Big Batch Trolley

Price:

Get Latest Price

In Stock

Product Specifications

| Frame material | 100x50 ism channel |

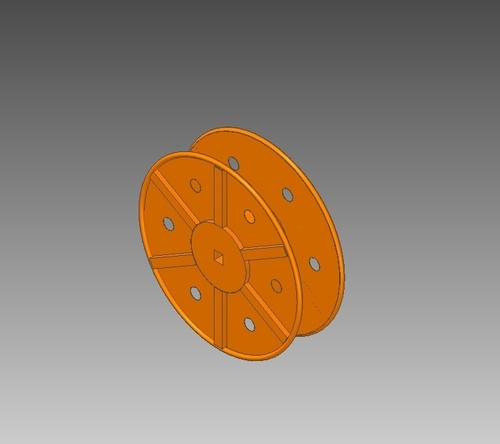

| Roll diameter | 220 mm |

| Roll cladding | SS 304 |

| Weight capacity | 4000 kg |

| Wheel type | High efficiency |

| Braking system | Efficient, one side |

| Coupling | One side |

| Features | High capacity, Smooth transport, Efficient braking, Easy locking, Durable frame, Safe handling |

Product Overview

Key Features

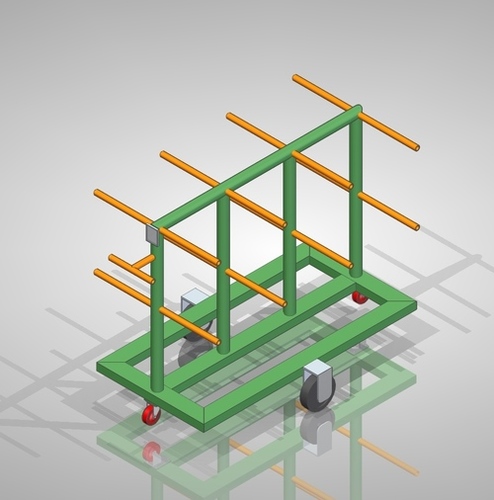

a frame trolley:-

a c most suitable for wet & dry processing

a c fabricated out of 100x50 ism channel so as to allow maximum weight capacity at lowest frame weight

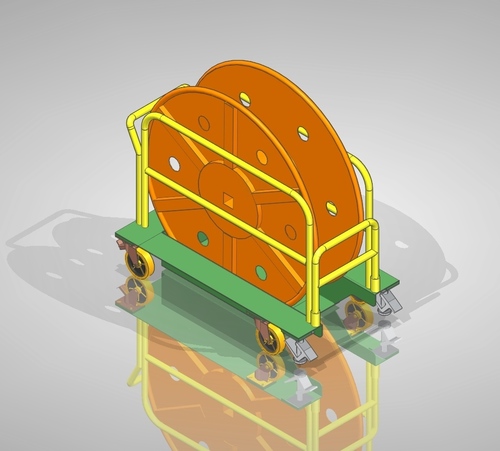

a c high quality bearings to withstand roll weight upto 4000 kg.

a c higly efficient wheels to allow smooth transportation around the plant

a c m. s. roll of dia220 mm duly cladded with s. s 304 for wet fabric rolling

a c trolley is provided with efficient braking on one side & coupling on other side

a c efficient locking system to fix the trolley at desired position

a c provision of handle on both sides for moving the trolley

Company Details

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

10

Establishment

2007

Working Days

Monday To Sunday

GST NO

27AOEPD8448M1ZI

Payment Mode

Cheque, Letter of Credit (L/C)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AOEPD8448M1ZI

Thane, Maharashtra

Director

Mr Ammol Vasant Desai

Address

Plot No. 1, Mourya Compound, Rambaug, Upvan Industrial Area, Pokhran Rd. No. 1, Thane west, Thane, Maharashtra, 400606, India

batching trolley in Thane

Report incorrect details