- Tradeindia

- Machineries

- Sand Blasting Machine

Sand Blasting Machine

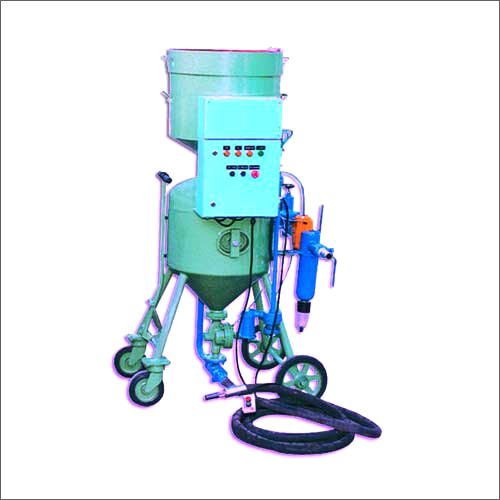

(291 products)Portable Sand Blasting Machine - Heavy-Duty Steel Build Compact Design for On-the-Go Use

Price: 300000.00 INR/Piece

MOQ1 Piece/Pieces

Payment TermsOthers Cheque

Supply Ability10-15 Per Month

Delivery Time1 Months

View More

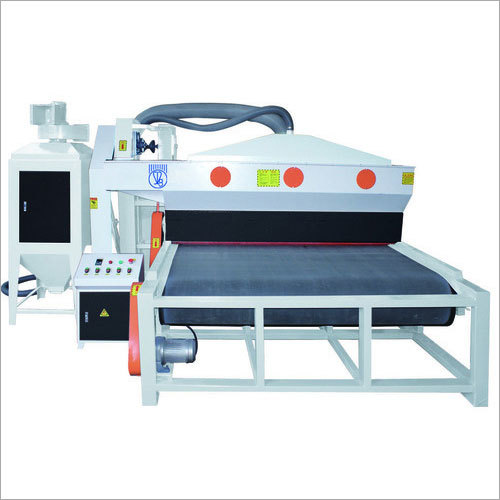

Roller Conveyor Shot Blasting Machine - Standard Size | Green and Blue Industrial Usage

Get Best Deal

Hanger Type Shot Blasting Machine - Heavy-Duty Steel Efficient Surface Preparation | Ideal for Industrial Applications

Price : 300000.00 INR

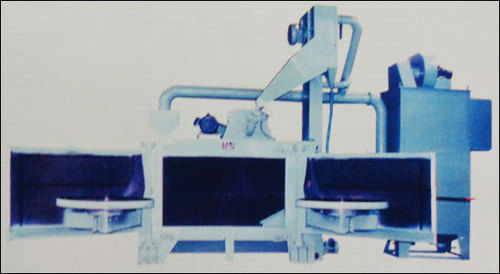

Table Shot Blasting Machine

Price : 300000.00 INR

Tumblast Shot Blasting Machine - Standard Size Polished Finish High Efficiency | Blue Color 240V Voltage 5-10 Capacity Corrosion and Shock Resistant Long Life

Price : 425000 INR

Portable Type Sand Shot Blasting Machine

Get Best Deal

Wet Sand Blasting Machine

Price: 185000 INR/Piece

MOQ1 Piece/Pieces

Country Of OriginIndia

Voltage220 Volt (v)

Product TypeOther Wet Sand Blasting Machine

Power SourceElectricity

Operating TypeAutomatic

ColorMulti color

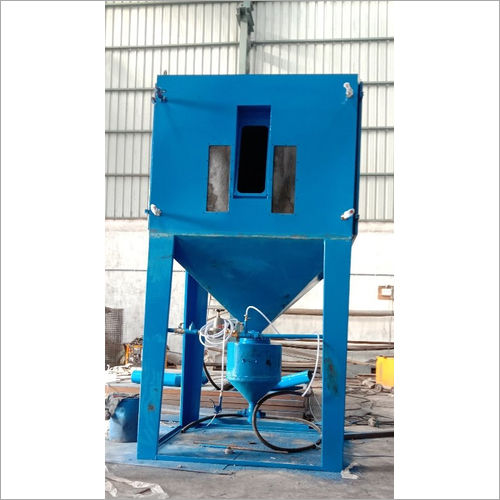

Abrasive Blast Machine - 200 Lts Capacity Blue Color | Automatic Operation 150-300 PSI Pressure Continuous Blast Time 45-50 Minutes

Product TypeOther

TechnologyOther

Operating TypeAutomatic

Pressure150 - 300 PSI

Surface TreatmentOther

ColorBlue

Stationary Sand Blasting Machine

Price Trend: 100000.00 - 1000000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability1-5 Per Month

Delivery Time1-2 Months

Portable Sand Blasting Hopper - Color: Brown

MOQ1 Unit/Units

UsageIndustrial

Product TypePortable Sand Blasting Hopper

ColorBrown

SizeStandard

Power SourceAc Power

SilentYes

Sand Blasting Work

MaterialSteel

Power10 Hp

Pressure100 Psi

Air Flow10 Cfm

Nozzle Size2Mm

Weight100 Kg

Heavy Duty Semi-Automatic Shot Blasting Line

Price: 350000.00 INR/Unit

MOQ1 Unit/Units

ColorOrange and Blue

Product TypeIndustrial Type

General UseShot Blasting Process

MaterialOther

ComputerizedNo

AutomaticYes

Portable Sand Blasting Machine - Semi Automatic Electric Powered Magnetic Technology | Surface Treatment for Metals Durable & Efficient

MOQ1 Unit/Units

TechnologyMagnetism

Power SourceElectricity

Operating TypeSemi Automatic

Surface TreatmentPainted

WarrantyYes

Usage & ApplicationsIndustrial

Sand Blasting Machine - Heavy Duty Steel Frame | Efficient Abrasive Flow Versatile Applications Rapid Cleaning

MOQas per requirement Piece/Pieces

Payment TermsLetter of Credit (L/C) Letter of Credit at Sight (Sight L/C) Paypal Western Union Delivery Point (DP) Telegraphic Transfer (T/T) Others Days after Acceptance (DA) Cash in Advance (CID) Cheque Cash Advance (CA)

Delivery Time1 Months

Sample AvailableYes

Blue And White Manual Sand Blasting Machine

MOQ1 Unit/Units

Product TypeSand Machine

General UseBlasting

MaterialStainless Steel

Weight (kg)15-20 Kilograms (kg)

ComputerizedYes

AutomaticYes

View More

Gray Glass Sand Blasting Machines

Get Best Deal

Blue Automatic Vertical Sand Blasting Machine

Get Best Deal

Portable Sand Blasting Machine - Feature: High Efficiency

MOQ1 Unit/Units

General UseIndustrial

MaterialStainless Steel Alloy

AutomaticYes

Control SystemFrequency Speed Control

Surface TreatmentPolishing

FeatureHigh Efficiency

Air Operated Semi-Automatic Sand Blasting Machine - 100 Kg Weight 200 Kg/Day Capacity | Blue Rust & Paint Removal Safety Remote Control

Price: 70000.0 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeOther

TechnologyOther

Power SourceElectricity

Operating TypeSemi Automatic

Power220 Volt (v)

Top Rated Products

Portable Sand Blasting Machine - Heavy-Duty Steel Build Compact Design for On-the-Go Use

Orbitech Shotblasting Equipments

FAQs Related to Sand Blasting Machine

Heavy Duty and Portable Sand Blasting Hopper

Product TypeOther Sand Blasting Hopper

ColorBlue

Usage & ApplicationsIndustrial

Breather Filter Cartridge - Special Filter Material | Enhanced Filtration Performance High Durability Improved Air Quality

Price: 1 USD ($)/Piece

MOQ10 Piece/Pieces

Product TypeOther

MaterialSpecial Filter

TechnologyOther

Surface TreatmentOther

Blue 1240 Watts Paint Coated Semi Automatics Industrial Sand Blasting Machine

Price: 135000 INR/Unit

MOQ1 Unit/Units

TechnologyMagnetism

Power SourceElectricity

Operating TypeSemi Automatic

Power1240 Watt (w)

Pressure120 PSI

Surface TreatmentPainted

Mec Shot Blasting Equipments Pvt. Ltd.

