- Tradeindia

- Pharmaceutical Machinery

- Tablet Making Machines

Tablet Making Machines

(366 products)Mini Rotary Tablet Press - Features: Stable Performance

MOQ1 Unit/Units

PhaseSingle / Three phase

Frequency50-60 Hertz (HZ)

FeaturesStable performance

Usage & ApplicationsPharma industry

MaterialStainless steel

Control ModeAutomatic

Tablet Making Machine - Stainless Steel, 220-440 Voltage, Silver Color | Automatic Control, 1 Year Warranty, 5 Power

Price: 350000 INR/Unit

MOQ1 Unit/Units

ColorSilver

TypeOther, Tablet Making Machine

MaterialStainless Steel

ComputerizedNo

Control ModeAutomatic

Voltage220-440 Volt (v)

Innovative Engineering Works

Ahmedabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Premium

Super Premium4 Years

View More

Silver Rotary Tablet Making Machine

Price : 455000 INR

High Speed Double Rotary Tablet Press With Pre-Compression - Color: Silver

Price: 28,00,000 INR/Unit

MOQ1 Unit/Units

ColorSTAINLESS STEEL

TypeTablet Pressing Machine

MaterialPOWDER

ComputerizedYes

Control ModeAutomatic

Voltage440 VOLTS Volt (v)

