- Tradeindia

- Material Handling Equipment

- Manual Stacker

Manual Stacker

(495 products)Manual Stacker Pump Repair Service - Mild Steel Material , Offline Inspection Services for Cylinder Equipment

3500 INR/Unit

MOQ1 Unit/Units

Wheel TypeOther, Polyurethane Wheels

FeaturesHigh-quality materials ergonomic handle design reliable performance

Lifting SpeedManual controlled speed

Handle TypeErgonomic

Rotation TypeFixed

Control SystemManual

View More

Durable Manual Hydraulic Paper Roll Stacker

Price : 40000 INR

Durable Manual Hydraulic Straddle Leg Stacker

Price : 45000 INR

Strong Manual Stacker Lift

Price : 40000 INR

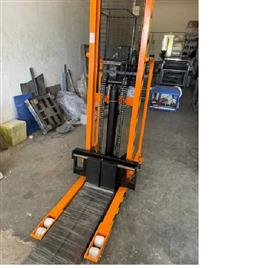

Fork Manual Stacker - Length: 900Mm & 1150Mm ( Forklenght ) Millimeter (Mm)

36000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

ConditionNew

Lifting Capacity500 Kilograms (kg)

Width550mm & 750mm ( ForkWidth ) Millimeter (mm)

Length900mm & 1150mm ( ForkLenght ) Millimeter (mm)

Warranty1 Year

Hydraulic Manual Stacker - Attributes: Durable

Price: 66500 INR/Unit

MOQ1 Unit/Units

Forkliftnil

Equipment Typenil

Lifting Speednil Km/s

Featuresnil

Motor Typenil

Handle Typenil

Lucrative Material Handling Industries

Faridabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

View More

Semi Electric Drum Stacker, Tilting: Manual/Electric

Get Best Deal

Durable Mild Steel Manual Hand Stacker

Price : 52000 INR

Hydraulic SS Manual Stacker

Price: 185000 INR/Number

MOQ1 Number

FeaturesStainless steel construction provides durability and resistance to corrosion

Handle TypeErgonomic handle

ForkliftManual Stacker fork mechanism

Control SystemManual

Wheel TypeOther, PU wheels for smooth movement

ConditionNew

Forcelift Material Movements

Bengaluru

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller5 Years

View More

Manual stacker or Hand Stacker

Price : 45000 INR

Industrial Manual Winch Stacker

Price : 45000 INR

Yellow Industrial Ms Manual Stacker

Price : 40000 INR

Industrial Hand Pallet Stacker - Mild Steel, 1.5 Tonne Capacity | Manual Operation, Compact Design, New Condition, 1 Year Warranty

Price : 43000 INR

Mini Manual stackers

Price : 40000 USD ($)

Manual Stacker By Action Construction Equipment Ltd.

Handle TypeErgonomic Manual Handle

Lifting SpeedManual Operation

Rotation TypeFixed

Control SystemManual

FeaturesCompact Durable and Efficient

Wheel TypePolyurethane Wheels, Other

Action Construction Equipment Ltd.

Faridabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller10 Years

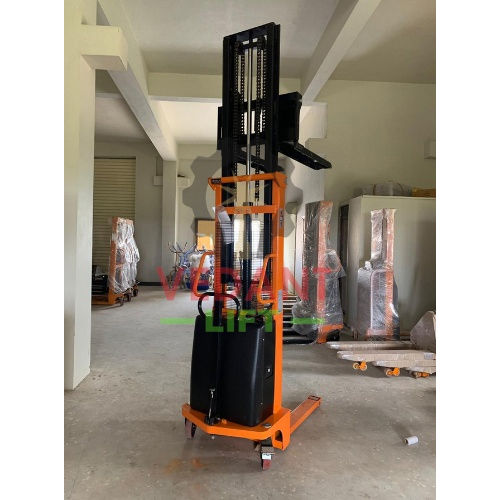

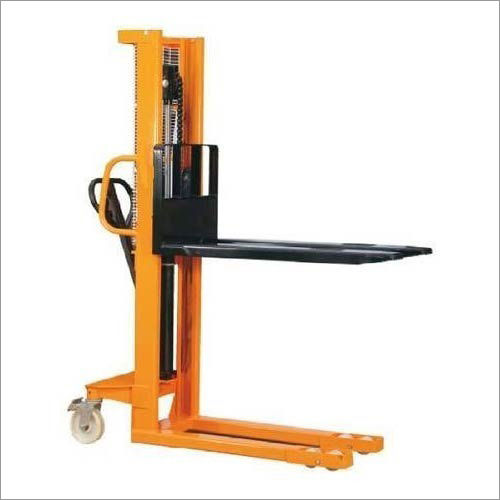

Manual Stacker By Shri Vinayak Packaging Machine Pvt. Ltd.

