Compressors & Allied Equipment

(4310 products)

Top Compressors & Allied Equipment Categories

Explore More Categories

Product Showcase

Compressors Spares Parts

Price Trend: 1500-45750 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Product Type - Spares Parts

Usage - Compressors

5 Years

Business Type: Manufacturer | Exporter

PRS COMPRESSORS PVT. LTD.

Made in India

Silver Double Inlet Impeller

Price: 600 INR (Approx.)/Piece

MOQ - 10 Piece/Pieces

Usage - Industrial

Color - silver

Material - Aluminium

14 Years

Response Rate: 82.22%

Business Type: Manufacturer | Exporter

RE BLOWERS INDIA PRIVATE LIMITED

Made in India

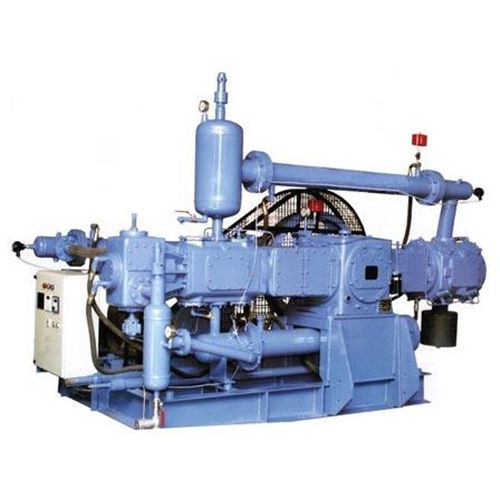

Industrial Air Compressor

Price: 110000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

17 Years

Business Type: Manufacturer | Supplier

AIR VAC EQUIPMENT

Made in India

Stainless Steel Rotary Air Compressor

Price: 60000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Product Type - Rotary Air Compressor

Usage - Industrial

Type Of Compressor - Turbo

16 Years

Business Type: Manufacturer | Exporter

LEELAM INDUSTRIES

Made in India

Air Compressor / Dryer & After Coolers

15 Years

Business Type: Manufacturer | Exporter

DYNAMIC ENTERPRISES INC.

Made in India

Danfoss Condensing Units Voltage: 220 Statampere (Sa)

Price Trend: 30000 - 250000 INR (Approx.)/Number

MOQ - 1 Number

Voltage - 220 Statampere (sA)

Driven Mode - Electric

9 Years

Business Type: Distributor | Supplier

ISHWAR CLIMATE SOLUTIONS PRIVATE LIMITED

Made in India

Direct Drive Screw Compressors

4 Years

Business Type: Manufacturer | Exporter

BERLIN MACHINERIES PRIVATE LIMITED

Made in India

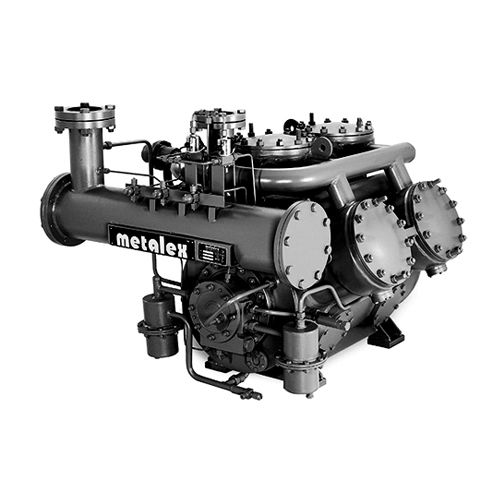

Lubricated Ammonia Single Cylinder Compressor

Price Trend: 300000.00 - 1200000.00 INR (Approx.)/, Set

MOQ - 1 , Set/Sets

Usage - Cold Storages , Chilling Plants , Dairies , Ice Plants.

Type Of Compressor - Piston

Allied Equipment - Other

13 Years

Business Type: Manufacturer | Supplier

METALEX CRYOGENICS LTD.

