- Tradeindia

- Trolleys & Carts

- Drum Lifter Trolley

Drum Lifter Trolley

(242 products)Drum Lifter Trolley Max. Lifting Height: 1000-1250 Mm

Price: 120000 INR/Piece

MOQ1 Unit/Units

Equipment TypeDrum Lifter Trolley

ConditionNew

Max. Lifting Height1000-1250 mm,1600 /3000 mm Millimeter (mm)

Future Industries Pvt. Ltd.

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller16 Years

Manual Drum Trolley - Material: Steel

Price: 7900 INR/Piece

MOQ100 Piece/Pieces

Product TypeTrolley

Trailer TypeSemi Trailer

Trailer UseOther

Brown Two Wheeler Drum Lifter Trolley

Price: 3500 INR/Piece

MOQ1 Piece/Pieces

ColorBrown

Product TypeTwo Wheeler Drum Lifter Trolley

UsageIndustrial & Commercial

Aaradhya Industries

Ahmedabad

Trusted Seller

Trusted Seller2 Years

Super Premium

Super PremiumDrum Pallet Truck Dimensions: 1025 X 915 X 1180 Millimeter (Mm)

Price Trend: 15000.00 - 50000.00 INR/Piece

MOQ1 Piece/Pieces

Weight75 Kilograms (kg)

ConditionNew

Rated Capacity300 Kg

Shri Vinayak Packaging Machine Pvt. Ltd.

New Delhi

Trusted Seller

Trusted Seller19 Years

Super Seller

Super SellerDurable Drum Jockey Handlers

Price: 45000.00 INR/Unit

MOQ1 Unit/Units

Weight16 Kilograms (kg)

UsageFor Drum Handling to Make It Empty

ConditionNew

Four Wheel Drum Trolley Capacity: 400 Kg/Hr

Price: 500000 INR/Set

MOQ1 Set/Sets

Colorother

MaterialStainless steel, Other

TypeMilling, Turning, Laser Machining, Other, Drilling, Broaching, Chemical Machining, Etching

Drum Trolley - Color: Blue

Price: 12500.0 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

SizeAll size

ConditionNew

Strong Drum Trolley

Price: 2600 INR/Piece

MOQ500 Piece/Pieces

UsageIndustrial

ConditionNew

Power SourceManual

Strong Drum Handling Trolley

Price: 5500 INR/Piece

MOQ1 Piece/Pieces

Product TypeDrum Handling Trolley

UsageIndustrial

ColorBlue

Mild Steel Drum Lifter Trolley

Price: 7200 INR/Unit

MOQ1 Unit/Units

Usageindustrial

Product TypeDrum Lifter Trolley

ConditionNew

Strong Drum Tilter Trolley

MOQ10 Unit/Units

SizeDifferent Sizes Available

ConditionNew

FeatureHigh Quality

Stacklift Equipments Private Limited

Pune

Trusted Seller

Trusted Seller2 Years

Super Seller

Super SellerDurable Drum Stacker

Price: 1 INR/Piece

MOQ1 Piece/Pieces

Length3-8 Meter (m)

Height3-8 Meter (m)

Weight230 Kilograms (kg)

Top Rated Products

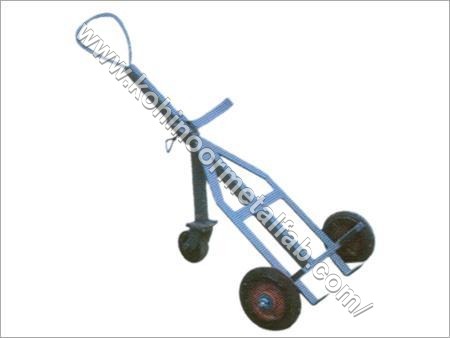

Manually Hand Operated Polished Finish Moveable 3 Wheeler Drum Lifter Trolley

Liftwell Engineers & Traders

FAQs Related to Drum Lifter Trolley

200L Oil Drum Trolley - Material: Iron

Price: 1210 USD ($)/Set

MOQ5 Set/Sets

Product TypeTrolley

Trailer TypeOther, Oil Drum Trolley

Trolley UseIndustrial

Jo Long Machine Industrial Co., Ltd.