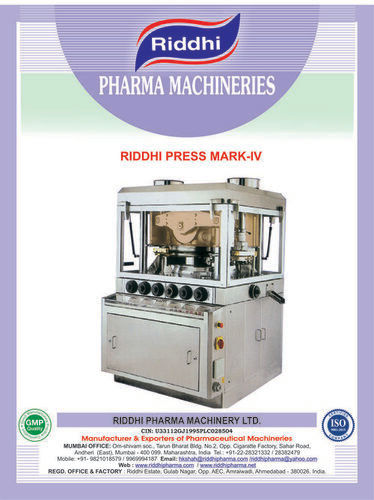

Riddhi Pharma Machinery Ltd

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller14 Years

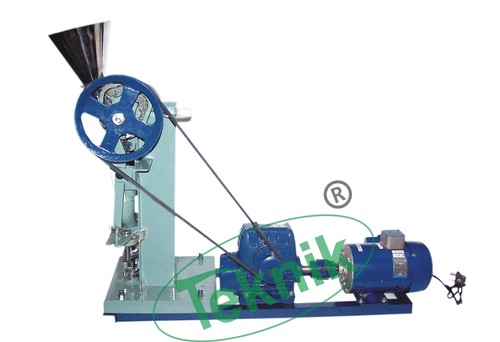

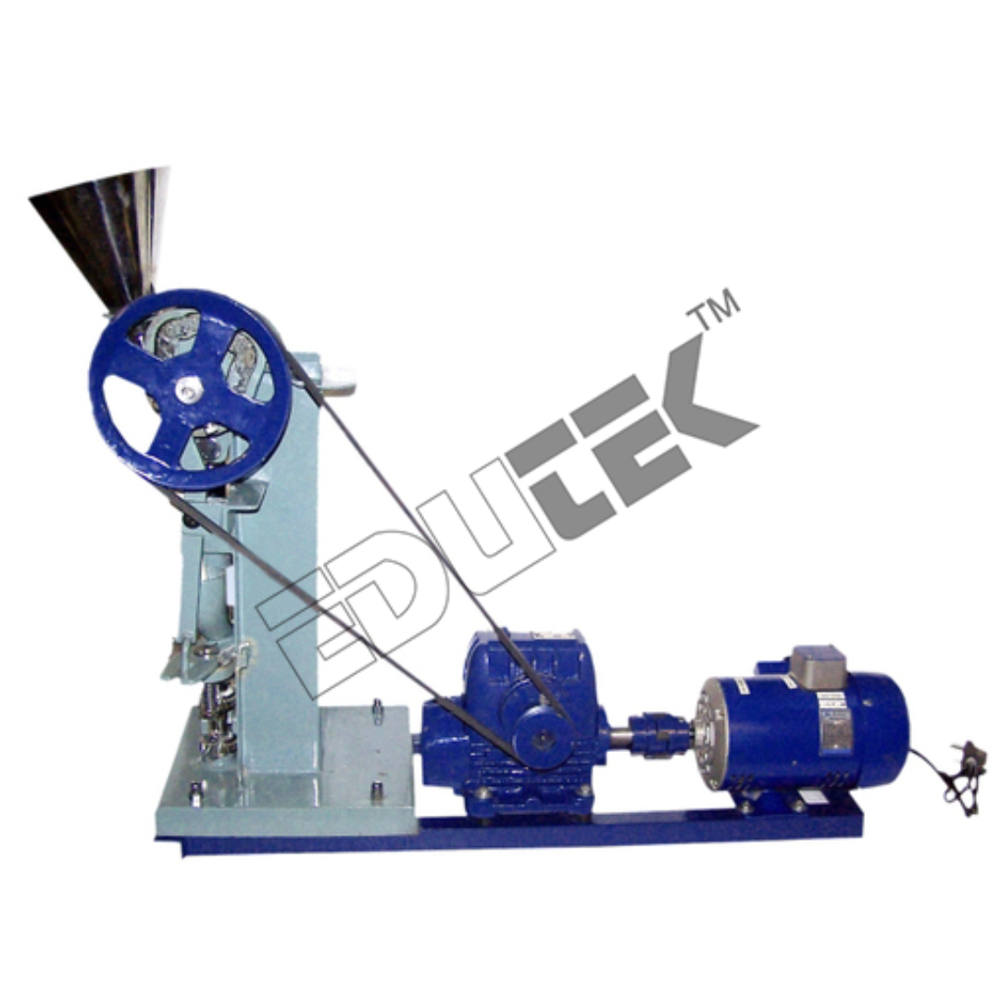

Electric Operated Tablet Making Machine

Automation GradeSemi-Automatic

Core ComponentsMotor Die and Punch Set Frame

FeatureElectric Operated

Capacity500-1000 tablets/hr

AccuracyHigh Accuracy

Frequency50 Hz

Bluefic Industrial & Scientific Technologies

Ambala

Trusted Seller

Trusted Seller Super Seller

Super Seller16 Years

Tablet Making Machine Electrically Operated - Chrome Steel Punch & Die Options 6mm, 9mm, 12mm | Hammer Type, 220V AC 50Hz Single Phase Motor

Price: 10 INR/Piece

MOQ1 , Piece/Pieces

Model NoStandard Model

Voltage220-240 V AC

FeatureHand Operated/Electrically Operated, CE Certified, Robust Construction

Measurement RangeFitted With 6 mm Die As Standard, Optional Punch Sets Available

AccuracyA+-2% tablet weight variation

Frequency50 Hz

View More

Blue Tablet Making Machine

Get Best Deal

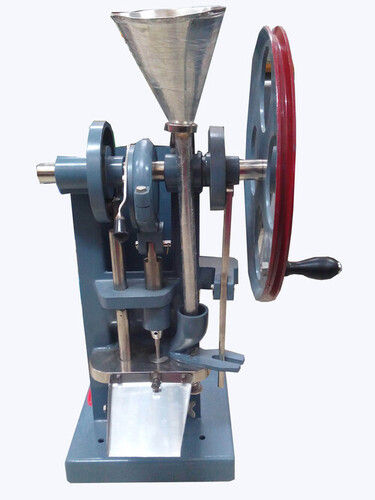

Tablet Making Machine

Machine TypeHand Operated

Compression TypeSemi-Automatic

Hopper MaterialSS 316

Hopper FinishPolished

Easily RotatingYes

DimensionsVariable

Micro Technologies

Ambala Cantt

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller5 Years

Kapoor Tablet Making Machine - Feature: High Performance

Price: 62000.0 INR/Piece

MOQ1 Piece/Pieces

Product TypeTablet Making Machine

MaterialStainless Steel Alloy

AutomaticYes

Voltage220 Volt (v)

