Automatic Bar Feeder Fabric Weight: 100-150 Grams (G)

Price:

Get Latest Price

In Stock

Product Specifications

| Bar Length | 3/4 Meters |

| Hydraulics | 100 Liter Tank |

| Electrical | 3-Phase, 50Hz, 0.75Hp |

| Weight | 600Kg |

| Rotation Speed | Up To 4000Rpm |

| Features | Automatic Loading, High-Speed Turning, Digital Positioning, Random Length Handling, Easy Guide Tube Change, Versatile Profile Feeding, Unattended Machining, High Filtration |

Product Overview

Key Features

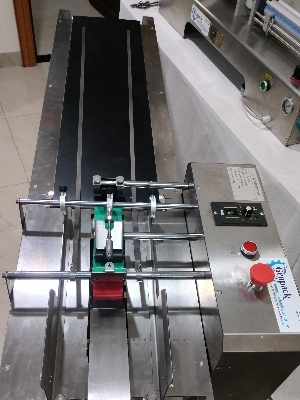

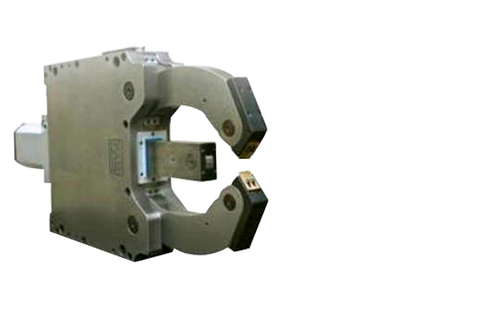

Automatic Bar Feeder

Owing to the huge demand of our clients, we are able to manufacture, supply and export Automatic Bar Feeder. These products are generally used for fully automatic loading of cylindrical tubing, pipe and bar stock in many industries. Owing to their features of handling random lengths, digital positioning of bars and automatic loading of bars, these products have carved a niche in the international market. These products are available with us in different models as per the needs of the clients. Automatic Bar Feeder is packed in damage proof packaging to ensure their safe and secure delivery.

FAR AUTO FEED can be attached to any kind of turning machines with out making any modification to the machine. It is specially suited for high speed turning machines. Unattended bar machining possible by interfacing to the CNC system of the machine.

Retractable half moon segment eliminate decentralization and ovalization.This increases the speed of rotation.

Guide tube can be changed within 3 minutes thus saving precious time.

Round, hexagon, square and other profile can be fed.

Ground guide way facilitates free lateral and longitudinal movement.

FAR AUTO FEED offers unique flexibility that, guiding tubes can be required as per requirement at any time.

FAR AUTO FEED has been tested by Central machine tool institute (CMTI) Bangalore India.

Products Specification:

- Bar Length: Standard models 3metres / 4metres (other length optional )

- Hydraulics: have self contained hydraulic unit with high capacity of filtration-valves, pressure gauge tank capacity-100 liter.

- Electrical equipment: Full protection and power circuits 3phase, 50hz, .75 hp, 440v

- Weight: 600kg( approx)

- Rotation speed: Rotational speed up to 4000rpm

Our Other Models:

| Models | Range |

| FAR AUTOFEED | 22 10 to 22 |

| FAR AUTOFEED | 36 10 to 36 |

| FAR AUTOFEED | 44 10 to 44 |

| FAR AUTOFEED | 54 10 to 54 |

| FAR AUTOFEED | 65 10 to 65 |

| FAR AUTOFEED | 80 10 to 84 |

Company Details

Fenwick and Ravi (FAR- registered Trademark) was established in 1990, primarily focussed at product development. Headquarters of FAR is located in Bangalore, Karnataka, India along with regional offices in Pune, Delhi and Chennai. FAR specialises in the manufacture of Steady Rest, Barfeeder, Angle Milling Head, Zero Point Clamping system as the primary products. FAR also has PROJECT DIVISION, where we have executed numerous project primarily for Indian Defence as a secondary manufacturer. We are equipped with the state of the machine shop, strong design team, dedicated applications team. Our backbone is our family of 100 employees. Every single export purpose or domestic product manufactured within FAR goes through the same manufacturing and quality procedure. About 45% of our products are off the catalogue, our strength lies in understanding the customer requirement and providing entire solution with necessary customisation. Our products have applications in diverse fields like automotive, defence, aerospace, railway, machine tool, oil and gas, energy, power transmission etc. We have over 20,000 products working in the field as of today.

Business Type

Exporter, Manufacturer, Supplier, Wholesaler, Retailer

Employee Count

100

Establishment

1990

Working Days

Monday To Sunday

GST NO

29AAAFF7864M1ZS

Certification

ISO 9001 : 2000

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 29AAAFF7864M1ZS

Bengaluru, Karnataka

Manager

Mr Sreekumar R

Address

No. 10/3, Lakshmipura Main Road, Chikkabanavara Post, Abbigere, Bengaluru, Karnataka, 560090, India

automatic feeders in Bengaluru

Report incorrect details