Gauges & Gauge Glasses

(3709 products)

Explore More Categories

Product Showcase

Gauge Board Grade: Industrial

Price: 20000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Usage - Industrial

Display - Analog

Size - Standard

14 Years

Business Type: Manufacturer | Supplier

JSN ENTERPRISE

Ultrasonic thickness gaugue UT-2A A-SCAN

Price: 265879 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Product Type - Thickness guague

Color - Yellow

5 Years

Business Type: Manufacturer | Supplier

AERICA ENGINEERING PRIVATE LIMITED

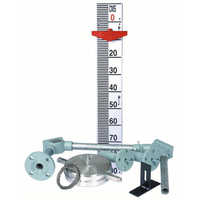

Silver Reflex Level Gauge Indicator

Price Trend: 6000.00 - 36000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Product Type - Reflex Level Gauge Indicator

Usage - Industrial

Color - Silver

11 Years

Business Type: Manufacturer | Exporter

KABIR INSTRUMENTS AND TECHNOLOGY

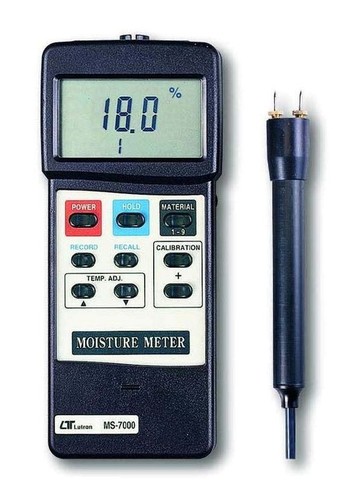

Water Level Gauge

Price Trend: 10800.00 - 33300.00 INR (Approx.)/Piece

MOQ - 10 Piece/Pieces

Usage - In Boiler Plats, Any type of chemical plants to check level of Chemicals , water and any type of liquids

Weight - 20-25 Kilograms (kg)

Size - Customizable

8 Years

Business Type: Manufacturer | Exporter

FLOWTECH MEASURING INSTRUMENTS PVT. LTD.

Regular Oil Level Gauge

Price: 230 INR (Approx.)/Piece

MOQ - 10 Piece/Pieces

Color - Regular

Product Type - Oil Level Gauge

Usage - Oil Tank

12 Years

Business Type: Manufacturer | Distributor

JACKTECH HYDRAULICS

FABRIC THICKNESS GAUGE ..

Price: 1 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

18 Years

Business Type: Manufacturer | Exporter

ASIAN TEST EQUIPMENTS

Baumer Temperature Transmitter Accuracy: 0.25 %

Price: 2250 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Color - Black

Size - 8-12 MM

Material - Metal

14 Years

Business Type: Manufacturer | Distributor

FUTURISTIC TECHNOLOGIES

Indian Inquiries Only

Sj210 Mitutoyo Surface Roughness Tester Grade: Industrial Grade

Price: 115500 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Usage - For Industrial And Laboratory Use

Width - 10-50 Millimeter (mm)

Color - White And Brown

17 Years

Business Type: Manufacturer | Supplier

SAMRUDDHI INDUSTRIES

Indian Inquiries Only

Magnetic Level Gauge With Transmitter Application: Chemical Processing

Price: 20000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Usage - Industrial

Color - Gray

Product Type - Magnetic Level Gauge With Transmitter

11 Years

Response Rate: 79.63%

Business Type: Manufacturer | Exporter

D. B. INSTRUMENTS & CONTROLS

Hypodermic Pressure Guage Accuracy: 160 Psi

Price: nan INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Usage - Industrial

Size - Standard

Color - Silver & White

16 Years

Business Type: Manufacturer | Distributor

BLASTECH

Indian Inquiries Only

Indian Inquiries Only

Steel Pressure Cum Temperature Gauges

Price Trend: 500.00 - 5000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Weight - 400-500 Grams (g)

Color - Silver

Material - Steel

15 Years

Business Type: Manufacturer | Exporter

DYNAMIC ENTERPRISES INC.

