Hydraulic Press Brakes

(690 products)

Explore More Categories

Automatic Nc Press Brake

Price: 2200000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Width - 4-8 Meter (m)

Product Type - Automatic

Usage - For Industrial

20 Years

Business Type: Manufacturer | Supplier

SIDDHAPURA MACHINE TOOLS

Made in India

Blue Hydraulic Press Brake

MOQ - 1 Unit/Units

Color - Blue

Product Type - Hydraulic Press Brake

Usage - Industrial

22 Years

Business Type: Manufacturer | Supplier

SANTEC EXIM PRIVATE LTD

Made in India

Blue Mechanical Press Brake Machine

MOQ - 1 Piece/Pieces

Product Type - Press Brake Machine

Usage - Industrial

Color - Blue

3 Years

Business Type: Manufacturer | Exporter

WELDOR ENGINEERING PVT. LTD.

Made in India

Orange And Black Hydraulic Press Brake

Price: 500000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Product Type - Hydraulic Press Brake

Length - Up To 10 Feet Foot (ft)

Width - 10-20 Millimeter (mm)

10 Years

Business Type: Manufacturer | Exporter

VIVEK MACHINE TOOLS

Made in India

CNC Press Brake

Price: 1500000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

8 Years

Response Rate: 85.37%

Business Type: Manufacturer | Exporter

NANDI MACHINERY

Made in India

Hydraulic Press Brake

Color - White and blue

Product Type - Hydraulic press brake

2 Years

Business Type: Manufacturer | Distributor

HARON CUTTING MACHINES CO., LTD

Made in India

30 Ton Double Cylinder Hydraulics Press Brake

Price Trend: 360000.00 - 370000.00 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Size - 1600

Usage - PRESS BREAK

Warranty - 24 MONTH

8 Years

Business Type: Manufacturer | Exporter

KIRAN HYDRAULICS

Made in India

Industrial Hydraulic Press Brake Machine Usage: Sheet Bending

Price: 850000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Product Type - Press Brake

Usage - Sheet Bending

13 Years

Business Type: Manufacturer | Supplier

GOLDEN MACHINEX CORPORATION

Indian Inquiries Only

Industrial Cnc Press Brake Bending Machine

Product Type - CNC Press Brake Bending Machine

Color - Black and Orange

6 Years

Business Type: Manufacturer | Distributor

MAANSHAN PRIMA CNC MACHINERY CO LTD.

Delem DA66T DA69T Double Pump Driven Type Electric Hydraulic CNC Press Brake Bending Machine

Color - White, Black

Product Type - CNC Press Brake Bending Machine

3 Years

Business Type: Manufacturer | Distributor

NANJING PRIMA CNC MACHINERY CO., LTD.

Made in India

Hydraulic NC Press Brake

Price: 235000.00 INR (Approx.)/Set

MOQ - 1 Set/Sets

Color - Mix

Product Type - Hydraulic NC Press Brake

Type - Other

4 Years

Business Type: Manufacturer | Distributor

PENTAGON MACHINES AND TOOLS

Indian Inquiries Only

Made in India

Hydraulic Press Brake C25H34O6

MOQ - 1 Number

2 Years

Business Type: Manufacturer | Exporter

Noel Machinery

Made in India

Hydraulic Press Brake Machines

Business Type: Manufacturer

TECHNO-MECH MACHINE TOOLS

Made in India

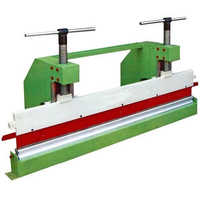

Vpb-1625 Hydraulic Press Brake Size: Various Sizes Available

Price Trend: 800000.00 - 10000000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Size - Various Sizes Available

Color - Green, Red, Blue

Usage - Industrial

1 Years

Business Type: Manufacturer | Supplier

Vimal Machine Tools

Made in India

Hydraulic Press Break Machhine For Industrial Use

Product Type - Hydraulic Press Brake Machine

Color - Multi Color

Usage - Industrial Use

1 Years

Business Type: Manufacturer | Exporter

BHAVYA MACHINE TOOLS LLP

Made in India

Cnc Hydraulic Press Brake Machine Size: Various Sizes Available

Price: 1300000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Usage - Industrial

Size - Various Sizes Available

Product Type - Hydraulic Press Brake

6 Years

Business Type: Manufacturer | Distributor

IPAN MACHINERIES (INDIA) PVT. LTD.

