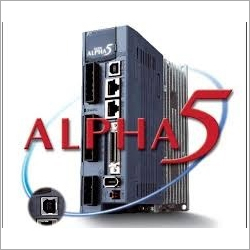

Professional Ac Servo System - 0.05kw To 2.9kw Power Range | Low Maintenance, Vibration Suppression Control, Easy Installation

Price:

Get Latest Price

In Stock

Product Specifications

| Power Range | 0.05kW to 2.9kW |

| Encoder | 17-bit incremental |

| Communication | RS485 |

| Protection | IP67 |

| Modes | Speed, Torque, Positioning |

| Inputs | 5 digital inputs |

| Outputs | 4 digital outputs |

| Features | Robust construction, Low maintenance, Easy installation, Precise control, High performance, Easy tuning, Simple synchronization, Wide range |

Product Overview

Key Features

We are a

renowned entity famous for manufacturing, supplying and exporting an all

inclusive range of Professional Ac Servo

System in the domestic as well as international market. The wide range of servo systems is

manufactured by using superior quality materials & components by our

experts. This Professional Ac Servo System finds huge application in textile

machine, machine tool, pick and place system, jewelry engraving, wire twister

and screw feeder.

Features

- Robust construction

- Low maintenance

- Easy to install

Professional Ac Servo System

We are offering Professional Ac Servo System. As the technology of microprocessor unit becomes more advanced and much further, the development and cost effectiveness of permanent magnet manufacturing technology for servo motor and high power and high performance semiconductor power devices is improved continuously.

Features

- Vibration Suppression Control for Pendulum type loads

- Easy Tuning- No expert programmer required. With Load Tunning for better performance

- Monitor O/P function - Two analog output are provided (0-10V)

- Simple Synchronization between multiple servo w/o PLC

- 15 bit Simulated Encoder output (diff. 5V A, B, Z pulse) for better CNC controls

- Operation Monitor on keypad, all modes - Positioning, Torque, Speed

- 5 digital input, 4 digital output

- 3 modes of operation - Speed, Torque, Positioning modes and combination of this modes

- Operating parameters on keypad, for speed, position, torque

- Side - By - Side installation

- 17 Bit Encoder - incremental

- Test operation function - Jog function - for wiring and mounting check

- Wide Range - 0.05kW to 2.9kW, Low inertia and Middle inertia

- RS485 port connection with simple LAN cable

- Two RS485 Port - For multiple Servo programming and monitoring

- IP67 Motor

- Preventive maintenance - Last 9 fault history recorded

Specially Designed for

- Winder / Unwinder

- Textile machine

- Machine Tool

- CNC

- Pick and Place system

- Jewelry Engraving

- Wire twister

- Screw feeder

- Cut to Length machine

- Packaging

- Printing

Servo Amplifier 0.05kW - 2.9kW

| Applicable motor rated speed | 3000 [r/min] | ||||||||

| Applicable motor output | 0.05kW | 0.1kW | 0.2kW | 0.4kW | 0.75kW | ||||

| Type RYC | D3-VVT2 | 500 | 101 | 201 | 401 | 751 | |||

| C3-VVT2 |

|

|

|

|

| ||||

| B3-VVT2 |

|

|

|

|

| ||||

| Outer frame number | Frame 1 | Frame 2 | |||||||

| Mass [kg] | 1.0 | 1.5 | |||||||

| Power supply | Main power | Phase | Single-phase | Single-phase, 3-phase | |||||

| Voltage | AC200 to 230 V -15 to +10% (-10 to +10% at Single-phase) | ||||||||

| Control power | Phase | Single-phase | |||||||

| Voltage | AC200 to 230 V -15 to +10% | ||||||||

| Control system | IGBT PWM sinusoidal PWM drive | ||||||||

| Feedback | 17-bit serial encoder (incremental) | ||||||||

| Functions, input/output signals | Sequence input | (1) Servo ON, (2) +over-travel, (3) -over-travel, (4) emergency sTop, (5) P-action, (6) free run command, (7) anti-resonant frequency selection 1, | |||||||

| Sequence output | (1) Servo ready, (2) positioning complete, (3) servo alarm detection a-contact, (4) servo alarm detection b-contact, (5) dynamic braking control, | ||||||||

| Encoder signa | Dividing setting | Pulse output setting 16 to 32768 (pulses/rev) | |||||||

| Signal form | (1) Line driver output A-phase, B-phase, and Z-phase, (2) open collector output Z-phase | ||||||||

| Monitor output | Analog voltage output for signal measurement (alternating, pulsating) | ||||||||

| Position control | Max. command pulse frequency | Pulse frequency (max.) command input 1 MHz (differential), 200 kHz (open collector), dividing output 500 kHz (differential) | |||||||

| Input pulse signal form | Compatible with two systems: (1) RS-422 line driver signals and (2) open collector signals | ||||||||

| Input pulse type | Selectable from (1) command pulse/command sign, (2) forward operation/reverse operation pulse, and (3) two 90 phase-different signals | ||||||||

| Command pulse |

| ||||||||

| Position control input | (1) Command pulse correction + selection 1, (2) command pulse correction a selection 2, (3) deviation clear, (4) command pulse disabled | ||||||||

| Speed control | Speed control range | 1:5000 | |||||||

| Acceleration | 0 to 10 s / 2000 r/min, acceleration and deceleration times can be set separately, two acceleration times and deceleration times can be set, S-curve acceleration/deceleration is possible. | ||||||||

| External speed command input | Torque control by analog voltage commands,10 V input, the voltage-speed scale and offset can be set by setting parameters. | ||||||||

| Internal speed setting | Three speeds can be set by setting internal parameters. | ||||||||

| Speed control input | (1) Multi-speed selection 1, (2) multi-speed selection 2, (3) forward operation, (4) reverse operation, (5) acceleration/deceleration time selection | ||||||||

| Torque control | External torque command input | Speed control by analog voltage commands,10 V input, the voltage-torque scale and offset can be set by setting parameters. | |||||||

| Torque control input | (1) Forward operation and (2) reverse operation can be assigned to sequence inputs CONT1 to CONT5 and used. (*1) | ||||||||

| Regenerative braking | Regenerative braking to DC intermediate circuit, the regenerative resistor can be externally installed. | ||||||||

| Additional functions | Zero clamp function, vibration suppressing control, notch filter, easy tuning, brake timing output, etc. | ||||||||

| Protection | Overcurrent (OC1, OC2), overspeed (OS), overvoltage (Hv), encoder error (Et), control power error (Ct), memory error (dE), regenerative transistor overheat (rH2) | ||||||||

| Working conditions | Installation place | For indoor use at max. altitude of 1,000 m or below. The installation place shall be free from dust, corrosive gas, or direct sunlight. To meet European standards: Pollution degree = 2, overvoltage category = | |||||||

| Temperature/humidity | -10 to 55oC, 10 to 90 %RH (without condensation) | ||||||||

| Vibration/shock resistance | 4.9m/s2 {0.5G} , 19.6m/s2 {2G} | ||||||||

| Standards | Conforming to UL/cUL (UL508c) and CE Mark (low voltage directive EN50178) | ||||||||

Motor with a brake

| Motor type | GYG501BC2 | GYG851BC2 | GYG132BC2 | GYG182BC2 | GYG292BC2 |

| Rated output [kW] | 0.5 | 0.85 | 1.3 | 1.8 | 2.9 |

| Rated torque [N.m] | 3.18 | 5.41 | 8.28 | 11.5 | 18.6 |

| Static friction torque [N.m] | 17 | 32 | |||

| Moment of inertia [kg.m2] | 13.6, 10-4 | 17.3, A A 10-4 | 24.5, 10-4 | 42.3, A A 10-4 | 56.0, 10-4 |

| Rated DC voltage [V] | 24 V DC- 10 % | ||||

| Attraction time [ms] | 120 | 170 | |||

| Release time [ms] | 30 | 50 | |||

| Brake input [W] | 14 (at 20oC) | 34.7 (at 20oC) | |||

| Mass [kg] | 8.6 | 9.7 | 12.0 | 23.5 | 27.5 |

Company Details

Focusing on a customer-centric approach, SPRINT CONTROLS has a pan-India presence and caters to a huge consumer base throughout the country. Get Industrial Automation from SPRINT CONTROLS at Trade India quality-assured services.

Business Type

Exporter, Importer, Manufacturer, Service Provider, Distributor, Supplier, Trading Company

Employee Count

45

Establishment

1998

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Mumbai, Maharashtra

Proprietor

Mr. Vaibhav Chokhawala

Address

K-121, Ansa Industrial Esate, Sakivihar Road, Andheri (E), Mumbai, Maharashtra, 400072, India

ac servo motor in Mumbai

Report incorrect details