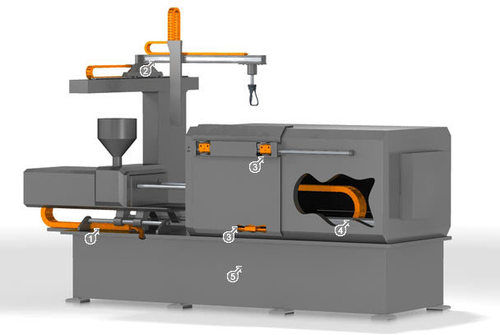

Injection Molding Machine - Durable Plastic Body, 15-350 Ton Clamping Force | High Efficiency With Microprocessor Control, Energy Saving Design

Price:

Get Latest Price

In Stock

Product Specifications

| Screw Diameter | 20-50 Mm |

| Shot Weight | 23-323 Gm |

| Injection Pressure | 1400-2240 Kg/Cm2 |

| Clamping Force | 30-180 Ton |

| Mould Platen Size | 310-710X650 Mm |

| Pump Motor | 3.75-18.75 Kw |

| Hydraulic Oil Tank | 110-400 Ltr |

| Features | High Performance, Easy Install, Long Life, Less Maintenance, Robust Structure, Energy Efficient, Smooth Functioning, Environment Friendly |

Product Overview

Key Features

By incorporating international standards of business integrity in our production process, we are able to manufacture and supply Injection Molding Machine. With precise engineering, these machines are used for manufacturing various plastic products. Equipped with a high-grade plastic body, these products have a longer service life with very less maintenance required. Owing to robust structure, smooth functioning, easy to install, environment friendliness and high performance, these products have earned a high demand in the market. In order to ensure the utmost satisfaction of our clients, we keep in mind their variegated while designing Injection Molding Machine.

Standard Specifications:

- Range from 15 ton and 350 ton.

- 5 stages injection speed/pressure

- 5 point tapper toggle

- Speed and pressure setting up to 99.99%

- Proportional temperature controller, interlock with screw-refilling

- Hydraulic ejector provided with 3 model: 1-hand, 2-pulsating, 3-stay put

- Display of pressure, flow time, temperature and operating keys with relevant's led's are easily accessible to operate on possible base fixed platten.

- Stable and energy efficient machine performance in attained via use of a unique speed and pressure matching hydraulic circuit which comprises of proportional value saves 20% power consumption.

Technical Specifications

| Item | Unit | IME 30 | IME 50 | IME 70 | IME 100 | IME 125 | IME 180 |

| Screw diameter | Mm | 20-25 | 25-30 | 30-35 | 35-40 | 40-45 | 45-50 |

| Shot weight(PS) | Gm | 23-36 | 49-70 | 80-105 | 122-160 | 188-238 | 262-323 |

| Theoretical shot vol. | Cm3 | 31-49 | 61-88 | 105-140 | 160-213 | 250-317 | 349-430 |

| Injection pressure | Kg/cm2 | 2240-1400 | 1800-1260 | 1880-1380 | 1785-1360 | 1968-1555 | 1769-1433 |

| Screw stroke | Mm | 100 | 125 | 150 | 170 | 200 | 220 |

| Plasticizing capacity | Kg/h | 10-16 | 23-40 | 40-50 | 50-62 | 65-80 | 90-110 |

| Nozzle stroke | Mm | 130 | 150 | 180 | 200 | 200 | 250 |

| Temperature | Zone | 4 | 4 | 4 | 4 | 4 | 4 |

| Clamping Unit |

|

|

|

|

|

|

|

| Mould clamping force | Ton | 30 | 50 | 70 | 100 | 125 | 180 |

| Mould opening stroke | Mm | 130 | 210 | 250 | 300 | 340 | 400 |

| Max/Min mould height | Mm | 200x100 | 250x125 | 300x150 | 300x200 | 400x250 | 450x250 |

| Max. Day light | Mm | 330 | 460 | 550 | 650 | 740 | 850 |

| Tie-bar distance HxV | Mm | 190x190 | 260x260 | 310x260 | 370x310 | 410x360 | 510x410 |

| Mould platen size | Mm | 310 | 400x400 | 470x430 | 530x470 | 610x530 | 710x650 |

| Ejector stroke | Mm | Mechanical | Mechanical | 50 | 70 | 80 | 100 |

| Ejector force | Ton |

|

| 2.2 | 3 | 4 | 4.5 |

| Electric Devices | |||||||

| Pump motor | kw | 3.75 | 5.62 | 7.5 | 9.3 | 11.25 | 18.75 |

| Heater | kw | 2.5 | 4 | 5 | 6 | 7.5 | 9 |

| Hydraulic oil tank | Ltr | 110 | 150 | 200 | 250 | 300 | 400 |

| Item | Unit | IME-15 | IME-30 | IME-50 | IME-70 | IME-100 | IME-125 | IME-150 |

