Lead Refining Pot - Boiler Steel Fabrication, 32mm To 46mm Thickness | Robust & Compact Design, Low Maintenance

Price:

Get Latest Price

In Stock

Product Overview

Key Features

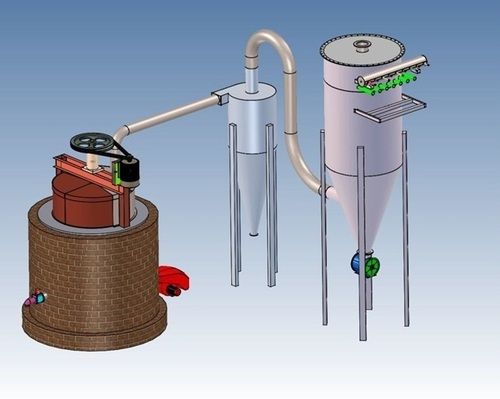

Being a prestigious business organization, our forte is to manufacture and export a superior range of Lead Refining Pot. These pots are used for melting lead batteries and for removing consumables items from the batteries. Our Lead Refining Pot is designed under the guidance of skilled professionals by using optimum quality materials, in compliance with international quality of standards and norms. Our clients can avail these pots from us at a reasonable price.

Features:

- Robust construction

- Compact design

- Low maintenance

Further Details:

The refining of crude lead takes place in a refining kettle at temperatures between

400 and 550C. If only battery scrap is used for lead production, 2 subsequent refining steps are required:

1. Removal of Cu which might have entered the melts through copper wires.

2. Removal of antimony originated from the former grid metal to produce pure lead

While the removal of Cu is done in adding elementary sulphur, Sb can be removed by selective oxidation or by adding sodium nitrate (NaNO3). The lead in the kettle is stirred and a dross formed. The impurities are now removed from the melt by Skimming of the dross formed. It is obvious that the success of the refining has to be controlled by chemical analysis. The refined metal is cast into ingots for shipment, sale or further manufacturing.

Refining pot/Alloying must be manufactured in boiler steel using 32mm to 46mm.

Company Details

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

20

Establishment

2006

Working Days

Monday To Sunday

GST NO

06AGEPB3375R1Z3

Related Products

More Product From This seller

Seller Details

GST - 06AGEPB3375R1Z3

Faridabad, Haryana

Proprietor

Mr. Dinesh Batra

Members since

2 Years

Address

Plot No-4, Gali No-1, Bajri Industrial Area, Badkhal Pali Road, Faridabad, Haryana, 121009, India

Furnace Manufacturers in Faridabad

Report incorrect details