MOQ1 Unit/Units

UsageIndustrial

ColorOrange & Black

Product TypeManual Stacker

Equipment TypeManual Stacker

ConditionNew

Power SourceElectric

Shri Vinayak Packaging Machine Pvt. Ltd.

New Delhi

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller21 Years

View More

Pallet Stacker Lifting Capacity: 1600 Kilograms (Kg)

Price Trend : 35000.00 - 100000.00 INR

Manual Pallet Stacker Application: Industrial

Get Best Deal

Yellow/Orange/Red Manual Hook Stacker

Price: 40000 INR/Unit

MOQ1 Unit/Units

ColorYellow/Orange/Red

Equipment TypeLifting equipment

UsageIndustrial

ConditionNew

Size1800X1250X1950

Lifting Capacityup to 2000 Kilograms (kg)

Helix Engineers

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

View More

Manual Hydraulic Stacker - Strong Yellow Design, 1000 kg Lifting Capacity | Easy To Operate, 1 Year Warranty

Price : 38000 INR

Manual Hydraulic Hand Pallet Stacker - 1 Ton Capacity, 2 Meter Lifting Height, Yellow Color | Strong, Easy To Operate, 1 Year Warranty

Price : 40000 INR

Hydraulic Manual Pallet Stacker - New, Yellow | Strong, Easy to Operate, 12 Months Warranty

Price : 42000 INR

Strong Manual Stacker Machine

Price : 37000 INR

Industrial Manual Stacker - 250kg Lifting Capacity, Max Load 500kg | Durable Strong Manual Material Handling Equipment

Price: 42000.0 INR/Unit

MOQ1 Unit/Units

Equipment TypeMaterial Handling

FeaturesDurable

ConditionNew

SizeStandard

Lifting Capacity250 Kilograms (kg)

Product TypeIndustrial Manual Stacker

Manual Stackers

Product TypeManual Stacker

Sealed BearingsYes

Pu WheelsYes

Body MovementsReduced

Maintenance FreeYes

Molds TransportYes

Maini Materials Movement Pvt. Ltd.

Bengaluru

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

FIE-111 Manual Pallet Stackers

Price: 40000 INR/Unit

MOQ1 Unit/Units

Wheel TypeOther, Polyurethane wheels

Rotation TypeFixed Mast

FeaturesEasy to maintain, corrosion resistant

ForkliftNo (Manual Stacker)

Control SystemHand/Foot Hydraulic pump

Lifting SpeedManual, depends on operator

Future Industries Pvt. Ltd.

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller17 Years

View More

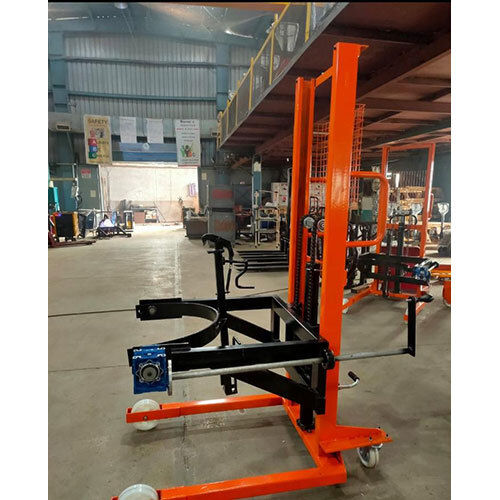

Drum Stacker Machine - Attributes: Easy To Operate

Price : 40000 INR

Manual Hand Stacker - Attributes: Strong

Price : 48000 INR

Portable Stacker - 400 kg Lifting Capacity, Yellow and Black Color, Mini Portable Design | Ideal for Industrial Use and Space Optimization

