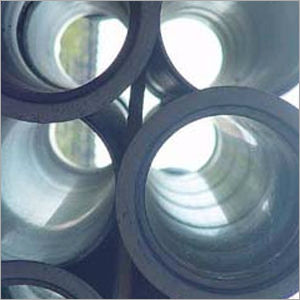

Ductile Cast Iron Spun Pipe - Color: Black

Price: 760.00 INR / Piece

(760.00 INR + 0% GST)

Get Latest Price

1 Pack Contains :

1

Minimum Pack Size :

300

In Stock

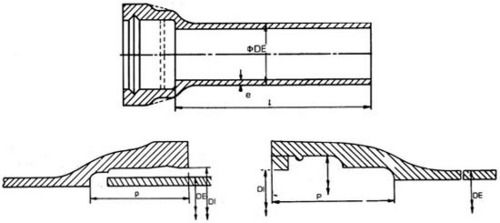

Product Specifications

| Color | Black |

| Other Material | Iron |

| Material | Cast Iron |

| Type | Casted |

| Shape | Round |

| Diameter | 5-100 Inch (in) |

| Length | 6 Meter (m) |

| Supply Ability | 1000 Per Month |

| Delivery Time | 15-30 Days |

| Main Domestic Market | All India |

| Product Unit | 300 Piece/Pieces |

| Packsize | 1 |

| Unit Type | Piece/Pieces |

| Price Type | fixed |

| Mop | 300 |

| Stock Quantity | 1500 |

| Returnable | No |

| Brand Name | BIKANER ENGINEERING WORKS |

| Currency | INR |

| Color | Black |

| Moq | 300 |

| Price | 760.00 INR (Approx.) |

| Minimum Ordered Packs | 300 |

| Minimum Order Quantity | 300 |

| GSTIN | 0% |

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

25

Establishment

1973

Working Days

Monday To Sunday

GST NO

08AAAFB9274F1ZF

Payment Mode

Cash Advance (CA)

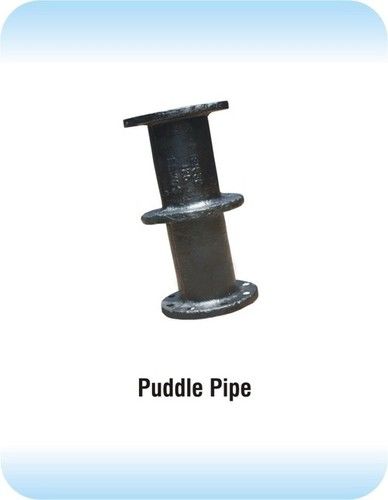

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 08AAAFB9274F1ZF

Jaipur, Rajasthan

Manager

Mr Tarun Mundhra

Members since

16 Years

Address

Parijat, O-12, Ashok Marg, C Scheme, Jaipur, Rajasthan, 302001, India

cast iron spun pipes in Jaipur

Report incorrect details