Transparent Gauge Glass

Price: 1900 INR (Approx.)/Piece

MOQ - 20 Piece/Pieces

14 Years

Business Type: Manufacturer | Supplier

SHREE UMIYA GLASS WORKS

High Quality Reflex Level Gauge

Price: 13000 INR (Approx.)/Unit

MOQ - 10 Unit/Units

Color - Blue

Usage - Chemical Plant,l Aboratory

Product Type - Reflex Level Gauge

15 Years

Business Type: Manufacturer | Supplier

FIDICON DEVICES INDIA

Magnehelic Differential Pressure Gauge

Price: 6000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Product Type - Analouge

Glass Size - 4"

Width - NA

2 Years

Business Type: Manufacturer | Supplier

Nextech Sensors & Controls

Black Reflex Level Gauge

Price: 25000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Usage - Industrial

Product Type - Reflex Level Gauge

Color - Black

13 Years

Business Type: Manufacturer | Supplier

METALEX CRYOGENICS LTD.

Verified Exporter

( Accepts only Foreign Inquiry)

Blue Manifold Pressure Gauge

Price: 2750 INR (Approx.)/Unit

MOQ - 10 Unit/Units

Color - Blue

Product Type - Manifold Pressure Gauge

Size - Different Available

2 Years

Business Type: Distributor | Trading Company

The Refrigeration House

Multicolor Length Gauge For Aggregate

Price: 390 INR (Approx.)/Piece

MOQ - 100 Piece/Pieces

Product Type - Length Gauge

Color - Multicolor

Size - All sizes are available

6 Years

Business Type: Trading Company

YESHA LAB EQUIPMENTS

Indian Inquiries Only

Gray Digital Tyre Pressure Gauge With 7 Emergency Tools

Price: 507.00 INR (Approx.)/Piece

MOQ - 100 Piece/Pieces

Color - Black

Size - 16.1 x 5 x 3.1 cm

Weight - 124.3 Grams (g)

7 Years

Business Type: Manufacturer | Supplier

JAINEX CORPORATE GIFTS

Gauges & Gauge Glasses Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Asian Test Equipments | Hapur, India | 18 Years |

| Samruddhi Industries | Ahmedabad, India | 17 Years |

| Blastech | Mumbai, India | 16 Years |

| Modern Traders | Mumbai, India | 15 Years |

| Dynamic Enterprises Inc. | Pune, India | 15 Years |

| Electronic & Engineering Co. (I) P. Ltd. | Mumbai, India | 15 Years |

| Fidicon Devices India | Ankleshwar, India | 15 Years |

| Spectec Techno Projects Pvt. Ltd. | New Delhi, India | 15 Years |

| Jsn Enterprise | Vadodara, India | 14 Years |

| Futuristic Technologies | Ahmedabad, India | 14 Years |

Gauges & Gauge Glasses: Types & Applications

Introduction

A gauge glass is a transparent tube used to monitor liquid levels in a tank or boiler. A sight glass, also known as a gauge glass, is used to determine the depth of a liquid. When installed in a tank or vessel, it provides a constant readout of the liquid's level.

One way to check the water level in a tank is with a sight glass instrument, which consists of a graduated tube made of toughened glass that is attached to the tank's interior at its base. The sight glass in the picture below is a straightforward method of gauging the contents of an open tank, as the liquid level in the sight glass precisely parallels the tank's actual contents.

Changes in the liquid level in the tank are reflected in the sight glass in a similar fashion. The sight glass can be used to determine how much liquid is in the storage tank.

Different types of gauges & gauge glasses

1. Multifunctional Glass

These tools incorporate not just the aforementioned capabilities, but also others, such as the ability to remove the sight glass for cleaning and examination.

2. 3D

This sight glass is similar to a bullseye, except instead of being flat, it protrudes from a tank. It also lets light travel through the oil, making it simpler to spot pollutants, and increases the number of perspectives from which you can examine the oil.

Most of these can withstand high pressure and high temperatures since they are constructed of glass, acrylic, or polyamide.