FeatureHigh Performance

Warranty1 Year

Sri Vigneshwara Industries

Bengaluru

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Automatic Tablet Making Machine - Capacity: 3000 Tablets/Hr Pcs/Hr

Price: 600000 INR/Piece

MOQ1 Piece/Pieces

FeaturesCorrosion Resistance

Usage & ApplicationsPharma

MaterialStainless Steel

Capacity3000 tablets/hr Pcs/hr

Control ModeAutomatic

Warranty1 Year

View More

Stainless Steel Rmg Tablet Making Machine - Capacity: 250 Ltr

Price : 650000 INR

Tablet Making Machines - Color: Silver

Price: 450000 INR/Unit

MOQ1 Unit/Units

FeaturesHigh Quality

Usage & ApplicationsIndustrial

ColorSilver

MaterialStainless Steel

Control ModeAutomatic

Voltage440 Volt (v)

Tablet Making Machine - Stainless Steel, 580x660x1450 mm, Silver - Automatic Control, 500 Kg Weight

Price: 400000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

TypeOther, Tablet Making Machine

MaterialStainless steel

Control ModeAutomatic

Weight (kg)500 Kg Kilograms (kg)

Dimension (L*W*H)580*660*1450 mm Millimeter (mm)

Bolus Tablet Making Machine - Color: Silver

Price: 590000.00 INR/Unit

MOQ1 Unit/Units

FeaturesUser-friendly control system

ColorSilver

TypeOther

MaterialStainless steel

Capacity10000 to 18000 Tablets Pcs/hr

Voltage415 V Volt (v)

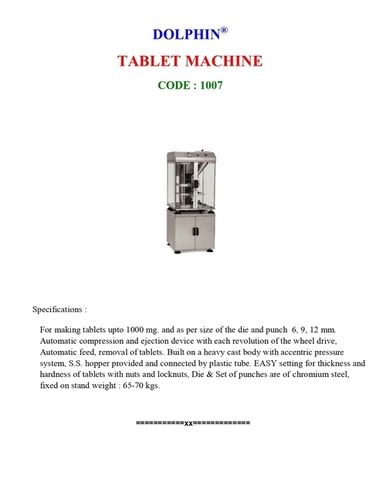

Automatic Tablet Making Machine - Color: Silver

Price: 210000 INR/Unit

MOQ1 Unit/Units

ColorSilver

TypeOther, Tablet Making Machine

MaterialMetal

Control ModeAutomatic

Weight (kg)65-70 Kilograms (kg)

WarrantyYes

Dolphin Pharmacy Instruments Pvt. Ltd.

Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller7 Years

Tablet Making Machine - Capacity: Approx. 300 Tablets/Minute Pcs/Hr

Price: 65000 INR/Piece

MOQ1 Piece/Pieces

FeaturesRobust construction easy operation

Usage & ApplicationsPharmaceuticals Tablet Manufacturing

PhaseSingle Phase

TypeOther

MaterialStainless Steel

CapacityApprox. 300 tablets/minute Pcs/hr

Allmach Pharma Machinery Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller8 Years