Jodhpur

Trusted Seller

Trusted Seller1 Years

View More

Shot Blasting Machines - Color: White And Black

Price : 1200000 INR

Airless Shot Blasting Machine - Color: White And Blue

Price : 1400000 INR

Portable Sand Blasting Machine - Heavy Duty M. S. Plates Auto Sealed Valve Hopper Design

Get Best Deal

Tunnel Type Airless and Wheel Shot Blasting Machine

Get Best Deal

Portable Abrasive Blaster - Durable Aluminum Compact Design Versatile Surface Cleaning Solutions

Price Trend: 35000.00 - 100000.00 INR/Number

MOQONE Number

Supply Ability10 Per Week

Delivery Time4-6 Week

Portable Sand Blasting Machine - Electric Semi-Automatic Blue | 1-Year Warranty Efficient Rust and Paint Removal

MOQ1 Unit/Units

Product TypeOther Sand Blasting Machine

Power SourceElectricity

Operating TypeSemi Automatic

ColorBlue

Warranty1 Year

Usage & ApplicationsIndustrial

300 Kg Sand Blasting Machine - Color: Black

Price: 75000 INR/Unit

MOQ1 Unit/Units

ColorBlack

Product TypeCleaning Machines

TechnologyOther

Power SourceElectricity

Operating TypeSemi Automatic

Power30 Hp Horsepower (HP)

View More

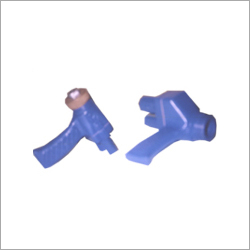

Rust Resistant Shot Blasting Machine Nozzle Weight: 100 Grams (G)

Price Trend : 4000.00 - 4100.00 INR

Pressure Sand Blasting Machine - Aluminium Semi-Automatic Design Roughness Finish Treatment with Coated Surface

Price : 1250000 INR

Industrial Oven Furnace Capacity: 100 Cl

Get Best Deal

Automatic Pressure Blasting Machine - 220V 50 Hz Single Phase | Automatic Operation Electric Power Source Ideal for Shot Blasting and Sand Blasting Applications

Price : 250000 INR

Durable Portable Type Sand Blasting Hopper Machine

Price : 75000 INR

Semi Automatic Sand Shot Blasting

Price: 45000 INR/Number

MOQ1 Number

Automatic GradeSemi Automatic

Power SourceElectric

Drive TypeElectric

Product TypeSand Shot Blasting

Recovery Unit Bucket Elevator System - Power: 2 Horsepower (Hp)

Price: 180000 INR/Unit

MOQ1 Unit/Units

Product TypeOther Bucket Elevator System

Power SourceElectricity

Power2 Horsepower (HP)

Surface TreatmentCoated

Warranty1 Year

Usage & ApplicationsRecovery of sand and shot blasting media in sand blasting application

Sand Blaster - Metal and Plastic 10X13X14 Inches | Medical Purpose Rubber Glove Built-in Light Exhaust Filter Large Glass Window

MOQ1 Unit/Units

ApplicationMedical Purpose

Product TypeSand Blaster

Power220 Volt (v)

Suitable ForHospital

MaterialMetal Plastic

Automatic Portable Abrasive Blaster

Price: 32000 INR/Set

MOQ1 Set/Sets

ColorAny

TypeManual / Automatic

MaterialMild Steel / Stain Less Steel

ComputerizedNo

Automatic GradeAutomatic

Control SystemFrequency Speed Control

White Semi Automatic Sand Blasting Machine

Price: 295000 INR/Piece

MOQ1 Piece/Pieces

ColorWhite

Product TypeSand Blasting Machine Other

TechnologyCNC

Power SourceElectricity

Operating TypeSemi Automatic

Power5 Horsepower (HP)

View More

White Blue Glass Sand Blasting Machine

Price : 295000 INR

Blue P-501R Portable Sand Blasting Machine

Price : 39000 INR

Semi Automatic Portable Sand Blasting Machine - Mild Steel 220-240 Volt Green Color | Semi-Automatic Operation Industrial Use

Price : 117000 INR

White Three Phase Sand Blasting Machine

Price : 575000 INR

P-301R Portable Sand Blasting Machine - Color: Blue

Price : 49000 INR

P-1001R Portable Sand Blasting Machine - Color: Blue

Price : 98000 INR

Heavy Duty Sand Blasting Machine - High Speed Silicon Grit Reinforced Hose with Graded Rubber & Ceramic/Tungsten Nozzle

TypeSand Blasting Machine

Portable Sand Blasting Machine - Color: Blue

Price: 90000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypeOther Portable Sand Blasting Machine

Power SourceElectricity

Operating TypeAutomatic

Surface TreatmentCoated

Warranty1 Year

View More

Sand Blasting Machine - Color: Blue

Price : 70000 INR

Portable Sand Blasting Machine - Color: Blue

Price : 83000 INR

Yellow Water Sand Blasting Machine - Feature: Stable Operation

Price: 18000 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

FeatureStable operation

ConditionNew

TypeBlasting Machine

Power2 Horsepower (HP)

Voltage220 Volt (v)

View More

Frosting Sand Blasting Machine - Feature: Stable Operation

Price : 21000 INR

Wet Sand Blasting Machine

Weight20Kg

Dimensions30X25X40Cm

Power220V

MaterialSteel

Current150A

Voltage230V

Rent/Hire Sand Blasting Machine Rental Services

MOQ1 Unit/Units

Supply Ability1 Per Day

Delivery Time24 Hours

View More

Sand Blasting Machine Rental Services

Get Best Deal

Latest from Sand Blasting Machine

Ready To Ship Sand Blasting Machine

About Sand Blasting Machine

Sand blasting machine is a useful equipment that is applied in the building construction procedures. It is a multipurpose machine which is used for the cleaning of roughened surface of different building materials such as stones bricks and concrete work. The machine consists of a blaster nozzle and air compressor that particularly removes the dust particles rust paint and minor surface flaws from the object. The sand blasting equipment is also used for the edge profiling and the reshaping of metal components. It gives the metal surface a smooth and textured finish that completely changes the surface of a metallic item.

Benefits of Using Sand Blasting Machine:

- The surface finishing is done with an ease with the help of sand blasting equipments. Before it was accomplished with the hands which is a time taking process.

- These machines provides an effective way to clean the metals and building materials. It also helps in preparing the smooth surface for the other processes such as painting welding coating and plating.

- It removes the scars paint graffiti and rust from the surface of a wall or any other object.

Types of Sand Blasting Machines and their Uses:

Pressure Pot: This type of equipment is more efficient and has a much higher sandblasting pressure. It is commonly used in the large industries and workplaces. The machines consists of a pressurized tank where the air is mixed with the abrasive materials before being thrown them out.

Siphon: The equipment consists of an air gun that can be fitted with two different hoses. One equipment blows the air and the other removes the abrasive material. It can be used for the commercial as well as industrial purposes.

Power Washer: This equipment consists of a pressure washer that mixes abrasives with the water before being shot them out from the nozzle. It is quite better than the other machines and are commonly used for removing painted items from the buildings.

Follow Google+

Client Testimonials & Reviews

AmanSingh

KAMEYO SYSTEMS PRIVATE LIMITED

I am thankful to tradeindia for being our partner and helping us to reach our potential buyers. I also thankful to their Executives and all others for giving a careful attention.

GovindSingh

FLEXITECH INDIA

We are the Manufacturers of CNC Routers Plasma Stealth S2 Viper PRO NBM Cobra XL and XXL. We are the member of tradeindia since 2010. We are comfortable with tradeindia services. Wishing all the Best to tradeindia.

BalvinderSingh

SATNAMIA GEAR COMPANY

We are using Tradeindia from the last so many years and It is very useful and helpful for our business and we are really grateful and thankful to the Tradeindia team. We are fully i.e. 100% satisfied with the Tradeindia.