3. BS&W Bowls

Bowls designed to collect sediment and water from the tank's base are called bottom sediment and water (BS&W) bowls. There is a release valve on several of them so that oil samples can be taken for testing.

These are significantly more compact than their columnar counterparts and can be installed towards the bottom of tanks, where they are more vulnerable to damage.

4. Columnar

These transparent, vertical tubes are installed on the exterior of storage tanks and provide a more comprehensive view of the oil inside than traditional bullseye sight glasses.

However, they are more challenging to install, and since they are usually placed near the tanks' bases, they are more likely to sustain damage.

Also, they have trouble detecting foaming because they draw from the tank's base. When compared to bullseye, the use of columnar Gauges & Gauge Glasses allows for the accurate marking of oil levels in both the running and idled states of a machine.

Target glasses can only differentiate between the two.

5. Bullseye

When installing a bullseye Gauges & Gauge Glasses, a hole is drilled into the tank at the ideal oil level. When installed, the sight glass resembles a bolt with a glass head and is threaded into the opening.

Several models feature a line in the sight glass at the proper oil level for operating machinery.

A bullseye Gauge Glasses can aid in the detection of foaming in the system. In the presence of water and other impurities, this frequently occurs, allowing you to spot issues before they become catastrophic.

6. Circular Sight Glass Fittings

Sight glasses, also known as sight windows or view ports, allow for inspection of the contents of a tank or vessel from the outside.

They are made up of two flanges that are bolted together and seal a glass disc with gaskets. Commonly used to check liquid levels and visually validate process steps.

Pressure vessels, tanks, silos, stirred vessels, separators, pipelines, etc., can all benefit from inspections using this method.

7. Sight Indicators

This is a device that is placed in a pipeline to check the flow of a liquid, powder, or gas. A body with a window or windows is what makes up this thing. This method is the most accurate for validating flow's direction, approximate rate, color, and clarity.

For clean rooms, hospitals, and other sterile environments, Sight Glass producers provide both regular and full-view flow indicators.

8. Metaglass Sight Glass Windows

The "METAGLAS®" brand of metal fused sight glasses has a sight glass fused into a steel ring. This is because glass and metal have differing expansion coefficients, leading to compressive stress within the glass. The steel ring's mechanized treatment allows for a wide range of potential building solutions.

9. Rectangular Sight Glass Fittings

Gauge Glasses, which are also known as sight windows or view ports, allow one to see inside a tank or vessel by way of two flanges that are bolted together and seal a glass disc with gaskets.

Most commonly employed for visual inspection of process material and liquid levels as well as verification of process phases. Tanks, stirred vessels, pressure vessels, separators, pipelines, silos, and so on are common places where this technology is put to use.

Applications of gauges & gauge glasses

1. Tanks and Reservoirs

Gauges & Gauge Glass, also known as sight glass, is an indispensable component of tanks and reservoirs because it allows for quick and easy monitoring of liquid levels. The Red Line variation, designed to be installed between the upper and lower Gauges & Gauge Glass valves, contains a red line that is tinted with white lines to facilitate readings.

2. High and Low pressure boiling

Gauge Glasses are perfect for liquid measurement in boilers due to their exceptional thermal endurance, great clarity, and consistent operation even at high temperatures.

3. Flow meters

Gauge Glasses provide precision, safety, and reliability for sectors that need to measure the volume of gas or liquid passing through a device. Industrial flow meters require gauge glasses because of their excellent resilience to chemical and thermal shock.

Things To Consider Before Purchasing Gauges & Gauge Glasses

1. Impact

Materials entrained in process fluids may strike the sight glass window in some operations, such as food processing. If you notice any scratches on your glasses, it's time to get a new pair.

2. Pressure

All high-pressure applications should employ fused-type sight glasses or cast-type plastic windows to prevent sight glass failure, as was previously mentioned.

3. Abrasion

Pick a material for the sight glass that won't wear down or become clouded by particles in the fluid being viewed. Sight glasses can be tested for scratches either visually or with the help of ultrasonic technology.

