Furnace Manufacturers

(2832 products)

Furnace Manufacturers specialize in crafting industrial furnaces for various applications. Their furnaces are known for their robust construction, ensuring durability and longevity. These furnaces are widely used in industries such as pharmaceuticals for precise temperature control processes. They offer a range of options, including Muffle Furnaces, Smoke House Furnaces, Electric Furnaces, Furnace Chimneys, and Furnance Di-dt, each designed to meet specific industrial needs.

...show moreThis context does not mention muffle furnace manufacturers.

The temperature range of Muffle Furnaces is 1200-1500 Celsius (oC).

The voltage of Muffle Furnaces is 110-240 Volt (v).

The material of Muffle Furnaces is aluminium.

The warranty of Smoke House Furnaces is 1 year.

Explore More Categories

Made in India

Electric Benchtop Muffle Furnace Usage: Industrial

Price: 65000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Usage - Industrial

Condition - New

3 Years

Business Type: Manufacturer | Distributor

CHROMATOGRAPHY WORLD

Made in India

Aluminium Melting Skelner Furnace

Price Trend: 1000000.00 - 7500000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

7 Years

Business Type: Manufacturer | Distributor

KAMINOX INDUSTRIES

Made in India

Rotary Klin Furnaces And Incinerator

Price: 35000000 INR (Approx.)/Set

MOQ - 01 Set/Sets

13 Years

Business Type: Manufacturer | Distributor

BIOLINE TECHNOLOGIES

Temperature Furnace

8 Years

Business Type: Manufacturer | Distributor

HAIDA INTERNATIONAL EQUIPMENT CO., LTD.

Reheating Furnace

Price Trend: 100000.00 - 150000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Type - Other, Reheating Furnace

Material - Cast Iron

Computerized - Yes

21 Years

Business Type: Manufacturer | Supplier

UGI ENGINEERING WORKS PVT. LIMITED

Made in India

2Kg Gold Bond Metro Gold Melting Induction Furnace

Price Trend: 500000.00 - 1000000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

16 Years

Business Type: Manufacturer | Supplier

ASHLYN CHEMUNNOOR INSTRUMENTS PVT. LTD.

Made in India

Muffle Furnace

20 Years

Response Rate: 70.73%

Business Type: Manufacturer | Exporter

CLASSIC SCIENTIFIC

Made in India

Muffle Furnace Application: Industrial

MOQ - 1 Unit/Units

Size - 23 x 10 x 10mm

Product Type - Muffle Furnace

Usage - Laboratory

15 Years

Business Type: Manufacturer | Distributor

META-LAB SCIENTIFIC INDUSTRIES

Muffle Furnace

Price: 35000 INR (Approx.)/Number

MOQ - 1 Number

12 Years

Business Type: Manufacturer | Exporter

HMG (INDIA)

Made in India

Muffle Furnace

14 Years

Business Type: Manufacturer | Exporter

EIE INSTRUMENTS PRIVATE LIMITED

Induction Based Copper Melting Furnace (1.5 Kg. In Three Phase)

1 Years

Business Type: Manufacturer | Supplier

Shapet Induction Company

Made in India

Furnace Selector Switches

Price Trend: 1000.00 - 10000.00 USD ($) (Approx.)/Piece

MOQ - 10 Piece/Pieces

11 Years

Business Type: Manufacturer | Exporter

THERMA FIELD POWER COMPONENTS PRIVATE LIMITED

Made in India

Compact Tube Furnace Application: Industrial

Price: 481000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Size - Different Available

Color - Grey

Condition - New

2 Years

Business Type: Supplier | Trading Company

BISHOPS SCIENTIFIC PRIVATE LIMITED

Made in India

Single Phase Muffle Furnace Application: 4 Inch X 4 Inch X 9 Inch*

Price: 45000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Weight - 25 Kilograms (kg)

Color - As per your requirement

Product Type - Testing Product

3 Years

Response Rate: 82.14%

Business Type: Manufacturer

TECHPLAST TESTING MACHINES

Muffle Furnace

Price: 16500 INR (Approx.)/Unit

MOQ - 1 Unit/Units

6 Years

Business Type: Trading Company

YESHA LAB EQUIPMENTS

Indian Inquiries Only

Laboratory Muffle Furnace - Application: Heating

Price: 1000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Condition - New

Usage - Heat Treatment furnace

Power - 220 Volt (v)

16 Years

Business Type: Manufacturer | Distributor

STANDARD STEEL

Made in India

Industrial Muffle Furnace Dimensions: 125 X 125 X 250 Mm Millimeter (Mm)

