Acrylic Polymers - Ready-to-use Waterproofing Slurry Coating, High Chemical Resistance, Non-toxic For Water Infiltration Protection

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | Acrylic Polymer |

| Color | Blue |

| Material | Acrylic polymer |

| Packaging | Barrel |

| Volume | 200 Liters |

| Weight | 200 kg |

| Dimensions | 550mm x 800mm |

| Features | Waterproofs surfaces, Easy application, Abrasion resistant, Good adhesion, Chemical resistant, Non-toxic, Cost effective |

Product Overview

Key Features

Acrylic Polymers

Holding years of experience and knowledge in this industry, our company has been able to mark its strong presence in the market as one of the most excellent manufacturers and suppliers of Acrylic Polymers. Owing to excellent abrasion and chemical resistance property, these polymers are highly used for waterproofing of swimming pools, roofs and water tanks. Moreover, we are committed to offer Acrylic Polymers to our esteemed clients within stipulated time frame at market leading prices.

Further details:

Acrylic Cementitious Waterproof Coating

Description

SAVE- IT 202 is READY TO USE acrylic polymer for making a cement based polymer modified waterproofing slurry coating. It is applied to concrete and mortar structures to prevent water infiltration and dampness.

Uses

SAVE- IT 202 is used for external and internal waterproofing, damp proofing, hairline crack sealing, and protection from chloride in the following structures:

A A A a A a A A. Water tanks

A A A a A a A A. Basements

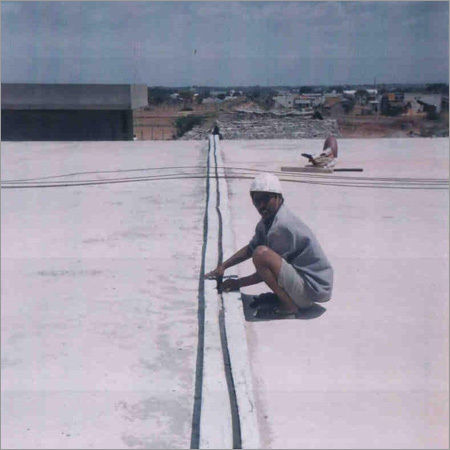

A A A a A a A A. Terraces and balconies

A A A a A a A A. Bridges

A A A a A a A A. Retaining Walls

A A A a A a A A. Small Flat Roofs

Advantages

SAVE- IT 202 provides the following beneficial properties:

A A Aca A A a A A. Easy to apply by brush, slurry consistency

A A A a A a A A. Good adhesion to sound & prepared substrates

A A A a A a A A. Good abrasion resistant

A A A a A a A A. Protects against water penetration, salt & carbonation

A A A a A a A A. Non-toxic when cured, suitable for contact with drinking water

A A A a A a A A. Slightly flexible

Coverage

Depending on type of application, 2 coats are always required. It gives coverage of 3 to 4 sqmtr / kg / coat. Normally two coats should be applied. In extreme cases three coats may be required.

Instructions for Use

Surface Preparation

Concrete, mortar and masonry surface must be clean, free from grease, oil and loosely adhering particles. Steel and iron surfaces must be free from scale, rust, grease and oil. The surface must be as true and flat as possible. Saturate absorbent surface thoroughly. Efficient surface preparation is essential to achieve high adhesive quality of the product.

Mixing

A pre-batched mixture of good quality cement with clean fine sand (500 microns) should be prepared with cement and sand in equal proportions by weight. This should be mixed with SAVE- IT 202 in proportion of one part SAVE- IT 202 to four parts of mixture to form a slurry. For trowellable consistency and putty, the proportions of SAVE- IT 202 should be reduced accordingly. The mixing of slurry should be done in a clean container by slowly adding the powder component to SAVE- IT 202 and stirring with a slow speed mixer (500 - 600 rpm). Mixing should be done until the consistency is free from lumps.

Application

Dampen all surfaces immediately ahead of the slurry application. Whilst the surface is still damp from saturation, apply the first coat and leave to harden (2-6 hrs.). For slurry consistency apply with a hard plastic bristled brush or broom. For trowellable mortars use a notched trowel. After the second coat has been applied, finish by rubbing down with a soft dry sponge. For water proofing slurry should be applied at the rate of 3-4 kg/m2 for two coats.

Curing

As with all cement based products, curing is important. Protect the freshly applied product against direct sunlight and strong winds. Use damp hessian or polythene to aid curing, for 3 days. Then allow to dry out.

Technical Data

Form : Liquid Type : Synthetic Dispersion

Sp. Gravity : Approx 1.1 kg. +/- 2% / Ltr Shelf Life : One year when unopened

Packaging : 10, 25, 50, 100, 200 kg Drums. Storage Condition : Protect from direct sunlight

Storage

Store under cover, out of direct sunlight and protect from extremes of temperature. Failure to comply with the recommended storage conditions may result in premature deterioration of the product or packaging..

Company Details

Focusing on a customer-centric approach, SAVE-IT WATERPROOFING & CONSULTING P. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Waterproof Materials from SAVE-IT WATERPROOFING & CONSULTING P. LTD. at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier, Trading Company

Establishment

2009

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Noida, Uttar Pradesh

Accepts only Domestic inquiries

Managing Director

Mr. Nirmal Badjate

Address

B-87, Sec 14, Noida, Uttar Pradesh, 201301, India

acrylic polymer in Noida

Report incorrect details