4. Corrosion

Sight glass windows can grow "cloudy" over time when exposed to certain caustic or acidic chemicals, reducing their transparency. Select a plastic or glass sight glass window that is less likely to corrode in these sorts of applications.

5. Thermal Shock

When deciding on a material for a sight glass, engineers must keep in mind how the material will react to extreme temperature swings. Since it has a lower coefficient of expansion than regular glass, borosilicate glass can better withstand temperature swings and is hence the material of choice for glass windows. Sight glass windows made of plastic can withstand variations in temperature because of their flexibility.

6. Maximum Operating Temperature

Regular soda lime sight glass windows and plastic view ports can only be used in environments with temperatures no higher than 300 degrees Fahrenheit. Glasses made of borosilicate or quartz/sapphire must be used above those temperatures.

7. Construction materials

The two most popular metals are carbon steel and stainless steel. For this reason, stainless steel is the industry standard in the pharmaceutical industry due to its superior corrosion resistance.

8. Process fluid

Before filling a reservoir or tank with fluid, find out what kinds of things it can corrode. If you need a sight glass, one with "excellent" chemical resistance is what you should be on the lookout for.

9. Past Issues

Check to see if there have been any past issues that you need to keep an eye on. Have you ever experienced lubricant contamination due to wear debris? If so, select a sight glass outfitted with a magnetic plug to aid in capturing the debris before proceeding with testing.

Conclusion

Depending on the gasket and clamp union you choose, the maximum temperature and pressure are also different. Sight glasses are vital tools in the process industries, where they are used to inspect tanks and pipelines for fluid and media levels

Sight glasses are a type of specialized instrument that have many applications in the processing industries. This post has provided an overview of sight glasses and how they are used in the pharmaceutical, food and beverage, semiconductor, utility, energy, oil and gas, and wastewater management industries.

FAQs: Gauges & Gauge Glasses

Q. Which type of gauge & gauge glass is commonly used in the laboratory?

Ans. Tubular Gauge Glasses are mostly used in Laboratories for liquid level uses in industrial steam boilers.

Q. How do Gauges & Gauge Glasses work?

Ans. Gauge glasses, once fitted, function as windows to allow operators to monitor internal activities in a variety of containers, such as tanks, vessels, reactors, and pipes. Gauge glasses are made from either soda lime glass or borosilicate glass because of their durability.

Q. What happens if the Gauge & gauge glass break?

Ans. That way, even if the gauge & gauge glass breaks, the stop ball will keep the water from escaping.

Q. What is the cost of Gauges & Gauges glass?

Ans. The cost of Gauge Glasses is between Rs 900- Rs 2,500 in India.