Made in India

Twin Lobe Air Blower

12 Years

Business Type: Manufacturer | Distributor

KPT INDUSTRIES LIMITED

Made in India

PG 45E-7 Electrical Screw Air Compressor Trolley

3 Years

Business Type: Manufacturer | Supplier

ELGI Equipments Limited

Made in India

Diaphragm Idmc Bunging Device

MOQ - 1 Unit/Units

Usage - Industrial, Automobile

Product Type - Bunging Device

Type Of Compressor - Diaphragm

3 Years

Business Type: Manufacturer | Distributor

WELD ARC ENGINEERS

DN20~DN200 Aluminum Pipe for Solar PV Project

MOQ - 1 Piece/Pieces

Product Type - Aluminum Pipe

2 Years

Business Type: Manufacturer | Supplier

SHANGHAI HAI HONG SHUN INDUSTRIAL CO., LTD..

Made in India

Black Zf40 Emerson Copeland Compressor

Price: 95,000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Color - Black

Usage - Industrial

Type Of Compressor - Other, Scroll

Business Type: Supplier | Exporter

A.K Trading

Made in India

Dc Fan Motor Series Air Oil Cooler Usage: Industrial

Price: 4065 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Product Type - Dc Fan Motor Series Air Oil Cooler

Usage - Industrial

Weight - 2 Kilograms (kg)

2 Years

Business Type: Trading Company

Durga Hydraulics

Yellow & Gray Rotary Screw Compressors

Price Trend: 300000-7500000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Color - Yellow & Gray

Usage - Industrial

Product Type - Rotary Screw Compressors

9 Years

Business Type: Distributor | Service Provider

ADVANCED EQUIPMENTS AND SOLUTIONS PRIVATE LIMITED

Made in India

Air Receiver

2 Years

Business Type: Manufacturer | Supplier

SUMMITS HYGRONICS PRIVATE LIMITED

Fluid Regulator - Color: Silver

Price Trend: 200.00 - 210.00 USD ($) (Approx.)/Set

MOQ - 10 Set/Sets

Color - Silver

Usage - Industrial

Size - Standard

6 Years

Business Type: Manufacturer | Distributor

JO LONG MACHINE INDUSTRIAL CO., LTD.

Made in India

Lubricated Packing Seal Assembly

Price: 3,145 INR (Approx.)/Piece

MOQ - 10 Piece/Pieces

Size - Different available

Usage - Industrial

Configuration - Portable

Business Type: Supplier | Trading Company

Mahad Infrastructure Private Limited

Made in India

Super Tech Compressor Vacuum Pump In Ghaziabad Super Tech Engineers

4 Years

Response Rate: 70.00%

Business Type: Manufacturer

SUPERTECH ENGINEERS

Indian Inquiries Only

Made in India

Cement Silo Compressor Application: Industrial

Price Trend: 110000.00 - 150000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Product Type - Compressor

Material - Cast iron, Other

Finish - Painted/Polsihed, Other

6 Years

Business Type: Manufacturer | Supplier

AIR VAC EQUIPMENTS

Blue/ Yellow/Green/Grey/Red (Customised Colour Available) Tractor Trolley Mounting Compressor (Khosla Kg2)

Price: 98500.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Height - 1.5 Meter (m)

Width - 1.5 Meter (m)

Weight - 500 Kilograms (kg)

2 Years

Business Type: Trading Company

VISHAL PNEUMATIC TOOLS

Made in India

Carter Vfd Compressor For Industrial Use Power Source: Ac Power

Price: 1000000 INR (Approx.)/Set

MOQ - 1 Set/Sets

Product Type - AIR SCREW COMPRESSOR

Type Of Compressor - Screw

Configuration - Other

9 Years

Business Type: Supplier | Service Provider

CARTER UNIQUE GROUP

Indian Inquiries Only

Made in India

Forging Crank Shaft Model- Single Stage Compressor (PCT 20)

2 Years

Business Type: Manufacturer | Supplier

PIONEER'S SERVICEES

Dental Air Compressors Gx-800 Power Source: Ac Power

Price Trend: 12500.00 - 20000.00 INR (Approx.)/Unit

MOQ - 50 Unit/Units

Configuration - Portable

Power Source - Ac Power

Silent - Yes

13 Years

Business Type: Distributor | Exporter

DEVAL ENTERPRISE LLP

Made in India

Oil Coolers 50 Hz In Faridabad Aab Heat Exchangers Private Limited, Frequency: 50 Hz

19 Years

Business Type: Manufacturer | Supplier

AAB HEAT EXCHANGERS PVT. LTD.

Blue Sy 300 A4Cbe Danfoss Scroll Compressor

Price: 85000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Usage - Domestic, Commercial & Industrial

Weight - 164 Kilograms (kg)

Product Type - SY 300 A4CBE Danfoss Scroll Compressor

2 Years

Business Type: Manufacturer | Supplier

NEW GALAXY REFRIGERATION

Indian Inquiries Only

Made in India

Blue And Black Compression Elbow

MOQ - 250 Unit/Units

Color - Blue and Black

Size - Different Size

Usage - Industrial

1 Years

Business Type: Manufacturer

EARTH WATER PIPE FITTINGS PRIVATE LIMITED

Made in India

Oil-Free Two Stage Air Compressors

Price: 15000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Usage - For Commercial Use

Product Type - Air Compressors

Color - Green

21 Years

Business Type: Manufacturer | Distributor

INTEGRATED ENGINEERS & CONTRACTORS

Compressors & Allied Equipment Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Integrated Engineers & Contractors | Sonipat, India | 21 Years |

| Aab Heat Exchangers Pvt. Ltd. | Faridabad, India | 19 Years |

| Air Vac Equipment | Ahmedabad, India | 17 Years |

| Leelam Industries | Ahmedabad, India | 16 Years |

| Dynamic Enterprises Inc. | Pune, India | 15 Years |

| Re Blowers India Private Limited | Mumbai, India | 14 Years |

| Metalex Cryogenics Ltd. | Pune, India | 13 Years |

| Deval Enterprise Llp | Ahmedabad, India | 13 Years |

| Kpt Industries Limited | Pune, India | 12 Years |

| Ishwar Climate Solutions Private Limited | Mumbai, India | 9 Years |

Compressors & Allied Equipment - Overview

In 1937, Allied Equipment established a new distribution center at 545 East 4th Street. The company distributed a wide variety of products, including snow plows, LED traffic signals, and farm machinery. A gas compressor is a machine that reduces the gas's volume in order to increase its pressure.

In addition to air, natural gas, oxygen, and nitrogen—all of which have significant industrial applications—are also compressed. Compressors can be categorized into three broad categories: positive displacement, centrifugal, and axial.

A high-speed impeller in a centrifugal compressor boosts the gas's kinetic energy, which is then converted to more pressure in a diffuser located at the compressor's divergent exit.

What type of equipment is an air compressor?

1. Rotary Screw compressor

Displacement compressors like rotary screws are among the most user-friendly, thanks to their built-in cooling systems that require little attention.

These machines are primarily used in industrial settings and are very huge. To provide power, rotary screw air compressors use two rotors spinning in opposite directions inside the machine. As the air builds up between the two rotors, the pressure inside the housing increases.

These air compressors have a horsepower range from 5 to 350 and feature an internal cooling system, making them suitable for 24/7 operation.

2. Reciprocating Air Compressors

Other common displacement compressors use a revolving compressor. They are commonplace in garages and domestic construction sites.

The reciprocating compressor, in contrast to the rotary screw compressor, is not intended for nonstop operation.

When it comes to moving parts, a reciprocating air compressor has more, and these are maintained with oil to provide a more efficient and quiet operation. In a reciprocating compressor, a piston moves within a cylinder, compressing and displacing air to increase pressure.

The pressure ranges that can be attained by different types of reciprocating compressors depend on whether or not they are single-stage or multi-stage designs.

3. Axial Compressors

Power is produced by dynamic Compressors & Allied Equipment, which work by drawing in air with rapidly spinning blades and then compressing it to increase pressure.

Then, the compressor will take that kinetic energy and convert it to static energy. When it comes to dynamic compressors, axial and centrifugal designs dominate the market.

Normal construction practices tend to avoid the use of axial air compressors. Instead, you can find them in the high-powered engines of ships and jets.

4. Centrifugal Compressors

Because of their high efficiency rate, axial compressors are well suited for aerospace applications needing high horsepower, but they are also significantly more expensive than other types of air compressors.

Air entering a centrifugal compressor is slowed and cooled by a diffuser to increase its potential energy. Since centrifugal compressors use a multi-phase compression process, they may generate a lot of power despite their compact size.

5. Oil Flooded Air Compressor

Compressors can also be categorized based on their lubrication, which can be either oil-flooded or oil-free. Compressors that are "oil flooded" have oil lubricating their moving parts. In particular, their compression chambers are sealed and lubricated with oil.

Oil-flooded designs are common in rotary screw and reciprocating compressors.

Oil-flooded compressors tend to last longer because of the regular lubricating they receive. But they can leak lubricant into the compressed air and ruin it.

6. Oil-Free Air Compressor

In contrast, oil-free air compressors don't use any kind of oil in the compression process. Instead, their moving parts are pre-lubricated with a long-lasting alternative lubricant that is integrated into the design. This means they can generate pollution-free air by removing all residues of potentially dangerous oil.

Generally speaking, centrifugal compressors don't require oil, and there are also oil-free rotary screw and reciprocating compressors.

These may cost more, but they're more efficient (meaning they use less energy) and quieter (meaning they don't disrupt your workday as much) than the alternatives. Because of these benefits, they are well-suited for building in high-traffic regions or environmentally conscious settings.

7. Scroll Air Compressor

According to international standards, scroll compressors create the cleanest air. Construction projects or businesses with stricter environmental requirements may benefit from using such equipment.

They are also adaptable, as they can function at a range of intensities. Scroll compressors are low-noise and low-maintenance, but they aren't the most powerful option available.

Although a different kind of compressor may be needed for heavy-duty tools and machinery, the passive uses are best suited to the more lightweight compressors.

Understanding Compressors : Types

i. Piston Compressor

Compressing gas in a cylinder (or cylinders) and releasing it through valving into high pressure receiving tanks is the job of a piston compressor, also known as a reciprocating compressor.

The tank and the compressor are frequently assembled into a single "packaged unit" on the same frame or skid.

Although delivering compressed air as an energy source is where piston compressors shine the brightest, pipeline operators also rely on piston compressors when transporting natural gas.

Both the desired pressure (in psi) and the desired flow rate play a role in determining which piston compressor to use (scfm).

ii. Diaphragm Compressor

It's an improved version of the reciprocating type, driven by a motor-mounted eccentric that vibrates a movable disc to increase and decrease the size of the compression chamber.

Similar to a diaphragm pump, the flexible disc separates the drive from the process fluid, preventing lubricant from mixing with any gas.

iii. Helical Screw Compressor

For applications that require constant use, such as construction or roadwork, a helical-screw compressor is an excellent choice among rotary compressor machines.

Geared based Compressors, meshing female and male draw in gas, compress it as the gas passes axially along the rotors' length, and then release the compressed gas through a port on the opposite end of the compressor casing. Because of the rotary screw compressors lower vibration, it operates more quietly than a reciprocating compressor.

iv. Sliding Vane Compressor

Sliding-vane compressors use a set of vanes mounted on a rotor to move down the curved wall of an eccentric chamber. As the vanes spin from the suction side to the discharge side of the eccentric cavity, they diminish the volume of space they are sweeping by, compressing the gas that is trapped within the space.

An oil film forms on the wall of the eccentric chamber, and the vanes slide along it, creating a seal. Although oil-free air from sliding-vane compressors is not possible, pulsation-free compressed air can be produced. Because of the low operating speeds and the use of bushings instead of bearings, these compressors are tolerant to environmental pollutants.

v. Scroll air Compressor

In a scroll air compressor, the volume of space between the fixed and orbiting spirals is reduced as the latter follow in the fixed spirals' footsteps. The gas is sucked in at the edges of the scrolls and released from its compressed state in the middle.

