- Tradeindia

- Briquettes Making Machines

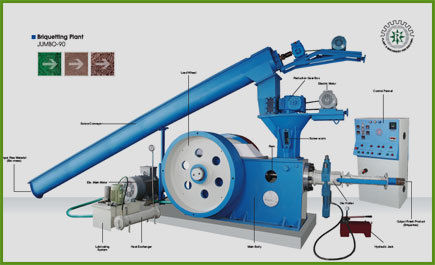

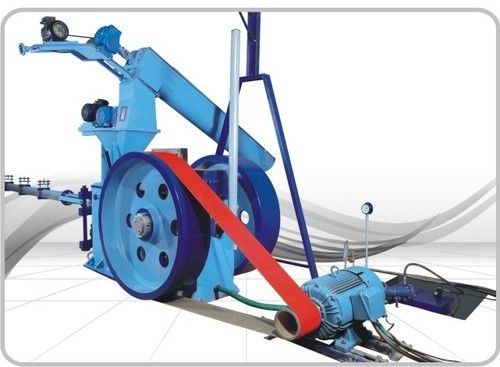

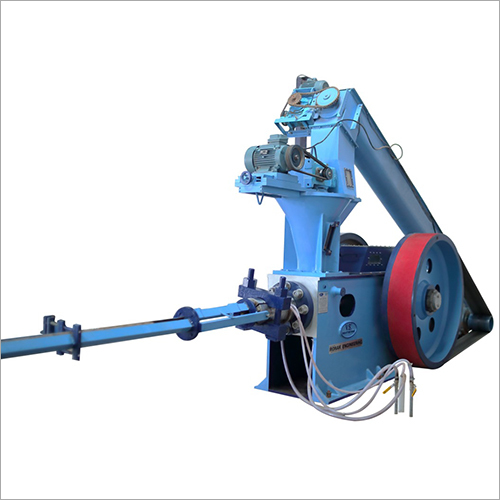

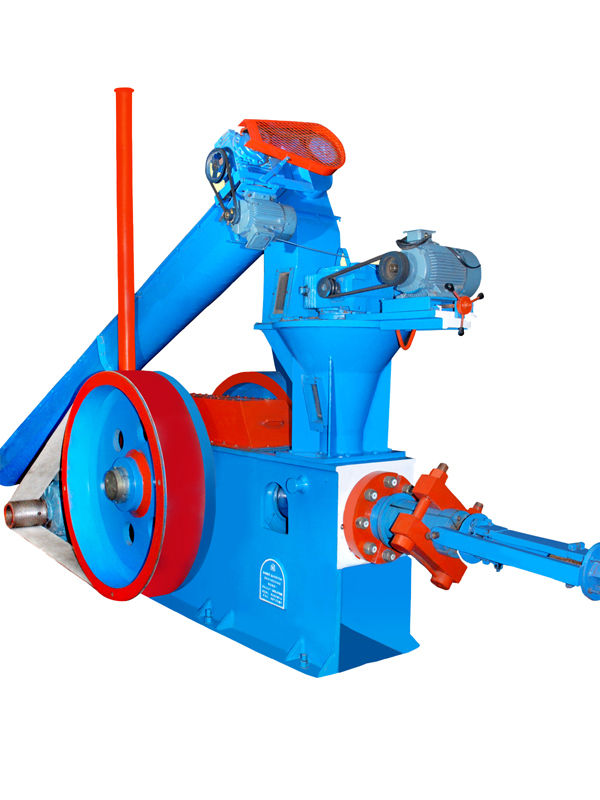

- Biomass Briquette Press

Biomass Briquette Press

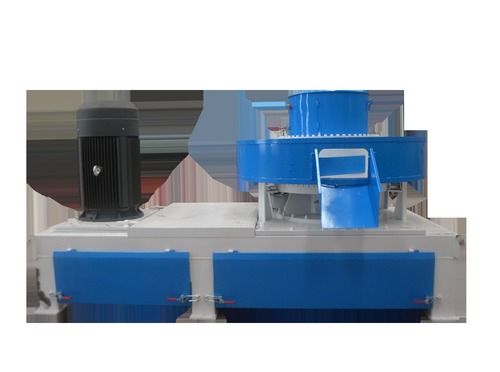

(53 products)Compact Structure Electric Briquette Making Plant

Price: 100000 INR/Unit

MOQ1 Unit/Units

Product TypeBriquette Plant

Production CapacityUp to 2000 Kg/hr

Product ShapeCylinder

Wooden Biomass Briquettes - Fixed Carbon: Yes

Price: 7000 INR/Metric Ton

MOQ100 Metric Ton

Product TypeBituminous Coal

MaterialBiomass Briquettes

ShapeBriquette

Biomass Briquetting Plant

Price Trend: 500000.00 - 1600000.00 INR/Piece

MOQ1 Piece/Pieces

Supply Ability1 Per Week

Delivery Time30 Days

Ecostan India Pvt Ltd

Ludhiana

Trusted Seller

Trusted Seller10 Years

Premium Seller

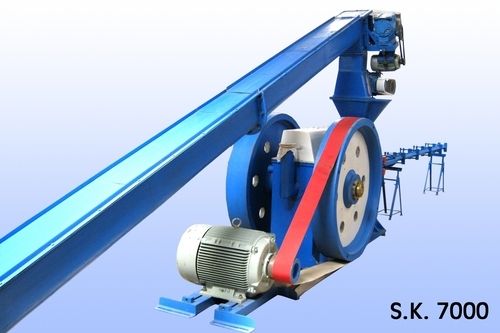

Premium SellerBiomass Briquetting Plant - Feature: High Efficifiency

Price: 2251000 INR/Number

MOQ1 Number

Product TypeBriquetting Plant

General UseIndustrial

AutomaticYes

Radhe Engineering Company

Rajkot

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerMetal Chips Briquetting Press Application: Industrial

Price Trend: 5000.00 - 30000.00 USD ($)/Set

MOQ1 Set/Sets,

Product TypeMetal Chips Briquetting Press

MaterialMETAL

ApplicationIndustrial

Biomass Briquetting Press Production Capacity: 500-1000 Kg/Hr

Price: 2100000 INR/Plant

MOQ1 Plant/Plants

Coloras per order

MaterialOther, Steel

Production Capacity500-1000 kg/hr,1000-1500 kg/hr Kg/hr

Sawdust Briquettes Biomass

MOQ10 Ton/Tons

Product TypeOther, Sawdust Briquettes Biomass

ShapeOther, Round

Biomass Briquettes Press

