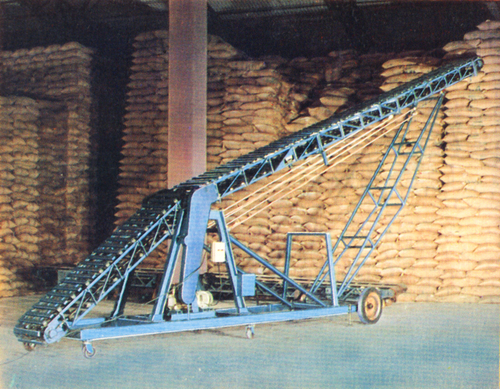

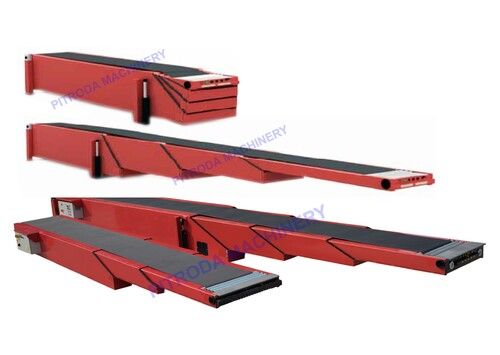

Mobile Truck Loading Conveyor - 415v Electric Power, 100kg Lifting Capacity | Durable, Rust Proof, Flexible Design For Efficient Material Handling

Price: 442000.00 INR / Unit

(442000.00 INR + 0% GST)

Get Latest Price

Minimum Pack Size :

1

In Stock

Product Specifications

| Usage | Loading Stacking |

| Condition | New |

| Lifting Capacity | 100 Kilograms (kg) |

| Power Source | Electric |

| Voltage | 415 Volt (v) |

| Warranty | 1 Year |

| Attributes | Durable, Rust Proof |

| FOB Port | FOB, CIF PORT |

| Payment Terms | Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque, Days after Acceptance (DA), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C) |

| Supply Ability | 10 Per Month |

| Delivery Time | 2 Week |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

| Main Domestic Market | All India |

| Certifications | IEC, ISO |

| Stock Quantity | 5 |

| Product Unit | 1 Piece/Pieces |

| Currency | INR |

| Price Type | fixed |

| Returnable | No |

| Brand Name | PITRODA MACHINERY |

| Unit Type | Piece/Pieces |

| Mop | 1 |

| Moq | 1 |

| Price | 442000.00 INR (Approx.) |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

| GSTIN | 0% |

Product Overview

Key Features

Components:

Conveyor Belt:

A durable belt that moves goods from one end of the conveyor to the other.

Frame:

The structural framework that supports the conveyor belt and other components.

Drive Unit:

Typically includes an electric motor and gear reducer to power the conveyor belt.

Rollers/Idlers:

Cylindrical components that support and guide the conveyor belt along its length.

Types of Truck Loading Conveyors:

Fixed Conveyors:

Permanently installed at a loading dock. Suitable for high-volume operations with consistent loading requirements.

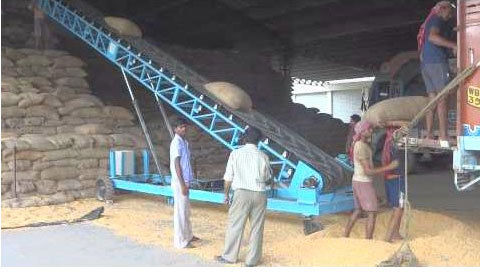

Mobile Conveyors:

Equipped with wheels or casters, allowing them to be moved to different locations as needed.

Telescopic Conveyors:

Feature a telescoping design that extends and retracts, providing flexibility in length for different truck sizes and loading conditions.

Flexible Conveyors:

Comprised of interconnected segments that can bend and flex, useful for maneuvering around obstacles.

Applications:

Warehouses:

Loading and unloading goods from storage areas to transport vehicles.

Distribution Centers:

Efficient handling of parcels and packages for dispatch.

Manufacturing Plants:

Transporting finished goods to shipping areas.

Agricultural Operations:

Loading bulk materials like grains or produce onto transport vehicles.

Benefits:

Increased Efficiency:

Speeds up the loading and unloading process, reducing the time trucks spend at the dock.

Labor Savings:

Reduces the need for manual labor, lowering labor costs and minimizing the risk of injury.

Versatility:

Suitable for handling a wide range of goods, from small parcels to large items.

Improved Safety:

Minimizes the risk of damage to goods and injuries to workers by providing a controlled loading environment.

Technical Specifications:

Belt Width:

The width of the conveyor belt, typically ranging from 500 mm to 1200 mm.

Conveyor Length:

The total length of the conveyor, which can be fixed or adjustable (telescopic).

Load Capacity:

The maximum weight the conveyor can handle, often specified in kilograms per meter.

Speed:

The speed at which the conveyor belt moves, usually adjustable and measured in meters per minute (m/min).

Power:

Electrical power requirements, typically ranging from 220V to 440V, depending on the motor and drive system.

In summary, truck loading conveyors are indispensable tools in modern logistics and material handling operations, providing significant improvements in efficiency, safety, and labor cost savings. Proper selection, use, and maintenance of these conveyors can greatly enhance the productivity of loading and unloading processes

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

7

Establishment

1990

Working Days

Monday To Monday

GST NO

24AAVPP9923A1ZF

Payment Mode

Cash Advance (CA)

Certification

9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AAVPP9923A1ZF

Ahmedabad, Gujarat

Accepts only Domestic inquiries

Proprietor

Mr Hasmukhbhai

Members since

2 Years

Address

Plot No.183/7, Phase-1, G.I.D.C. Naroda, Ahmedabad, Gujarat, 382330, India

bag stacker in Ahmedabad

Report incorrect details