The compressor does not require any lubricating oil because the scrolls do not come into contact with one another.

Capacity for scroll compressors is limited due to the absence of oil used in other systems to remove the heat of compression.

vi. Centrifugal Compressor

Pump-like impellers spin rapidly in centrifugal compressors, increasing the kinetic energy of the gas and thus the pressure.

They are typically found in high-output applications such commercial refrigeration units (100 hp+) and large processing plants (20,000 hp+, delivering quantities of up to 200,000 cfm+).

To enhance the speed of gas, centrifugal compressors work by propelling it outward at high velocities via a rotating impeller, much like a centrifugal pump. The gas's velocity decreases and its pressure increases as it expands inside the casing's volute.

8. Axial Compressor

Axial compressors can produce the highest supplied air volumes, anywhere from 8,000 to 13 million cfm, making them ideal for use in large industrial machinery. Compressors of this type are used in jet engine systems to create volumes throughout an even larger spectrum.

Axial compressors, because of their low compression ratios, are typically more complex multi-stage designs than centrifugal compressors.

When compared to other forms of energy production, air compressors are far more secure and user-friendly. Construction workers naturally benefit greatly from this because of the increased dangers they face on the job. If you keep your air compressor well-lubricated, it has a significantly lower risk of overheating.

Air conditioners can be quite pricey to repair or replace due to the high cost of the compressor. It is more cost-effective to replace the entire AC unit than to repair individual parts. If the compressor is making grinding noises or is hard to start up ("hard starting"), you should get it fixed as soon as possible.

FAQs: Compressors & Allied Equipment

Q. What is compressor equipment?

Ans. A mechanical device, compressor equipment reduces the volume of a gaseous substance while simultaneously increasing its pressure. One variety of gas compressors is the air compressor.

Q. Which oil is used in compressor?

Ans. Synthetic oil and Mineral oil are two types of oil used for operating compressor device.

Q. What SAE is compressor oil?

SAE is non detergent air compressor oil. This is the best option for an air compressor that runs on oil. A shorter compressor lifespan is a direct result of the use of detergent oils, which can lead to carbon buildup.

Q. What are the parts of compressor?

Ans. Compression Cylinder, Air Filters, Rotors, Rollers, Bearings, Discharge Valve, Suction Valve, Oil Filters, Gaskets & Seals, Separators, and Storage Tanks are some parts of Compressor.

Related Categories

Abrasives

Acoustic Products

Acrylic Sheets

Air Blowers

Air Compressors & Air Separation Plants

Air Cooler

Air Dryers

Air Receiver

Air Valves

Aluminum Castings

Anchors

Anti Vibration Mounts

Ball & Roller Bearings

Ball Valves

Ballast Making Machines

Bearing Parts & Components

Bearings

Bellows & Expansion Joints

Belt Pulleys

Boilers, Components & Spares

Bolts

Bright Bars

Bristles

Burners/Industrial Burners & Incinerators

Bushings & Bushing Parts

Butterfly Valves

CNC Machined Components

Cable Pulleys

Capital Goods

Carbon & Graphite Products

Castor Wheels

Centrifugal Pumps

Centrifuges

Ceramics

Chains & Chain Link Fence Fittings

Cleaning Equipment

Clips, Clamps

Coils

Combustion Equipment

Compression Springs

Compressors & Allied Equipment

Control Valves

Conveyor & Conveyor/Industrial Belts

Cooling Tower & Chilling Plants

Corrosion Protection Materials

Coupling

Cranes

Cryogenic Equipment

Cutting Tools, Broaches & Cutters

Departmental Shelving

Diaphragm Valves

Die Castings

Dies & Moulds

Dies,Jigs,Fixtures

Diesel Engine & Electric Locomotive Spares

Draught Fan

EOT Cranes

Electric Hoists

Electric Motors & Engines

Electroplating Chemicals & Equipment

Elevators, Lifts & Escalators

Energy Management System

Engine Valves

Engineering Goods & Equipment

Engineering Plastics

Engraving Equipment

Extruded Profiles

Fasteners

Fiberglass Products

Filter Cartridges & Media

Filter Cloth, Filter Industrial

Filters-Air, Gas, Liquid

Filtration & Sedimentation Units

Flat Metal Processing Equipment

Float Valves

Fork Lift Truck Parts

Fork Lift Trucks

Forklifts

Foundry Raw Material & Equipment

Furnace Manufacturers

Galvanized Fasteners

Gantry Cranes

Gaskets

Gate Valves

Gauges & Gauge Glasses

Gear Boxes, Reduction Gears & Gear Cutting

Girder Cranes

Glass & Glass Products

Glass Cutting Tools/Glass Cutters

Globe Valves

Goliath Cranes

Grating

Hand & Allied Tools

Hand Pump

Hardware & Tools

Heat Exchangers

Heating Elements

Hex Bolts

Hex Nuts

Hooks & Mounts

Hoses

Hot Air Oven

Humidification & Ventilation Equipment

Hydraulic Hoses & Flexible Metal

Hydraulic Press

Hydraulic Press Brakes

Hydraulic Products & Equipment

Hydraulic Valves

Induction Heating Equipment

Industrial Automation

Industrial Brakes

Industrial Brushes

Industrial Clothing

Industrial Clutches

Industrial Cylinders

Industrial Dryers

Industrial Evaporators

Industrial Knives

Industrial Nets

Industrial Ovens

Industrial Rollers

Industrial Supplies Stocks

Industrial Supplies-General

Industrial Tape

Industrial Tools

Industrial Valves

Industrial Vibrator

Inspection Equipment

Instrumentation

Internal Combustion Engine

Jib Cranes

Laboratory Furniture

Laboratory Glassware & Equipment

Laundry Equipment

Lined Valves

Machine Tools Accessories

Marking Systems

Material Handling Equipment

Measuring Tools & Equipment

Mechanical Seals

Metallised Capacitor Films

Mining Equipment

Mining, Exploration & Drilling Machinery

Model Making Materials

Motor Couplings

Moulded Components

Moulds

Needle Valves

Needles

Nuts

Oil Seals

Outdoor Cooling Systems

Overhead Cranes

PVC Hoses

PVC Products

Paint Brushes

Painting Equipments & Maintenance

Perforated Sheets

Plastic Processing Machinery Parts

Plastic Valves

Plastic Welding Equipment

Plate Valves

Plug Valves

Pneumatic Products & Tools

Pneumatic Valves

Polish & Polishing Material/Machinery

Power Press

Precision Brass Components

Pressed Components

Pressure Gauges

Pressure Vessels

Pulleys

Pulverizers

Pump Spares Parts

Pumps & Pumping Equipment

Radiators

Refrigeration & Equipment

Rope Pulleys

Rope,Twines & Webbings

Ropes

Rotary Valves

Rubber & Rubber Products

Rubber Gaskets

Rubber Roller

Rubber Seals

Rubber Transmission Belts

Screws

Seals

Sensors & Transducers

Shaft Couplings

Shafts & Shaft Collars

Sheet Metal Components & Parts

Solenoid Valves

Springs

Stainless Steel Bolts

Stainless Steel Fasteners

Stainless Steel Nuts

Stainless Steel Valves

Storage Systems

Storage Tanks

Submersible Pumps

Surface Finishing Equipment

Synthetic Industrial Diamonds

Testing & Measuring Equipment

Thermostatic Bimetals & Thermostats

Trolleys & Carts

Tungsten Carbide

Ultrasonic Equipment

V-Belts

Vacuum Equipment & System

Valves

Valves Fittings

Vibrating Screen

Washers

Water Coolers

Weighbridge

Welding & Soldering Supplies

Welding Electrodes

Welding Equipment

Winches

Wire Drawing Dies

Wire Rope Hoists

Wire Ropes