Wave Soldering Machine - High Quality Stainless Steel, Precise Pcb Positioning | Advanced Computer Control With Emergency Manual Override, Optimized Heating Method For Dead Angle Elimination, Touch Screen With Automatic Counting Function

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Dimensions | Customizable |

| Temperature Control | PID |

| Power | Variable |

| Heating Zones | Multiple |

| Conveyor Speed | Adjustable |

| Insulation | Aluminum Silicate |

| Features | Precise Heating, Uniform Temperature, Lead-free Design, Easy Operation, High Efficiency, Safe Operation, Durable Design, Accurate control, Rapid Heating |

Product Overview

Key Features

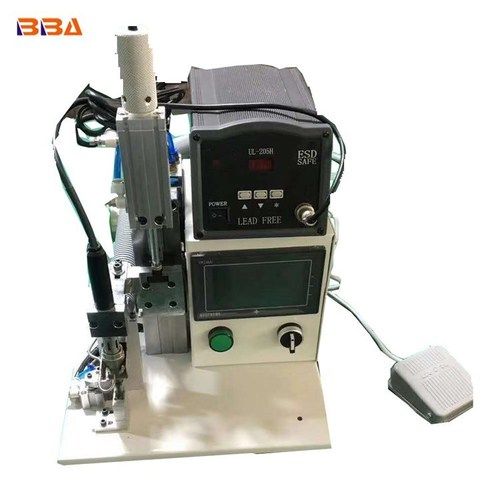

1. two kinds of control methods are designed: computer control and emergency manual control, with security function.

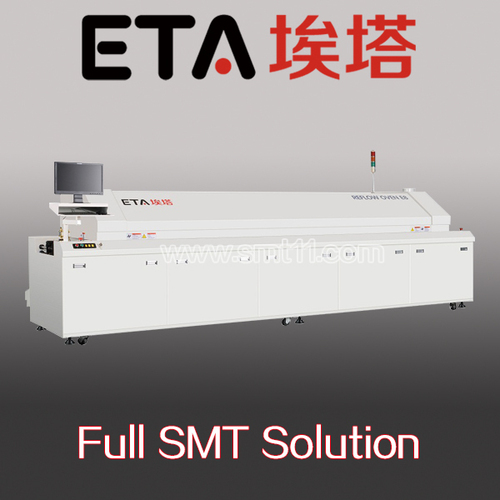

2.The leading heating method solved dead angle problem in the reflow soldering. It is suitable for the welding of electrical components of CSP, BGA, 020ICHIP etc.

3. The professional wind wheel design brings the stable wind speed, thus effectively guaranty the hot wind uniformity when. PCB is heating, so as to achieve the maximum repeated heating;

4.The forced independent circulation is used in each temperature zone. The independent PID control and the upper and lower independent heating method enable the accurate and uniform temperature of the furnace chamber with the large heat capacity.

5.The high quality aluminum silicate insulation materials are used in the insulation layer, thus brings the sound insulation effect and fast heating; the time it takes from room temperature to operating temperature < 20min.

6. Furnace lead-free design; all made of high quality imported stainless steel plate; High quality, high temperature and high-speed motor bring the steady wind transmission, with minor vibration and low noise;

6.The furnace uses cylinder lifting and safety rod support, which is safe and convenient.

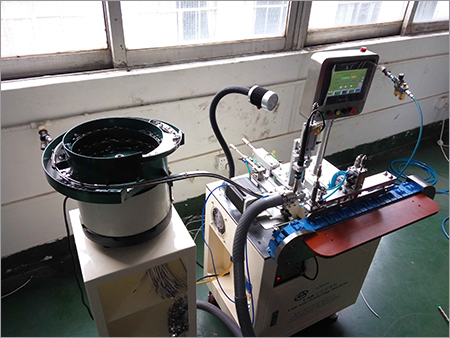

7. The positioning and fixing methods of PCB include a variety of different forms of precise positioning of reference holes positioning, reference edge positioning and the both positioning of the reference holdand edge as well as template positioning;

8. The touch screen features with the time display function, automatic counting function of printing times and screen saver function;

9. The machine with the left and right scraper speed adjustment functions and emergency stop safety function.

Company Details

Focusing on a customer-centric approach, SHENZHEN BENO PRODUCTS MANAGEMENT CO., LTD has a pan-India presence and caters to a huge consumer base throughout the country. Buy Welding & Soldering Supplies in bulk from SHENZHEN BENO PRODUCTS MANAGEMENT CO., LTD at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

20

Establishment

2015

Working Days

Monday To Saturday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Guangdong, Guangdong

Ms Rina Wei Rina

Address

NO.5, Chongqing road Baoan, district Shenzen, Guangdong, Guangdong, 518010, China

soldering machines in Guangdong

Report incorrect details