SurenderSharma

KESHAV ENTERPRISES

Tradeindia is Very good application for Good inquiry and Better Promotion. Its useful for better B2B service. There is good inquiry.

SanjaySakhiya

RONAK ENGINEERING

It was difficult to find Buyers in this competitive world for our unique business but well worth the wait. Wea ve worked with tradeindia.com now for several years and trust their team to meet our needs. Throughout their time with us. tradeindia.com has provided consistent quality solutions and service helping our business to move forward.

VijayMaurya

MAURYA UDYOG

Being the Manufacturer of High Speed Shoe Lace Fully and semi Automatic Tipping Machine Shoe Lace Waxing Machine and Spare parts Semi and fully Automatic Tipping Machine for Carry Bags. We have been associated with tradeindia.com India's largest B2B Portal for last one year. I am using as a Marketing Tools. I Wish tradeindia team for Bright future.

SudershanChekuri

THREAD FORM MACHINE INDUSTRIES

We are satisfied with tradeindia.com. We are getting the business from it.

RajnishSanger

S. B. MACHINE TOOLS

I am associated with tradeindia from 8 years and we are having a very satisfactory response from them in our business expansion. We are very confidently look forward to a long-term relation with tradeindia for our sales and promotion in future also.

Deepak

SIDDHAPURA MACHINE TOOLS

We are happy to be member of Trade India since last five year and Trade India has helped us to increase our business internationally and domestic market and achieved pioneer name in the market. We thanks to trade India to be a one of the partner of our firm to grow our business with hand to hand.

We already associated with tradeindia. This has helped us to exponentially to expand our presence not only Domestically with in India but also in different International markets.

Sand Blasting Machine Price List

Product Name | Expected Price |

|---|---|

| Mini Sand Blasting Machine | 45000 |

| Portable Sand Blasting Machine | 75000 |

| Sand Blasting Machine | 35000 |

| Sand Blasting Machine | 100000 |

| Sand Blasting Machine | 100000 |

| Sand Blasting Machine | 65000 |

| Cabinet Type Suction Sand Blasting Machine | 125000 |

| Industrial Sand Blasting Machine | 100000 |

| 0.5 HP Sand Blasting Machine | 51000 |

| 7 HP Sand Blasting Machine | 69000 |

This Data was Last Updated on 2025-06-14

Sand Blasting Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Blastech Mumbai India | 17 Years |

Ramsons Garment Finishing Equipments (p) Ltd. Bengaluru India | 16 Years |

Ankit Air Compressor Services Ahmedabad India | 15 Years |

Kushal Udhyog Jodhpur India | 15 Years |

Bhambra Glass Concepts Faridabad India | 12 Years |

Shree Sai Associates Faridabad India | 12 Years |

Kataria Construction Bharuch India | 11 Years |

Blastclean Systems Private Limited Mumbai India | 10 Years |

S. K. Glass Machines (india) Pvt. Ltd. Ghaziabad India | 10 Years |

Orbitech Shotblasting Equipments Vadodara India | 9 Years |

Upcoming Tradeshows

IFSEC INDIA 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

STEEL CONSTRUCTION EXPO 2025

Thu, 27 Nov, 2025 - Sat, 29 Nov, 2025

INDIAN ICE CREAM CONGRESS & EXPO 2025

Mon, 06 Oct, 2025 - Wed, 08 Oct, 2025

The Harit Bharat Expo 2025

Fri, 25 Jul, 2025 - Sun, 27 Jul, 2025

Auto EV Bharat 2025

Wed, 19 Nov, 2025 - Fri, 21 Nov, 2025

CBD - China (Guangzhou) International Building Decoration Fair 2025

Tue, 08 Jul, 2025 - Fri, 11 Jul, 2025

Mercom India Renewables Summit 2025

Thu, 24 Jul, 2025 - Fri, 25 Jul, 2025

Shanghai World of Packaging (swop) 2025

Tue, 25 Nov, 2025 - Thu, 27 Nov, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

The 5th China International Corrugated & Folding Carton Festival 2025

Thu, 30 Oct, 2025 - Sat, 01 Nov, 2025

Popular Categories