Product DescriptionWe offer our client an excellent quality range of Briquettes. These can be customized as per our precious customers specifications. These are widely known for its durability and quality. Our Briquette can be availed at industrial leading price.\015\012\015\012Benefits\015\012 100% Depreciation on

A Grade 100 Percent Pure Best Quality Eco-Friendly Natural Groundnut Biomass Briquettes

Price: 9,300 INR/Ton

MOQ100 Ton/Tons

Product TypeBituminous Coal

MaterialCoal

ShapeBriquette

Biomass Briquette Making Machine

Price Trend: 25000.00 - 35000.00 USD ($)/set

MOQ1 set

Product TypeBiomass Briquette Making Machinery

MaterialCommon Steel

Capacity1000 Kilogram(Kg)

Biomass Briquette Press

Product DescriptionThese Biomass Briquetting Press are widely used to generate heat as an industrial fuel like steam generation in boilers, heating purpose, drying process & gasification plant to replace existing conventional fuel like coal, wood & costly liquid fuel like FO, Diesel, LDO, kerosene etc. Use of Biomass

Biomass Briquette Making Machine

Product DescriptionClients can avail from us an impregnable range of Biomass Briquette Making Machine. Our product array is designed and developed in line with the global quality parameters. These Biomass Briquette Making Machines are highly demanded for their superior construction, easy installation and maintenance

Top Rated Products

Metal Chips Briquetting Press Application: Industrial

Anyang Forging Press Machinery Industry Co., Ltd

FAQs Related to Biomass Briquette Press

Who are the top biomass briquette press manufacturers in India?

- Jay Khodiyar Machine Tools

- Ronak Engineering

- Ecostan India Pvt Ltd

- Solid Ply Pvt Ltd

- Anyang Forging Press Machinery Industry Co., Ltd

- Haritima Bio Energy

- Radhe Engineering Company

Which cities have the largest number of biomass briquette press suppliers?

- Rajkot

- Ludhiana

- Malerkotla

- Ambernath

- Vadodara

- Yamunanagar

- Zhengzhou

- Gongyi

- Anyang

- Guangzhou

- Jinan

What is the price range for biomass briquette press offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| Radhe Engineering Company | INR | Biomass Briquetting Plant | 2251000 |

How many trusted sellers are available for biomass briquette press?

- SOLID PLY PVT LTD

- ECOSTAN INDIA PVT LTD

- Radhe Engineering Company

- Shree Khodiyar Engineering Works

What is the minimum order quantity for biomass briquette press?

Do listed companies have registration & certifications?

- JAY KHODIYAR MACHINE TOOLS

- ECOSTAN INDIA PVT LTD

- Radhe Engineering Company

- ANYANG FORGING PRESS MACHINERY INDUSTRY CO., LTD

- RONAK AGROTECH ENGINEERING PVT. LTD.

- Shandong Rotex Machinery Co.,ltd

What is the get latest price feature?

What types of payment methods are accepted by the biomass briquette press suppliers?

Biomass Briquette Press

Product DescriptionWe are an eminent processor and supplier of Biomass Briquette Press those are made by high grade of material. These are according to the client specification

Om Wholesale

Choudwar

Ms Briquette Machine

Price Trend: 1085000.00 - 1835000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeBriquette Press machine

Weight7000 Kilograms (kg)

ColorYellow

Fine Finish Biomass Briquettes

Payment TermsCash on Delivery (COD), Cash Against Delivery (CAD), Others, Cash in Advance (CID), Cheque, Cash Advance (CA)

Delivery Time1 Week

Sample PolicyContact us for information regarding our sample policy

Double Roller Structure Biomass Briquetting Machine Briquette Size: 32Mm

Price: 32000 USD ($)/Set

MOQ1 Set/Sets

Product TypeBiomass Briquetting Machine

MaterialSawdust

Production Capacity1.5-2.5 T/hr

Charcoal Briquette Press Machine

Price: 5000 USD ($)/Set

MOQ1 Set/Sets

MaterialQ235

Power5.5-15 Kw Siemens Volt (S )

Voltage415 Siemens Volt (S )

Briquette Biomass

Product DescriptionBeing a quality focused organization,we are betrothed in manufacturing and supplying a pristine quality Briquette Biomass . Offered biomass is availed from coal or charcoal substitutes, which is used in power generating industries for heating boilers in order to produce electricity. The provided

Biomass Briquetts

Price: 5000 INR/Ton

MOQ30 Ton

Payment TermsCash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID)

Supply Abilityas per customers' demand Per Month

Main Domestic MarketRajasthan

Coal Briquette Plant

Product DescriptionWe are affianced in providing a wide range of Coal Briquette Plant to the clients. Further, these products are manufactured using the latest technology and advanced machinery. These Coal Briquette Plant are highly reliable as these are fabricated using optimum quality material. Features of Kehua coa

White Lime Powder Briquette Machine For Powdery Materials Pressing

Product DescriptionLoaded with vast industrial knowledge and expertise, we have emerged as a major Exporter, Manufacturer & Supplier of Lime Powder Briquette Machine For Powdery Materials Pressing in Zhengzhou, Henan, China. Lime powder briquette machine is using the high pressure powder materials briquette machine, p

Biomass Briquette Machine

Product DescriptionBiomass briquettes, mostly made of green waste and other organic materials, are mainly used as biofuel substitute to coal and charcoal in electricity generation, heat, and cooking fields. They can be used to heat industrial boilers in order to produce electricity from steam. The most common use of b

Biomass Briquette Machine

Product DescriptionWe are engaged in offering excellent quality Biomass Briquette Machine to our valuable clients. Charcoal briquettes are made of all kinds of agro-wastes and forest residues. If there are abundant biomass resource available, you can consider starting a charcoal briquette plant. Charcoal briquettes ha

Flat Die Biomass Briquette Press

Product DescriptionFlat die biomass briquette press is a specially designed machine for making biomass waste into briquette which is a green fuel. The briquette machine can not only be used for making biomass fuel, but also for making feedstuff. Biomass briquette is an environmental protection, clean and reproducible

