Continuous Casting Machine - Zinc Alloy, 500 Mt Production Capacity | Zero Maintenance, High Operational Fluency, Flawless Performance

Price:

Get Latest Price

In Stock

Product Specifications

| Melting Furnace Capacity | 10 Mt |

| Melt Rate | 1 Mt/Hr |

| Casting Machines | 2 |

| Rolling Mill Stands | 9 |

| Wire Drawing Machines | 2 |

| Features | Zero Maintenance, Flawless Performance, Sturdy Construction, High Fluency |

Product Overview

Key Features

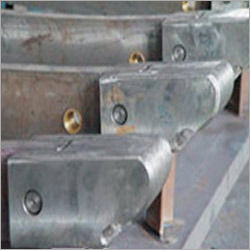

With our rich industry experience and knowledge, we are betrothed in offering elevated quality range of Continuous Casting Machine that is highly demanded due to its high operational fluency. This machine is precisely manufactured by making use of optimum grade components and latest technology in adherence with prevalent industry norms. The machine offered by us is mainly used for continuous casting, rolling and wire drawing process. Available in numerous technical specifications, this Continuous Casting Machine can be purchased from us at industry-leading prices.

Features:

-

Zero maintenance

-

Flawless performance

-

Sturdy construction

-

High operational fluency

Process description:

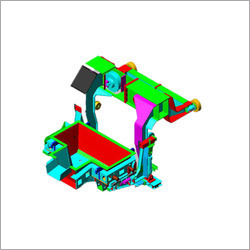

Zinc ingots are loaded in to the hydraulic tilting type zinc melting furnace. Molten zinc from the melting furnace is fed to the continuous caster . The cast bar from the caster is passes through tandem rolling mill for size reduction. A round wire of size 5.5 mm is produced by continuous casting and rolling process. Further size reduction is carried by specially designed wire drawing machine. Wire produced is packed in cardboard drum by drum packer machine.

Machine configuration to produce 500 MT of Zinc wire is as below:

10 MT capacity melting furnace with a melt rate of 1MT/Hr 2 no.

-

Continuous casting machine 1 no.

-

Cast Bar Cutter 1 no.

-

Metal launder system 1 set

-

9 stand Rolling Mill 1 no.

-

Swan Neck coiler 1 nos.

-

basket - 10 no

-

draw Wire Drawing machine 1 no.

-

draw high speed wire drawing machine for wire size from 3.15 mm to 1.5 mm

-

Spooler 8 nos.

-

MCC panel 1 no.

-

VFD Panel 1 no.

-

.Cooling Tower 1 no.

-

Furnace Oil Tank 1 no.

-

Water Pump 8 nos.

-

Furnace Oil pump 2 nos.

-

Line heater for furnace oil 1 no.

-

Lube Oil Pump 2 nos.

-

Hydraulic Trolley 2 nos.

-

Weighing Scale 1 nos.

-

.Tensile Testing Machine 1 No.

-

Air Compressor 1 no

-

Plate Heat Exchanger 1 no.

-

AC Motor 125HP 1 no.

-

Pipeline and Valve 1 set

-

Cabling 1 set

-

Transformer1 no.

Complete specification can be provided as per the requirement. We are the first company in India who has built zinc wire rod plant on turnkey basis indigenously and is running successfully over last several years.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

14

Establishment

2000

Working Days

Monday To Sunday

GST NO

24ABQPJ2589Q1ZR

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ABQPJ2589Q1ZR

Vadodara, Gujarat

Proprietor

Mr N. C. Jain

Members since

3 Years

Address

E-28, GIDC, Manjusar, Taluka Savli, Vadodara, Gujarat, 391775, India

continuous casting machines in Vadodara

Report incorrect details