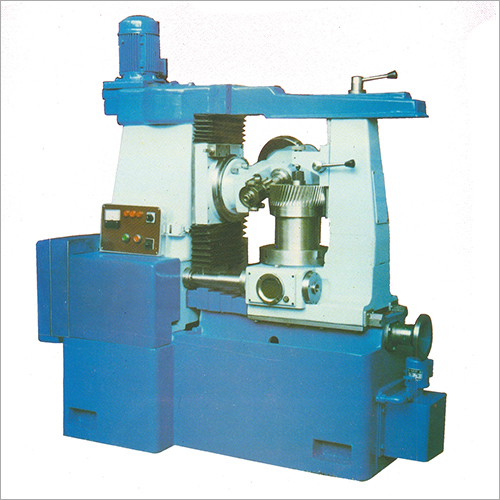

Shuttle Series

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel, Aluminum |

| Dimensions | Variable |

| Motor | Dc/Ac |

| Ratio | 24:1 |

| Display | 10.4 Tft |

| Storage | 80 Molds |

| Interface | Parallel Printer |

| Features | Modular Design, Precise Control, Cold Start, Replaceable Barrel, Fast Cycle, Programmable Heads, Microprocessor Control, Easy Setup |

Product Overview

Key Features

Extruder

- Bobbing movement extruder

- Modular type extruder with an option of smooth or grooved barrel

- Large size

extruder with DC Electric motor & drive and smaller sizes are with

AC drive motor & frequency inverter for precise screw speed control

even at low R P M - Cold Start Protection

- All extruders are with 24 L:D ratio

- Replaceable Grooved barrel

Clamp

- Tie-bar less clamp mechanism

- Linear motion guide rails for carriage and mould open / close movements

- On line Top, Bottom and Neck side deflashing

- Fully supported clamp does not require any hook system to compensate the deflection under calibration station

- Closed loop proportional control of clamp open / close and carriage shuttle movement

- Fastest Dry cycle

Extrusion Heads

- Uniloy Milacron designed single / two / three / four parison head

- All heads are programmable for parison thickness control

- Parison thickness controller - Actuator & Servo valve

- All heads are suitable for parison support air and pre-blow function with flow control for individual parison

- Bleed screw on the head for quick resin colour change

- Various types of parison shutters like Hot Knife, Rotating Knife, Cutting and Sealing device etc.

Microprocessor Control

- 10.4'' TFT colour display monitor

- Individual keys for manual functions

- 200 point parison programming

- Set parison profile display on screen

- 80 mould data storage

- Timer precision in 0.01 second

- Digital set up and display for speed, position, time and pressure

- Quick set up menu to set and view the valve of different pages in one page

- Statistical process control

- Process data for last 200 cycles with graph

- 1000 alarm stored in alarm history

- Freely programmable smart input and output

- Parallel printer interface

- Configurable multi level password

- Auto heat start up and shut down

- Partial Mould opening to reduce cycle time

Hydraulic

- Accumulator assisted machine

- Independent closed loop proportional control valve for mould open / close and carriage movement

- Position of all valves are close to the hydraulic actuators in order to provide accurate and consistent movements

Company Details

Focusing on a customer-centric approach, Plastics Processing Machine Manufacturer Pvt Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from Plastics Processing Machine Manufacturer Pvt Ltd at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

200

Establishment

1996

Working Days

Monday To Sunday

Certification

ISO 9001

Related Products

More Product From This seller

Seller Details

Ahmedabad, Gujarat

Vice President- International Sales

Mr. Jagdish Bhandari

Address

Plot no. 93/2 & 94/1, Phase-1, G.I.D.C., Vatva, Ahmedabad, Gujarat, 382445, India

Machineries in Ahmedabad

Report incorrect details