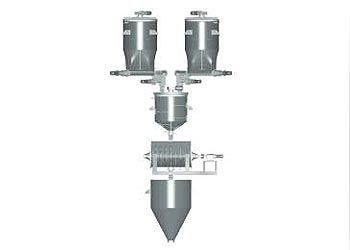

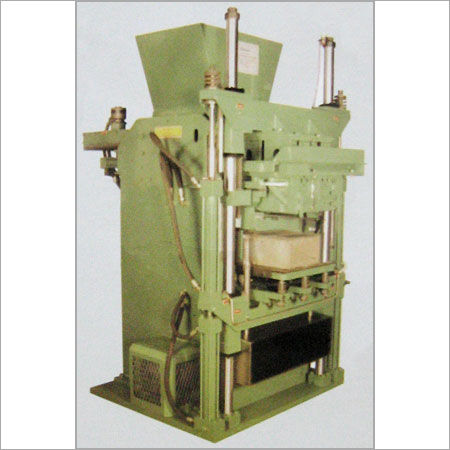

Batching System - Custom Designed For Bulk Materials | Automatic Target Weigh Set, Multiple Weigh Hoppers, Efficient Liquid Addition Scale Systems

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel,aluminum |

| Dimensions | Variable |

| Power | 220V |

| Capacity | Customizable |

| Weight | Variable |

| Accuracy | High |

| Control | PLC based |

| Features | Accurate metering, Auto target weigh, Easy operation, Flexible use, Customizable hoppers, Efficient liquid addition, Automatic logging, Bulk material handling |

Product Overview

Key Features

Company Details

A range of emissions and contaminants, especially airborne particles are released into the air during various industrial processes like sandblasting, machining, welding and grinding. This calls for the use of Dust Suppression Systems, Dust Extraction Systems, Fume Extraction Systems, etc., which can efficiently capture these unwanted airborne particles, minimizing their effect on human health. Be it for environmental protection or improved safety, i.e., limiting your exposure to hazardous materials, if you are looking for high-capacity, innovative systems that help minimize emissions and contaminants within your premises, then contact P-Square Technologies a company that has been engineering top of the line products featuring long lasting filters and heavy-duty cyclone separators to easily trap any kind of airborne contaminants, hazardous particles or fumes before they escape into the environment. Almost all the systems the company markets come with automatic controls that can quickly detect any kind of fluctuations in the environmental conditions like temperature, humidity, or wind speed.

Experts at P-Square Technologies believe that quality is more than engineering durable and functionally reliable products. There still exists a gap where product manufacturers and suppliers simply dwell on the manufacturing part and overlook the rest. Besides, some customers underline the generalities but often fail to articulate what they exactly require when it comes to quality. Customer quality demands also keep changing with time. Mindful of this gap, the company turned to strategies that could help it take the right step towards quality control, equipment storage and delivery methods. It currently upholds a companywide commitment to rendering all the benefits customers seek- a quality product, good pricing, time bound delivery and responsive after sales support. Talking about services, it never fails to take into account what customer desires even after the closure of the deal and swiftly renders the best possible services relevant to Dust Suppression System, Dust Extraction System, Fume Extraction System, etc., as a qualified service provider. It also takes feedback following each sale and conducts regular customer satisfaction surveys to keep an eye on how its existing customers and other business prospects perceive its products/services and rate them against solutions offered by competitors.

Leadership

One of the things that have always worked in favour of the company is good leadership, which is non-negotiable and essential for making a lasting impression on customers. The company feels honoured to be guided by the very talented Mr. Prasad S Kamthe who over the years have helped it rightly identify shifts in consumer and market trends and attain excellent figures, both in terms of sales and trust. With his invaluable guidance, it wishes to offer exemplary services to all its existing customers along with gaining goodwill of potential purchasers, nationwide.

Industries Served

Its range of Dust Suppression System, Dust Extraction System, Fume Extraction System, etc., stands out from the competition because of good material quality, unparalleled designs and functional reliability. Engineered in harmony with all applicable laws and regulatory requirements, they not just perform their intended tasks well but also function optimally with minimal maintenance and fewer repairs for years, therefore generating great savings in the long run. Product reliability and excellent lifespan only means that the company has to deal with zero customer complaints, post sales. Many of its happy customers are from the following sectors:

- - Mining

- - Engineering

- - Automobile

- - Foundries

- - Wood, Laminates & Particle Board Plants

- - Dairy & Cattle Feed

- - Food & Beverages

- - Boiler Manufacturing

- - Ceramics & Tiles

- - Pharmaceuticals

- - Rubber

- - Glass

- - Robotic Welding & Welding Workshops

Why Choose P-Square Technologies?

Many Indian manufacturing companies fail to establish a reputation that lasts- some for their subpar manufacturing standards, some for poor customer service operations and a few others for their ineffective delivery strategies. Unlike others, P-Square Technologies has been successful in achieving good ratings and has remained competitive in the market because of the following:

- - Building advanced systems equipped with heavy duty filters, which leads to lower energy consumption and reduced downtime.

- - Conducting quality checks at all levels to detect any aesthetic or functional defects in products, if any.

- - Offering services to customers as per priorities they attach to various advantages.

- - Matching and exceeding needs of customers in terms of product/service pricing and delivery timelines.

Team

No one can deny the advantages of having a cohesive and supportive team. P-Square Technologies too reaps benefits of recruiting talented experts who work together to come up with innovative ideas and complete projects ahead of deadlines. Each engineer, quality controller, researcher or marketer the company hires has commendable problem-solving skills, compassion and foresight that leads to increased productivity of the company and better employee-customer relations.

Vision

The company aims to leverage technically sophisticated people to build improved designs in Dust Suppression System, Dust Extraction System, etc., and expand its business reach beyond the national market in the future.

Fact Sheet of P-Square Technologies

| Nature of Business | Exporter, Manufacturer, Service Provider and Supplier |

| Business Location | Pune, Maharashtra |

| Company Leader | Mr. Prasad S Kamthe |

| Year of Establishment | 2001 |

| No. of Staff | 25 |

| Export Turnover | 20% |

| Sales Volume | INR 5 Crore |

| No. of Production Lines | 01 |

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

25

Establishment

2008

Working Days

Monday To Sunday

GST NO

27AJZPK1545N1ZE

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AJZPK1545N1ZE

Pune, Maharashtra

Business Head - Sales & Marketing

Mr Prasad S Kamthe

Members since

16 Years

Address

1st & 2nd Floor, "RK Villa", Chandrama Society, Market Yard Road, Near Bank of Maharashtra, Pune, Maharashtra, 411037, India

batching machine in Pune

Report incorrect details