Price : 35000.00 INR

Hydraulic Pallet Stacker Lifting Capacity: 2-5 Tonne

Price : 40000 INR

Fie-112 1 Ton Manual Stacker - Attributes: Strong

Price : 90000 INR

Manual Double Mast Hand Stacker - Attributes: Durable

Price: 165000 INR/Piece

MOQ1 Piece/Pieces

ColorYellow, Black

Equipment TypeManual Double Mast Hand Stacker

UsageIndustrial

ConditionNew

Sizecustomized

Product TypeMild Steel Manual Double Mast Hand Stacker

View More

Manual Roll Stacker - Attributes: Durable

Price : 95000 INR

Manual Pallet Stacker - Load Capacity: 1800 Kilograms (Kg)

Price : 45000 INR

Manual Hand Stacker - Strong Manual Equipment, Orange Color, New Condition | 1-Year Warranty, Ideal for Industrial Usage

Price : 75000.00 INR

Manual Hydraulic Stacker - Attributes: Strong

Price : 55000 INR

Hydraulic Manual Hand Stacker, Type: Fork Stacker

Get Best Deal

Manual Stacker Height: Max 2100Mm Millimeter (Mm)

Price: 45000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

Equipment TypeManual Stacker

ConditionNew

HeightMax 2100mm Millimeter (mm)

Lifting Capacity2000 kg Kilograms (kg)

Max. Lifting Load1000 Kilograms (kg)

Siddh Krupa Steel Fab

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller10 Years

View More

Yellow Hydraulic Manual Stacker

Price : 45000 INR

Orange Hydraulic Manual Stacker (Double Mast)

Price : 75000 INR

Wall Mounted Single Mast Stacker Power Source: Hydraulic

Price: 25000 INR/Unit

MOQ1 Unit/Units

Equipment TypeConstruction Wall Mounted Single Mast Stacker

ConditionNew

Power SourceHydraulic

WarrantyYes

India Hydraulics & Elevators

Faridabad

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller12 Years

Verified Seller

Verified SellerView More

Fork Type Manual Stacker

Get Best Deal

Manual Stacker - 2000 kg Capacity, 2100 mm Lift Height | Eco-Friendly Manual Operation, 12 Month Warranty

Price: 45000 INR/Unit

MOQ1 Unit/Units

UsageMaterial Handling

ConditionNew

Lifting Capacity2000 Kilograms (kg)

Max. Lifting Height2100 Millimeter (mm)

Power SourceManual

Width600 Millimeter (mm)

FAQs Related to Manual Stacker

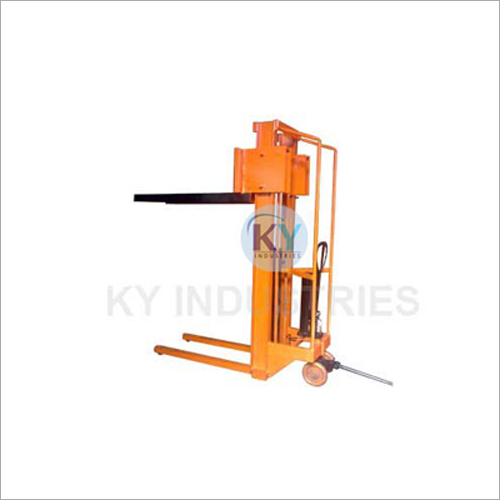

Who are the top manual stacker manufacturers in India?

- Shri Vinayak Packaging Machine Pvt. Ltd.

- Servo Tech India

- Future Industries Pvt. Ltd.

- Urja Systems

- India Hydraulics & Elevators

- K Y Industries

- Action Construction Equipment Ltd.

- Siddh Krupa Steel Fab

- Sai Samarth Industries

- Mahindra Stiller Auto Trucks Limited

Which cities have the largest number of manual stacker suppliers?

- Pune

- Mumbai

- Chennai

- Bengaluru

- Kolkata

- Delhi

- Hyderabad

- Jaipur

- Ahmedabad

- Coimbatore

- Faridabad

- Vadodara

- Surat

- Gurugram

- Noida

- Thane

- Rajkot

- Ghaziabad

- Ludhiana

- Indore

What is the price range for manual stacker offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| Gaison Material Handling Private Limited | INR | Manual Stacker | 35000 |

| TECHNOSYS EQUIPMENT | INR | Manual Stackers | 50000 |

| Ventra Locomotives Pvt. Ltd. | INR | Manual Stacker | 45000 |

| TRIRATNA ENTERPRISES | INR | Manual Stacker | 40000 |

| Swastik Hydraulics And Racking System | INR | Manual Stacker | 48500 |

| Seemax Resources Ltd. | INR | Manual Stacker | 65000 |

| Perfectto Engineering | INR | Stainless Steel Manual Stacker | 22000 |

| SHYAM PLASTIC INDUSTRIES | INR | Fully Automatic Stacker | 225000 |

| SITARAM ENGINEERING WORKS | INR | Manual Stacker | 38500 |

How many trusted sellers are available for manual stacker?