Price: 52000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Feature - Temperature Control, Temperature Control, Digital Display,Digital Display

Usage - Muffle Furnace

Power - 220 V AC Single Phase 50 Hz Volt (v)

15 Years

Business Type: Manufacturer | Supplier

TEXCARE INSTRUMENTS

Made in India

Muffle Furnace Dimensions: 150 X 150 X 300 Millimeter (Mm)

Price: 80000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Usage - Industrial

Weight - 100 Kilograms (kg)

Condition - New

13 Years

Business Type: Manufacturer | Exporter

SOUTHERN SCIENTIFIC LAB INSTRUMENTS PRIVATE LIMITED

220V Voltage 620*500*1050Mm Dimension Tilting Gold Smelting Furnace Dimensions: 620*500*1050 Millimeter (Mm)

Length - 620 Millimeter (mm)

Width - 500 Millimeter (mm)

Weight - 78 Kilograms (kg)

13 Years

Business Type: Manufacturer | Distributor

AROTEK SCIENTIFIC INSTRUMENTS PVT. LTD.

Made in India

Reheating Furnace

5 Years

Business Type: Manufacturer | Supplier

ROLLTECH ENGINEERING PVT. LTD.

Indian Inquiries Only

Blue Direct Biomass Fired Hot Air Furnace

Price Trend: 50000 - 1000000 USD ($) (Approx.)/Set

MOQ - 1 Set/Sets

Product Type - Direct Biomass Fired Hot Air Furnace

Condition - New

Type - Direct Biomass Fired Hot Air Furnace

11 Years

Business Type: Manufacturer | Distributor

Zhejiang Meibao Industrial Technology Co., Ltd.

Metal Vacuum Dewaxing Furnace

12 Years

Business Type: Manufacturer | Exporter

BRITISH SUPER ALLOYS PVT. LTD.

Indian Inquiries Only

Made in India

Scan Master Heating Furnace

Price: 1700000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

1 Years

Business Type: Manufacturer | Distributor

PLASMA INDUCTION (INDIA) PRIVATE LIMITED

Made in India

18 Kilowatt 440 Voltage Easy To Install Aluminium Melting Cum Holding Furnace Application: Industrial

Price: 150000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Color - Silver

Feature - Easy To Install

Weight - 1500 Kilograms (kg)

3 Years

Business Type: Manufacturer | Supplier

CERATHERM TECHNOLOGIES INDIA PVT.LTD.

Made in India

Muffle Furnace

15 Years

Business Type: Manufacturer | Exporter

STEELFAB INDUSTRIES

Made in India

Oil Heater

12 Years

Business Type: Manufacturer | Distributor

JALDHARA INDUSTRIES

Made in India

Billet Annealing Furnace Application: For Cutting And Warping

Price: 550000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Color - Silver

Feature - Longer Life

Condition - New

11 Years

Business Type: Manufacturer | Distributor

PANCHASARA MACHINE TOOLS

Silver Heat Treatment Furnace

MOQ - 1 Unit/Units

Usage - Industrial

Product Type - Heat Treatment Furnace

Size - Different Size

3 Years

Business Type: Trading Company

ESS ESS CERATECH

Indian Inquiries Only

Furnace Manufacturers Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Ugi Engineering Works Pvt. Limited | Kolkata, India | 21 Years |

| Classic Scientific | Boisar, India | 20 Years |

| Ashlyn Chemunnoor Instruments Pvt. Ltd. | Thrissur, India | 16 Years |

| Standard Steel | Ambala Cantt, India | 16 Years |

| Meta-Lab Scientific Industries | Mumbai, India | 15 Years |

| Texcare Instruments | Greater Noida, India | 15 Years |

| Steelfab Industries | Vasai, India | 15 Years |

| Eie Instruments Private Limited | Ahmedabad, India | 14 Years |

| Bioline Technologies | Thane, India | 13 Years |

| Southern Scientific Lab Instruments Private Limited | Chennai, India | 13 Years |

What is a furnace?

A furnace is a direct-fired heating appliance used in industries that demand temperatures above 400 degrees Celsius (752 degrees Fahrenheit). An industrial furnace is used in any process that requires high temperatures, such as the generation of a chemical reaction or the heating of raw materials. The most dependable among the many machines and tools used in manufacturing and processing are furnaces. Direct or indirect contact heating is used to bring the temperature of raw materials and finished goods up to the desired level prior to use.