Industrial Hydraulic Press Brake Height: 1200 Millimeter (Mm)

Price: 543750.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Width - 2000 Millimeter (mm)

Height - 1200 Millimeter (mm)

Size - 2540MM x 3MM(MS)

9 Years

Business Type: Distributor | Exporter

VIKAS MACHINERY AND AUTOMOBILES

Made in India

Black Cnc Press Brake Bending Machine

Price: 3000000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Color - Black

Product Type - CNC Press Brake Bending Machine

Usage - Sheet Bending

Business Type: Manufacturer | Exporter

Energy Mission Machineries India Limited

Press Brake Manual Machine

7 Years

Business Type: Manufacturer | Supplier

JEET MACHINE TOOLS CORPORATION

Indian Inquiries Only

Made in India

Multicolor Paint Coated Front Cylinder Press Brake Machine

Price Trend: 450000.00 - 10000000.00 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Weight - 2750 Kilograms (kg)

Size - 2200x1200x1910 mm (LxWxH)

Product Type - Cylinder Press Brake Machine

Business Type: Manufacturer | Distributor

SHAILESH MACHINE TOOLS PVT.LTD

Made in India

CNC Hydraulic Press Brake Machine

Price: 1600000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Color - White and Gray

Product Type - Hydraulic Press Brake Machine

2 Years

Business Type: Manufacturer | Distributor

Joe Machinery

Made in India

Press Brake

Price: 180000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

2 Years

Business Type: Manufacturer

SAGAR MACHINE TOOLS

Made in India

Red Angel Press Brake

MOQ - 1 Piece/Pieces

Size - Standard

Color - Red

Product Type - Angel Press Brake

Business Type: Manufacturer | Distributor

ANGEL INDIA CAD CAM PVT.LTD.

Nc Hydraulic Press Brake Machine, Normal Force: 1600 kN

3 Years

Business Type: Manufacturer | Exporter

MAHAKALI ENGINEERING

Made in India

Back Mounted Hydraulic Press Brake

17 Years

Business Type: Manufacturer | Supplier

KESHAV ENTERPRISES

White Cnc Press Brakes

Price: 2700000 INR (Approx.)/Piece

MOQ - 1 Piece/Pieces

Size - Standard

Usage - Bending

Color - White

6 Years

Business Type: Manufacturer | Distributor

ESSELL

Indian Inquiries Only

Made in India

Heavy Duty Power Press Machines

2 Years

Business Type: Manufacturer | Exporter

ESS KAY LATHE & MACHINE TOOLS

Made in India

White Automatic Hydraulic Press Brake

Price: 550000 INR (Approx.)/Unit

MOQ - 1 Unit/Units

Product Type - Hydraulic Press Brake

Color - White

Size - Different Available

1 Years

Response Rate: 98.04%

Business Type: Manufacturer | Exporter

Shivam Industries

Hydraulic Press Brakes Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Santec Exim Private Ltd | Gurugram, India | 22 Years |

| Siddhapura Machine Tools | Rajkot, India | 20 Years |

| Keshav Enterprises | Delhi, India | 17 Years |

| Golden Machinex Corporation | Kolkata, India | 13 Years |

| Vivek Machine Tools | Rajkot, India | 10 Years |

| Vikas Machinery And Automobiles | Rajkot, India | 9 Years |

| Nandi Machinery | Ahmedabad, India | 8 Years |

| Kiran Hydraulics | Mumbai, India | 8 Years |

| Jeet Machine Tools Corporation | Delhi, India | 7 Years |

| Maanshan Prima Cnc Machinery Co Ltd. | Maanshan, China | 6 Years |

What is Hydraulic Press?

Material fabrication, assembly, and maintenance all benefit from the usage of hydraulic presses. It uses the force exerted by a cylinder of steel being pushed into the material by a pump to achieve the desired effect.

Pascal's law asserts that any change in pressure exerted on a contained fluid would be felt throughout the fluid, making hydraulic presses possible. A pumping piston within the hydraulic press applies a tiny amount of mechanical force to a localized region of the sample. Similarly, there is a piston with a bigger surface area that generates a more substantial mechanical force.