| Screw Diameter | mm | 20 | 20-25 | 25-30 | 30-35 | 35-40 | 40-45 | 45-50 |

| Shot weight (PS) | CCM | 23 | 23-26 | 44-63 | 78-108 | 108-140 | 165-214 | 262-323 |

| Theoretical shot volume | CM | 31 | 31-49 | 58-84 | 105-144 | 144-188 | 226-286 | 350-431 |

| Injection pressure | Kg/cm | 1800 | 2200-1400 | 1800-1260 | 1850-1380 | 1780-1300 | 1950-1550 | 1950-1550 |

| Screw stroke | mm | 100 | 100 | 120 | 150 | 150 | 180 | 220 |

| Screw Revolution | rpm | 260 | 260 | 300 | 300 | 260 | 260 | 260 |

| Nozzle stroke | mm | 130 | 130 | 150 | 180 | 200 | 250 | 250 |

| Temperature | Zone | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Clamping Unit | ||||||||

| Mould clamping Force | Ton | IME-15 | IME-30 | IME-50 | IME-70 | IME-100 | IME-125 | IME-150 |

| Mould opening stroke | mm | 110 | 130 | 250 | 300 | 350 | 375 | 400 |

| Max/Min Mould | mm | 150/100 | 200/100 | 250/125 | 300/150 | 350/200 | 400/200 | 400/200 |

| Max day light | mm | 260 | 300 | 500 | 600 | 700 | 775 | 800 |

| Tiebar distance | mm | 180x180 | 210x210 | 260x260 | 310x310 | 370x370 | 410x410 | 460x460 |

| Mould platen size | mm | 290x290 | 310x310 | 400x400 | 470x470 | 520x520 | 610x610 | 670x670 |

| Ejector stroke | mm | Mechanical | Mechanical | 40 | 60 | 70 | 80 | 80 |

| Pump Motor | HP | 3 | 3 | 5 | 75 | 12.5 | 15 | 20 |

| Heater | KW | 2.5 | 3 | 4 | 5 | 6 | 7.5 | 7.5 |

| Oil tank | Ltr | 70 | 100 | 150 | 200 | 250 | 300 | 300 |

| Item | Unit | IME-180 | IME-225 | IME-320 | IME-400 | IME-500 |

| Screw Diameter | Mm | 50-55 | 55-66 | 65-70 | 70-75 | 75-80 |

| Shot weight (PS) | CCM | 368-445 | 576-685 | 1094-1269 | 1343-1542 | 1855-2060 |

| Theoretical shot volume | CM | 490-594 | 760-904 | 1458-1692 | 1790-2056 | 2473-2746 |

| Injection pressure | Kg/cm | 1750-1450 | 1950-1540 | 2044-1889 | 2224-2073 | 1800-1580 |

| Screw stroke | mm | 250 | 250 | 340 | 360 | 420 |

| Screw Revolution | rpm | 260 | 235 | 215 | 205 | 190 |

| Nozzle stroke | mm | 300 | 300 | 300 | 350 | 350 |

| Temperature | Zone | 5 | 5 | 5 | 5 | 5 |

| Clamping Unit | ||||||

| Mould clamping Force | Ton | IME-180 | IME-225 | IME-320 | IME-400 | IME-500 |

| Mould opening stroke | mm | 400 | 550 | 660 | 730 | 780 |

| Max/Min Mould | mm | 400/250 | 580/200 | 660/300 | 750/320 | 800/350 |

| Max day light | mm | 850 | 1130 | 1320 | 1480 | 1580 |

| Tiebar distance | mm | 510x410 | 570x570 | 660x660 | 760x760 | 820x820 |

| Mould platen size | mm | 710x650 | 860x860 | 970x970 | 1130x1130 | 1320x1320 |

| Ejector stroke | mm | 100 | 180 | 180 | 200 | 180 |

| Pump Motor | HP | 25 | 30 | 40 | 50 | 60 |

| Heater | KW | 9 | 14.8 | 21.5 | 25.5 | 36 |

| Oil tank | Ltr | 400 | 320 | 415 | 450 | 520 |

Company Details

Focusing on a customer-centric approach, ESEM ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Injection Moulding Machine in bulk from ESEM ENGINEERS at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

7

Establishment

1999

Working Days

Monday To Sunday

GST NO

24ABMPJ6987C1ZE

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ABMPJ6987C1ZE

Ahmedabad, Gujarat

Accepts only Domestic inquiries

Partner

Mr. Jagdish Jha

Address

No. 132/133, Rajdeep Industrial Estate, B.B. Talav, Vatva, Ahmedabad, Gujarat, 382440, India

plastic molding machines in Ahmedabad

Report incorrect details