foils in various sizes and thicknesses. These heavy-duty machine elements are typically manufactured by using stainless steel and alloys that give high rigidity with excellent anti-wearing properties. There is a wide variety of these top-grade textile rollers available in the market which include work rollers, slitters, bridle rollers, winding rollers, and more. These specialized rollers are machined with the help of advanced CNC machines to make them free from sharp edges, uneven surface finish, and other manufacturing flaws. Industrial rollers greatly improve production capacity as well as eliminate the risk of damage to raw materials.

Industrial rollers for the Printing/Packaging Industry

There are many different types of heavy-duty rollers that can be used in the printing and packaging industries for efficient and streamlined production. Some of the most popular types of rollers that can be used in the printing and packaging sectors are:

-Feed Rollers: They are used to grab and feed the substrate materials such as paper, films, foils, and fabric into the machine with controlled speed and positional accuracy.

-Inking Rollers: These specialized machine rollers are designed to transfer inks from the supply source to printing plates to ensure efficient and smudge-proof printing.

-Impression Rollers: The purpose of these types of rollers is to apply pressure on substrates and printing plates for sharp and clean printing.

-Laminating Rollers: In packaging industries, it is required to make a fine layer over products for efficient and quick packaging, this is done with the help of specialized laminating rollers.

-Material Handling Rollers: They are commonly used within heavy-duty conveyor machines to move heavy objects at desired speed without a labor force.

Top Industrial Roller Manufacturers in India.

Given below is the list of some of the renowned Industrial roller manufacturers in India:

Hi-tech Applicator: It is a Gujarat, India-based manufacturer, supplier, and exporter of heavy-duty rollers. The offered rollers can be delivered to our clients in various customized sizes.

Natraj Corrugating Machinery Company: Established in the year 1970, this leading firm deals in manufacturing and supplying best-in-class rollers that are made up of top-grade materials such as alloyed steel, aluminum, rubber, thermoplastics, and various other materials.

Hri Engineering Company We are offering top-grade that can be used in textile, printing, metal foil production, and various other applications.

Gayatri Rubber & Fibre Plast Industry: This Gujarat, India-based manufacturing facility offers a wide range of sturdy and durable rollers that are manufactured by using synthetic materials such as rubbers and high-density thermoplastics.

FAQs: Industrial Roller

Q. What is an industrial roller?

Ans. Industrial Roller is a sturdy machine element that can be used for various purposes such as material moving, raw material processing, textile printing, lamination, and many more. This machine spare is designed and developed by using advanced production methods and top-grade alloyed materials that lead to flawless design and high rigidity. The offered roller is designed to withstand heavy loads, vibrations, high temperatures, and corrosion. It comes in various customized sizes according to the machine in which it is going to be installed. The high load-bearing capacity, rust resistance, and versatility make it highly demanded among our customers and various industrial operations. It can also be used in recycling machines, metal foil production, and paper printing. Roller for industrial machines greatly improves the efficiency and production capacity of machines.

Q. What are the types of industrial rollers?

Ans. There are many different types of light to heavy-duty Industrial Rollers available in the market that can be used in various industrial sectors and machines. The most common types of rollers are:

-Idler Rollers: Made up of high-density rubber and polyurethane these premium-grade machine components are designed to guide and support conveyor belts.

-Conveyor Rollers: They are specially designed for material handling machines to safely move various types of products within industrial facilities. Top-grade engineering materials such as steel and aluminum are used for the fabrication of these rollers to impart high rigidity and strength.

-Drive Rollers: These types of rolling elements are commonly used within the transmission system of various industrial machines to efficiently transfer rotational power with the help of a belt or chain drive mechanism.

-Printing Rollers: Printing rollers are in high demand within industrial-class printing machines to make high-quality prints on various types of materials such as paper, fabric, plastic film, and many more.

Q. How industrial rollers are made?

Ans. Industrial Rollers are sturdy cylindrical-shaped machine components that are commonly used in heavy-duty machines such as conveyors, textile printers, and many more. These highly finished metallic units are fabricated by using advanced machining technologies that give high dimensional accuracy and a smoother surface finish. There are various steps involved in manufacturing various types of industrial rollers:

Selection of Raw Materials: The very first step is to choose materials as per the types of machines for which rollers are required. There are various types of materials such as steel, high-density plastic, rubber, stainless steel, and aluminum are commonly used for the fabrication of rollers.

-Machining: The selected raw material is then machined with the help of advanced CNC machining technologies to achieve desired diameter and length with precision.

-Heat Treatment: To enhance the internal strength of machined rollers they are needed to undergo a heat treatment process to improve internal crystalline structure that leads to high impact strength and rigidity.

-Surface Finishing: After heat treatment, the industrial rollers are then transferred to the surface treatment section to provide a high-class finish as well as provides excellent protection against rust and corrosion.

-Quality Control: At the end, it is required to perform an inspection of the final products to determine if there are any manufacturing flaws.

Related Categories

Abrasives

Acoustic Products

Acrylic Sheets

Air Blowers

Air Compressors & Air Separation Plants

Air Cooler

Air Dryers

Air Receiver

Air Valves

Aluminum Castings

Anchors

Anti Vibration Mounts

Ball & Roller Bearings

Ball Valves

Ballast Making Machines

Bearing Parts & Components

Bearings

Bellows & Expansion Joints

Belt Pulleys

Boilers, Components & Spares

Bolts

Bright Bars

Bristles

Burners/Industrial Burners & Incinerators

Bushings & Bushing Parts

Butterfly Valves

CNC Machined Components

Cable Pulleys

Capital Goods

Carbon & Graphite Products

Castor Wheels

Centrifugal Pumps

Centrifuges

Ceramics

Chains & Chain Link Fence Fittings

Cleaning Equipment

Clips, Clamps

Coils

Combustion Equipment

Compression Springs

Compressors & Allied Equipment

Control Valves

Conveyor & Conveyor/Industrial Belts

Cooling Tower & Chilling Plants

Corrosion Protection Materials

Coupling

Cranes

Cryogenic Equipment

Cutting Tools, Broaches & Cutters

Departmental Shelving

Diaphragm Valves

Die Castings

Dies & Moulds

Dies,Jigs,Fixtures

Diesel Engine & Electric Locomotive Spares

Draught Fan

EOT Cranes

Electric Hoists

Electric Motors & Engines

Electroplating Chemicals & Equipment

Elevators, Lifts & Escalators

Energy Management System

Engine Valves

Engineering Goods & Equipment

Engineering Plastics

Engraving Equipment

Extruded Profiles

Fasteners

Fiberglass Products

Filter Cartridges & Media

Filter Cloth, Filter Industrial

Filters-Air, Gas, Liquid

Filtration & Sedimentation Units

Flat Metal Processing Equipment

Float Valves

Fork Lift Truck Parts

Fork Lift Trucks

Forklifts

Foundry Raw Material & Equipment

Furnace Manufacturers

Galvanized Fasteners

Gantry Cranes

Gaskets

Gate Valves

Gauges & Gauge Glasses

Gear Boxes, Reduction Gears & Gear Cutting

Girder Cranes

Glass & Glass Products

Glass Cutting Tools/Glass Cutters

Globe Valves

Goliath Cranes

Grating

Hand & Allied Tools

Hand Pump

Hardware & Tools

Heat Exchangers

Heating Elements

Hex Bolts

Hex Nuts

Hooks & Mounts

Hoses

Hot Air Oven

Humidification & Ventilation Equipment

Hydraulic Hoses & Flexible Metal

Hydraulic Press

Hydraulic Press Brakes

Hydraulic Products & Equipment

Hydraulic Valves

Induction Heating Equipment

Industrial Automation

Industrial Brakes

Industrial Brushes

Industrial Clothing

Industrial Clutches

Industrial Cylinders

Industrial Dryers

Industrial Evaporators

Industrial Knives

Industrial Nets

Industrial Ovens

Industrial Rollers

Industrial Supplies Stocks

Industrial Supplies-General

Industrial Tape

Industrial Tools

Industrial Valves

Industrial Vibrator

Inspection Equipment

Instrumentation

Internal Combustion Engine

Jib Cranes

Laboratory Furniture

Laboratory Glassware & Equipment

Laundry Equipment

Lined Valves

Machine Tools Accessories

Marking Systems

Material Handling Equipment

Measuring Tools & Equipment

Mechanical Seals

Metallised Capacitor Films

Mining Equipment

Mining, Exploration & Drilling Machinery

Model Making Materials

Motor Couplings

Moulded Components

Moulds

Needle Valves

Needles

Nuts

Oil Seals

Outdoor Cooling Systems

Overhead Cranes

PVC Hoses

PVC Products

Paint Brushes

Painting Equipments & Maintenance

Perforated Sheets

Plastic Processing Machinery Parts

Plastic Valves

Plastic Welding Equipment

Plate Valves

Plug Valves

Pneumatic Products & Tools

Pneumatic Valves

Polish & Polishing Material/Machinery

Power Press

Precision Brass Components

Pressed Components

Pressure Gauges

Pressure Vessels

Pulleys

Pulverizers

Pump Spares Parts

Pumps & Pumping Equipment

Radiators

Refrigeration & Equipment

Rope Pulleys

Rope,Twines & Webbings

Ropes

Rotary Valves

Rubber & Rubber Products

Rubber Gaskets

Rubber Roller

Rubber Seals

Rubber Transmission Belts

Screws

Seals

Sensors & Transducers

Shaft Couplings

Shafts & Shaft Collars

Sheet Metal Components & Parts

Solenoid Valves

Springs

Stainless Steel Bolts

Stainless Steel Fasteners

Stainless Steel Nuts

Stainless Steel Valves

Storage Systems

Storage Tanks

Submersible Pumps

Surface Finishing Equipment

Synthetic Industrial Diamonds

Testing & Measuring Equipment

Thermostatic Bimetals & Thermostats

Trolleys & Carts

Tungsten Carbide

Ultrasonic Equipment

V-Belts

Vacuum Equipment & System

Valves

Valves Fittings

Vibrating Screen

Washers

Water Coolers

Weighbridge

Welding & Soldering Supplies

Welding Electrodes

Welding Equipment

Winches

Wire Drawing Dies

Wire Rope Hoists

Wire Ropes