Use of Hydraulic Press

1. Sword Making

Swords are pressed flat with a hydraulic press to get the desired shape throughout the manufacturing process.

2. Military uses

Most of the air force base relies on hydraulic presses. In most cases, they are utilized to load the shells.

3. Designing Aircraft

The Aerospace sector relies on hydraulic presses for metal forming and machinery fabrication. Hydraulic presses are used to manufacture aircraft parts like windshield wipers, gear components, body panels, and wings.

4. Making Automobile parts

The automobile industry makes extensive use of hydraulic presses for bending and shaping purposes. Hydraulic presses are used to produce a wide variety of automotive components, including sealing components, floor mats and carpets, fuel supply parts, insert molding, truck bed liners, brake pads, electrical connectors and insulators, vibration control, and many more.

5. Manufacturing Ceramics

While traditionally ceramics were made in heat kilns that reached temperatures of more than 1800 degrees Fahrenheit, modern hydraulic presses can produce the same results while only requiring a temperature of around 70 degrees Celsius.

With this method, ceramics like cement, tiles, bricks, etc. can be produced with less pressure and in a shorter amount of time. Ceramics are compressed into ceramic form using hydraulic presses.

6. Manufacturing Electrical parts

The housings and switches utilized by switching stations are assembled utilizing Hydraulic Press. Additionally, thermostats, which are used to keep buildings at a comfortable temperature, are produced using this method.

7. Making Electronic Appliances

Hydraulic presses are frequently used for the assembly of refrigerator parts, as well as for the shape of panels used in the manufacture of microwaves, dishwashers, and washing machines.

Different Types of Hydraulic Press

1. H-Frame hydraulic Pressure

Let's say you have a widget that's too huge and heavy to put on the bed of a regular H-frame style press without damaging the machine or causing it to malfunction. You'll need to press a bushing out of it, as opposed to using a forklift or an overhead hoist, if you want to load it.

Because of the varying dimensions of the widgets, you'll also need some daylighting leeway. This tricky situation can be solved with the use of a portable table press. The pressure of moveable table presses may be adjusted from 25 tons to 200 tons, making them ideal for a wide range of applications.

Work safely by loading your part onto the table with a forklift, overhead hoist, or two strong persons, and then rolling the table beneath the work head.

2. Movable Frame hydraulic Press

Maybe you need to straighten a steel plate or a shaft (which in itself can be a challenge). Just picture yourself trying to straighten a 6-foot-long shaft with an H-frame press.

You have to constantly juggle the component to get it in position over the spot where you need to apply pressure. Bringing the part to the work head and consistently hitting the target is next to impossible. But what if you didn't have to go to the work head to do the part?

Simply use a frame press that allows the frame to move. Safely load your part from any orientation, including from above, then position the frame over the area you need to press and the work head over the precise place you need to make contact with. As of this point on, everything is gravy, and you may finish the job quickly, without risk.

3. Bench frame press

These presses are similar to H-frame presses in that they also consist of a press cylinder and a steel frame. Bench frame presses are more compact than their H-frame counterparts; they may be installed on desktops or workbenches and typically come with hand pumps and detachable cylinders.

Huber says that, in comparison to bigger H-frame types, bench frames take up much less floor area and allow for faster assembly of bearings and other parts in facilities with higher throughput requirements.

4. Air Operated hydraulic Press

Is there no electricity in your workshop, but you have access to compressed air and would rather not hand-pump a press? In some cases, you may need to use a press in potentially dangerous conditions. To remedy the situation, you should invest in an air-operated hydraulic press.

You'll get the same amount of pressing power as an electric press, but without the hassle of wires and outlets. The tonnage range of these presses is 25–200 tons.

5. Arbor Press and C-Frame

When compared to bigger H-frame machines, both these presses have a more compact and portable construction.

There is a detachable cylinder in addition to the sturdy steel frame of these presses. Presses with an arbor frame are intended to be installed on a surface, while C-frame presses are freestanding.

To meet the demands of more demanding pressing tasks, arbor frame presses can accommodate greater tonnages. C-frame presses are more easily moved around, and they can be used to hold components in place during assembly, to remove components, or to mount to a bench for performing routine activities like bearing installation.

6. Double-Acting Hydraulic Press

Many businesses invest in hydraulic presses for jobs that need a fixture or die attached to the tool's piston. In many cases, they incorrectly choose a single-acting press.

