Zinc Casting Machine General Medicines

Price:

Get Latest Price

In Stock

Product Specifications

| Mold Capacity | 25 Kg |

| Mold Dimensions | 600X100X40 Mm |

| Number Of Molds | 60 |

| Mold Material | Sg Cast Iron |

| Production Rate | 4 Ton/Hour |

| Knockout System | Automatic Dual |

| Drive Motor | 2 Hp |

| Features | Rugged Design, High Output, Easy Maintenance, Smooth Operation |

Product Overview

Key Features

Widely used in metallurgical industry for melting of zinc metal, offered Zinc Casting Machine is manufactured in line with set international standards using quality-approved components and ultra-modern technology. Under the strict guidance of our dexterous professionals, we manufacture, export and supply a wide collection of this machine that is extensively demanded due to its salient features given below. Additionally, we provide this Zinc Casting Machine to clients in a variety of specifications at pocket friendly prices.

Features:

-

Rugged design

-

Unmatched performance

-

Maintenance free

-

High operational fluency

Other Info:

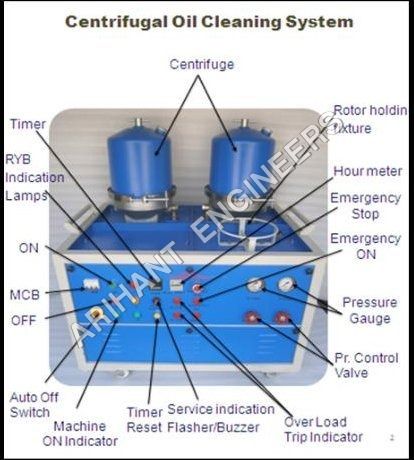

Arihant Engineers Ingot Casting machine has been developed to give trouble free production of all type of non ferrous metal and its alloy. Metal is poured from the furnace in to the casting wheel/Tundish and the system accurately controls the volume of metal in to each mould. The filled moulds travel up the incline , where they are water cooled. As the molds pass around the head sprocket , they invert , allowing the ingots to fall by gravity- assisted by two knock out hammer.

-

Mould type - 25 kg capacity

-

Mold Dimensions 600 mm long x 100 mm width x 40Mm height

-

Number of molds 60

-

Mould material SG cast iron

-

Production rate 4 ton per hour

-

Mould cooling Water spray , 9 spray heads, Total water consumption at 2 bar pressure 100 lts per hour

-

Knock out system Automatic dual Knock out system

-

Pouring system Casting wheel/ Cam operated tundish, Drive off main chain

-

Drive Motor 2 HP AC variable frequency drive

-

Gear box 750:1 double reduction worm gear

-

Conveyor chain 150 mm pitch bolted assembly

-

Machine inclination 13 degree

-

Machine construction Robust frame fully welded Construction . Frame is made Out of 200 x100 mm C chanel

-

Overall dimension 6 meter long x 1100 mm wide

-

Inclined table for mold sliding shall be provide.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

14

Establishment

2000

Working Days

Monday To Sunday

GST NO

24ABQPJ2589Q1ZR

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ABQPJ2589Q1ZR

Vadodara, Gujarat

Proprietor

Mr N. C. Jain

Members since

3 Years

Address

E-28, GIDC, Manjusar, Taluka Savli, Vadodara, Gujarat, 391775, India

zinc die casting machine in Vadodara

Report incorrect details