- LUCRATIVE MATERIAL HANDLING INDUSTRIES

- FORCELIFT MATERIAL MOVEMENTS

- ACTION CONSTRUCTION EQUIPMENT LTD.

- SHRI VINAYAK PACKAGING MACHINE PVT. LTD.

- HELIX ENGINEERS

- INHYMA SOLUTIONS LLP

- MAINI MATERIALS MOVEMENT PVT. LTD.

- FUTURE INDUSTRIES PVT. LTD.

- VEDANT LIFT

- SIDDH KRUPA STEEL FAB

- INDIA HYDRAULICS & ELEVATORS

- JAYKSHIT INDUSTRIES

- K Y INDUSTRIES

- 4g international

- A.K ENGINEERING

- SAI SAMARTH INDUSTRIES

- Shree Raj International Private Limited

- LIFT MECH INDUSTRIES

- Globe Machmovers

- URJA SYSTEMS

- PRIME ENGINEERS

- SERVO TECH INDIA

- HUNTER EQUIPMENTS

- STACKLIFT EQUIPMENTS PRIVATE LIMITED

- M/S SAMRUDHI ENGINEERS

- MEDHINI ENGINEERING SERVICES

- MAHINDRA STILLER AUTO TRUCKS LIMITED

- UNICORN CORPORATION

What is the minimum order quantity for manual stacker?

Do listed companies have registration & certifications?

- HELIX ENGINEERS

- MAINI MATERIALS MOVEMENT PVT. LTD.

- K Y INDUSTRIES

- SERVO TECH INDIA

What is the get latest price feature?

What types of payment methods are accepted by the manual stacker suppliers?

Material Handling Manual Stacker

FeaturesDurable construction Easy maneuverability

Control SystemManual

Wheel TypeOther, Polyurethane Wheels

Handle TypeErgonomic

ForkliftNo

Lifting SpeedManual speed dependent on operator

View More

Manual Stacker 1.5 and 2 mtr

Get Best Deal

Manual Stacker By K Y Industries

Get Best Deal

Manual Stacker 2 Ton Capacity

Get Best Deal

Self Loading Stacker - Color: Blue

Price: 65000.0 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

ConditionNew

UsageIndustrial

SizeAll size

Product TypeSelf Loading Stacker

Loading Capacity1000 Kilograms (kg)

View More

Manual Stacker - 2000kg Lifting Capacity, New Industrial Equipment - Yellow Finish, 1 Year Warranty

Price : 61500.0 INR

Manual Stacker - Application: Warehouse

Price : 32500 INR

Manual Stacker ( H Channel ) - Color: Yellow

Price : 29000 INR

Hydraulics Manual Stackers - Heavy-Duty Steel, Ergonomic Design , Load Capacity of 2000 kg

Price: 45000 INR/Pallet

MOQ1 Ton/Tons

FeaturesAdjustable Fork Width, Foot Brake for Safety

Lifting SpeedManual, Dependent on Operator

Equipment TypeStacker

Wheel TypeOther, Polyurethane Swivel & Fixed Wheels

Control SystemManual Hydraulic Pump

Rotation TypeFixed Direction

A.K Engineering

New Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller5 Years

Hydraulic Manual Hand Stacker - Lifting Capacity: 500-100000 Kilograms (Kg)

Price: 1 INR/Piece

MOQ1 Piece/Pieces

ConditionNew

Lifting Capacity500-100000 Kilograms (kg)

Max. Lifting Load100000 Kilograms (kg)

Power SourceHydraulic

AttributesStrong, Durable, Easy To Operate, Rust Proof, Flame Proof, Consume Less Power, Other

