Versapet

Price:

Get Latest Price

In Stock

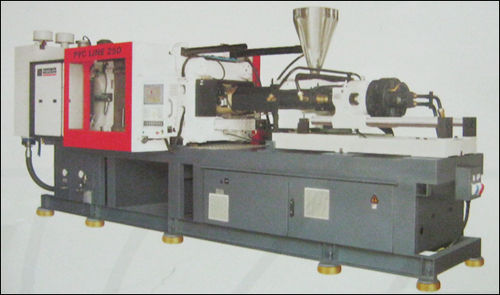

Product Specifications

| Material | Steel, Plastic |

| Capacity | 0.2-2 Liters |

| Clamp Type | Full Electric |

| Heating | Infrared |

| Control | Plc-Based |

| Features | High Capacity, Low Cycle Time, Energy Efficient, Easy Maintenance, Quick Changeovers, Reliable Operation, User Friendly, Precise Control |

Product Overview

Key Features

Why PET ?

- PET bottles are gaining immense popularity worldwide, both amongst consumers and manufacturers since it is....

- Totally lnert, Non-toxic.

- Exhibits excellent resistance to chemicals like acids, alkalis, alcohols and commonly used chemicals and oils/fats.

- Crystal clear and can be colored for better UV and light resistance.

- Adaptable to both metal and plastic caps.

- Gives consistent fill point and brimful volumes

- Lighter than glass bottles - reduces packaging and handling cost, also reduces hassles in transportation.

Why Versa PET ?

- The simple

and reliable linear machine; covers most frequently used container

sizes from 0.2 to 2 liters uses feature-advantage combinations viz. - Huge capacities - Lower cycle time

- Energy efficient - All Electric Clamp

- Less Connected Load - Optimized INFRARED emitter rating

- Reduced Utilities - Special manifold design

- Reduced changeover time - Less numbers of mandrels

- Maintainability - Easy mould access area.

Applications

- Mineral Water

- Fresh Milk

- Carbonated Soft Drinks

- Edible Oil & Vinegar

- Fruit Juices

- Agro Chemicals

- Pharmaceuticals

- Cosmetics

- Liquors

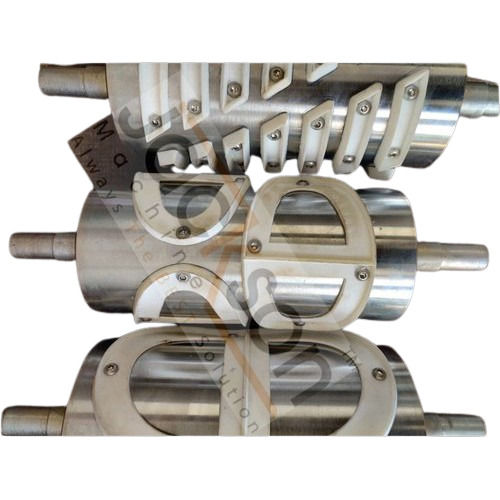

Clamp

- Fully automatic machine from preform hopper to ejection of bottles.

- Full Electric clamp mechanism.

- Fast clamp cycling by servomotor with reduced power requirement.

- Easy access to mould and quick product changeovers.

- Even clamp force distribution minimizes parting lines on finished product.

Blow and Stretch Rods

- Blowing process enabled only with optimized preform temperature and presence.

- Fast and easy adjustable 2 phase stretch rods mechanism.

- Individual blow system for optimized processing performance.

Oven

- Infrared, lamp heating with lamp failure monitoring.

- Continuous monitoring of preform temperature by infrared sensing device.

- Optimized heating and conditioning for high performance and flexibility.

- Water cooled heat shield for neck protection in heating area.

Transport

- Race track transport with optimized time motion transfer.

- Individual pallet with roller bearing mandrel rotation for accurate and extended life operation.

- Quick change and economical mandrel finger design for multiple format operation.

Control

- All process parameters accessible and stored in operator panel with real time access.

- User friendly control with fault diagnosis and alarms.

Company Details

Focusing on a customer-centric approach, Plastics Processing Machine Manufacturer Pvt Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from Plastics Processing Machine Manufacturer Pvt Ltd at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

200

Establishment

1996

Working Days

Monday To Sunday

Certification

ISO 9001

Related Products

More Product From This seller

Seller Details

Ahmedabad, Gujarat

Vice President- International Sales

Mr. Jagdish Bhandari

Address

Plot no. 93/2 & 94/1, Phase-1, G.I.D.C., Vatva, Ahmedabad, Gujarat, 382445, India

Machineries in Ahmedabad

Report incorrect details