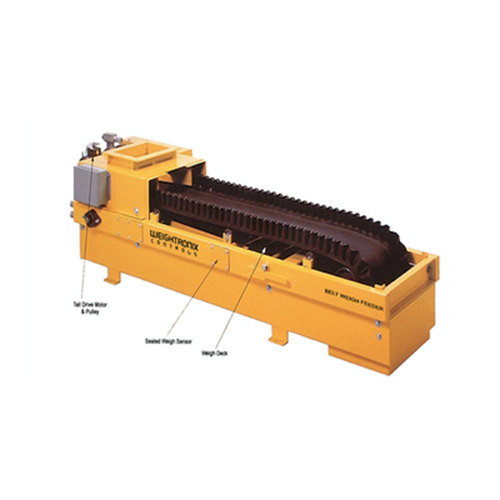

Weigh Feeder By Om Industries & Services

Price: 450000 INR

Get Latest Price

In Stock

Product Specifications

| Attributes | Strong, Durable, Easy To Operate, Rust Proof, Flame Proof |

Product Overview

Key Features

This Gravimetric Weigh feeder design ensures the joint extraction and weighing of any gravity flowing product through a feeding hopper provided. The weigh feeder has been specially designed for use in the cement, steel, fertilizer production, minerals, power plant, agricultural industry and other activity sectors using dosing systems.

This Gravimetric Weigh Feeder is operated by closed loop control system enabling feeding at a controlled rate and maintains precise control over rate of flow based on micro controller settings. The system is capable of accepting signals from other controllers and plant process computers. Each system is equipped with control & local panels, Load cell to measure belt load and belt speed measuring device and feeder is driven by an AC or DC motor coupled through gearbox as per requirement. This Weigh Feeder is used to measure flow-rate of bulk material with accuracy from +/-0.5% to +/-1% depending on the application and product behaviour.

The standard model ranges from 1t/h to 2000t/h.

Benefits of Weigh Feeders:

a Accurate Material Control: Weigh feeders provide precise measurement and control of material flow rates, ensuring accurate dosing, blending, or batching of materials. This helps maintain consistent product quality and minimize material waste.

a Process Optimization: By controlling the material flow rate, weigh feeders contribute to process optimization. They help maintain the desired material-to-product ratios, ensure uniform feeding of materials, and enable better process control and efficiency.

a Inventory Management: Weigh feeders provide real-time data on the amount of material being fed, allowing for accurate inventory management. This helps prevent material shortages or overflows and assists in planning production schedules.

a Improved Efficiency: With their ability to control and monitor material flow, weigh feeders help optimize energy consumption and reduce production costs. They minimize variations in material feed, leading to improved process efficiency and productivity.

a Customizable and Flexible: Weigh feeders can be customized to suit specific application requirements.

Features of Weigh Feeders:

a Weighing Mechanism: Weigh feeders incorporate accurate weighing mechanisms such as load cells or strain gauge sensors to measure the weight of the material being fed.

a Control System: They are equipped with a control system that adjusts the feed rate based on the measured weight, ensuring precise and consistent material flow.

a Maintenance and Calibration: Weigh feeders often have features that facilitate maintenance and calibration, such as easy access to components, self-diagnostic functions, and calibration routines to ensure accurate weighing performance.

Applications of Weigh Feeders:

a Cement Industry: Weigh feeders are widely used in cement plants for accurate dosing of raw materials, additives, and fuel to the kiln or grinding mills. a Mining Industry: Weigh feeders are employed in mining operations to control the flow of materials such as ores, coal, and aggregates into processing equipment.

a Power Generation: Weigh feeders play a crucial role in power plants, where they are used to control the flow of coal or biomass into boilers for efficient combustion.

a Food Processing: Weigh feeders find application in the food industry for precise feeding of ingredients, such as grains, powders, or liquids, in food production processes.

a Chemical and Pharmaceutical Industries: Weigh feeders are utilized in chemical and pharmaceutical manufacturing for accurate dosing and blending of materials in batch or continuous processes.

#processingequipment #msmesector #WF #omindservice

Company Details

Focusing on a customer-centric approach, Om Industries & Services has a pan-India presence and caters to a huge consumer base throughout the country. Buy Material Handling Equipment in bulk from Om Industries & Services at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

20

Establishment

2013

Working Days

Monday To Saturday

GST NO

27AGIPR0801N1Z6

Payment Mode

Cheque

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AGIPR0801N1Z6

Mumbai, Maharashtra

Manager

Mr Prashant Mene

Address

Plot No. 30, Gorai Praneeta, Gorai Road, Borivali (W) Mumbai, Maharashtra, 400092, India

weigh feeder in Mumbai

Report incorrect details