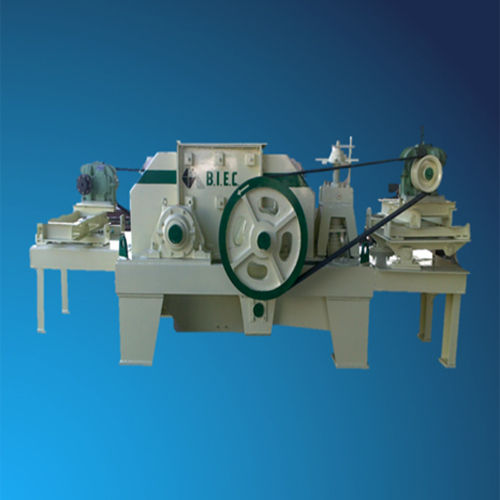

Four Roll Crusher - Optimized For Fine Grinding Processes| Adjustable Crushing Gap, Integrated Overload Protection, Efficient Material Feeding

Price:

Get Latest Price

In Stock

Product Specifications

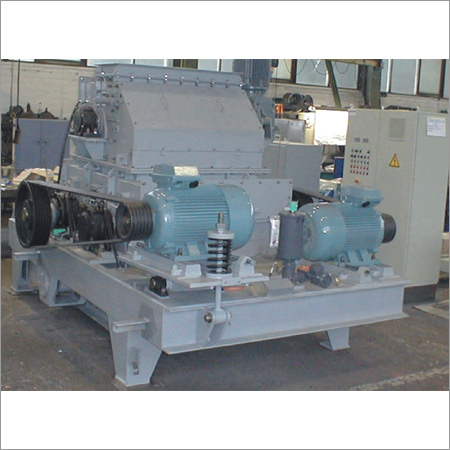

| Product Type | Roll Crusher |

| Dominant Color | Blue |

| Roll Material | Steel |

| Capacity | Variable |

| Power | Electric |

| Dimensions | Customizable |

| Usage | Primary and secondary crushing of raw materials in various industries, including fertilizer production and chemical processing. |

| Safety Features | Overload protection |

| Features | Fine grinding, Low dust, Easy adjust, Overload protection, Durable design |

Product Overview

Key Features

Four Roll Crusher

Fields

of Application:

Four

Roll Crushers are used for primary and secondary crushing. They are

particaularly suitable for medium and fine grinding processes,

demanding a narrow particle size distribution and a low dust content.

Feed

Materials

Raw

materials and products for example in the

- Fertilizer

industry - Power

plant technology - Chemical

industry

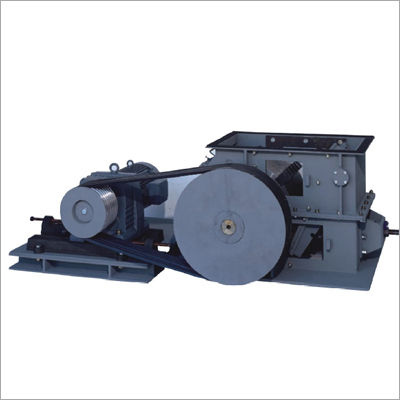

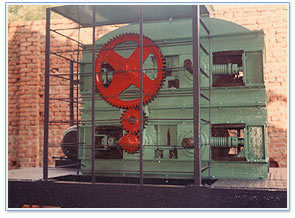

Mode of Operation

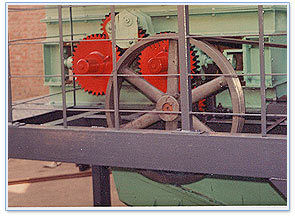

The crushing rolls are individually or driven in pair by electrical motors. Counterrotating via V-belts. The material is fed into the primary crushing stage by conveyors while it is spread over the whole width of the roll. The favourable angle of entry. determined by the optimum arrangement of the primary crusher rolls and corresponding grooves guarantees efficient feeding into the primary crushing stage, even in case of large feed lumps.

The optimum material guiding and the careful adjusting of the roll diameter towards the roll speed of both crushing stages guarantee a gentle grinding process with a minimum of wear and tear.

Special Features

Gap width of the primary crushing stage may be adjusted independently of the secondary crushing stage and ensures an easy and optimum coordination between the crushing stages.

Depending on the application. the primary crusher rolls are equipped with either grooves or teeth. In case feed materials are used with a tendency to clog, the crushing chamber and the material guides are lined with rubber.

The Four Roll Crusher integrates an overload protection in both crushing stages. Which allows foreign particles to pass without causing damage to the machine.

In order to facilitate maintenance, the roller shafts are arranged in amply-dimensioned spherical roller bearings. The bearing housings are equipped with lubricated labyrinths to avoid dust and dirt penetration.

Company Details

Focusing on a customer-centric approach, AMBICA CRUSHTECH PRIVATE LIMITED has a pan-India presence and caters to a huge consumer base throughout the country. Buy Construction Machinery in bulk from AMBICA CRUSHTECH PRIVATE LIMITED at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

15

Establishment

1998

Working Days

Monday To Sunday

GST NO

24AABCA6087H1ZQ

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AABCA6087H1ZQ

Vadodara, Gujarat

Director

Mr Urmit Hirubhai Patel

Address

987/2, G.I.D.C. Industrial Estate, Makarpura, Vadodara, Gujarat, 390010, India

roll crushers in Vadodara

Report incorrect details