Dali

Trusted Seller

Trusted Seller6 Years

Premium Seller

Premium SellerHydraulic Drum Lifting Trolley Body Material: Steel

Price: 29000 INR/Unit

MOQ1 Unit/Units

Product TypeHydraulic Drum Lifting Trolley

SizeDifferent Available

ColorYellow

Caretech Engineering

Chennai

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerDrum Stacker Manual Vinxdhs400 - Color: As Per Requirement

Price: 58500 INR/Unit

MOQ1 Unit/Units

ColorAs per requirement

Product TypeDrum Stacker

UsageIndustrial

Drum Lifter Trolley - 500 kg Lifting Capacity, Blue Color | 12 Months Warranty, Manual Power Source, New Condition

Price: 7500 INR/Unit

MOQ1 Unit/Units

ColorBlue

UsageIndustrial

Product TypeManual

Durable Drum Lifter Tilter

Price: 50000 INR/Unit

MOQ1 Unit/Units

Product TypeMATERIAL HANDLING EQUIPMENT

UsageIndustrial

ColorGolden ellow

Drum Trolley

Price Trend: 5000.00 - 32000.00 INR/Unit

MOQ100 Unit/Units

Supply Ability1000 Per Month

Delivery Time7 Days

Main Export Market(s)Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Easy To Operate Color Coated Mild Steel Three Wheel Drum Lifter Trolley (Loading Capacity 0-200 Kg)

Price: 5700 INR/Unit

MOQ1 Unit/Units

Product TypeDrum Lifter Trolley

UsageMaterial Handling use

Equipment TypeDrum Lifter Trolley

Manually Hand Operated Polished Finish Moveable 3 Wheeler Drum Lifter Trolley

UsageFor Transport Barrel from One Point to Another

SizeStandard

Product TypeDrum Lifter Trolley

Liftwell Engineers & Traders

Faridabad

Trusted Seller

Trusted Seller4 Years

Premium Seller

Premium SellerStrong Manual Drum Tilter And Lifter

MOQ1 Unit/Units

UsageFor Industrial Use

ColorOrange & Blue

Equipment TypeTilter and Lifter

Wheeled Overpack Drum 50 Gallons - Application: Industrial

Price: 17500 INR/Piece

MOQ1 Piece/Pieces

Product TypeWheeled Overpack Drum 50 Gallons

ColorYellow

MaterialPlastic

952Ex Drum Rollers Compactors Commercial

MOQ10 Unit/Units

General UseCommercial

MaterialStainless Steel

ComputerizedNo

Case New Holland Construction Euipment India Private Limited

Gurugram

Trusted Seller

Trusted Seller2 Years

Premium Seller

Premium SellerMild Steel Three Wheel Drum Lifter Trolley Application: Industrial

Price: 5000 INR/Unit

MOQ2 Number

TypeLifter Trolley

MaterialMild Steel

ApplicationIndustrial

Maa Rajdevi Steel & Fabrication Works

Gurugram

Trusted Seller

Trusted Seller3 Years

Premium Seller

Premium SellerFloor Cleaner Trolley Length: Standrard Inch (In)

Price: 4800 INR/Piece

MOQ1 Piece/Pieces

Product TypeTrolley

Trailer UseOther

Trolley UseIndustrial, Storage, Other, Travel

Mahalaxmi Industries

Delhi

Trusted Seller

Trusted Seller20 Years

Premium Seller

Premium SellerDrum Tilter

Product DescriptionWe are involved in manufacturing and supplying a wide range of Drum Tilter in Noida, Uttar Pradesh, India. Our range of Drum Tilter is widely appreciated by our clients which are situated all round the nation. Ideal for materials handling industry. Moreover, it can be availed at manageable price

