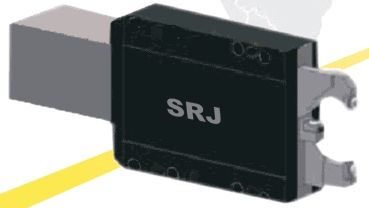

Crankshaft Steady Rest

Price:

Get Latest Price

In Stock

Product Specifications

| Material | High Quality |

| Actuation | Hydraulic/Pneumatic |

| Air Connection | Compressor Air |

| Lubrication | Centralized System |

| Chip Guard | 3 Piece |

| Bracket | Rigid |

| Sealing Strip | Replaceable |

| Features | High Accuracy, Automatic Centering, Increased Productivity, Safety Valve, Adjustable Guard |

Product Overview

Key Features

Steady Rest

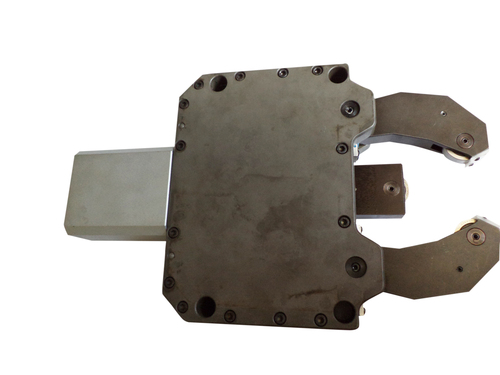

With immense experience and expertise, we are able to manufacture, supply and export Steady Rest. Made of high quality raw material, these products are used for used for turning outside diameters, inside diameters, grinding, induction hardening, facing and drilling. Equipped with pneumatic and hydraulic motors, these products facilitate increased production and high centering accuracy. These products are packed in special packaging material in order to ensure their safe and secure transit. Steady Rest is available with us in different specifications in accordance to the clients' requirements.

Steady Rest are normally used efficient machining of long slender shafts. On conventional steady rest three screws 120o apart are adjusted manually. This type of centering process is not reliable and depends on operators skill.

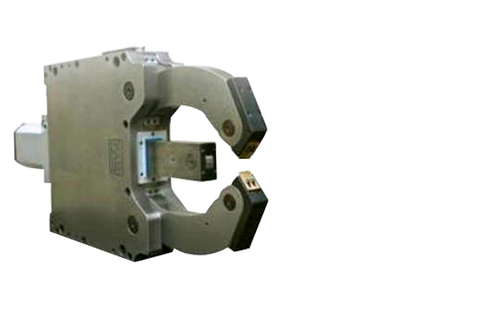

FAR self centering steady rest work on an entirely different principle. Three rollers hold the work piece at point approx 120o apart. These rollers move such that they always inscribe concentric circles between them. This feature along with the internal compensating system prevents the dislocation of work piece center under changing clamping pressure. This results in high centering accuracy By mounting accordingly these steady rests can be used for turning outside diameters, inside diameters, facing, drilling, grinding, induction hardening etc.

Steady rest can be operated either hydraulically or pneumatically with the only difference being the clamping cylinder bore.

Specifications:

- High centering accuracy.

- Provide replaceable sealing strip and provision for compressor air connection that prevent the of coolant and dirt to the body

- Automatic centering that reduces the cycle time and increased productivity.

- Have provision for centralized lubrication system in all steady rest

- Provide Actuating cylinder which have integral safety valve that ensure support of the work under sudden pressure drops.

- Based on special cam design, which is proved in the field

- Consist of Adjustable 3 piece chip guard for outer rollers with low reduction of clamping range

- It can be mounted either on slant or flat bed lathes

- made with Rigid and precisely bracket that ensure centering accuracy

This series is made for machines where the rear mounted cylinder may foul with the sheet metal enclosures or other machine enclosures To achieve this the actuating cylinder of the steady rest is mounted on the side of steady rest.

Standard Features:

- Safety Valve

- Provision for max opening feedback

- 1 set swarf guard 3-piece

- Provision for compressed air connection

- Provision for centralized lubrication

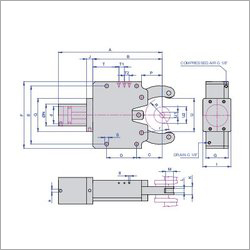

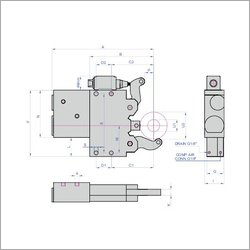

| STEADY REST TYPE |

| FRU-B3 | FRU-B3.1 | FRU-B4 | FRU-B5 | FRU-B6 | FRU-B7 | FRU-B8 |

|

| A | 348 | 356 | 480 | 6125 | 823 | 1001 | 1130 |

|

| B | 308 | 316 | 437 | 500 | 709 | 8975 | 1019 |

|

| C | 115 | 123 | 146 | 178 | 215 | 320 | 375 |

|

| D | 135 | 135 | 240 | 270 | 330 | 440 | 500 |

|

| E | 262 | 262 | 365 | 400 | 610/640 | 650 | 855 |

|

| F | 290 | 290 | 400 | 450 | 680 | 710 | 930 |

|

| G | 85 | 85 | 110 | 145 | 145 | 180 | 190 |

|

| J | 52 | 52 | 67 | 80 | 83 | 112 | 110 |

|

| K | 45 | 45 | 60 | 75 | 75 | 100 | 100 |

|

| L | 25 | 25 | 25 | 29 | 29 | 32 | 32 |

|

| M | 47 | 47 | 52 | 62 | 80 | 100 | 100 |

|

| N | 25 | 25 | 32 | 36 | 43 | 55 | 60 |

|

| O | 40 | 40 | 43 | 112.5 | 114 | 103.5 | 111 |

|

| P2 | 74 | 74 | 85 | 85 | 125.8 | 130 | 130 |

|

| P3 | 57 | 57 | 68 | 85 | 89.2 | 130 | 130 |

|

| R | 117.5 | 124 | 172 | 209 | 290 | 398 | 402 |

|

| S | 18 | 18 | 23 | 23 | 27 | 27 | 35 |

|

| T | 199 | 198 | 246 | 325 | 383 | 405 | 487 |

|

| V | 91.5 | 99.5 | 128 | 160 | 182 | 283.5 | 290 |

|

| Y | 19 | 19 | 19 | 20 | 27 | 27 | 27 |

| Centering range without chip guard. | U1 | 12 | 20 | 30 | 50 | 125 | 200 | 230 |

| U2 | 152 | 165 | 245 | 310 | 460 | 530 | 630 | |

| Centering range with 3 piece chip guard | U1 | 21 | 20 | 30 | 50 | 125 | 200 | 230 |

| U2 | 152 | 165 | 245 | 310 | 460 | 530 | 630 | |

| Cylinder Bare | d | 80 | 80 | 100 | 100 | 130 | 150 | 150 |

| e | 58 | 58 | 68 | 85 | 55 | 191 | 191 | |

| f | 27 | 27 | 39 | 40 | 50 | 50 | 50 | |

| g | 180 | 180 | 220 | 270 | 430 | 450 | 450 | |

| Hyd. Connection (BSP) | h | 1/4 | 1/4 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 |

| Operating pressure Min/Max | bar | 8/60 | 8/60 | 8/60 | 8/80 | 8/70 | 8/70 | 8/70 |

| Max. Clamp force/roller | daN | 1000 | 1000 | 1500 | 2000 | 3000 | 4000 | 4000 |

| Clamping press/roller at 15bar | daN | 250 | 250 | 400 | 400 | 600 | 880 | 890 |

| Centering accuracy over the whole clamping range | mm | 0.04 | 0.04 | 0.05 | 0.06 | 0.05 | 0.08 | 0.08 |

| Repeatability | mm | 0.007 | 0.007 | 0.007 | 0.01 | 0.01 | 0.02 | 0.02 |

| Max. Peripheral speed | M/min | 800 | 8000 | 720 | 650 | 525 | 570 | 570 |

| Weight Approx | kg | 53 | 53 | 115 | 190 | 500 | 1000 | 1300 |

Technical Specifications

| Model | Holding Diameter | ||

| Rear Mounted cylinder | Side mounted cylinder | Min (mm) | Max (mm) |

| FRU1 |

| 04 | 64 |

| FRU2 | FRUB2 | 08 | 101 |

| FRU3 | FRUB3 | 12 | 152 |

| FRU3.1 | FRUB3.1 | 20 | 165 |

| FRU3.2 | FRUB3.2 | 50 | 200 |

| FRU4 | FRUB4 | 30 | 245 |

| FRU5 | FRUB5 | 45 | 310 |

| FRU5.1 | FRUB5.1 | 85 | 350 |

| FRU6 | FRUB6 | 125 | 460 |

| FRU7 | FRUB7 | 200 | 530 |

| FRU8 | FRUB8 | 230 | 630 |

Company Details

Fenwick and Ravi (FAR- registered Trademark) was established in 1990, primarily focussed at product development. Headquarters of FAR is located in Bangalore, Karnataka, India along with regional offices in Pune, Delhi and Chennai. FAR specialises in the manufacture of Steady Rest, Barfeeder, Angle Milling Head, Zero Point Clamping system as the primary products. FAR also has PROJECT DIVISION, where we have executed numerous project primarily for Indian Defence as a secondary manufacturer. We are equipped with the state of the machine shop, strong design team, dedicated applications team. Our backbone is our family of 100 employees. Every single export purpose or domestic product manufactured within FAR goes through the same manufacturing and quality procedure. About 45% of our products are off the catalogue, our strength lies in understanding the customer requirement and providing entire solution with necessary customisation. Our products have applications in diverse fields like automotive, defence, aerospace, railway, machine tool, oil and gas, energy, power transmission etc. We have over 20,000 products working in the field as of today.

Business Type

Exporter, Manufacturer, Supplier, Wholesaler, Retailer

Employee Count

100

Establishment

1990

Working Days

Monday To Sunday

GST NO

29AAAFF7864M1ZS

Certification

ISO 9001 : 2000

Related Products

More Product From This seller

Seller Details

GST - 29AAAFF7864M1ZS

Bengaluru, Karnataka

Manager

Mr Sreekumar R

Address

No. 10/3, Lakshmipura Main Road, Chikkabanavara Post, Abbigere, Bengaluru, Karnataka, 560090, India

steady rests in Bengaluru

Report incorrect details