A single-acting work head relies on a spring return, which might be compromised by a hefty die. Because of this, a double-acting hydraulic press is an invaluable tool.

They have greater lifting capacity, so your dies and fittings can stay there precisely when you need them to.

7. Manual Hydraulic Press

Consider a submarine with a miniature machine shop on board. A press is an essential instrument in addition to the standard repair equipment. Both electricity and square footage are in short supply. In other words, what do you do?

A simple answer to your predicament can be found in a manual H-frame press. Nothing to press, and no strength is required.

Working Process of Hydraulic Press

This is a perfect opportunity to learn the basics of how a hydraulic press works:

- By creating a pressure differential between two pistons, a hydraulic press can apply a compressive force times larger than that of a conventional mechanical press.

- The simplest form of this device has a tube filled with fluid connecting two pistons of equal size. When one piston is raised by the operator, fluid in the cylinder is pumped into the other piston.

- A downward force of the same magnitude is applied to both pistons. So, anything in the space between them is being pressed from every side.

- Squeezing a contained fluid generates force, as described by Pascal's law, and is the basis of hydraulic presses.

- The law of uniform coercivity states that when applied pressure to a contained fluid, the forceful change happens uniformly throughout the liquid. When you apply pressure to only a small section of the device, the force is communicated throughout the entire mechanism.

Hydraulic presses are all essentially the same in operation, although there is a wide variety of sizes and styles to choose from. Knowing the different kinds of presses as well as how they function will help you select the most appropriate machine for your needs. One of the most flexible and commonly used pieces of equipment in today's factories is the hydraulic system.

FAQs: Hydraulic Press Brakes

Q. What are the main advantages of the hydraulic press?

Ans. Here are the main advantages:

- Weight reduction and material conversation

- Having fewer parts also helps keep mold costs down.

- Low starting and running costs

- High Tonnage Capacity

- As opposed to the riskier mechanical press, this one is much more secure.

- Integrated safety features against overloading

- Less noise

Q. How hydraulic press is used?

Ans. Hydraulic presses have two connected cylinders. The larger cylinder contains more hydraulic fluid. The Ram is larger than the Plunger. Because liquids don't compress easily, a hydraulic press is employed. The hydraulic press presses fluid by applying a modest force to the plunger. This uniform pressure boosts the Ram. The Plunger and Ram destroy anything between them.

Q. What are the safety rules for using a hydraulic press?

Ans. Here are the safety tips:

- Before you start the press, make sure it's in working order.

- Determine where the power button and the emergency stop are located.

- Remember to Take Care of Yourself

- Maintain a Safe Working Distance When Handling Materials

- Employ Guarded H-Frame Presses

Q. What are the applications of the hydraulic press?

Ans. Here are the applications:

- To exert force on an object, hydraulic presses are a reliable and affordable option.

- Forging, food and other product compacting, metalworking, welding, appliance manufacturing, airplane construction, etc. all rely on it.

- Hydraulic presses are ideal for numerous heavy-duty jobs, including extruding plastic pipe, twisting large diameter tubing, Embossing and shaping sheet metal, and forging.