Three Wheel Drum Lifter Trolley 3, No Of Wheels: 3

Product DescriptionThree Wheel Drum Lifter Trolley

Drum Lifter - Automatic Grade: Semi-Automatic

Price: 63000.00 INR/Piece

MOQ1 Piece/Pieces, Piece/Pieces, Piece/Pieces

ColorYellow

UsageDrum handling

Weight32.00 Kilograms (kg)

Latest from Drum Lifter Trolley

Drum Lifter Trolley In Chennai V Lift Material Handling Sales Services

By:

V Lift Material Handling Sales & Services

What are Drum Lifter Trolleys?

Drum Lifter trolleys or drum lifting trolleys are heavy-duty machinery that are used for lifting and transporting drums from one space to another. These drum lifter trolleys use a sophisticated grab mechanism that holds and lifts the drums from the rim. The hydraulic cylinder equipped in the lifter trolley operates the lifting and lowering of the drums. The hydraulic cylinders are operated and controlled using a foot pedal pump for lifting the drums. The hand lever is utilized for smooth lowering control of drums. The increased lifting height of the lifting trolley allows for vertical stacking of drums. Drum lifter trolleys are used to move industrial-sized drums and barrels manually around the workplace.

Lifter trolleys are designed to improve the speed and efficiency of operations in a workplace. With the help of lifter trolleys, the drums and barrels can be transported from one location to another. They prevent injuries to workers and improve safety standards in industrial settings. Drum lifters are warehouse trolleys that are specifically designed for the convenient handling of drums. There are different types of lifter trolleys, each built for different purposes. Some lifter trolleys can be utilized with forklifts for lifting drums from the base. Some lifters operate with an overhead hoist and chain. Some of the lifter trolleys use pincers to grip the drum around the rim.

Exploring the Different Types of Drum Lifter Trolleys

There are several types of drum lifter trolleys available to streamline the operations of any workplace. Each lifter serves a distinct function to improve material handling efficiency and worker safety. For maximizing the performance and safety in material handling operations, a good lifter trolley is necessary. While selecting an appropriate drum lifter trolley, the load capacity, the material being handled, space limits, and needed mobility should be kept in mind.

Manual Drum Lifter Trolleys

Manual Drum Lifters, as the name suggests, are manually operated to lift and transport drums. These trolleys are affordable and are perfect for drums with smaller loads. They are equipped with a lever mechanism that is used to lift drums.

Hydraulic Drum Lifter Trolleys

Hydraulic drum lifters use hydraulic systems to provide increased lifting power with minimal effort. These trolleys are perfect for lifting heavier drums. They offer enhanced control for lifting and lowering the drums.

Battery-Powered Drum Lifter Trolleys

Battery-powered Drum Lifter Trolleys use a rechargeable battery. The battery powers their lifting mechanism to increase the mobility and convenience of lifting machines. These trolleys are excellent for use in areas without easy access to power outlets.

Overhead Drum Lifter Trolleys

Overhead Drum Lifter Trolleys are specifically designed to lift drums vertically. These trolleys are ideal for constrained spaces where there is limited horizontal movement. They are commonly widely used in manufacturing or warehouses.

Clamp-Style Drum Lifter Trolleys

Clamp-Style Drum Lifter Trolleys are equipped with clamps. The clamps are used to secure drums for lifting to the desired height. The trolley’s clamp allows for a more secure grip on different types of drums, made of steel or plastic.

Drum Rotators Lifter Trolleys

Drum Rotators Lifter Trolleys are used for lifting and rotating the drums as well. These trolleys can be useful in pouring or decanting liquids. They are suitable for industries where controlled pouring is needed.