View More

Drum Stacker - Attributes: Durable

Price : 1 INR

Hydraulic Manual Stacker With Hand Pump

Price Trend : 420000.00 - 65000.00 INR

Manual Hydraulic Stacker - Mild Steel, 1000 kg Capacity, 1500 mm Lift Height, 1200 mm Fork Length, Orange Color , Easy to Operate, Maintenance Free

Price Trend : 38500.00 - 65000.00 INR

Stacker Machine - Attributes: Easy To Operate

Price: 48000 INR/Unit

MOQ1 Unit/Units

ColorORANGE, YELLOW

UsageIndustrial

Equipment Typematerial handling equipment

MaterialIron

ConditionNew

Size2050*1100*150

Shree Raj International Private Limited

Kolkata

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

Hydraulic Manual Stacker Height: 2200 Millimeter (Mm)

Price: 40000 INR/Unit

MOQ1 Unit/Units

Usageindustrial

TypeOther

Height2200 Millimeter (mm)

Product TypeHydraulic Manual Stacker

Length1750 Millimeter (mm)

Manual Wide Leg Hydraulic Stacker - Mild Steel, 1500 kg Load Capacity, 400 mm Lift Height | Durable, Easy to Operate, Stylish Orange-Black Finish, 12-Month Warranty

Price: 60000 INR/Piece

MOQ1 Piece/Pieces

ColorOrange-Black

Equipment TypeStacker

UsageIndustrial

ConditionNew

Lifting Capacity1500 Kilograms (kg)

Product TypeManual Wide Leg Hydraulic Stacker

Manual Stacker - Attributes: Durable

Price: 80000.0 INR/Piece

MOQ1 Piece/Pieces

ConditionNew

UsageIndustrial

Equipment TypeManual Stacker

Product TypeManual Stacker

Weight240 Kilograms (kg)

Power SourceElectric

Urja Systems

Greater Noida

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller14 Years

Manual Stacker 2 Ton - Attributes: Strong

Price: 26000 INR/Unit

MOQ1 Unit/Units

ColorOrange

UsageIndustrial

Equipment TypeStacker

ConditionNew

SizeAll size

Product TypeManual Stacker

View More

Manual Stacker 1 Ton - Attributes: Strong

Price : 21000 INR

Manual Stacker With Tilter - Attributes: Strong

Price : 182.0 INR

Holden Yellow Manual Hydraulic And Electric Stackers

Price : 65000.00 INR

Manual Stacker - Color: Yellow Black

Price: 42000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

SizeStandard

ColorYellow Black

TypeOther, Manual Stacker

MaterialMild Steel

Power SourceManual

Strong Manual Hand Operated Stacker

Price: 36000 INR/Unit

MOQ100 Unit/Units

ColorYellow & Black

UsageIndustrial

Equipment TypeManual Hand Operated Stacker

ConditionNew

Product TypeManual Hand Operated Stacker

Power SourceManual

Hunter Equipments

Chennai

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

View More

Manual Hand Stacker - Rated Load Capacity 500 Kg, Max Fork Height 1600 Mm, Durable Yellow and Red Design, Low Maintenance, Easy to Operate

Price : 35000 INR

Mild Steel Manual Hand Operated Stacker - Rated Lifting Capacity 500-2000kg, Durable Design, Low Maintenance, Color Coated Finish

Price : 36000 INR

Strong 1000Kg Capacity Manual Stacker

Price : 30000 INR

Hydraulic Hand Stacker - Mild Steel, 1400 mm Lifting Height, Yellow/Red/Blue/Black | Durable, Easy to Operate, High Work Capacity, Low Maintenance

Price : 36000 INR

Durable Hunter Manual Stacker

Price : 35000 INR

Yellow Manual Stacker

MOQ1 Unit/Units

Equipment TypeTrolley

UsageIndustrial

ConditionNew

SizeDifferent Size

Product TypeManual Stacker

ColorYellow

Stacklift Equipments Private Limited

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller3 Years

Manual Hydraulic Stacker - Stainless Steel, Lifting Height 1500/3000/1600 mm, Load Capacity 1000/2000 kgs, Color Black & Red, Strong & Rugged Design

Price: 36800.00 INR/Piece

MOQ1 Piece/Pieces

Control Systemyes

Colorblack and red

Equipment Typestainless steel

ConditionNew

Power SourceElectric

AttributesStrong

M/s Samrudhi Engineers

Hyderabad

Trusted Seller

Trusted Seller Super Seller

Super Seller6 Years

Manual Stacker - Color: Yellow

Price: 75000.00 INR/Unit

MOQ4 Unit/Units

ColorYellow

Metal TypeMild Steel

Load Capacity1000 Kilograms (kg)

Product TypeManual Stacker

MaterialSteel

Plastic TypeHDPE

Manual Stacker By Mahindra Stiller Auto Trucks Limited

Price: 468000 INR/Unit

MOQ1 , Unit/Units

Supply Ability9-10 Per Month

Delivery Time6-8 Week

Mahindra Stiller Auto Trucks Limited

Faridabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller9 Years

Manual Winch Stacker - Attributes: Durable

Price: 30000 INR/Unit

MOQ10 Unit/Units

Equipment TypeStacker

UsageIndustrial

ConditionNew

Power SourceManual

FeatureGood Quality

WarrantyYes

Unicorn Corporation

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

Popular Manual Stacker

Discover How Manual Stackers Make Material Handling Jobs So Easy?

Material Handling operations are very critical. There can be no mistakes, because of which the working environment becomes dangerous. Several industries carry out material handling tasks using manual stackers including lifting, stacking, and transporting various equipment. These efficient equipment offer high performance, swift operations, flexibility, and safety. This article highlights the benefits, applications, and features of manual stackers to understand how they make material handling jobs so easy.

Major Benefits of Manual Stackers

-

Cost Effective

Compared to other types of material handling equipment, manual stackers are highly cost-effective. They have low upfront investment, neither use electricity nor fuel to run and with simple design, their parts are easily available for replacement.

-

Versatile

Manual stackers can carry out material handling tasks in almost every environment, lifting and moving every type of material, palletized load, crates, boxes, etc. Equipped with size-adjusting forks, they can handle every type of weight. This makes them versatile for several industrial applications.

-

Compact Design

Manual stackers are compact and efficiently maneuverable in confined spades, narrow passages, and low-space workstations. They can be easily turned and move forward & backward in confined spaces with efficiency.

-

Easy to Use

The working principle and design of manual stackers are not so overly complicated. They are easy to operate with just a short training period of a few hours. The controls are very simple and all the functions can be used with one push button.

-

No Power Medium

Manual stackers function and are operated using any external power source. They neither require fuel nor electricity to perform material handling tasks. Because of this reason, they can be used for hours continuously in remote areas or sites without a power medium.

-

Low Maintenance

Manual Stackers are assembled using very few components in comparison to electric or fuel-powered sackers, reducing their maintenance requirements. With only routine inspection and oiling sessions they can return to tip-top condition.

-

Improved Safety

Designed by leading manufacturers, manual stackers come equipped with enhanced safety features such as overload protection, emergency brakes, safety release valves, etc to protect operations from any type of injuries at work. These operations can work with peace of mind, efficiently, and complete material handling operations swiftly.

-

Environmental Friendly

Manual stackers produce zero submissions because they do not rely on electricity or fuel to function. During the operations, they are operated through workers manually. This makes them environmentally friendly promoting sustainability across the globe.

-

Maneuverability

Manual stackers are easy to operate, equipped with wheels, they have enhanced maneuverability, even in confined spaces. Their unique design and swivel casters offer improved mobility and control, allowing operators to easily avoid obstacles while operating.

-

Reliability

Manual Stackers being high-performance, durable, versatile, and easy to maneuver, are very reliable material handling equipment. Developed using the highest grade raw materials they are designed to be operated in the harshest environment, offering peak performance levels.

Applications of Manual Stackers

-

Warehousing

Manual stackers are widely used in warehouses for tasks such as loading and unloading pallets, stacking goods on shelves, and transporting materials within the facility. They are essential tools for inventory management and order fulfillment processes.

-

Manufacturing

In manufacturing facilities, manual stackers are used for moving raw materials, components, and finished products between production areas. They help streamline workflow and facilitate efficient material handling operations on the factory floor.

-

Retail

Retail stores and distribution centers utilize manual stackers for handling merchandise, stocking shelves, and organizing inventory. They are especially useful for small-scale lifting and stacking tasks in retail environments.

-

Construction

Manual stackers are employed in construction sites for lifting and positioning building materials such as bricks, blocks, and bags of cement. They aid in construction activities such as masonry work, landscaping, and renovation projects.

