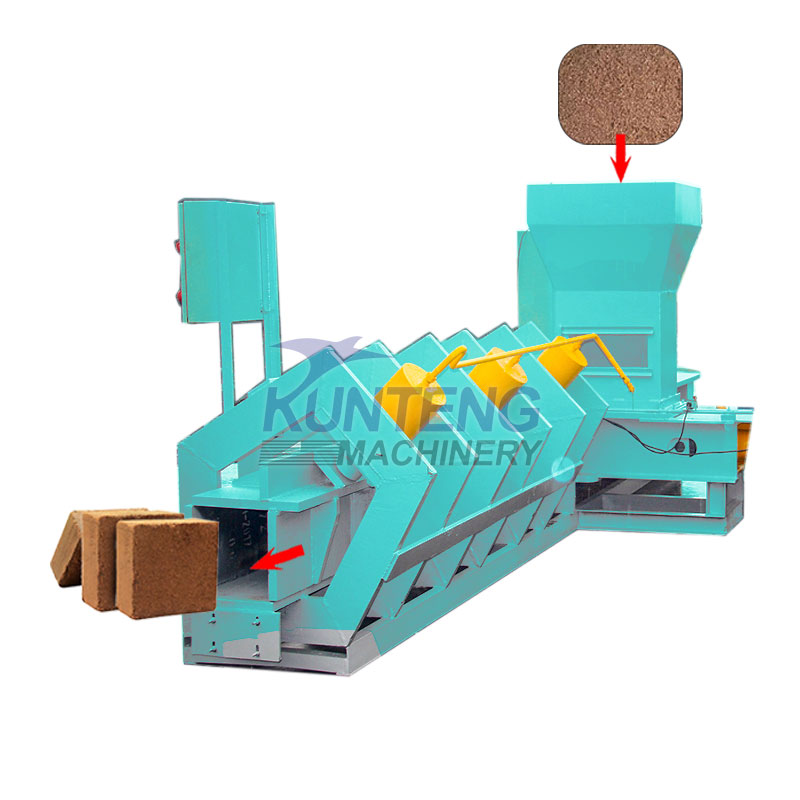

Olive Residue Charcoal Ball Press Machine Charcoal Coffee Residue Charcoal Briquetting Machine - Briquette Size: Customized

Price: 138335 INR

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | Olive residue charcoal ball press machine |

| General Use | Charcoal powder, coconut shell charcoal powder, mineral powder, rice husk charcoal powder, palm shell charcoal powder, etc |

| Production Capacity | 6-7 T/hr |

| Product Shape | Customized |

| Weight (kg) | 1500 Kilograms (kg) |

| Type | Briquette Machines, Briquette Press Machine |

| Computerized | Yes |

| Automatic | Yes |

| PLC Control | Yes |

| Voltage | 220-420 Volt (v) |

| Motor | AC Motor |

| Briquette Size | customized |

| Dimension (L*W*H) | 1.95*2.75* 2.1 Meter (m) |

| Feature | Low Consumption, Energy Saving, Compact Structure, High Efficifiency, Automatic Feeding System, Automatic Discharging System, Customized Accessories |

| Color | Other |

| Warranty | 1 year |

| Payment Terms | Letter of Credit (L/C), Paypal, Telegraphic Transfer (T/T), Others |

| Supply Ability | 10 Per Month |

| Delivery Time | 10 Days |

| Sample Available | No |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | container |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

| Certifications | CE,ISO,CCC |

Product Overview

Key Features

MODEL | ROLLER DIAMETER (mm) | CAPACITY (T/H) | POWER (KW) | REDUCER |

290 | 290 | 1-2 | 5.5-7.5 | 350 |

360 | 360 | 2-3 | 7.5-11 | 350 |

450 | 450 | 4-5 | 18.5-22 | 400 |

550 | 550 | 5-8 | 22-30 | 500 |

650 | 650 | 8-10 | 30-45 | 650 |

850 | 850 | 15-20 | 90 | 850 |

1000 | 1000 | 25-30 | 110 | 1000 |

Company Details

KUNTENG company was founded in 1999. We have been engaged in manufacturing all kinds of industrial dryer machines, mesh belt dryers, heat pump dryers, brush roller washing machines, Air bubble washing machines, vegetable and fruit slicers, and food processing machines for many years. We got more patented technologies and honor. Our machine has passed ISO9001:2000CCC and CE certification. We provide customers with a one-stop service of design solutions, complete equipment, on-site installation, and after-sales support. Welcome to cooperation.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

59

Establishment

2018

Working Days

Monday To Sunday

Payment Mode

Online Payments (NEFT/RTGS/IMPS), Cheque/DD

Certification

EN ISO 12100:2010; EN 60204-1:2018

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zhengzhou, Henan

Manager

Mr Kun Teng

Members since

1 Years

Address

No. 8, Chuangye Avenue, Zhanjie Town, Zhengzhou, Henan, 450000, China

charcoal briquette machine in Zhengzhou

Report incorrect details