FAQs Related to Tablet Making Machines

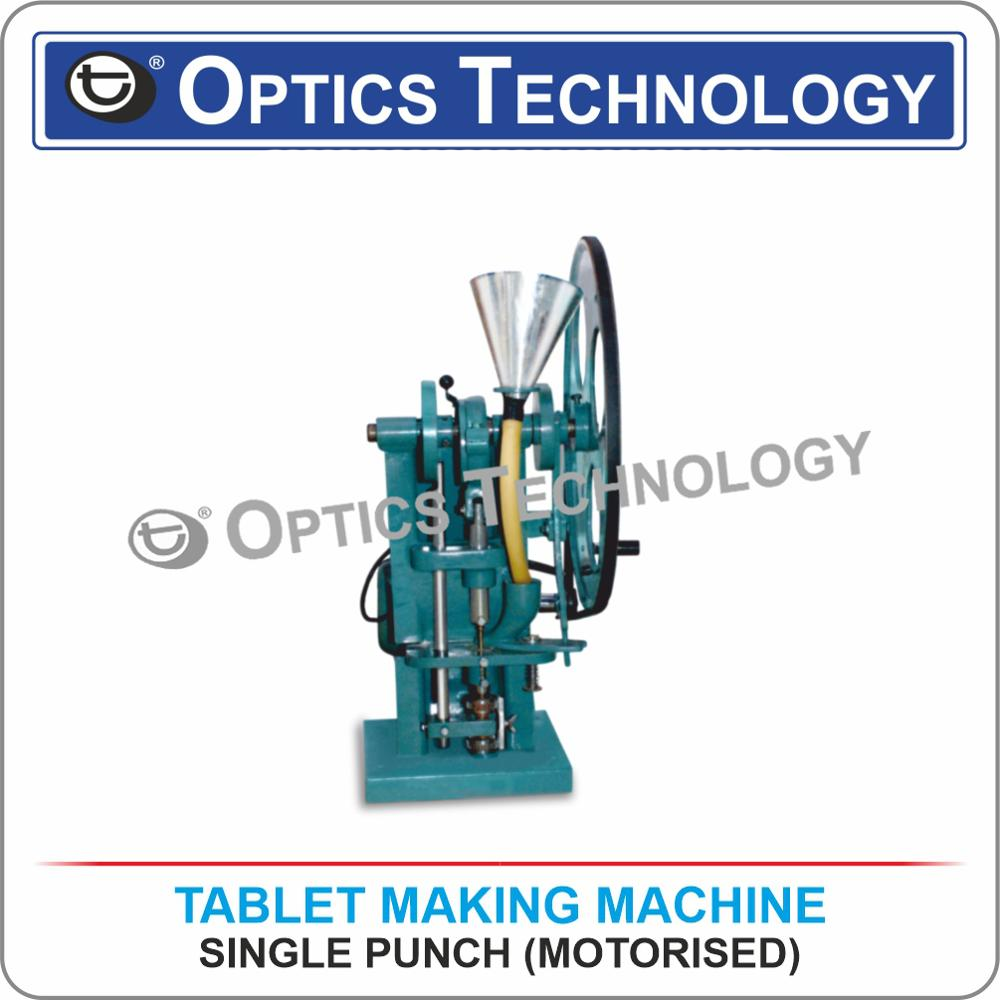

Tablet Making Machine By Ajanta Export Industries

Price: 18000 INR/Piece

MOQ1 Piece/Pieces

PhaseSingle Phase

FeaturesRobust construction, Easy operation, Low maintenance, Precise tablet size control

Frequency50 Hz

Noise LevelLow

ColorSilver/Blue

TemperatureAmbient

Ajanta Export Industries

Ambala Cantt

Trusted Seller

Trusted Seller Premium Seller

Premium Seller15 Years

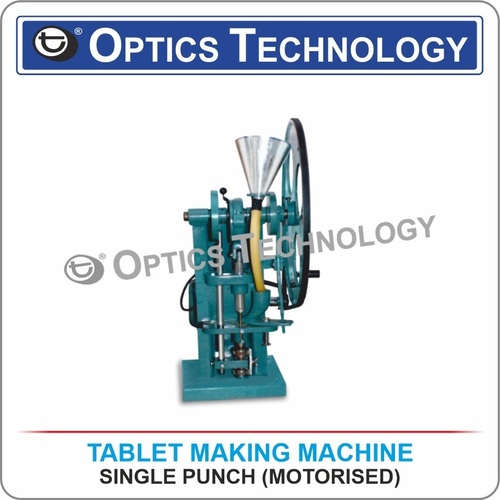

Tablet Making Machine Motorised - Color: Grey

MOQ1 Unit/Units

FeaturesLong Working LIfe

Usage & ApplicationsDairy Instruments

MaterialStainless Steel Body

ComputerizedNo

Control ModeSemi-Automatic

Dimension (L*W*H)12 - 13mm Millimeter (mm)