Stainless Steel Drum Lifter Trolleys

Stainless Steel Drum Lifter Trolleys are designed for industries that need to follow strict hygiene standards. They are widely used in industries like pharmaceuticals or food processing. These trolleys are widely used because they prevent contamination and corrosion.

How Do Drum Lifter Trolleys Work?

Drum lifter trolleys are used in industrial settings where large drums need to be moved around the workplace. They are designed to safely lift and transport drums. These lifter trolleys are made up of various interconnected parts that work together to lift the drums and barrels. The lifter trolley has a strong metal frame or a frame made from another durable material. The frame of the lifter trolley offers stability to the lifting mechanism. The lifting mechanism of the lifter trolley depends upon the type of trolley being used. Manual, pneumatic, or hydraulic systems can be equipped with a drum-lifting trolley.

While some trolleys feature chains or belts that are utilized to hold the drum in place for lifting or transporting. Some lifter trolleys have clamps or grips that securely grasp the drum. The wheels or casters on drum lifter trolleys make it easier to transport the trolley over the floors of the workplace. Several trolleys are designed with controls to activate the lifting mechanism or they can have handles for maneuverability of the machine. The controls could be levers, buttons, or pedals, which depends upon the type of machine, either powered or manual. When using any type of drum lifter trolleys, safety should always be the first priority. Operators must receive training before using the machines on how to use them correctly. The weight restrictions should be observed by the operators. They should adhere to any safety instructions provided by the manufacturer. The lifting trolley should undergo routine maintenance and inspections for smooth functioning.

Top Reasons You Need Drum Trolleys For Transportation

Drum Lifter Trolleys allow the safe distribution of large industrial containers from one place to another. There are several advantages of using lifter trolleys for different industries. Drum lifter trolleys are specifically designed for industrial workplaces. These trolleys are fabricated from non-reactive polyethylene because it is durable, sturdy, and cost-effective. They can catch unwanted spills or leaks because they are built with sumps. The use of these trolleys reduces the risk of injury to workers in any industrial setting that can be potentially hazardous. These trolleys allow for industrial-sized drums to be transported manually, quickly and ensure efficient operations. Drum lifter trolleys of the best quality improve the health and safety standards of the workplace. They are produced from non-reactive polyethylene which makes them cost-effective, long-lasting, and robust. Minimal training and supervision are required for the operators who are going to operate the machine. These lifter trolleys are versatile pieces of industrial equipment that can be reused repeatedly with a minimum requirement of maintenance.

Drum Lifter Trolley Price List

Product Name | Expected Price |

|---|---|

| Hydraulic Drum Lifter Trolley | 45000 |

| Drum Lifter Trolley | 5000 |

| Drum Handling Trolley | 38000 |

| Industrial Drum Handling Trolley | 18000 |

| Ss Drum Trolley | 5000 |

| RB-109 Hydraulic Drum Pallet Stacker | 20000 |

| Three Wheel Drum Lifter Trolley | 5000 |

| Two Wheeler Drum Lifter Trolley | 3500 |

| Three Wheel Drum Lifter Trolley | 5500 |

| Pneumatic Wheel Drum Lifter Trolley | 6500 |

This Data was Last Updated on 2024-12-15

Drum Lifter Trolley Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Mahalaxmi Industries Delhi, India | 20 Years |

Shri Vinayak Packaging Machine Pvt. Ltd. New Delhi, India | 19 Years |

Future Industries Pvt. Ltd. Ahmedabad, India | 16 Years |

Kohinoor Metal Fabricators Ankleshwar, India | 15 Years |

Solutions Packaging Ludhiana, India | 15 Years |

Unique Safety Services Mumbai, India | 10 Years |

Siddh Krupa Steel Fab Ahmedabad, India | 9 Years |

Sai Samarth Industries Ahmedabad, India | 9 Years |

Shree Ambica Engineering Works Ahmedabad, India | 7 Years |

Jo Long Machine Industrial Co., Ltd. Dali, Taiwan | 6 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories