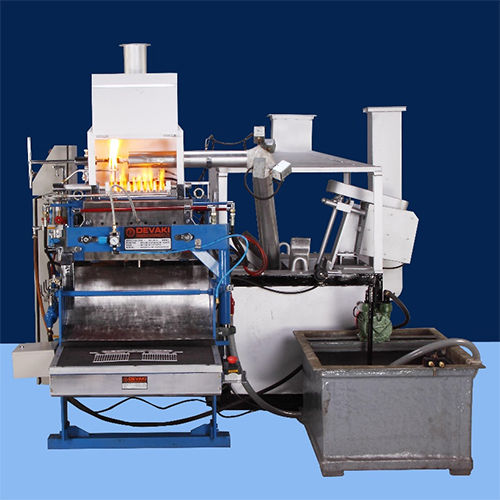

Automatic Grid Casting Machine By Power Battery Equipments

Price: 1121000.00 INR / Unit

(950000.00 INR + 18% GST)

Get Latest Price

MRP:

11210000.00 INR / Unit

Weight :

2000.00 Kilogram

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Color | blue |

| Product Type | Other |

| Technology | CNC |

| Power Source | Electricity |

| Operating Type | Automatic |

| Power | 415 Volt (v) |

| Pressure | 10 Bar |

| Surface Treatment | Other |

| Weight (kg) | 2000 Kilograms (kg) |

| Warranty | 1 year |

| Production Capacity | 10 Pcs/min |

| Usage & Applications | Battery Making Machine |

| Payment Terms | Paypal |

| Supply Ability | 2 Per Month |

| Delivery Time | 21 Days |

| Sample Available | No |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Wooden box at additional cost |

| Main Export Market(s) | Australia, Central America, Asia |

| Main Domestic Market | All India |

| Certifications | ISO, MSME |

| MRP | 11210000.00 INR |

| Stock Quantity | 2 |

| Product Unit | 1 Unit/Units |

| Color | blue |

| Shipping Type | free |

| Pkg Box Height | 65.00 cm |

| Pkg Box Length | 120.00 cm |

| Returnable | No |

| Pkg Box Breadth | 50.00 cm |

| Unit Type | Unit/Units |

| Currency | INR |

| Moq | 1 |

| Mop | 1 |

| Brand Name | Power Battery Equipments |

| Packsize | 1 |

| GSTIN | 18% |

| Price Type | fixed |

| Weight | 2000.00 Kilogram |

| Price | 950000.00 INR (Approx.) |

| Minimum Order Quantity | 1 |

| Minimum Ordered Packs | 1 |

Product Overview

Key Features

An Automatic Grid Casting Machine Power Battery Equipments Make is a type of industrial machinery used in the production of grid components, often for batteries, solar panels, or other applications that require metal grids. These machines automate the process of casting metal into grid molds to produce uniform and precise grid structures. Below are the typical features and applications of an automatic grid casting machine:

Key Features:

Automation: The primary feature of these machines is automation. They are designed to eliminate the need for manual labor and significantly reduce human error. The entire casting process, from pouring the molten metal to cooling and solidifying, is automated.

Casting Molds: The machine typically has molds where the molten metal is poured to form the grid structure. The molds are often made of materials that can withstand high temperatures and repeated use.

Precision Control : These machines allow precise control over the metal pouring, mold filling, and cooling process. This ensures that the grids produced have consistent dimensions and structural integrity.

High Throughput : Automatic grid casting machines are designed for high productivity. They can produce large volumes of grid components in a short amount of time, which is crucial for industries like battery manufacturing.

Cooling System : After the metal is poured into the molds, cooling systems are used to solidify the grids. These systems may use water or air cooling methods to quickly reduce the temperature of the cast components.

Safety Features : Given the high temperatures involved in metal casting, automatic grid casting machines are equipped with safety features such as temperature sensors, automatic shutdown mechanisms, and protective shields to ensure operator safety.

Material Handling : Many machines come with automated systems for material handling, such as conveyors or robotic arms, to transport the metal and the finished grids.

Applications : Battery Manufacturing : One of the most common uses for automatic grid casting machines is in the production of lead-acid batteries. The grids made by these machines are used as the conductive elements in the battery plates.

Solar Panels : These grids are essential for conducting electricity in solar panels.

Automotive and Electrical Industries : Grid casting machines can be used to produce various grid-like components used in electrical systems, capacitors, or other devices. Metal Alloy Production : In some cases, these machines are used to cast metal grids for use in other industries that require specific grid structures for heat conduction, electrical conductivity, or as mechanical supports. Advantages: High Efficiency : The machine can produce grids faster than manual casting, improving overall productivity. Consistency: Automated systems ensure that every grid produced has the same quality and dimensions, reducing variability. Reduced Labor Costs : Automation reduces the need for manual labor and can minimize human error.

Scalability : These machines can often be scaled up for large-volume production, making them ideal for industries with high demand.

In essence, automatic grid casting machines play a vital role in industries requiring precise, high-quality metal grids, particularly in battery and solar panel manufacturing.

Quality : Optimum

Grade : Premium

Brand : Power Battery Equipments

Country Of Origin : India

Condition : New

Durability : Long Lasting

Company Details

Power battery equipments is one of the leading manufacturer of lead acid battery machine manufacturer in India, & also a leading supplier to foriegn countries.

Business Type

Exporter, Manufacturer, Distributor, Supplier

Employee Count

10

Establishment

1999

Working Days

Monday To Sunday

GST NO

29ADGPR2296G1Z4

Payment Mode

Days after Acceptance (DA)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 29ADGPR2296G1Z4

Bengaluru, Karnataka

Proprietor

Mr. A. Riyaz

Address

No. 24, Opp. St. Micheal English School, Gangamma Circle, Jalahalli Post, Bengaluru, Karnataka, 560013, India

automatic grid casting machine in Bengaluru

Report incorrect details