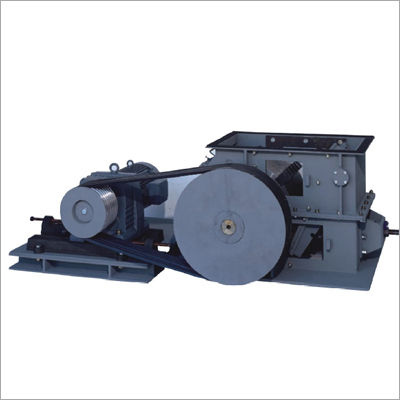

Roller Screen - For Classifying Coarse & Moist Materials | High Throughput, Adjustable Heated Scrapers, Effective For Coal And Lignite Processing

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Roll Speed | Adjustable |

| Roll Spacing | Adjustable |

| Disc Shape | Variable |

| Capacity | Variable |

| Power | Variable |

| Features | High Throughput, Low Power Use, Quiet Operation, Efficient Sorting, Easy Maintenance, Durable Design, Versatile Setup |

Product Overview

Key Features

Roller Screen

Fields of Application

Roller Screens are suitable for classifying coarse. Moust or clayey raw materials. They are used for primary screening as well as for classifying (after crushing). Roller Screens are used in coal processing plants, in the cement, pit and quarry industries as well as around coal power stations.

Feed Materials

Hard coal and lignite, limestone, gypsum and similar materials.

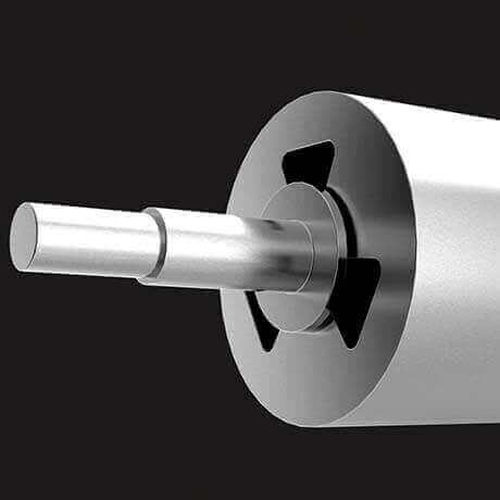

Mode of Operation

Roller Screens sort feed materials with rotating rolls that are driven in parallel. The rolls are equipped with discs which may vary in shape. The size reduction of over sized parts separated at the screen overflow is carried out by Double Roll Sizer or Hammer Mills. For sorting into specific grain sizes the rolls are arrayed at a set distance. Thus, square or rectangular screen apertures are formed. Allowing the passage of feed material with the desired dimension. Feed material the does not pass through the screening rolls is discharged and conveyed to the downstream crusher. Due to the even rotation of the Roller Screen rolls, the feed material is subject to a harmonic rolling motion and gently classified. In case of very moist, sticky or clayey raw materials the rolls are fitted with scrapers which clean the bottom of the roll to ensure efficient classification. The scrapers are individually adjustable and can be heated for extreme tasks.

Versatility

Depending on the application, various machine design and/or accessories can be used:

- Roller Screens with horizontal arrangement

- Roller Screens with inclined arrangement

- Firmly installed adjustable scrapers

- Heated scrapers (Steam-heated)

- Surrounding scrapers being linked via band chain

The Swivel-Arm Crusher- Simultaneous Crushing and Classifying.

Swivel-Arm Crushers combined with Roller Screens are mainly used for lignite processing in power plants. When compared to other crushing systems, the Swivel Arm Crusher is not installed after the Roller Screen but integrated above the screening surface. This option offers the significant advantage of simultaneous crushing and classifying of feed materials. The swivel-arms are connected in parallel and fitted with driven crushing discs to reduce the crushable constituents contained in the feed material. In case of foreign particles the slewable arm is automatically raised to allow separate passing of the parts to the overflow.

Design

Feed material specification and throughout capacity determine machine size, shape of the discs as well as distance and speed of the rolls. Roller Screens are arranged either horizontally or inclined. In most cases each shaft is individually driven.

Advantages

- High specific throughput capacity at low power requirements

- Low spare parts requirement

- Smooth and quiet run

- Adequate primary screening machine for downstream crushers (i.e. Double Roll Sizer, Hammer Mils and similar)

Company Details

Focusing on a customer-centric approach, AMBICA CRUSHTECH PRIVATE LIMITED has a pan-India presence and caters to a huge consumer base throughout the country. Buy Construction Machinery in bulk from AMBICA CRUSHTECH PRIVATE LIMITED at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

15

Establishment

1998

Working Days

Monday To Sunday

GST NO

24AABCA6087H1ZQ

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AABCA6087H1ZQ

Vadodara, Gujarat

Director

Mr Urmit Hirubhai Patel

Address

987/2, G.I.D.C. Industrial Estate, Makarpura, Vadodara, Gujarat, 390010, India

roller screen in Vadodara

Report incorrect details