Air and flue blowers, heat exchangers, burners, fuel control, a pilot or ignition mechanism, control circuits, and a thermostat are all components of a furnace's build. Even though these are standard features, there are many other furnace designs to choose from depending on the task at hand.

Types of furnace

1. Rotary Tube Furnaces

Due to their versatility and ability to apply heat in different thermal control zones, rotary tube furnaces are frequently employed for continuous material processing.

These furnaces have a wide range of applications, from clinker and alumina production to oxidation.

2. Tensile Testing Furnaces

Material properties such as ultimate tensile strength, yield strength, strain-hardening, and many more can be determined with the help of a tensile testing furnace.

Quality control testing often involves using special furnaces that apply controlled tension on samples until they break.

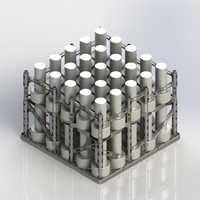

3. Sintering Furnaces

Sintering furnaces are used to increase the strength, transparency, thermal conductivity, or electrical conductivity of a material while decreasing its porosity.

Sintering is the process of making a solid mass of material through the application of pressure or heat without completely melting the sample.

4. Annealing Furnaces

The purpose of an annealing furnace is to heat a material and keep it at that temperature until it has cooled sufficiently. It's possible that different cooling rates and temperatures will be used for different tasks.

To improve its cold workability, machinability, and mechanical and electrical properties, a sample can be annealed in a heat treatment procedure.

5. Tempering Furnaces

Due to the potential for excessive hardness, stress, and brittleness following hardening or quenching, iron-based alloys are commonly tempered in a subsequent furnace. During tempering, steel is heated to a certain temperature before being slowly cooled in air.

The amount of hardness lost while heating metal depends on the temperature used.

6. Calcination Furnaces

In most cases, most Furnace Manufacturers suggest a calcining furnace is used to either recover the base material after another process has been performed, or to prepare raw materials for further processing.

A calcination is a form of heat treatment in which a sample, such as a mineral or ceramic powder, is heated to a temperature over its critical temperature but below its melting point in order to bring about a phase transition, thermal breakdown, or the removal of a volatile portion.

7. Ashing Furnace

A sample is burned in an ashing furnace, which measures the amount of ash that is produced. Petroleum compounds, lubricating lubricants, and coal are common ash samples utilized in these furnaces.

When ash is created, this method is commonly used to determine the presence of pollutants in the sample.

Before doing chemical analysis, ash is often used as a preconcentration technique to identify any lingering impurities.

8. Blast Furnaces

Blast furnaces can take the form of tall cylindrical structures or towers with special linings designed to withstand extremely high temperatures. By doing so, they drive gases and hot air through the furnace's contents.

The ore, fuel, and limestone go through a chemical reaction as they move down the cylinder and are pushed out the top of the furnace by the incoming air.

9. Electric Furnaces

To generate high temperatures, an electric furnace makes advantage of electrical resistance. They are made out of a variety of materials that can withstand high temperatures.

The temperature of the materials, gas, or air being heated is monitored by a sensor located outside of the enclosed enclosure.

Electric heaters may be set to a fixed temperature or allowed to fluctuate. Coal and oxygen can be added to boost the stove's temperature.

10. Gas Furnaces

With the ever-increasing cost of energy, gas-fueled furnaces have become a more financially viable option.

Gas furnaces are categorized by their condensing efficiency, which must be at least 90%, and their annual fuel usage efficiency (AFUE), which is the percentage of fuel converted into usable heat.

11. Induction Furnaces

To heat metal, induction furnaces combine the effects of electrical resistance and hysteresis losses. When compared to other types of furnaces, they are cleaner and use less energy.

12. Vacuum Furnaces

To reduce the likelihood of unwanted surface reactions, vacuum furnaces function in an airtight, vacuum environment. Contamination is prevented by the absence of air and gases.

Vacuum furnaces are able to braze, sinter, and heat-treated metals under consistent and precise circumstances due to the high temperatures they can reach.

Working principles of a furnace

There are two ways to generate the furnace between two electrodes:

- High Tension (HT) method

- Low Tension (LT) method

1. HT Method

H. T. furnaces are created by keeping a constant air gap between two conducting electrodes. The electrodes are linked to the step-up transformer's high-voltage secondary winding, while the primary winding is supplied with a controllable alternating current.

Now, the voltage across the high tension secondary winding—and hence across the electrodes—must be raised progressively in order to strike an electric furnaces. The medium between the electrodes is ionized and becomes conducting at a specific voltage.