Related Categories

Abrasives

Acoustic Products

Acrylic Sheets

Air Blowers

Air Compressors & Air Separation Plants

Air Cooler

Air Dryers

Air Receiver

Air Valves

Aluminum Castings

Anchors

Anti Vibration Mounts

Ball & Roller Bearings

Ball Valves

Ballast Making Machines

Bearing Parts & Components

Bearings

Bellows & Expansion Joints

Belt Pulleys

Boilers, Components & Spares

Bolts

Bright Bars

Bristles

Burners/Industrial Burners & Incinerators

Bushings & Bushing Parts

Butterfly Valves

CNC Machined Components

Cable Pulleys

Capital Goods

Carbon & Graphite Products

Castor Wheels

Centrifugal Pumps

Centrifuges

Ceramics

Chains & Chain Link Fence Fittings

Cleaning Equipment

Clips, Clamps

Coils

Combustion Equipment

Compression Springs

Compressors & Allied Equipment

Control Valves

Conveyor & Conveyor/Industrial Belts

Cooling Tower & Chilling Plants

Corrosion Protection Materials

Coupling

Cranes

Cryogenic Equipment

Cutting Tools, Broaches & Cutters

Departmental Shelving

Diaphragm Valves

Die Castings

Dies & Moulds

Dies,Jigs,Fixtures

Diesel Engine & Electric Locomotive Spares

Draught Fan

EOT Cranes

Electric Hoists

Electric Motors & Engines

Electroplating Chemicals & Equipment

Elevators, Lifts & Escalators

Energy Management System

Engine Valves

Engineering Goods & Equipment

Engineering Plastics

Engraving Equipment

Extruded Profiles

Fasteners

Fiberglass Products

Filter Cartridges & Media

Filter Cloth, Filter Industrial

Filters-Air, Gas, Liquid

Filtration & Sedimentation Units

Flat Metal Processing Equipment

Float Valves

Fork Lift Truck Parts

Fork Lift Trucks

Forklifts

Foundry Raw Material & Equipment

Furnace Manufacturers

Galvanized Fasteners

Gantry Cranes

Gaskets

Gate Valves

Gauges & Gauge Glasses

Gear Boxes, Reduction Gears & Gear Cutting

Girder Cranes

Glass & Glass Products

Glass Cutting Tools/Glass Cutters

Globe Valves

Goliath Cranes

Grating

Hand & Allied Tools

Hand Pump

Hardware & Tools

Heat Exchangers

Heating Elements

Hex Bolts

Hex Nuts

Hooks & Mounts

Hoses

Hot Air Oven

Humidification & Ventilation Equipment

Hydraulic Hoses & Flexible Metal

Hydraulic Press

Hydraulic Press Brakes

Hydraulic Products & Equipment

Hydraulic Valves

Induction Heating Equipment

Industrial Automation

Industrial Brakes

Industrial Brushes

Industrial Clothing

Industrial Clutches

Industrial Cylinders

Industrial Dryers

Industrial Evaporators

Industrial Knives

Industrial Nets

Industrial Ovens

Industrial Rollers

Industrial Supplies Stocks

Industrial Supplies-General

Industrial Tape

Industrial Tools

Industrial Valves

Industrial Vibrator

Inspection Equipment

Instrumentation

Internal Combustion Engine

Jib Cranes

Laboratory Furniture

Laboratory Glassware & Equipment

Laundry Equipment

Lined Valves

Machine Tools Accessories

Marking Systems

Material Handling Equipment

Measuring Tools & Equipment

Mechanical Seals

Metallised Capacitor Films

Mining Equipment

Mining, Exploration & Drilling Machinery

Model Making Materials

Motor Couplings

Moulded Components

Moulds

Needle Valves

Needles

Nuts

Oil Seals

Outdoor Cooling Systems

Overhead Cranes

PVC Hoses

PVC Products

Paint Brushes

Painting Equipments & Maintenance

Perforated Sheets

Plastic Processing Machinery Parts

Plastic Valves

Plastic Welding Equipment

Plate Valves

Plug Valves

Pneumatic Products & Tools

Pneumatic Valves

Polish & Polishing Material/Machinery

Power Press

Precision Brass Components

Pressed Components

Pressure Gauges

Pressure Vessels

Pulleys

Pulverizers

Pump Spares Parts

Pumps & Pumping Equipment

Radiators

Refrigeration & Equipment

Rope Pulleys

Rope,Twines & Webbings

Ropes

Rotary Valves

Rubber & Rubber Products

Rubber Gaskets

Rubber Roller

Rubber Seals

Rubber Transmission Belts

Screws

Seals

Sensors & Transducers

Shaft Couplings

Shafts & Shaft Collars

Sheet Metal Components & Parts

Solenoid Valves

Springs

Stainless Steel Bolts

Stainless Steel Fasteners

Stainless Steel Nuts

Stainless Steel Valves

Storage Systems

Storage Tanks

Submersible Pumps

Surface Finishing Equipment

Synthetic Industrial Diamonds

Testing & Measuring Equipment

Thermostatic Bimetals & Thermostats

Trolleys & Carts

Tungsten Carbide

Ultrasonic Equipment

V-Belts

Vacuum Equipment & System

Valves

Valves Fittings

Vibrating Screen

Washers

Water Coolers

Weighbridge

Welding & Soldering Supplies

Welding Electrodes

Welding Equipment

Winches

Wire Drawing Dies

Wire Rope Hoists

Wire Ropes