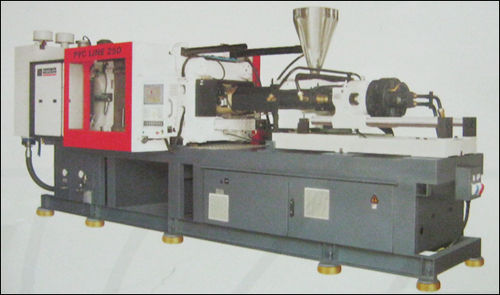

Sigma

Price:

Get Latest Price

In Stock

Product Specifications

| Tie Bar Dia | Variable |

| Clamp Type | Adjustable |

| Injection System | Precise |

| Control System | Programmable |

| Safety Features | Multiple |

| Material | Steel, Aluminum |

| Dimensions | Variable |

| Features | High Productivity, Low Maintenance, Environment Friendly, Safe Operation, Easy Operation, Modular Design, Durable Machine, Precise Control, Efficient Production |

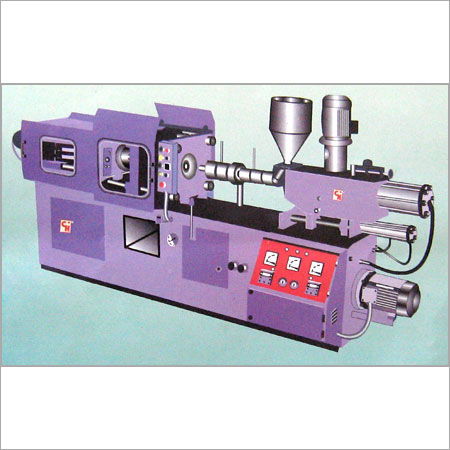

Product Overview

Key Features

SIGMA | |

Modern day processor

| |

New Millennium Norms | What it means |

Productive |

|

Efficient | Produce more parts from |

Safe to work with | Safe for humans, safe for moulds. |

Durable | Deterioration shall not be the reason for replacement, but, a different requirement. |

Adaptable | Not necessarily versatile. Versatility is costly. Modular construction makes it adaptable, may be upgradeable, as well. |

Simple | Simple in construction, for operation and for maintenance. |

Pleasing | Good looks. |

Environment Friendly | Use less power, oil, water and space. Produce less waste to be disposed off. Less noisy. |

SIGMA range has all the | |

| Milacron India | Competitor - A | Competitor - B | |||

| Model | Tie Bar Dia in mm | Model | Tie Bar Dia in mm | Model | Tie Bar Dia in mm |

| Sigma 30 | 45 | ||||

| Sigma 50 | 55 | 60 | 50 | ||

| Sigma 80 | 70 | 85 | 55 | 80 | 65 |

| Sigma 110 | 80 | 100 | 55 | 130 | 70 |

| Sigma 150 | 85 | 150 | 70 | ||

| Sigma 180 | 95 | 180 | 80 | 180 | 80 |

| Sigma 200 | 95 | 200 | 90 | ||

| Sigma 275 | 115 | 250 | 90 | 250 | 100 |

| Sigma 400 | 135 | 450 | 120 | 350 | 120 |

| Sigma 500 | 160 | 500 | 120 | 450 | 140 |

|

|

| INJECTION |

|

| EJECTOR |

|

| TEMPERATURE CONTROL |

|

| HYDRAULICS |

|

|

|

Company Details

Focusing on a customer-centric approach, Plastics Processing Machine Manufacturer Pvt Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Injection Moulding Machine in bulk from Plastics Processing Machine Manufacturer Pvt Ltd at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

200

Establishment

1996

Working Days

Monday To Sunday

Certification

ISO 9001

Related Products

More Product From This seller

Seller Details

Ahmedabad, Gujarat

Vice President- International Sales

Mr. Jagdish Bhandari

Address

Plot no. 93/2 & 94/1, Phase-1, G.I.D.C., Vatva, Ahmedabad, Gujarat, 382445, India

cp bath fittings in Ahmedabad

Report incorrect details