Effluent Treatment Plant - Batch And Continuous Operating Units For Lead Recycling | Efficient Ph Balancing, Flocculation, And Sludge Dewatering Process

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless steel |

| Dimensions | Customizable |

| Capacity | 10 kl/day |

| Treatment process | Clarification, flocculation, sedimentation, filtration |

| Sludge disposal | Recycling |

| pH adjustment | Caustic or lime |

| Automation | Optional |

| Features | Effluent treatment, Lead recycling, Water reuse, Sludge recycling, Batch or continuous, Low maintenance, Environmentally friendly, Cost-effective |

Product Overview

Key Features

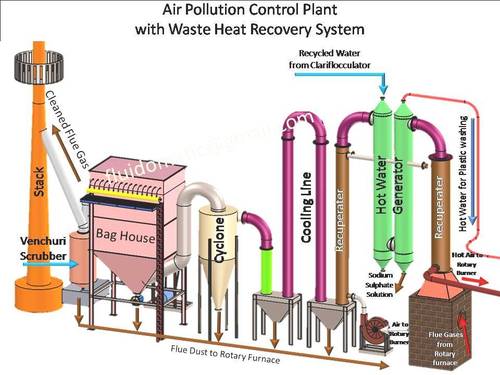

Coagulation. The effluent is then mixed for Flocculation. The flocks so formed are settled and dewatered on a Sludge Bed (or through Filter Press). Treated effluent after this is further polished using filters. While treated water may be disposed or used as permitted by law, sludge is recharged into furnaces for recycling and reclamation of lead*.

An Effluent Treatment Plant for lead recycling units can be designed as a Batch Type unit or as a Continuous Unit. This mainly depends on the quantity of effluent to be handled. While smaller quantities can be treated in batches, quantities above 10 kl/day are to be treated in Continuous Operating Units.

Company Details

we, FLUIDOMATIC have emerged as a one stop solution for the best battery manufacturing and USed Battery Breaking & Recycling machines and Its allied technology. We are a renowned company dealing in various battery manufacturing machines and allied products. We came into existence in the year 1989 and since then have achieved tremendous success in manufacturing premium quality machines. Today, we are a leading manufacturer, and exporter of Used Battery Recycling Plant, Battery Making Plant, such as Battery Assembly Line, Battery Heat Sealing Machine, Battery Recycling Plant, Battery Breaking Plants, Lead Smelting Plants, Lead Recycling Machines, & Battery Part making Machines, Container Punching Machine, Inter Partition Welding Machine, Stress Testing Machine, Lid Heat Sealing Machine, Air Leakage Testing Machine, Short Circuit Testing Machine, Grid Casting Machine, Grid Pasting Machine, Drying & Curing Oven, Incinerators, Dead Human Cremation Furnace, Waste Recycling Plant, E-Waste Recycling Plant, etc.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

30

Establishment

1989

Working Days

Monday To Sunday

GST NO

09AUUPS7718P2Z7

Certification

IS0 9001:2015, CE Certified

Related Products

More Product From This seller

Seller Details

GST - 09AUUPS7718P2Z7

Noida, Uttar Pradesh

Ceo

Mr. G

Members since

18 Years

Address

B-24, Sector-60, Noida, Uttar Pradesh, 201301, India

Effluent & Sewage Treatment Plants in Noida

Report incorrect details