-

Workshops

In workshops and maintenance facilities, manual stackers assist with lifting heavy machinery, equipment, and tools. They enable workers to safely maneuver and position objects for repair, assembly, or maintenance tasks.

-

Transportation and Logistics

Manual stackers play a role in transportation and logistics operations, where they are used for loading and unloading cargo from trucks and containers. They help optimize space utilization and facilitate the movement of goods in distribution centers and freight terminals.

-

Food and Beverage Industry

In food processing plants, breweries, and commercial kitchens, manual stackers are utilized for handling palletized goods, packaging materials, and bulk ingredients. They ensure efficient material flow and compliance with hygiene standards in food handling environments.

-

Agriculture

In agricultural settings such as farms and nurseries, manual stackers assist with lifting and transporting supplies like bags of feed, fertilizer, and seedlings. They help farmers and growers streamline harvesting, storage, and distribution activities.

-

Event Management

Manual stackers are used in event venues and exhibition halls for setting up temporary structures, stages, and booths. They facilitate the installation and removal of equipment and supplies for trade shows, concerts, and other large-scale events.

-

Small Businesses

Manual stackers are popular among small businesses and startups that require cost-effective solutions for material handling. They provide a versatile and practical alternative to larger, powered equipment, enabling efficient operations in limited workspace environments.

What is the Weight Lifting Capacity of a Manual Stacker?

The weighing capacity of manual stackers depends upon the different types of models:

-

Light Manual Stackers

These types of manual stackers are used for small-scale material handling operations having a weighing capacity between 500 kg to 1000 kg. Light manual stackers are preferred when occasional lifting operations are carried out.

-

Medium Capacity Manual Stackers

Medium-class manual stackers are designed for lifting heavier loads than light manual stackers, with a weighing capacity ranging from 1000 kgs to 2000 kgs. These are most commonly hired for frequent material handling operations in warehouses, workshops, and many industrial spaces.

-

Heavy Duty Manual Stackers

With a weighing capacity of more than 2000 kg, heavy-duty manual stackers are employed for large-scale material handling operations. These stackers are extensively hired for industrial spaces including manufacturing units, large warehouses, automotive industry, etc.

What Safety Features Are Available on Manual Stackers?

Here are the major safety features installed on manual stackers to make the working environment extremely safe for workers:

-

Overload Protection

Many manual stackers are equipped with overload protection mechanisms that prevent the lifting of loads exceeding the stacker's rated capacity. This feature helps to avoid overloading the equipment, which can lead to instability and potential accidents.

-

Safety Release Valve

A safety release valve is designed to prevent over-pumping of the hydraulic system, which could cause damage to the stacker or result in sudden lowering of the load. The valve ensures controlled descent of the load in the event of hydraulic failure or operator error.

-

Braking System

Manual stackers may feature a braking system to prevent unintended movement while the stacker is stationary or in transit. This helps to enhance stability and safety during loading, unloading, and stacking operations.

-

Stability Enhancements

To prevent tipping and ensure stability during lifting and maneuvering, manual stackers often feature wide-set legs, stabilizing outriggers, or additional support structures. These features help to distribute the weight evenly and maintain balance, especially when handling heavy or bulky loads.

-

Foot Guards and Safety Toe Caps

Some manual stackers are equipped with foot guards or safety toe caps to protect operators' feet from accidental contact with the stacker's moving parts or the load being lifted. This helps to minimize the risk of foot injuries during operation.

Client Testimonials & Reviews

YougenderPandita

NEW INDIA EQUIPMENTS

In todays world, We are surrounded by so many Business portals. As we are on different portals, but the experience with tradeindia is exceptionally the best in every aspect. whether flow of enquirers, genuine & positive enquirers.The support of the tradeindia team. I highly appreciate your cooperation.

Ia m very excited to write to express my thanks to you. From the beginning of tradeindia membership, with your guidance and hard working, I have started the google campaign service, also you give me a lot of valuable information and advises, which help me increase the quantity and quality of inquiry. The deep impression to me is your dedication in work. For my website resign, during past 1 month, you spent lots of personal effort to optimize the website, and update the product details and confirm with you one by one, during the process, we have so many emails back and forth, and you make so many voice calls to me to confirm and guarantee the website and campaign quality. This is the reason I continue the trust to you and your tradeindia team. Your professional attitude and patience indeed impress me, and I expect to get more positive effect and inquiries with you and your team's work, really appreciate you and your team's hard working, let's look forward to better feedback and we do the long team collaboration.

ANU

URJA SYSTEMS

Tradeindia is good platform for business promotion, we are happy with the services of tradeindia.com.

ShreekantNalawade

MB CRUSHER INDIA PRIVATE LIMITED

We are grateful for quick responses and proactive communication. Your team's efficiency and professionalism have made our partnership seamless.

FuleshPatel

Mansi Instruments

We are thankful to tradeindia.com for its services and promotion of our products. We wish good luck.

VishalChauhan

MM DESPRO ENGINEERING PVT. LTD.

We thanks for your kind valuable support as tradeindia team members or web promotion partner which help us to connect with new valuable customers to grow business circle/activity.

ShrenikJithra

AMRATLAL CHHAGANLAL

We M/S Amratlal Chhaganlal and Co are member of tradeindia.com for the past 3 years. We would really like to appreciate the working of tradeindia.com and their team members. They are very friendly, helpful and understanding in their behavior. We are the Manufacturer, Exporter, Supplier, Trader and Service Provider for a gamut of industrial accessories like Open socket, Closed socket, Ratchet lever hoist, Single legged chain sling, Two legged chain sling, Three legged chain sling, Four legged chain sling, Plate lifting clamps, Vertical lifting clamps, Horizontal lifting clamps and we are getting good quarries via this portal from the very beginning. Their service Executive Mr. Sandeep Chandankhede used to visit us from time to time and hence we are getting good chance to express our views and suggestions for the better services. Tradeindia portal is one of the best business portal and we have been a regular advertiser on its portal. We are really benefited and we have increased business and our presence in the domestic markets by advertising in our category. We are happy and satisfied with the service and response from tradeindia.com, hence would like to continue with them in the ensuring years. We wish the tradeindia team of professionals good luck for their hard work and bright future ahead.

BanojMohanty

UTKAL ENGINEERS

We are associate with tradeindia.com since 2 years. We are happy to announce that tradeindia.com is very good B2B portal and we receive very good and general inquiries from your services. We satisfied with your services. We are one the leading manufactures and Trade of Gujarat raising our network across India for which 2 year back we associated with Tradeindia.com and getting nice genuine inquires

IrshadAlam

SAIFI CON-FAB SYSTEM PVT. LTD.

We have been associated with M/s. Infocom Network Ltd., for more than decade and feel happy to say that, your services has been excellent during our courtship and has become our effective marketing tool to explore the national and international market. We wish to continue with your improving services in years to come. All the best for Trade India team.

MayurWelekar

VIKRANT CRANES INDIA PVT.LTD.

We are associated with tradeindia since long time back. We have grown our business with the support of tradeindia, and able to achieve new heights. We would like to continue our relationship with tradeindia in the coming years also.

Manual Stacker Price List

Product Name | Expected Price |

|---|---|

| Manual Stacker | 35000 |

| Manual Stackers | 50000 |

| Manual Stacker | 45000 |

| Manual Stacker | 40000 |

| Manual Stacker | 48500 |

| Manual Stacker | 65000 |

| Stainless Steel Manual Stacker | 22000 |

| Fully Automatic Stacker | 225000 |

| Self Loading Stacker | 82500 |

| Manual Stacker | 38500 |

This Data was Last Updated on 2025-12-19

Manual Stacker Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Shri Vinayak Packaging Machine Pvt. Ltd. New Delhi, India | 21 Years |

Servo Tech India Alwar, India | 19 Years |

Future Industries Pvt. Ltd. Ahmedabad, India | 17 Years |

Urja Systems Greater Noida, India | 14 Years |

India Hydraulics & Elevators Faridabad, India | 12 Years |

K Y Industries Ahmedabad, India | 11 Years |

Action Construction Equipment Ltd. Faridabad, India | 10 Years |

Siddh Krupa Steel Fab Ahmedabad, India | 10 Years |

Sai Samarth Industries Ahmedabad, India | 10 Years |

Mahindra Stiller Auto Trucks Limited Faridabad, India | 9 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

INTERNATIONAL CAFE AND BEVERAGE SHOW (ICBS) 2026

Thu, 07 May, 2026 - Sat, 09 May, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories