Fully Automatic Grid Casting Machines

Price:

Get Latest Price

In Stock

Product Specifications

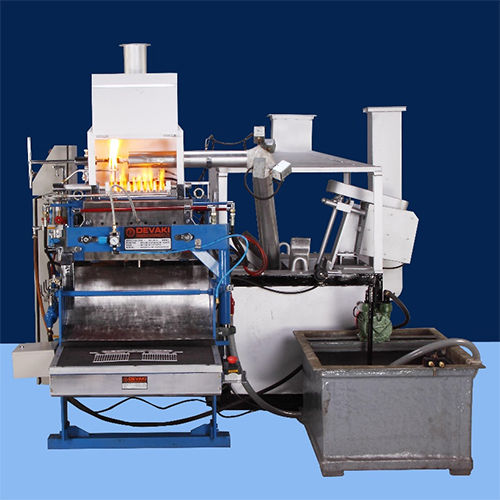

| Power | 415V, 33Kw/15Kw |

| Capacity | 8-14 Grids/Minute |

| Furnace | 800 Kg |

| Casting Size | 350X150 Mm |

| Casting Thickness | 1.4-4 Mm |

| Materials | Steel, Alloys |

| Moulds | 2 Grid Moulds |

| Features | High Output, Fully Automatic, Easy Operation, Low Maintenance, Versatile Alloys, Digital Control, High Efficiency |

Product Overview

Key Features

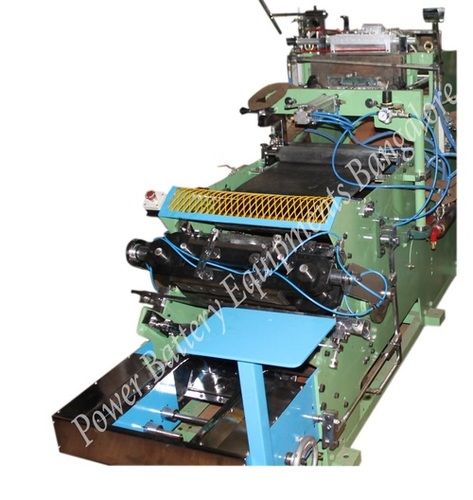

The machine is fully automatic and can produce up to 10 trimmed grid panels per minute depending upon the lead alloy and the grid design. This equipment is ideal for high volume production battery and battery plate manufactures. The construction of machine is rugged and built for low maintenance. The grid mould opening a cum closing cum grid ejection and ladle tilting is pneumatically operated. Grid alinging chute, grid-trimming device, grid stacking mechanism are all operated by mechanical cams. Heating is by electrical resistance heaters (Also given provision for additional heating by lpg at the gate of the ladle). The operations are simple and easy.

The machine is Fully Automatic and Suitable for any Alloy.

Built in trim scrap conveyor

Trimmed Grids are stacked for easy removal

Digital Temperature Controllers for better Monitoring & Control

Casting Thickness 1.4 to 4 mm

Maximum Casting size including lugs a 350 x 150 mm

Power : 415V, 33KW (Electrically Heated Furnace) / 15KW (Diesel or LPG heated Furnace)

Capacity : 8 to 14 Grid Pannels Per Minute

Furnace : 800 Kg

Company Details

The company was started in the year 1972 by Mr. E. Sundaran, as a proprietor concern doing precision jobs for Public Sector engineering units such as HMT, ITI, MICO, BHEL, BEML along with numerous other small and medium industries. Mr. E. Sundaran, an experienced professional soon saw the opportunities in the field of special purpose machines (SPM) and ventured into the same by manufacturing custom made SPM's for the Lead Acid Battery manufacturing by 1982. The company continues to manufacture these SPM with more advancement. The company is well equipped with modern machineries and technical workforce to compete with its competitors. It is located in Peenya Industrial Area in Bangalore, INDIA with built-up facility of 20000Sft in 45000 Sft Land, which is a manufacturing hub. The company is now a private limited concern with highly qualified and experienced professional in its board. The company has been growing constantly and updates itself with current technologies to be the leader in the field. Our products are well known in the battery industries for its advancement, quality and customer friendly design. The equipments are supplied all over India and few have been exported also. The company has a full fledged service team to cater to the needs of its customers. Apart from numerous small scale battery manufacturers, Large battery industries such as Exide Industries Ltd., AmaraRaja Batteries Ltd., Su-Kam power Systems, Hyderabad Batteries Ltd., Luminous Power Technologies Ltd, Okaya Batteries Ltd, Base Corporation, etc., are few of the names in our impressive client list. The company with a dedicated workforce of about 70 Employees has a turnover of INR 100 Million last year and is steadily increasing.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

55

Establishment

1972

Working Days

Monday To Saturday

GST NO

29AAACD5128R1Z5

Payment Mode

Cash in Advance (CID)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 29AAACD5128R1Z5

Bengaluru, Karnataka

Director

Mr Mohan Sunder

Members since

22 Years

Address

396, 3rd Main Road, 11th Cross, Fourth Phase, Peenya Industrial Area, Bengaluru, Karnataka, 560058, India

automatic grid casting machine in Bengaluru

Report incorrect details