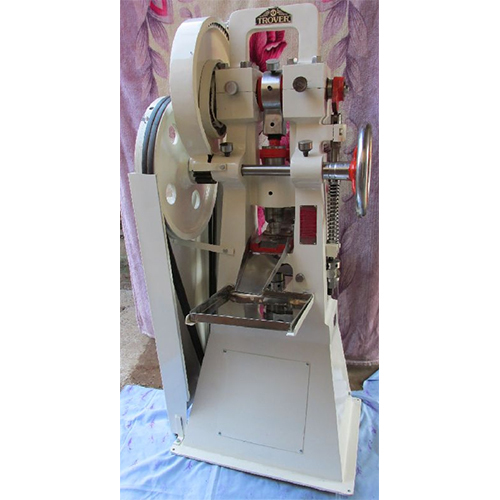

Tablet Making Machine - Color: Silver

Price: 225000.0 INR/Unit

MOQ1 Piece/Pieces

ColorSilver

General UseIndustrial

AutomaticYes

Control SystemHuman Machine Interface

Voltage220-240 Volt (v)

FeatureLower Energy Consumption

Trover Pharmamach (regd.)

Nakodar

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

Tablet Making Machine - Stainless Steel, Automatic Control Mode, Silver Color | Customizable Design for Precise Tablet Production

Price: 450000 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

MaterialStainless Steel

Control ModeAutomatic

Create Industries

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller4 Years

Tablet Making Machine - Mild Steel, 1000mg Single Punch, Automatic Compression and Ejection Device, Noise-less Operation, Rugged Design

Price: 18800 INR/Piece

MOQ10 Piece/Pieces

UsageUse For Industrial

TypeOther, Machine

Product TypeHand Operated

Voltage220-240 Volt (v)

MaterialMild Steel

ApplicationGood Working

Giga Press Tablet Compression Machine for High End Production

MOQ1 Unit/Units

Usage & ApplicationsPharmaceutical industry

FeaturesHigh Performance

TypeOther, Press Tablet Compression Machine

MaterialMetal

Warranty1 Year

Chamunda Pharma Machinery Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

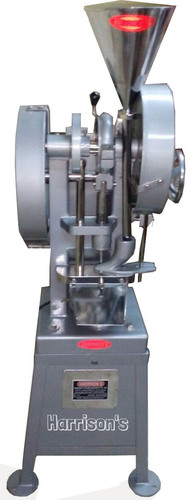

Multi Punch Tablet Making Machine - Color: Blie

Price: 325000.00 INR/Piece

MOQ1 Piece/Pieces

ColorBlie

Frequency50 Hertz (HZ)

Usage & ApplicationsIndustrial

TypeTablet Pressing Machine

ComputerizedNo

Control ModeSemi-Automatic

Harrison's Pharma Machinery Pvt. Ltd.

Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller12 Years

View More

Tablet Making Machines Capacity: High Kg/Hr

Price : 18000 INR

Tablet Making Machine / Single Punch - Capacity: 300 Kg/Hr

Price : 84500 INR

Tablet Making Machine College Model (Hand Operated) - Color: Blue

Price : 14500.00 INR

Small Automatic Pill Making Machine - Color: Silver

Price: 5000 USD ($)/Unit

MOQ1 Unit/Units

FeaturesHard Structure

TypeOther, Small Automatic Pill Making Machine

MaterialStainless steel

ColorSilver

Warranty1 Year

Tablet Making Machine - Electrically Operated Model ETP-204A, Steel Material, Compatible with 6, 9, 12 mm Dies | 220V AC, 50Hz, Single Phase

ModelETP-204A

Power220V AC

Frequency50Hz

PhaseSingle

MaterialSteel

Die Size6,9,12 mm

Double Rotary Tablet Press - Capacity: 125000 T/Hr

Price: 550000 INR/Piece

MOQ1 Number

FeaturesAutomatic

Frequency50 Hertz (HZ)

Phase3

ColorSilver

Noise Level65 db

Usage & ApplicationsTablet Compression

Fluid Bed Dryer Machine - Capacity: 30 Kg/Hr

Price: 650000.00 INR/Unit

MOQ1 Unit/Units

ColorOther, silver

MaterialStainless Steel

ComputerizedNo

Capacity30 Kg/hr

Control ModeSemi-Automatic

Power5 Horsepower (HP)