The electric furnace is formed between the electrodes at this point. Because the resistance of the conducting gap between the electrodes is so much lower than that of the air gap after striking the furnaces, the voltage across the electrodes must be lowered from its high-tension (H. T.) value to its low-tension (L. T.) value. The air gap between the electrodes determines the minimum H. T. voltage needed.

2. LT Method

A schematic representation of the L. T. method of electric arc striking. When using this technique, an furnaces can be formed between electrodes with a relatively low voltage, on the order of the supply voltage. The step-down transformer's low-voltage secondary winding is linked to the two conducting electrodes in this technique.

A furnace is created when a brief short circuit is made between these electrodes, followed by their instantaneous separation.

Uses of furnace

1. Atmospheric Controlling

The industrial furnace can be run in either a conventional environment (with the tube furnaces) or an inert atmosphere (with the gas-sealed box furnaces). The furnace has fast cooling and heating rates, consistent temperature control, a small footprint, and a robust build, making it one of the most trusted and commonly used lab furnaces on the market. At high temperatures, these furnaces won't hot spot, and they're durable.

2. Thermal Cycling

High-purity alumina fiber is used in the graded insulating package used in furnaces. Since this insulation has low heat conductivity and is lightweight, extremely rapid thermal cycling is feasible. At high temperatures, these furnaces won't hot spot, and they're durable.

3. Metallizing

These metal-melting furnaces come in a range of sizes to accommodate a variety of applications and output rates. Furnaces are still actively engaged in this activity. It didn't take long for us to progress from metalizing to co-firing multilayer ceramic packaging. The furnaces series includes anything from little benchtop models to massive, factory-wide installations.

4. Brazing

Features such as various zone controls, wax or binder removal sections, low or high dewpoint features, preheat section, and a turn-key automated pusher is included to accommodate applications such as brazing.

5. Calcining

Furnaces are trusted and commonly used calcining devices. You can heat or cool something quickly with them, and they have precise temperature regulation, a small footprint, and a durable design to last for years.

6. Sintering

A furnace provides debinding and sintering capabilities in their batch environment furnaces, making them ideal for process development and low-volume production runs. The furnaces are economical to run. They're built to last and require almost no upkeep to keep functioning well.

7. Annealing

When it comes to processing wire, rod, strand, strip, and tube products, the continuous annealing furnaces are built to last for years with no maintenance. Copper alloys, stainless steel, nickel, nickel chrome, Copper, titanium, and refractory metals are most suited for use in these furnaces.

From the manufacture of plastics to the deformation of metals, industrial furnaces have become indispensable. Many of the things we use every day have been heated in a factory oven before they reached the tables. Industrial furnaces have been a major source of the problem for decades, if not centuries. Manufacturers and consumers alike are constantly working to enhance industrial furnace operations in order to mitigate their shortcomings.

FAQs: Furnace

Q. What is a furnace used for?

Ans. Warm air is pumped through the house via ducts from the furnace. Water boilers produce either hot water or steam for use in space heating.

Q. Does the furnace need water to run?

Ans. No, while water heaters serve the same purpose, furnaces do it without the need of water. Furnaces, on the other hand, use combustion gas produced by natural gas burners to heat the air; no water is used in this process.

Q. Is a furnace only for heat?

Ans. All heaters can be thought of as furnaces, but not all furnaces can be thought of as heaters.

Q. How does a furnace work in a house?

Ans. Your furnace's burner lights the gas once it has been drawn from a tank (for liquid propane) or the local gas distribution system (for natural gas). The heat exchanger in your furnace is where the cold air from your home is heated by the burning gas.

