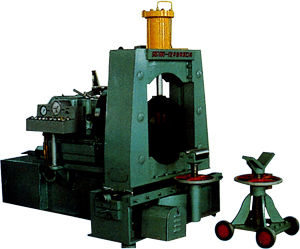

Pipeline Beveling Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Features | Precise Cutting, Automatic Beveling, Plc Control, High Efficiency, Multi-Axis Cutting, Versatile Applications |

| Payment Terms | Western Union, Paypal, Letter of Credit (L/C), Telegraphic Transfer (T/T) |

| Delivery Time | 1 Months |

Product Overview

Key Features

1. Several models available (16"type, 24" type, 32" type, 48" type, 60" type);

2. Automatic pipe cutting precision: + 1mm;

3. PLC system control;

4. High efficient pipe cutting with automatic self-measuring, automatic pipe end beveling; Intersection line profiling for both main and branch pipe function;

5. Multi-axis cutting machine can profile more complicated outlines with bevel;

6. Widely used for C. S / Alloy Steel pipe spool fabrication.

It has features as following:

1. Several models available (16"type, 24" type, 32" type, 48" type, 60" type);

2. Automatic pipe cutting precision: + 1mm;

3. PLC system control;

4. High efficient pipe cutting with automatic self-measuring, automatic pipe end beveling; Intersection line profiling for both main and branch pipe function;

5. Multi-axis cutting machine can profile more complicated outlines with bevel;

6. Widely used for C. S / Alloy Steel pipe spool fabrication.

AUTO Two-axis/Six Axis CNC Flame / Plasma Pipe Cutting and Profiling Machine can be used for the cutting and beveling with various pipe materials in fixed angle, different pipe end shapes, grooves and holes. It is consists of CNC rotating and lifting roller conveyor, CNC vertical cutting carriage, guide rail, electric control system, air course system, plasma system, loading/unloading mechanism, etc. By feeding the workpiece onto the CNC rotating/lifting roller conveyor, and then lowering the conveyor leaving workpiece onto the rotating roller, it is able to cut and bevel pipes automatically with selected parameters through Programmed Control System.

The combination of automatic programming and manual programming can realize the jacking cutting, with the function of cutting uprightly, cutting in any angle (manual adjustment), cutting with angle turning, multi-section elbow unfold cutting, intersection line cutting of plug-type/riding-type, etc. It is with characteristics of reasonable organization, easy operation, and high efficiency.

NAEC provides optimized consulting/ designing / planning / implementation services to EPC companies, contractors, fabricators, etc. For Oil & Gas industries. We are professional to provide a package of solutions to help customers achieve higher efficiency, non-defective quality and better management of fabrication projects, thus increasing customers' value.

We can help you with the following:

1. Planning your workshop, even the plot and providing the most suitable layout

2. Providing all solutions including material shot blasting and painting, cutting, edge beveling, fitting-up, welding, handling, non-destructive testing(DR/UR), PWHT

3. Providing management solution covering the entire lifecycle of a project from its preliminary material list, through planning, designing and to final implementation

4. Providing fast installation and dismantling solution of fabrication workshop

5. Providing Pre-WPS and supporting clients to do WPS/PQR that meeting API650, ASME, AWS standards

6. We can help you to get average 0.25manhour/DI layout design

For more questions, kindly pls contact with us. Thank you!

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company, Wholesaler, Producer

Employee Count

50

Establishment

2011

Working Days

Monday To Sunday

Payment Mode

Letter of Credit at Sight (Sight L/C)

Certification

ISO 9001:2008

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Cangzhou, Hebei

Mrs Lemon

Address

905 of One World Business Center, Cangzhou, Hebei, 061000, China

pipe beveling machine in Cangzhou

Report incorrect details