Roll Compactor Cgmp (Cpm Lab Rc 25) - Capacity: 2 To 10 Kg Pcs/Hr

MaterialStainless Steel

Dimensions25X25X50Cm

Power220V

Capacity25Kg/Hr

SpeedVariable

Weight100Kg

Cijen Pharma Machinery Private Limited

Ahmedabad

Trusted Seller

Trusted Seller2 Years

Big Tablet Making Machines

Product TypeTablet Press

Max Tablet Dia210 mm

Tablet Weight50mg-1kg

Tablet ShapesMultiple

MaterialStainless Steel

Power1-5 HP

Semi Automatic Homeopathic Liquid Medicine Making Machine - Stainless Steel AISI 316L, 100x110x200cm, Mirror Polish Finish | 10,000 kg/hr Capacity, Computerized Control, 1-Year Warranty

Price: 496225.00 INR/Unit

MOQ1 Unit/Units, Unit/Units, Unit/Units

ColorMirror polish

TypeTablet Pressing Machine

MaterialStainless steel

Capacity10000 Kg/hr

ComputerizedYes

Control ModeSemi-Automatic

Microtech Engineering

Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller13 Years

Rotary Tablet Punching and Making Machine 35 Station

MaterialStainless Steel

Capacity25Mm Tablets

Speed40 Rpm

Stations35 Stations

Layers3 Layers

Output96,600 Tablets/Hour

View More

Stainless Steel Tablet Making Machine

Price : 1 INR

Silver Double Rotary Tablet Making Machine

Price : 600000 INR

Tableting Machine - Color: White

Price : 250000 INR

Gmp Tablet Making Machine - Color: Silver

Price: 125000.0 INR/Piece

MOQ1 Piece/Pieces

ColorSilver

TypeOther, GMP Tablet Making Machine

MaterialStainless Steel

Voltage220 V Volt (v)

Dimension (L*W*H)98 x 102 x 182 mm Millimeter (mm)

View More

Tablet Making Machine - Color: Blue

Get Best Deal

Popular Tablet Making Machines

What are Tablet Making Machines

A mechanical tool called a tablet press compresses material into tablets of uniform shape and weight. Pharmaceuticals, nutraceuticals, cleaning products, industrial pellets and cosmetics can all be made into tablets using a tablet press. The granular powder material must be metered into a cavity created by two punches and a die, and then the material must be fused together by applying tremendous force to the punches.

The combined pressing action of two punches and a die results in the formation of a tablet. The bottom punch is lowered into the die to create a cavity into which the granulated feedstock is introduced in the first step of a typical operation.

Types of Tablet Making Machines

- Single station, single punch, eccentric design tablet press

- For research and small scale production, the single punch tablet press machine compresses a granule/powder mixture using a pair of punches (top and bottom) and a die.

- Multi-punch, multi-station and rotary tablet compression machines

Unlike single punch tablet presses, multi-station presses are mechanical devices with multiple rotary stations that quickly and efficiently compress granule and powder combinations into tablets of consistent size, shape and weight. They are designed to increase tablet productivity.

How Tablet Making Machines Work

A tablet press is a device that compresses powder form into tablets of consistent size and weight and is extensively used in pharmaceutical businesses. The force of compression is downloaded by high-pressure compression rolls which change the granular material and hold them together into a rigid tablet. After compression is done, the lower punch is lifted to expel the tablet out.

Reasons for the quick development of the tablet press

Innovations in new technologies in tablet production like the direct compression technology.

High and strict standards of adherence to cleanliness rolled forth by the Current Good Manufacturing Process(CGMP). Cleanliness and Uniformity are well maintained by the use of these technologies.

The exponential increase in population leads to an increase in lifestyle diseases and higher demand

The Advantages of Using Tablet Making Machines

The main features of a tablet press: They may have interchangeable turrets that allow them to produce round, irregular or engraved tablets.

