Lead Refining Pot - Heavy Ms Plate, 3.0 To 20.0 Tons Per Batch Capacity | Mechanical Mixing Device, Efficient Heating Arrangement, Versatile Melting Processes

Price:

Get Latest Price

In Stock

Product Specifications

| Material | MS plate, refractory bricks |

| Capacity | 3-20 tons |

| Dimensions | Variable |

| Mixer | Electro-mechanical |

| Heating | Oil/Diesel/Wood |

| Outlet | Pipe and valve |

| Accessories | Optional |

| Features | Efficient melting, Impurity removal, High capacity, Durable design, Easy operation, Versatile use, Cost effective |

Product Overview

Key Features

Capacity of such pots depends upon the requirements of particular units. Standard pot capacities made are from 3.0 Tons per Batch to 20.0 Tons per Batch. Higher capacity pots are also manufactured as required by any particular establishment.

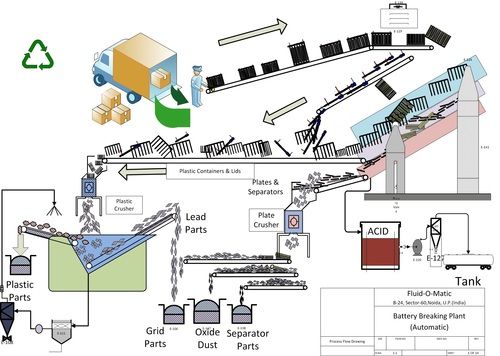

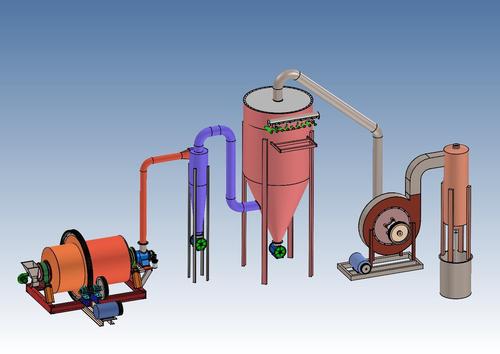

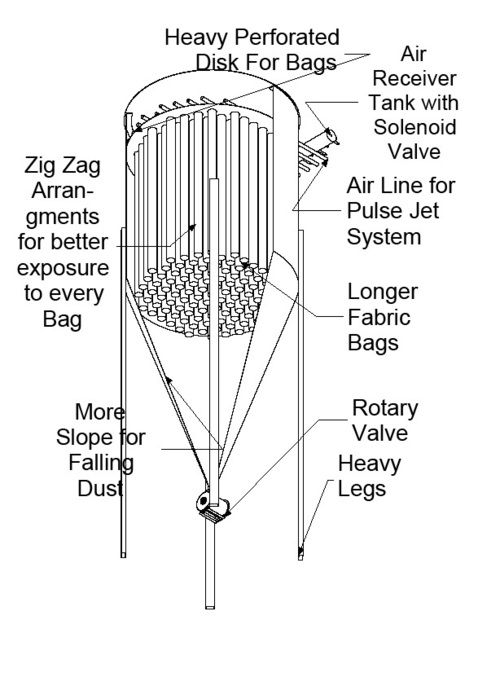

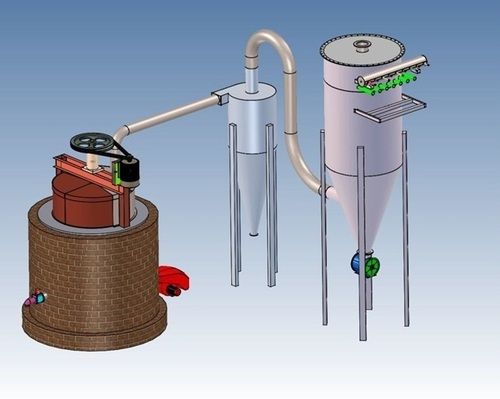

Melting pots are installed both with and without accessories which may include Ingot Casting Machine, Ball Making Machine (where Ball Mills are installed down the line), Air Pollution Control Systems, Jib Cranes etc.

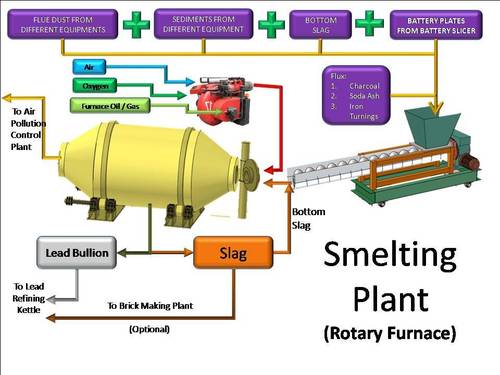

Melting Processes have been grouped as

a c Re-Melting Process

a c Refining Process

a c Alloying Process

Company Details

we, FLUIDOMATIC have emerged as a one stop solution for the best battery manufacturing and USed Battery Breaking & Recycling machines and Its allied technology. We are a renowned company dealing in various battery manufacturing machines and allied products. We came into existence in the year 1989 and since then have achieved tremendous success in manufacturing premium quality machines. Today, we are a leading manufacturer, and exporter of Used Battery Recycling Plant, Battery Making Plant, such as Battery Assembly Line, Battery Heat Sealing Machine, Battery Recycling Plant, Battery Breaking Plants, Lead Smelting Plants, Lead Recycling Machines, & Battery Part making Machines, Container Punching Machine, Inter Partition Welding Machine, Stress Testing Machine, Lid Heat Sealing Machine, Air Leakage Testing Machine, Short Circuit Testing Machine, Grid Casting Machine, Grid Pasting Machine, Drying & Curing Oven, Incinerators, Dead Human Cremation Furnace, Waste Recycling Plant, E-Waste Recycling Plant, etc.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

30

Establishment

1989

Working Days

Monday To Sunday

GST NO

09AUUPS7718P2Z7

Certification

IS0 9001:2015, CE Certified

Related Products

More Product From This seller

Seller Details

GST - 09AUUPS7718P2Z7

Noida, Uttar Pradesh

Ceo

Mr. G

Members since

18 Years

Address

B-24, Sector-60, Noida, Uttar Pradesh, 201301, India

Furnace Manufacturers in Noida

Report incorrect details