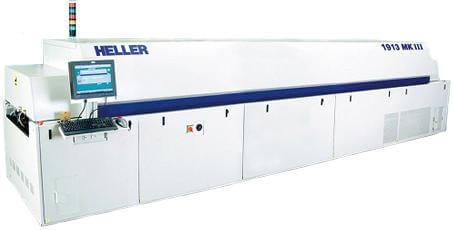

Plc Controlled High-efficiency Hot Air Circulation Lead-free Reflow Oven - 15 Inch Lcd Display, Ultra-fast Heating And Cooling System, Independent Temperature Zones Monitoring

Price:

Get Latest Price

In Stock

Product Specifications

| Condition | New |

| Power Source | Electric |

| Product Type | Lead Free Reflow Oven |

| Usage | PCB Soldering |

| Type | Other Ovens |

| Payment Terms | Telegraphic Transfer (T/T) |

Product Overview

Key Features

Electrical control system is stable and reliable.

1. The control system adopts PLC, PC brand computer, with genuine Windows XP operating system and 15 inch LCD display, ensure that the control system is stable and reliable.

2. The control software is powerful, has control of the process parameters and the temperature curves of flexible, operation interface English can always switch.

3. The WOGO terminal; important electrical components imported brand, all signal cables shielding.

Recovery system

1. Forced cooling system using two forced fan cooling zone, satisfy lead-free process; cooling curve is smooth, no

mutation,sufficient heat exchange, the cooling rate is up to -5 a /S.

2. Rosin directional flow, replace the cleaning is very convenient. Using special pipe exhaust lifelong

maintenance.

Smooth and reliable transmission system

1. Symmetric double groove guide, not high temperature deformation, heat absorption of small. The standard chain, chain network.

synchronous speed parallel transport (can be connected and online automatic SMT), optional dual rail transportation system or the

central support system.

2. Width adjustment using three synchronous width adjusting structure, with a guide rail heat expansion automatic extension across

the device, effectively ensure the parallel guide rails, prevent off board, card board, cleaning, easy adjustment.

3. UPS power-off protection function, ensuring that the PCB suddenly switched off after the normal output, not damaged.

Company Details

Shenzhen Pengchuangxin automation equipment co., LTD. is a professional design and manufacture of sales SMT equipment series technical comprehensive service enterprises, the main products are series of SMT domestic LED placement machine, solder paste printer, solder paste mixer, full computer lead-free reflow, lead-free wave welding machine, glue machine, LED soft article lamp soldering machine, article light plate, light the whole board glue machine, light bar cutting machine, LED soft article lamp reel machine, article LED lights the whole board test board, LED lights article sealing machine and other series of electronic equipment.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Wholesaler

Employee Count

50

Establishment

2008

Working Days

Monday To Friday

Payment Mode

Paypal

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shenzhen, Guangdong

Mrs May

Address

No. 224-1 Xiangshan Avenue Luotian Community, Songgang Street, Baoan District, Shenzhen, Guangdong, China

smt reflow ovens in Shenzhen

Report incorrect details