They usually have a robust and strong body that reduces any form of noise during operation and avoids any dust settling.

It is a safe and easy to use process that can produce volumes depending on the machine used.

The tabletting process performed by the tablet press machine. This is a two-stage process, the first stage being the lowering of the bottom punch on the die to create a gap for the granulated powder. How far the punch is lowered is controlled by the machine according to the specifications.

Key Features to Look for in a Tablet Making Machine

1. Scalability

Scaling up a tableting process from R&D to production can be problematic as formulation problems are likely to occur in the form of tablet defects. Advanced R&D presses help to avoid difficulties by emulating the tablet compression characteristics of high-speed production equipment. Compression simulators, for example, can duplicate the punch movement and speed of a rotary tablet press, simulating compression time, dwell time and strain rate.

2. Return on investment (ROI)

Return on investment (ROI) Price is critical for pharmaceutical laboratories, but ROI is what matters most. The right tablet press should result in significant cost reductions for your organisation. It is important to choose a system with complete data collection and processing software. This can help to analyse tablet quality and develop more robust formulations, which means fewer faults and downtime during production.

With compaction simulation technology, companies can avoid the need to carry out experimental development work on their production equipment. As well as the obvious benefit of freeing up the industrial press for commercial production, this can lead to various cost reductions.

3. Ease of use

Tablet compression and powder characterisation technology is inherently complex, but it shouldn’t seem so to consumers. Most suppliers will claim to deliver intuitive software, therefore it’s crucial to investigate what activities were done throughout development to ensure this.

What are tablet making machines used for?

Applications of Tablet Press Machine, Double Cone Mixer and Rapid Mixer Granulator

In the tablet manufacturing process, numerous types of machines are used for various applications at different stages from manufacturing to packaging. Different versions of tablet press machine like single sided rotary tablet press machine, double sided rotary tablet press machine and high speed rotary tablet press machine are used for manufacturing the tablets of various shapes and sizes. The production capacity and features of these machines may vary depending on the type. For mixing dry powders and granules, companies generally use Double Cone Blender. Similarly, the Rapid Mixer Granulator is used for mixing ingredients and wet granulation.

Fluid Bed Dryer, Multi Mill, Octagonal Mixer and V Cone Mixer Applications

Drying is one of the most critical stages in the tablet manufacturing process and the Fluid Bed Dryer is used to dry the product as a wet powder at a specific temperature. Multi Mill is a multi-purpose machine used for granulating, pulverising, mixing, shredding and chopping materials at high speed. For blending different types of materials, the pharmaceutical industries generally use modern machines such as Octagonal Blender and V Cone Blender. These machines are also widely used in the food and cosmetic industries for mixing components.

Vibro Sifter, Conventional Coating Pan and Automatic Tablet Coater Applications

The Vibro Sifter is a high tech machine mainly used to separate the mass composition of solids, liquid from solid. Its other main application is the sorting of materials according to particle size. Masking the smell and taste of the drug is highly crucial for the pharmaceutical companies and this process is properly done by the conventional coating pan. With the ever increasing demands of pharmaceutical products, most of the companies use Automatic Tablet Coater for tablet coating.

FAQs: Tablet Making Machines

Q. What are the different types of tablet making machines available?

Ans. Tablet Press IV Machine: The Tablet Press IV machine is a square designed, high speed rotary tablet press machine manufactured in accordance with all GMP regulations. These machines produce high tablet output and are therefore suitable for high volume production. The machine incorporates a helical gear ring to drive the turret. It also boasts a specially designed dust extractor that can be connected to a dust extractor away from the machine.

Rotary Tablet Press: The Rotary Tablet Press also has a square construction consisting of an AC variable speed drive & electromagnetic clutch. It provides a paint free tablet manufacturing zone and includes an operator friendly material feeding mechanism. The Rotary Tablet Press Machine also incorporates reversible direction motion protection to prevent any significant mishap.

Mini Tablet Press Machine:The Mini Press - Rotary Tablet Press, Mini Tablet Press is square shaped, durable machine constructed as per GMP guidelines. The machine ensures trouble free operation, produces low level of noise and is very easy to clean. The 'D' & 'B' tooling requirements like 6 tonne pressure, maximum tablet diameter 22 mm etc. can be applied for achieving greater output in its range.

Q. What is the cost of a tablet making machine and what factors impact its cost?

Ans. A tablet press, also known as a tablet compressing machine or tableting machine, is used to compress pharmaceutical powder formulations into tablet form, creating tablets of uniform size, shape and weight.

Q. What is the price of tablet pill machine?

Ans. The price of tablet pill maching is around Rs 70,000

Client Testimonials & Reviews

SnehaNair

THE GLOBAL PHARMA EQUIPMENTS

Tradeindia is a great platform for Buyers and Sellers to get in touch with New Client to grow your business Globally. We are associated with tradeindia only last few months, but we hope that we will grow our business with associated with Tradeindia and definitely help us find new business partners with its professionally trained and co-operative staff. Thank you tradeindia.

ChiragSerasiya

Jacks Pharma Machinery

TradeIndia is a trusted company doing great business all over the world. We are associated with TradeIndia from a long time and having a good experience. Their team is cooperative and always ready to help. We appreciate TradeIndia's hardwork in creating good business opportunities.

We are associated with tradeindia.com. It was such a good platform, which has helped us a lot to increase our reach and sales. We are wishing for healthy and long term relationship with tradeindia.com.

SANDIPSHUKLA

CREATE INDUSTRIES

We have been advertising with tradeindia.com for the last two years now and find it to be an effective tool for advertising and promoting our business in the international market. During this period, we have received many products inquiries both from India and abroad, and would suggest all Indian manufactures and exporters aspiring to cash on the export market to make Exporters Yellow Pages a part of their media plan. We are thankful to Indocom Network for the excellent services offered and looking forward for better business relations with the company in the coming years and also best services from it's officers / executives.

GhanshyamPatel

CHITRA MACHINERIES PVT. LTD.

I have found the Trade India is providing excellent service to the customer. The advertisement of customer is also with excellent features, well designed and well administrated.

ManishKapadia

PARAG EXPORTS (C/o PRAGATI ENGINEERS)

We have enrolled our company with tradeindia just one month ago. We are happy with their prompt replies and guidance given to us while preparing our website. Everyone who spoke to us from tradeindia are professional in their work. We hope to obtain good business through tradeindia portal in the coming months.

JALPESHGAJJAR

GARUDA ENGINEERS

Here with we are the constomers of tradeindia.com for the last 2 years. We are satisfied with the promotion activity and the team work of tradeindia.com. We have got the benifits by the promotion activity and the services provided by the CRM Department. Thanks to Infocom Family and hope to keep our Relations more healthier this year.

Tablet Making Machines Price List

Product Name | Expected Price |

|---|---|

| Tablet Making Machines | 450000 |

| Sodam Tablet Making Machine | 50000 |

| Automatic Tablet Making Machine | 600000 |

| Tablet Making Machine | 450000 |

| Ss Tablet Making Machine | 300000 |

| Automatic Tablet Making Machine | 58000 |

| Odonil Tablet Making Machine | 225000 |

| Tablet Making Machine | 350000 |

| Manual Tablet Machine | 22000 |

| Tablet Making Machine | 18000 |

This Data was Last Updated on 2025-12-23

Tablet Making Machines Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Dhiman Udyog (regd.) Nakodar, India | 18 Years |

Bluefic Industrial & Scientific Technologies Ambala, India | 16 Years |

Ajanta Export Industries Ambala Cantt, India | 15 Years |

Riddhi Pharma Machinery Ltd Ahmedabad, India | 14 Years |

Micro Teknik Ambala Cantt, India | 13 Years |

Microtech Engineering Delhi, India | 13 Years |

Labsoul India Ambala Cantt, India | 12 Years |

Harrison's Pharma Machinery Pvt. Ltd. Delhi, India | 12 Years |

Edutek Instrumentation Ambala Cantt, India | 11 Years |

Prime Machinery Ahmedabad, India | 8 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories