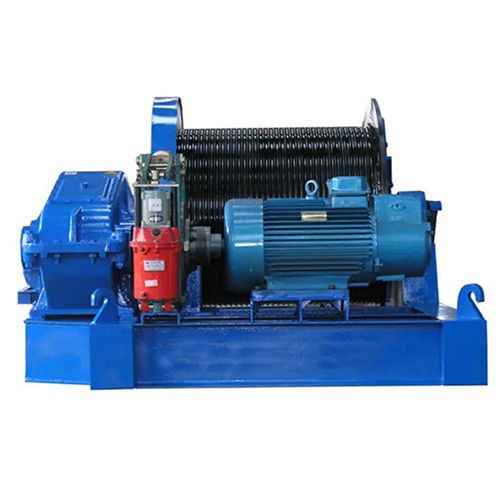

H Container Spreader

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | 6058 mm - 12192 mm |

| Weight | 9500 kg |

| Power | 9 kW |

| Electrical feed | 400 V / 50 Hz |

| Hydraulics | For 20 - 30 - 40 ft. containers |

| Probing | Inductive |

| Features | Container handling, Heavy lifting, Precise control, Efficient operation, Safe operation, Durable construction, Versatile application |

Product Overview

Key Features

CS 2040 H Container Hoist

CS - 2040 H container hoist's infrastructure consists of

middle frame, telescoping arms, telescoping gables, hydraulic,

electric and control system. Different operating functions can be

added by equipping the basic frame with accessories such as:

longitudinal moving of centre of gravity, longitudinal tilting,

rotating/turning, bail swing damping, head block connection or fixed

rope equipment.

CS - 2040 - BTR container hoist is

developed for constant and demanding use in changing and harsh

climate.

STRUCTURE

Telescoping arms

Box grid structure, material used: S355 SFS-EN and Raex steel. Guide tracks equipped with machinery. Grease lubrication for guide tracks.

Telescoping shafts

- Welded steel composition, material used: S355 SFS-EN.

- Guide tracks equipped with machinery

- Grease lubrication for guide tracks.

Telescoping gables

- Welded steel composition, material used: S355 SFS-EN.

- Attaching method of corner locks is so called floating construction.

- Equipped with corner steering wheel.

- Side and gable guides are firmly attached, the structure is flexible and collision-proof.

Hydraulics system

- Power unit designed from standard components especially to container hoist for demanding circumstances.

- Both gables equipped with own valve groups for controlling corner locks and controls.

- Piping and tubing are leak-proof and shock-resistant.

Electrical and control system

- Reservation for feeding and control cables (cabling from hoist is not included in the delivery).

- High-quality components.

- Weather-proof central case with cooler/heater.

- Marked wirings for terminal blocks.

- Logic controlled control and locking information.

Lubrication

Every lubrication point is equipped with lubrication nipple. Centralized and covered lubrication option available. Lubrication instructions are delivered with maintenance instructions.

Surface treatment

EPPUR120/2-FeSa2,5 ( = 120 ). Shade of color RAL 1006 ( yellow ). Different surface treatment on request.

Documents

Maintenance and operation instructions, CE certification, conformity assurance, spare part catalogue and related drawings are included in the delivery. Documents are also delivered in digital form.

Approvals

BOFO products designed and manufactured by Rannikon Konetekniikka Oy are manufactured from high-class materials and products are tested at factory before delivering them to customer. Manufacturing process always follows necessary standards and regulations set by authorities.

CONTAINER HOIST FUNCTIONS

Length adjusting of telescoping arms

- Length adjusting according to containers length is controlled from hoists cockpit

- Arms are resized to next pre-programmed length with selection extend / shorten

- At the length of 20 ft the telescoping arms calibrate themselves

- If the length of telescoping arms is changed due to a collision, the arms will resize themselves to the right length after corner locks are opened.

Corner locks

- Corner locks have open / close function, which is controlled from hoists cockpit

- State data is acquired from corner locks which is permission condition for lifting

- Open / close stance is secured both mechanically and electrically

- Corner locks can not be opened during the lift and lift cannot be performed if all four corner locks aren't open / close. Corner locks can be opened or closed only after container has been identified

- Corner locks can be opened also manually under special condition

- As standard equipment there is connection for hydraulic hand pump in both gables (each containing control for two corner locks). Hand pump can be acquired as an accessory.

Side and gable controls

Controllers have also up / down function which is controlled from hoists cockpit. Controlling: sides and gables separately or side + gable concurrently.

ACCESSORIES

Telescoping arms for 40t load

extra weight approx...1400 kg

Longitudinal moving of centre of gravity (hydraulically controlled)

- path+800

- extra weight approx...700 kg

Longitudinal tilting (hydraulically controlled)

- tilting angle +5

- extra weight approx. 500 kg

Limited manual turning (hydraulically controlled)

- path +15

- extra weight.2000 kg

Unlimited manual / automatic turning N x 360 degrees (hydraulically/electromechanically controlled)

extra weight approx .700 kg

Head block

Lifting capacity 50 tn

extra weight approx..3200 kg

Bail sway damping (hydraulic, manual control)

extra weight approx. 250 kg

ACCESSORIES FUNCTIONS

Telescoping arms for 40t load

Sturdy telescoping arms for extra large cargo. Makes it possible to handle a 40t, 40ft. container. Manouvres as standard version. NOTE! Unloaded weight of container hoist increases by 1400kg!

Longitudinal moving of centre of gravity

- Hydraulically moved carriage is controlled from hoists cockpit to obtain balanced state

- Path +800mm, movement time is about 15 sec for both directions

- Carriage is returned in center position automatically after releasing the corner locks

Longitudinal tilting

- To ease container handling on inclined plane

- Tilting angle +5 degrees. Movement time about 8 seconds to both directions

- Hydraulically controlled from hoists cockpit

Limited manual turning

- To ease the positioning the hoist and placing the container

- Hydraulically operated turning + 15 degrees, controlled from hoists cockpit

- Turning time about 10 seconds per 15 degrees

Unlimited manual turning

- To ease the positioning the hoist and placing the container

- Hydraulically operated turning N x 360 degrees, controlled from hoists cockpit

- Turning speed 1-1,5 / min

Automated beam following

To ease loading and unloading the container will keep it's position related to the hoists beam during the turning. Electrically operated rotation can be N x 360 degrees. Hoist is equipped with separated probe and control center. Customer is responsible for cabling he system.

Head block

An accessory for portal bridge cranes and portal cranes

Manually fitted and locked intermediate gantry on container hoist with pulleys for ropes.The size and location of head block's pulleys is always determined by customers hoist

Hydraulic bail sway damping

For damping the lifting ropes swinging in the multipurpose hoist. Loops for attaching to the lifting ropes. Damping with two hydraulic dampers. Adjustable damping sensitivity

General Technical Information

Main dimensions | |

Length | |

Telescoping arms min. extension | 6058 mm |

Telescoping arms max. extension | 12192 mm |

Width | 2440 mm |

Height | 1460 mm |

Electrical feed | 400 V ( 660 V ) / 50 Hz |

Unloaded weight approx. | 9500 kg |

Electrical feed | 400 V ( 660 V ) / 50 Hz |

Power consumption approx. | 9 kW |

Logical controller Siemens Simatic S7-200 | |

Lugs | 4 pcs |

Length adjusting | |

Hydraulic | For 20 - 30 - 40 ft. containers |

Probling | Pulse probe / inductive |

Side and gable controls | |

Hydraulic | |

No. of controllers | 2 + 2 + 1 + 1 ( tot. 6 pcs) |

Corner locks | 4 pcs |

Hydraulic movement | 90 degrees |

Structural movement | 7 mm |

Probing | Inductive |

Hydraulics | |

Main motor | 7,5 kW |

Oil volume approx. | 100 l |

Oil heating | 1,5 kW |

Company Details

Focusing on a customer-centric approach, BOFO SOLUTIONS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Material Handling Equipment in bulk from BOFO SOLUTIONS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

20

Establishment

2009

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Pune, Maharashtra

Project Manager

Mr. Manish Palwe

Address

Flat No.6, Sneha Society, Chaphalkar Colony, Market yard Road, Pune, Maharashtra, 411037, India

container spreader in Pune

Report incorrect details