Related Categories

Abrasives

Acoustic Products

Acrylic Sheets

Air Blowers

Air Compressors & Air Separation Plants

Air Cooler

Air Dryers

Air Receiver

Air Valves

Aluminum Castings

Anchors

Anti Vibration Mounts

Ball & Roller Bearings

Ball Valves

Ballast Making Machines

Bearing Parts & Components

Bearings

Bellows & Expansion Joints

Belt Pulleys

Boilers, Components & Spares

Bolts

Bright Bars

Bristles

Burners/Industrial Burners & Incinerators

Bushings & Bushing Parts

Butterfly Valves

CNC Machined Components

Cable Pulleys

Capital Goods

Carbon & Graphite Products

Castor Wheels

Centrifugal Pumps

Centrifuges

Ceramics

Chains & Chain Link Fence Fittings

Cleaning Equipment

Clips, Clamps

Coils

Combustion Equipment

Compression Springs

Compressors & Allied Equipment

Control Valves

Conveyor & Conveyor/Industrial Belts

Cooling Tower & Chilling Plants

Corrosion Protection Materials

Coupling

Cranes

Cryogenic Equipment

Cutting Tools, Broaches & Cutters

Departmental Shelving

Diaphragm Valves

Die Castings

Dies & Moulds

Dies,Jigs,Fixtures

Diesel Engine & Electric Locomotive Spares

Draught Fan

EOT Cranes

Electric Hoists

Electric Motors & Engines

Electroplating Chemicals & Equipment

Elevators, Lifts & Escalators

Energy Management System

Engine Valves

Engineering Goods & Equipment

Engineering Plastics

Engraving Equipment

Extruded Profiles

Fasteners

Fiberglass Products

Filter Cartridges & Media

Filter Cloth, Filter Industrial

Filters-Air, Gas, Liquid

Filtration & Sedimentation Units

Flat Metal Processing Equipment

Float Valves

Fork Lift Truck Parts

Fork Lift Trucks

Forklifts

Foundry Raw Material & Equipment

Furnace Manufacturers

Galvanized Fasteners

Gantry Cranes

Gaskets

Gate Valves

Gauges & Gauge Glasses

Gear Boxes, Reduction Gears & Gear Cutting

Girder Cranes

Glass & Glass Products

Glass Cutting Tools/Glass Cutters

Globe Valves

Goliath Cranes

Grating

Hand & Allied Tools

Hand Pump

Hardware & Tools

Heat Exchangers

Heating Elements

Hex Bolts

Hex Nuts

Hooks & Mounts

Hoses

Hot Air Oven

Humidification & Ventilation Equipment

Hydraulic Hoses & Flexible Metal

Hydraulic Press

Hydraulic Press Brakes

Hydraulic Products & Equipment

Hydraulic Valves

Induction Heating Equipment

Industrial Automation

Industrial Brakes

Industrial Brushes

Industrial Clothing

Industrial Clutches

Industrial Cylinders

Industrial Dryers

Industrial Evaporators

Industrial Knives

Industrial Nets

Industrial Ovens

Industrial Rollers

Industrial Supplies Stocks

Industrial Supplies-General

Industrial Tape

Industrial Tools

Industrial Valves

Industrial Vibrator

Inspection Equipment

Instrumentation

Internal Combustion Engine

Jib Cranes

Laboratory Furniture

Laboratory Glassware & Equipment

Laundry Equipment

Lined Valves

Machine Tools Accessories

Marking Systems

Material Handling Equipment

Measuring Tools & Equipment

Mechanical Seals

Metallised Capacitor Films

Mining Equipment

Mining, Exploration & Drilling Machinery

Model Making Materials

Motor Couplings

Moulded Components

Moulds

Needle Valves

Needles

Nuts

Oil Seals

Outdoor Cooling Systems

Overhead Cranes

PVC Hoses

PVC Products

Paint Brushes

Painting Equipments & Maintenance

Perforated Sheets

Plastic Processing Machinery Parts

Plastic Valves

Plastic Welding Equipment

Plate Valves

Plug Valves

Pneumatic Products & Tools

Pneumatic Valves

Polish & Polishing Material/Machinery

Power Press

Precision Brass Components

Pressed Components

Pressure Gauges

Pressure Vessels

Pulleys

Pulverizers

Pump Spares Parts

Pumps & Pumping Equipment

Radiators

Refrigeration & Equipment

Rope Pulleys

Rope,Twines & Webbings

Ropes

Rotary Valves

Rubber & Rubber Products

Rubber Gaskets

Rubber Roller

Rubber Seals

Rubber Transmission Belts

Screws

Seals

Sensors & Transducers

Shaft Couplings

Shafts & Shaft Collars

Sheet Metal Components & Parts

Solenoid Valves

Springs

Stainless Steel Bolts

Stainless Steel Fasteners

Stainless Steel Nuts

Stainless Steel Valves

Storage Systems

Storage Tanks

Submersible Pumps

Surface Finishing Equipment

Synthetic Industrial Diamonds

Testing & Measuring Equipment

Thermostatic Bimetals & Thermostats

Trolleys & Carts

Tungsten Carbide

Ultrasonic Equipment

V-Belts

Vacuum Equipment & System

Valves

Valves Fittings

Vibrating Screen

Washers

Water Coolers

Weighbridge

Welding & Soldering Supplies

Welding Electrodes

Welding Equipment

Winches

Wire Drawing Dies

Wire Rope Hoists

Wire Ropes