Related Categories

Abrasives

Acoustic Products

Acrylic Sheets

Air Blowers

Air Compressors & Air Separation Plants

Air Cooler

Air Dryers

Air Receiver

Air Valves

Aluminum Castings

Anchors

Anti Vibration Mounts

Ball & Roller Bearings

Ball Valves

Ballast Making Machines

Bearing Parts & Components

Bearings

Bellows & Expansion Joints

Belt Pulleys

Boilers, Components & Spares

Bolts

Bright Bars

Bristles

Burners/Industrial Burners & Incinerators

Bushings & Bushing Parts

Butterfly Valves

CNC Machined Components

Cable Pulleys

Capital Goods

Carbon & Graphite Products

Castor Wheels

Centrifugal Pumps

Centrifuges

Ceramics

Chains & Chain Link Fence Fittings

Cleaning Equipment

Clips, Clamps

Coils

Combustion Equipment

Compression Springs

Compressors & Allied Equipment

Control Valves

Conveyor & Conveyor/Industrial Belts

Cooling Tower & Chilling Plants

Corrosion Protection Materials

Coupling

Cranes

Cryogenic Equipment

Cutting Tools, Broaches & Cutters

Departmental Shelving

Diaphragm Valves

Die Castings

Dies & Moulds

Dies,Jigs,Fixtures

Diesel Engine & Electric Locomotive Spares

Draught Fan

EOT Cranes

Electric Hoists

Electric Motors & Engines

Electroplating Chemicals & Equipment

Elevators, Lifts & Escalators

Energy Management System

Engine Valves

Engineering Goods & Equipment

Engineering Plastics

Engraving Equipment

Extruded Profiles

Fasteners

Fiberglass Products

Filter Cartridges & Media

Filter Cloth, Filter Industrial

Filters-Air, Gas, Liquid

Filtration & Sedimentation Units

Flat Metal Processing Equipment

Float Valves

Fork Lift Truck Parts

Fork Lift Trucks

Forklifts

Foundry Raw Material & Equipment

Furnace Manufacturers

Galvanized Fasteners

Gantry Cranes

Gaskets

Gate Valves

Gauges & Gauge Glasses

Gear Boxes, Reduction Gears & Gear Cutting

Girder Cranes

Glass & Glass Products

Glass Cutting Tools/Glass Cutters

Globe Valves

Goliath Cranes

Grating

Hand & Allied Tools

Hand Pump

Hardware & Tools

Heat Exchangers

Heating Elements

Hex Bolts

Hex Nuts

Hooks & Mounts

Hoses

Hot Air Oven

Humidification & Ventilation Equipment

Hydraulic Hoses & Flexible Metal

Hydraulic Press

Hydraulic Press Brakes

Hydraulic Products & Equipment

Hydraulic Valves

Induction Heating Equipment

Industrial Automation

Industrial Brakes

Industrial Brushes

Industrial Clothing

Industrial Clutches

Industrial Cylinders

Industrial Dryers

Industrial Evaporators

Industrial Knives

Industrial Nets

Industrial Ovens

Industrial Rollers

Industrial Supplies Stocks

Industrial Supplies-General

Industrial Tape

Industrial Tools

Industrial Valves

Industrial Vibrator

Inspection Equipment

Instrumentation

Internal Combustion Engine

Jib Cranes

Laboratory Furniture

Laboratory Glassware & Equipment

Laundry Equipment

Lined Valves

Machine Tools Accessories

Marking Systems

Material Handling Equipment

Measuring Tools & Equipment

Mechanical Seals

Metallised Capacitor Films

Mining Equipment

Mining, Exploration & Drilling Machinery

Model Making Materials

Motor Couplings

Moulded Components

Moulds

Needle Valves

Needles

Nuts

Oil Seals

Outdoor Cooling Systems

Overhead Cranes

PVC Hoses

PVC Products

Paint Brushes

Painting Equipments & Maintenance

Perforated Sheets

Plastic Processing Machinery Parts

Plastic Valves

Plastic Welding Equipment

Plate Valves

Plug Valves

Pneumatic Products & Tools

Pneumatic Valves

Polish & Polishing Material/Machinery

Power Press

Precision Brass Components

Pressed Components

Pressure Gauges

Pressure Vessels

Pulleys

Pulverizers

Pump Spares Parts

Pumps & Pumping Equipment

Radiators

Refrigeration & Equipment

Rope Pulleys

Rope,Twines & Webbings

Ropes

Rotary Valves

Rubber & Rubber Products

Rubber Gaskets

Rubber Roller

Rubber Seals

Rubber Transmission Belts

Screws

Seals

Sensors & Transducers

Shaft Couplings

Shafts & Shaft Collars

Sheet Metal Components & Parts

Solenoid Valves

Springs

Stainless Steel Bolts

Stainless Steel Fasteners

Stainless Steel Nuts

Stainless Steel Valves

Storage Systems

Storage Tanks

Submersible Pumps

Surface Finishing Equipment

Synthetic Industrial Diamonds

Testing & Measuring Equipment

Thermostatic Bimetals & Thermostats

Trolleys & Carts

Tungsten Carbide

Ultrasonic Equipment

V-Belts

Vacuum Equipment & System

Valves

Valves Fittings

Vibrating Screen

Washers

Water Coolers

Weighbridge

Welding & Soldering Supplies

Welding Electrodes

Welding Equipment

Winches

Wire Drawing Dies

Wire Rope Hoists

Wire Ropes