Biomass Briquette Machine

Product Descriptionit can press the straw (agricultural waste) into briquette.The product is biomass fuel.It can be run with electrical power and diesel power. the raw materials are all kind of agricultural wastes. and the moisture can be 5%-30%.The diameter of the raw material is from power to 55mm. productivity is 1

9YP-630 Briquette press

Product DescriptionIntroduction This machine is used for making briquette from sawdust, straw, hulls, rice hull,branch,leaf,etc .These raw materials are pressed and chared into solid fuel,the shape could be square and round type .The working process doesnt require any additive. Less smoke while burning. This model has

Biomass Briquette Machine

Product Descriptionbiomass briquette machine is based on the introduction of advanced equipment from Europe by our company, with key component using the imported material, the remaining parts achieving localization .After more than two years of market validation, we\342\200\231ve proved that our equipments are superio

Latest from Biomass Briquette Press

Biomass Briquette Press Machine

By:

Hitech Agro Projects Pvt Ltd

Briquette Press Machine

By:

Ecostan India Private Limited

Flat Die Biomass Briquette Press

By:

Azeus Charcoal Briquette Machinery

Biomass Briquette Press Machine Spare Parts

By:

Kranti Engineering

Industrial Biomass Briquette Press

By:

Ronak Engineering

Biomass Briquette Press

By:

Radhe Equipments India

Bio Coal Briquetting Press

By:

Ronak Agrotech Engineering Pvt. Ltd.

Briquettes Plants

By:

Shree Khodiyar Engineering Works

Explore More Cities

Explore in hindi

बायोमास ब्रिकेट प्रेस

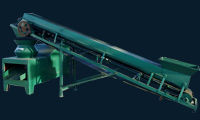

Biomass briquette presses are robustly designed machines that are widely used for making briquettes. Available in both manual as well as automatic mode, these are easy to operate and produce briquettes of a uniform size with the general productivity rate of 600-1000 briquettes per hour. The presses can make briquettes from various biomass materials such as rice husk, wood and saw dust, coconut shells and many more. Furthermore, apart from biomass, these can also make briquettes from coal.

Briquettes are a bio fuel alternative to traditional fuel sources. These have a comparatively higher calorific value and burn for a longer period of time, thus increasing overall efficiency of boilers, furnaces and other systems where these are used. Due to this, biomass briquettes are gradually becoming more favored than raw mineral coal or charcoal. As a result, there is an increasing demand for biomass briquette press all over the world, with their manufacturers providing the presses in various specifications and also with a wide range of features.

Manufacturing Processes of Biomass Briquette Press

Biomass Briquette Press Machines are Generally Manufactured Using Either One of the Conventional Methods Such as :

Welding

Casting

Milling

Attributes of Biomass Briquette Press

The presses do not corrode when these come in contact with water or moisture.

Biomass briquette presses work flawlessly in all weather conditions.

These have no sharp edges, thus ensuring the safety of operator.

The presses have minimal noise levels, thus eliminating any chance of the occurrence of hearing problems in people who are working nearby these.

Briquette presses generally have an average life span exceeding 8-10 years.

These are designed to resist fatigue arising out of continuous vibration.

Different Biomass Briquette Press Designs

Biomass briquette press machines are available in various designs, with respect to component and the mechanical process used for making briquettes. Some examples are:

Biomass briquette screw press

Biomass briquette piston press

Biomass briquette lever press

Biomass Briquette Press Price List

Product Name | Expected Price |

|---|---|

| Biomass Briquetting Plant | 2251000 |

| Biomass Briquetting Presses | 2251000 |

This Data was Last Updated on 2024-12-12

Biomass Briquette Press Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Jay Khodiyar Machine Tools Rajkot, India | 19 Years |

Ronak Engineering Rajkot, India | 18 Years |

Ecostan India Pvt Ltd Ludhiana, India | 10 Years |

Solid Ply Pvt Ltd Visakhapatnam, India | 2 Years |

Anyang Forging Press Machinery Industry Co., Ltd Anyang, China | 2 Years |

Haritima Bio Energy Rawatsar, India | 2 Years |

Radhe Engineering Company Rajkot, India | 1 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories